Abstract

In this paper, the effects of extrusion–shear (ES) on the microstructures and mechanical properties of AZ31 magnesium alloy has been studied, which has been achieved by conducting a lot of experiments and tests, including ES process, direct extrusion with different billet temperatures, microstructure analysis, hardness test, tensile & compression tests. The results show that the ES-processed rods has higher strengths (yield strength and tensile strength) than the direct extrusion ones with the same billet temperature, which contributed to their lower averaged grain size obtained from microstructure analysis according to Hall–Petch relation. Besides, the hardness of ES-processed AZ31 magnesium alloy decreases with the increasing of billet temperature. By comparing the two processes, it can be seen that the ES process could refine the microstructure and improve the mechanical properties of magnesium alloy.

Introduction

Wrought magnesium (Mg) alloys have a great potential as lightweight structural materials and they have wide industrial applications [1–3], such as the automobile industry [4, 5]. Many new techniques have been developed and a lot of experiments have been conducted to improve/refine the microstructure [6–12], such as asymmetric extrusion [6], accumulative roll bonding [8] and equal channel angular extrusion (ECAE) [11], and they were found to be effective in improving the formability of Mg alloys owing to grain refinement. ECAE, a severe plastic deformation (SPD) technique, has attracted great interests in manufacturing high-strength Mg alloys [13, 14]. However, it is only used in the laboratory and there is still existing an unbridgeable gap to be overcome to put it into applications in industry. In the study of Orlov et al. [15], he combined conventional extrusion and equal channel angular pressing in a single processing step and the processed material exhibited an excellent balance of strength and tensile ductility due to the synergy of fine-grained microstructure. Recently, a novel processing technique named extrusion–shear (ES), which is continuous extrusion processes combining the extrusion and two successive shears, has been studied by our research team [16–18].

As there is very little systematic researches about the relationship between the process parameters and the microstructure and mechanical properties of the ES processed parts, it is necessary to optimize the process parameters in ES in order to ensure high-performance of Mg alloy. The ES die and extrusion die have been designed, manufactured and carried out under different billet temperatures. Effects of process parameters, especially the billet temperatures, on the grain sizes and mechanical properties of AZ31 Mg alloy have been explored.

Experiment

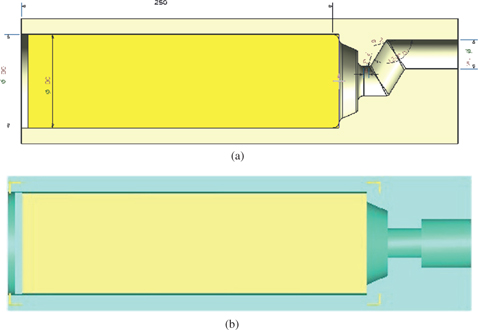

The ES die and direct extrusion die have been designed and manufactured with their longitudinal section schematic diagrams shown in Figure 1. As can be seen in Figure 1(a), the ES die includes direction extrusion part and two steps of ECAE with the channel angle of 120 °. The direct extrusion die with extrusion ratio 12 has been shown in Figure 1(b). The diameter of extrusion rods extruded by ES process and direct extrusion are 15 mm. There are three deformation zones in ES die, which includes ordinary extrusion zone, first shear deformation zone and second shear deformation zone. Experiments have been conducted by using the tonnage of 500 ton on the horizontal extrusion machines with container diameter of 85 mm.

Schematic diagrams of longitudinal section (unit: mm): (a) ES die structure and (b) direct extrusion structure.

This study focuses on AZ31B Mg alloy, and the AZ31 wrought Mg alloy has a typically proof stress of 160–240 MPa [19]. The billets have been machined into billets as cast ones with diameter of 80 mm. During the experiments in this study, three billet temperatures (370, 400 and 420 ℃) and three different die temperatures (350, 380 and 400 ℃) have been used with the extrusion speed kept as 0.5 m/min.

All the samples have been taken from the center of fabricated rod. To reveal the microstructures, the AZ31 Mg alloy samples for microstructures observations were fist prepared with standard metallographic procedures, including sectioning, mounting, grinding with SiC papers up to the grit size of 1,000 and polishing with diamond suspension down to 0.5 µm, and then etched with an acetic acid and picric acid solution [20], which composes 2 ml acetic acid, 1 g picric acid, 5 ml water and 20 ml of ethanol. In order to quantify the grain size, a measurement method from Wang et al. [21] was applied with multiple microscope images from different area measured to achieve accurate results. The hardness of AZ31 Mg alloy has been evaluated by Vickers micro-hardness tests with the load of 100 g conducted at five randomly selected separate points.

