Abstract

StExCell, a novel sulfur-free and chlorine-free biorefinery concept, based on mild steam explosion followed by mild caustic extraction, oxygen delignification and bleaching, is introduced to produce dissolving pulp for textile application. Steam explosion of Betula pendula at 210 °C for 7 isothermal min (equivalent to a P-factor of ca. 1,250), combined with a total-chlorine-free purification sequence resulted in a fully bleached pulp with only 3.6 % xylan, a slightly wider cellulose molar mass distribution and a higher pulp yield, while consuming only about half of the chemicals, in reference to a prehydrolysis-kraft process. The chemical recovery and valorization of the extracted wood component were not covered by the scope of this work but speculated to be simpler than in a kraft process.

Abbreviations

- AS

-

Acid sulfite

- COP

-

Cross-over point

- CSE

-

Catalyzed steam explosion

- DBNH

-

1,5-diazabicyclo [4.3.0] non-5-ene

- DMAc

-

N, N-dimethylacetamide

- DP

-

Degree of polymerization

- DR

-

Draw ratio

- DWP

-

Dissolving wood pulp

- E

-

Caustic extraction stage

- HPAEC

-

High-performance anion-exchange chromatography

- HPLC

-

High-performance liquid chromatography

- IL

-

Ionic liquid

- κ

-

Kappa number

- L:W

-

Liquor-to-wood ratio

- MALS

-

Multi-angle light-scattering

- MMCFs

-

Man-made cellulosic fibers (also called regenerated cellulosic fibers)

- MMD

-

Molar mass distribution

- O

-

Oxygen delignification stage

- P

-

Peroxide bleaching stage

- PDI

-

Polydispersity index

- PH

-

Prehydrolysis

- PHK

-

Prehydrolysis-kraft

- SE

-

Steam explosion

- SEC

-

Size exclusion chromatography

- TCF

-

Total-chlorine-free

- W

-

Pulp water washing stage

- Z

-

Ozone bleaching stage

1 Introduction

Ever since the dawn of civilization, humankind has constantly been aspiring for fibrous materials. On the lower end of the application spectrum locate the fibers for daily textile products. Since the beginning of the Contemporary Period, due to the population growth and improved living quality, global fibers production has grown substantially from 34 million tons in 1975 to 109 million tons in 2020 and is expected to reach 146 million tons by 2030 (Textile-Exchange 2021). Up till the Modern Era, humankind depended heavily on natural sources (such as cotton, flax, wool, and silk) for textile fibers. The advances in synthesis chemistry and petroleum refining technology resulted in a new class of textile: the synthetic fibers, which, henceforth, has become the dominant textile source (Textile-School 2018). Despite their excellent properties, fossil-based fibers impose a heavy burden on the environment. Therefore, the recent decades have witnessed a renewal of interest in bio-based fibers. Production of traditional natural fibers (cotton, wool, silk) stagnates due to sustainable issues (Carpenter et al. 2002), which leaves man-made cellulosic fibers (MMCFs), produced by regenerating the dissolved cellulose in a solvent, as the most realistic alternative to synthetic fibers in the foreseeable future. The most important raw material for MMCFs is dissolving wood pulp, which is characterized by high cellulose purity (>90 %), i.e. low hemicellulose content (typically <6–7 %) (Sixta 2006b). The dissolving pulp production capacity has been steadily expanded since the 2010s, reaching 10 million tons per annum in 2021 and is forecast to further grow in the foreseeable future (The-Fiber-Year 2023).

Prehydrolysis-kraft (PHK) and acid sulfite (AS) pulping are currently the dominant industrial-scaled processes for dissolving pulp production. The kraft process is by far the dominant pulping process, as it enables the production of strong paper pulps (classical kraft) or high purity dissolving pulps in the case of a preceding pre-hydrolysis step (PHK) and a closed cycle of active cooking chemicals. However, the disadvantage is the instability of hemicelluloses in aqueous alkaline solution, leading to the conversion of more than 50 % of hemicelluloses into a variety of different hydroxy carboxylic acids, making the valorization of this important lignocellulosic fraction almost impossible (Sjöström 1993; Sixta 2006a). Furthermore, the commercial use of kraft lignin is also restricted due to the organically bound sulfur. The AS process is more suitable for a biorefinery than the kraft process as the hemicellulose fraction in the spent liquor consists mainly of sugars, which are predominantly present as monosaccharides and, after reduction, are marketed as sugar alcohols, e.g., xylitol. Another important commercial by-product is furfural, formed during the AS cook by dehydration of pentosans, typically in an amount of about 1 % based on the original hardwood (Sixta 1986). Besides, water-soluble sulfonated lignin (lignosulfonate) from AS process is already a well-accepted product on the market, outperforming kraft lignin in the commercial sector. However, the reasons for the continuous capacity reduction of AS pulp production are the high environmental impact of the process as the recovery of SO2 is limited to 80 %, the weak mechanical properties of the pulp produced and finally the restrictions on the use of resinous softwoods (Sixta 2006a).