The AZ31 Mg alloy samples for tensile tests were machined according to the ASTM standard with the gauge length of 7 mm. Three tensile test specimens have been prepared for each process condition and the tensile tests were conducted using an electronic universal testing machine CMT 5150 at room temperature with the rate of 1 mm/min.

Results and discussions

Effects of billet temperatures on grain sizes

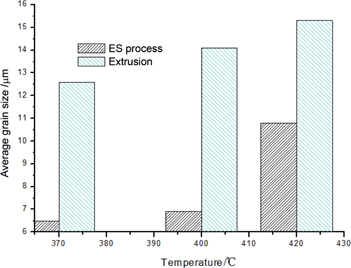

The billet temperatures applied in the ES process are 370, 400 and 420 ℃, respectively. The effects of the billet temperature on the average grain sizes of Mg alloy are presented in Figure 2, and the comparison of microstructure between direction extrusion and ES is presented in Figure 3. It can be seen that the averaged grain size increases obviously with the increasing of billet temperature. For the direct extrusion process, the mean grain sizes of the AZ31 samples deformed at 370, 400 and 420 ℃ are 12.5, 14 and 15.5 µm, respectively (Figure 4). The Mg alloys are prone to dynamic recrystallization (DRX) by hot extrusion process. However, the higher temperature also results in the growth of the DRXed grains size. The grain size became larger with the increasing of the billet temperature, which indicates that the extrusion temperature is an important factor in controlling the microstructure of AZ31 Mg alloy [22, 23]. The same phenomenon of the effects of temperature on the microstructure of Mg alloys during extrusion has also been observed [7, 24, 25].

Microstructure of bars with different billet temperatures: (a) 370 ℃, (b) 400 ℃ and (c) 420 ℃.

Microstructure of bars at the billet temperature of 400 ℃: (a) direct extrusion and (b) ES process.

Average grain sizes fabricated by ES process and direct extrusion with different billet temperatures.

For the ES process, the relationship between billet temperature and grain size is not as same linear as that in direct extrusion. As shown in Figure 4, the average grain sizes of Mg alloy fabricated by ES are much smaller than those prepared by direct extrusion and they increase slowly when the billet temperature increase from 370 to 400 ℃, but increase significantly from 400 to 420 ℃, which demonstrates that billet temperatures have significant effect on the sizes of grains. The finer microstructure in ES could be attributed to the shear deformation in ES process. The extremely large shear strain has also found in ECAE, and the shear stress has been proven to be very effective to refine the microstructure [26]. Gong et al. [27] investigated the differential speed rolling on Mg alloys and found that the grain refinement could be achieved by the intense shear deformation. The grain refinement mainly occurs in the shear bands because the main portion of the plastic deformation is thought to take place in the shear bands during rolling. A smaller grain size in the shear bands indicates that more intense plastic deformation concentrates on the shear bands during the differential speed rolling process. The results validate that ES process could refine the grains effectively if the billet temperature of billets is lower.

Effects of billet temperatures on microhardness

The Vickers’s indentation tests have been conducted at different positions in longitudinal sections of Mg alloy rods fabricated by ES processes with different billet temperatures, respectively, and the test results are shown in Figure 5. The positions 1, 2 and 3 are located at the head part, middle part and tail part of extruded rods, respectively. It can be seen that the hardness will increase with the increasing of the plastic deformation from positions 1–3 at the billet temperature of 370 ℃. The hardness at position 1 strip is about HV 65 and increase to HV 68.5 at position 3, which states that the hardness of the alloy could be improved by plastic deformation attributed to the strain hardening effect and grain refinement.

Micro-hardness of different position of rods fabricated by ES process (error range: 3HV).

By comparing Figure 5, it can be seen that the hardness values decrease with the increasing of billet temperatures. This is because DRXs happen fully and recrystallized grains grow up with billet temperature increasing during the ES process [28, 29]. The mechanical properties are also consistent with the microstructure observation from Figure 2 and grain size measurement from Figure 4.

Effects of billet temperatures on tensile properties

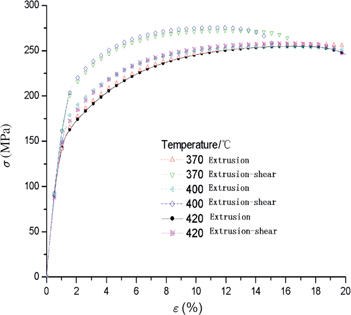

The stress–strain curves from tensile tests are shown in Figure 6. The tensile properties, including elongation, yield strength and tensile strength, of AZ31 Mg alloy fabricated by direct extrusion and ES process with different billet temperatures are shown in Figure 7. It is obvious that strengths (yield strength and tensile strength) for AZ31 Mg alloy rods fabricated by ES are much higher than that formed by direct extrusion with about 20 % sacrifice of the elongation.

Engineering stress (σ) and strain curves of the AZ31 Mg alloy processed by ES process and direct extrusion.

Effects of billet temperatures on properties of Mg alloy fabricated by ES process and direct extrusion at different temperatures: (a) elongation, (b) yield strength and (c) tensile strength.

As shown in Figure 7(b), the yield strengths of Mg alloy fabricated by ES process are about 45 MPa higher than those fabricated by direct extrusion with billet temperatures of 370 and 400 ℃. But the difference decreases when billet temperature is 420 ℃. The tensile strength of Mg alloy formed by ES is higher than those fabricated by direct extrusion with the same billet temperatures, as shown in Figure 7(c). The effects of temperature on the tensile properties are complicated. Generally, the increase of the billet temperature will result in the decrease of the yield strengths and tensile strengths.

According to Hall–Petch equation [30], in the relationship between strength and average grain size, the strength increases as the average grain size is reduced. As to the effect of billet temperature, the higher the billet temperature, the coarser the microstructure, and subsequently the lower the strength. Besides, comparing to direct extrusion rods, the ES-processed rods present smaller grain size and the strengths are much higher. However, the elongation is smaller for the ES processed rods, because the elongation is not only influenced by the grain size, it is also impacted by the internal stress and dislocation density [31–33]. Further study is needed to study the stress, texture in the AZ31 extrusion rods. In addition, heat treatment is needed to explore the further increase of the plasticity in order to meet industrial application of Mg alloys.

Conclusions

As an SPD technique, ES process has the ability to process Mg alloy with fine grains and superior mechanical properties. The effect of ES conditions, especially for billet temperature, on the microstructures and mechanical properties of AZ31 Mg alloy has been investigated in this study by performing ES process and direct extrusion under different billet temperatures, microstructures analysis, hardness tests, compression tests and tensile tests. The major findings are summarized as follows:

For both direct extrusion and ES processes, the averaged grain size of AZ31 Mg alloy increases with the increasing of billet temperature. Subsequently, the hardness of Mg alloys fabricated by ES process decreases with billet temperatures increasing.

The average grain sizes prepared by ES are smaller than that fabricated by direct extrusion with the same billet temperatures. The shear deformation in the ES could be attributed to the grain refinement.

When comparing with the Mg alloy formed by direct extrusion, ES-processed Mg alloy have a higher yield strength and tensile stresses with lower elongations under the same billet temperatures.

Funding statement: Funding: This work was supported by the foundation of the post doctorate in Chongqing (project number is Xm201327), and China Postdoctoral Science Foundation funded project 2014M552575 and 2015T81087, and Chongqing Natural Science Foundation Project of cstccstc2014jcyjA50004. This work was also supported by Scientific and Technological Research Program of Chongqing Municipal Education Commission (Grant No. KJ1500939).

References

[1] X. Gong, H. Li, S.B. Kang, J.H. Cho and S. Li, Mater. Design, 31 (2010) 1581–1587.10.1016/j.matdes.2009.09.021Search in Google Scholar

[2] Z. Wu, M. Song and Y. He, Mater. Sci. Eng. Powder Metall., 4 (2008) 001–009.Search in Google Scholar

[3] H. Hu, J. Fan, Z. Zhai, H. Wang, Y. Li and X. Gong, Russ. J. Non-Ferrous Metals, 55 (2014) 254–262.10.3103/S1067821214030067Search in Google Scholar

[4] J. Hirsch, T. Al-Samman, Acta Mater., 61 (2013) 818–843.10.1016/j.actamat.2012.10.044Search in Google Scholar

[5] K. Hamad, B.K. Chung and Y.G. Ko, J. Alloy. Compd., 615 (2014) S590–S594.10.1016/j.jallcom.2013.12.195Search in Google Scholar

[6] L.L. Chang, Y.N. Wang, X. Zhao and J.C. Huang, Mater. Sci. Eng. A, 496 (2008) 512–516.10.1016/j.msea.2008.06.015Search in Google Scholar

[7] Z. Wu, M. Song and Y. He, Mater. Sci. Eng. A, 504 (2009) 183–187.10.1016/j.msea.2008.11.030Search in Google Scholar

[8] A.A. Roostaei, A. Zarei-Hanzaki, H.R. Abedi and M.R. Rokni, Mater. Des., 32 (2011) 2963–2968.10.1016/j.matdes.2011.01.038Search in Google Scholar

[9] H. Qin, W. Yue, C. Ke, M. Zhou, X. Zhang and B. Lin, 15th International Conference on Electronic Packaging Technology (ICEPT) (2014), 587–591.Search in Google Scholar

[10] M. Song, Z. Wu and Y. He, Mater. Sci. Eng. A, 497 (2008) 519–523.10.1016/j.msea.2008.07.020Search in Google Scholar

[11] M. Al-Maharbi, I. Karaman, I.J. Beyerlein, D. Foley, K.T. Hartwig, L.J. Kecskes and S.N. Mathaudhu. Mater. Sci. Eng. A, 528 (2011) 7616–7627.10.1016/j.msea.2011.06.043Search in Google Scholar

[12] H. Qin, B. Li, W. Yue, C. Ke, M. Zhou and X. Zhang, IEEE 64th Electronic Components and Technology Conference (ECTC) (2014), pp. 2249–2254.Search in Google Scholar

[13] M.Y. Zheng, S.W. Xu, K. Wu, S. Kamado and Y. Kojima, Mater. Lett., 61 (2007) 4406–4408.10.1016/j.matlet.2007.02.013Search in Google Scholar

[14] R. Zhu, Y.J. Wu, W.Q. Ji and J.T. Wang, Mater. Lett., 65 (2011) 3593–3596.10.1016/j.matlet.2011.07.111Search in Google Scholar

[15] D. Orlov, G. Raab, T.T. Lamark, M. Popov and Y. Estrin, Acta Mater., 59 (2011) 375–385.10.1016/j.actamat.2010.09.043Search in Google Scholar

[16] D.F. Zhang, H.J. Hu, F.S. Pan, M.B. Yang and J.P. Zhang. Trans. Nonferr. Met. Soc. China, 20 (2010) 478–483.10.1016/S1003-6326(09)60165-5Search in Google Scholar

[17] H.J. Hu, D.F. Zhang, M.B. Yang and M. Deng, Trans. Nonferr. Met. Soc. China, 21 (2011) 243–249.10.1016/S1003-6326(11)60705-XSearch in Google Scholar

[18] H.J. Hu, D.F. Zhang, F.S. Pan and M.B. Yang, Acta Metall. Sin. (Engl. Lett.), 22 (2009) 353–364.10.1016/S1006-7191(08)60109-XSearch in Google Scholar

[19] K. Matsuyama, Y. Miyahara, Z. Horita and T.G. Langdon, Acta Mater., 51 (2003) 3073–3084.10.1016/S1359-6454(03)00118-6Search in Google Scholar

[20] S.C. Lee, S.Y. Ha, K.T. Kim, S.M. Hwang, L.M. Huh and H.S. Chung, Mater. Sci. Eng. A, 371 (2004) 306–312.10.1016/j.msea.2003.12.029Search in Google Scholar

[21] K. Wang, W. Zeng, Y. Shao, Y. Zhao and Y. Zhou. Rare Metal Mater. Eng., 38 (2009) 398–403.Search in Google Scholar

[22] W. Liu, J. Ma, M.M. Atabaki and R. Kovacevic, Mater. Des., 68 (2015) 146–157.10.1016/j.matdes.2014.12.028Search in Google Scholar

[23] W. Liu, J. Ma, G. Yang and R. Kovacevic, J. Mater. Process. Technol., 214 (2014) 2823–2833.10.1016/j.jmatprotec.2014.06.018Search in Google Scholar

[24] X. Lei, T. Liu, J. Chen, B. Miao and W. Zeng, Mater. Trans., 52 (2011) 1082–1087.10.2320/matertrans.MC201004Search in Google Scholar

[25] M. Song, Z. Wu and Y. He, Mater. Sci. Eng. A, 497 (2008) 519–523.10.1016/j.msea.2008.07.020Search in Google Scholar

[26] W.J. Kim, S.I. Hong, Y.S. Kim, S.H. Min, H.T. Jeong and J.D. Lee, Acta Mater., 51 (2003) 3293–3307.10.1016/S1359-6454(03)00161-7Search in Google Scholar

[27] X. Gong, H. Li, S.B. Kang, J.H. Cho and S. Li, Mater. Charact., 97 (2014) 183–188.10.1016/j.matchar.2014.09.014Search in Google Scholar

[28] K. Matsubara, Y. Miyahara, Z. Horita and T.G. Langdon, Metall. Mater. Trans. A, 35 (2004) 1734–1744.10.1007/s11661-004-0082-zSearch in Google Scholar

[29] Q. Yang, B. Jiang, G. Zhou, J. Dai and F. Pan, Mater. Sci. Eng. A, 590 (2014) 440–447.10.1016/j.msea.2013.10.045Search in Google Scholar

[30] E.O. Hall, Proc. Phys. Soc. Lond. B, 64 (1951) 747–753.10.1088/0370-1301/64/9/303Search in Google Scholar

[31] Z. Qian, S. Chumbley, T. Karakulak and E. Johnson, Metall. Mater. Trans. A, 44 (2013) 3147–3156.10.1007/s11661-013-1688-9Search in Google Scholar

[32] Z. Qian, S. Chumbley and E. Johnson, Mater. Sci. Eng. A, 529 (2011) 246–252.10.1016/j.msea.2011.09.024Search in Google Scholar

[33] S. Liu, W. Liu, M. Harooni, J. Ma and R. Kovacevic, Opt. Laser Technol., 62 (2014) 124–134.10.1016/j.optlastec.2014.03.007Search in Google Scholar

©2016 by De Gruyter

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Research Articles

- Effects of Extrusion–Shear Process Conditions on the Microstructures and Mechanical Properties of AZ31 Magnesium Alloy

- Degradation of TiB2/TiC Composites in Liquid Nd and Molten NdF3–LiF–Nd2O3 System

- Investigation of Oxygen Diffusion in Irradiated UO2 with MD Simulation

- Grain Size Effect on Fracture Behavior of the Axis-Tensile Test of Inconel 718 Sheet

- Modeling Superionic Behavior of Plutonium Dioxide

- Influence of Grain Refinement on Oxidation Behavior of Two-Phase Cu–Cr Alloys at 973–1,073 K in Air

- Synthesis and Characterization of Cadmium Sulfide Nanoparticles via a Simple Thermal Decompose Method

- Short Communication

- Simple Thermal Decompose Method for Synthesis of Nickel Disulfide Nanostructures

- Research Articles

- Dynamic Recrystallization Behavior of Ti22Al25Nb Alloy during Hot Isothermal Deformation

- Reduction Smelting Low Ferronickel from Pre-concentrated Nickel-Iron Ore of Nickel Laterite

- Physics-Based Constitutive Model to Predict Dynamic Recovery Behavior of BFe10-1-2 Cupronickel Alloy during Hot Working

- Influence of Oxides on Microstructures and Mechanical Properties of High-Strength Steel Weld Joint

Articles in the same Issue

- Frontmatter

- Research Articles

- Effects of Extrusion–Shear Process Conditions on the Microstructures and Mechanical Properties of AZ31 Magnesium Alloy

- Degradation of TiB2/TiC Composites in Liquid Nd and Molten NdF3–LiF–Nd2O3 System

- Investigation of Oxygen Diffusion in Irradiated UO2 with MD Simulation

- Grain Size Effect on Fracture Behavior of the Axis-Tensile Test of Inconel 718 Sheet

- Modeling Superionic Behavior of Plutonium Dioxide

- Influence of Grain Refinement on Oxidation Behavior of Two-Phase Cu–Cr Alloys at 973–1,073 K in Air

- Synthesis and Characterization of Cadmium Sulfide Nanoparticles via a Simple Thermal Decompose Method

- Short Communication

- Simple Thermal Decompose Method for Synthesis of Nickel Disulfide Nanostructures

- Research Articles

- Dynamic Recrystallization Behavior of Ti22Al25Nb Alloy during Hot Isothermal Deformation

- Reduction Smelting Low Ferronickel from Pre-concentrated Nickel-Iron Ore of Nickel Laterite

- Physics-Based Constitutive Model to Predict Dynamic Recovery Behavior of BFe10-1-2 Cupronickel Alloy during Hot Working

- Influence of Oxides on Microstructures and Mechanical Properties of High-Strength Steel Weld Joint