PHK and AS are approaching their technological maturity, leaving little window for major improvements. Since the middle of the 20th century, extensive research effort has been invested on alternative pulping technologies in organic solvents. With a few exceptions, organosolv fractionation is commonly performed under slight acidic conditions, where delignification occurs via the hydrolysis of β–O–4 bonds. The classical organosolv pulping with ethanol/water pulping enabled the production of competitive paper-grade and dissolving pulp from hardwood (Kleinert and Tayenthal 1931; Kleinert 1971; Peter and Hoglinger 1986; Pye and Lora 1991), but suffers from the high operational pressure and (recently discovered) significant loss reactions (Sharazi and van Heiningen 2017). Other organosolv processes do not offer significant improvement than the ethanol/water method but suffering from several drawbacks such as higher pressure and toxicity (methanol) or corrosiveness (carboxylic acids). Recently, biorefinery concepts were developed based on γ-valerolactone/water fractionation for producing dissolving pulp (Granatier et al. 2023; Lê et al. 2016), sugars (Luterbacher et al. 2014) or furfural (Alonso et al. 2013). However, acidic organosolv pulping exhibited limited delignification towards more recalcitrant species such as birch or coniferous biomass. Unfortunately, there has been no commercial organosolv pulp mill with stable operation.

Challenges with organosolv pulping technologies encourage the revisiting of alternative biomass fractionation concepts in fully aqueous system. For paper-grade pulp production, kraft and acid sulfite processes are unsurpassable due to the employment of the best, yet reasonably priced, nucleophiles (HS− and HSO3−), thus boosting the selectivity of delignification over the carbohydrate removal. However, in dissolving pulp production, where hemicellulose should also be removed, and cellulose shall be degraded to a certain degree, such selectivity of delignification over carbohydrate degradation might be omitted, thus questioning the need of a nucleophile. Moreover, to sustainably reduce the pulping chemical consumption, intense thermal and mechanical treatment could partly replace the chemical activity required to degrade the cell wall structure to facilitate defibration. Inspired by the pioneering work of Chanzy in the late 80s (Chanzy et al. 1986), where unbleached steam-exploded aspen wood was successfully converted to lyocell fibers, this work explores the possibility of producing bleached dissolving pulp with steam explosion technology.

Steam explosion was invented in the end of 1920s and early 1930s as a chemical-free mean to defibrate wood (Mason 1926a,b; Mason 1928) or to produce sugars and alcohol from wood (Babcock 1932). Steam explosion is a physicochemical process in which the biomass is treated with high temperature and pressure saturated steam (typically >200 °C and 15 bar) for a relatively short retention time (in the order of min), followed by a sudden discharge (in the order of seconds) to atmospheric pressure, thus inducing an explosive decompression of biomass (Wang et al. 2015). During the treatment, saturated steam under high pressure penetrates the recalcitrant cell wall by diffusion, and the mechanical separation of fibers is achieved by the sudden evaporation of condensed moisture from the pressure release. Correspondingly, a shear force is generated and acts on the surrounding structure, resulting in the mechanical breakdown of lignocellulosic biomass (Jeoh 1998). During the penetration of saturated steam into the biomass cell wall, similar to the prehydrolysis, the hemicelluloses, especially xylan, are debranched, releasing acetic acid and uronic acids, creating a slightly acidic environment, promoting the hydrolytic degradation of the hemicelluloses and a cellulose into oligomeric and monomeric carbohydrates or, with increased treatment intensity, even further into furanics compounds and humins (Sjöström 1993; Wang et al. 2015). Under mild acidic but high temperature conditions, lignin undergoes simultaneous depolymerization and recondensation (Li et al. 2007), i.e. too harsh treatment could yield a highly condensed and unreactive lignin fraction, which impairs the subsequent treatment of the solid residue from steam explosion.

Due to the extremity of treatment conditions, existing research effort has been naturally oriented to employ steam explosion for deconstructing and valorizing biomass at molecular level such as monosaccharides, ethanol, bio-oil or syngas. For boosting the enzymatic digestibility of both cellulose and hemicelluloses in the conversion of biomass to monosaccharide platform chemicals, steam explosion (optionally catalyzed by SO2, H2SO4 or NaOH) were conducted on a wide variety of substrates such as wood (eucalyptus (Park et al. 2012), spruce (Monavari et al. 2009) or fir (Kumar et al. 2010)), annual plants (bamboo (García-Aparicio et al. 2011a), willow (Sassner et al. 2008)) or agricultural waste (rice straw (Chen et al. 2013), wheat straw (Horn et al. 2011) or corn stover (Öhgren et al. 2007)). Steam explosion has also been playing an important role in tackling the lignocellulosic recalcitrance for the high-yield production of second-generation bioethanol (García-Aparicio et al. 2011b; Monavari et al. 2010; Moreno et al. 2013). Cellunolix™ technology developed by St1, Finland is at the forefront, already operating in commercial scale, producing bioethanol, CO2, wood vinasse, furfural, turpentine and biogas from softwood sawdust (Yamamoto et al. 2020). Another less explored but still promising pathway is the gasification of steam-exploded wood, yielding a synthesis gas with a higher C and lower O content (Gunarathne et al. 2014).

Despite being a less popular field of research, a few notable works on valorizing biomass in macromolecular fibrous form by steam explosion were reported. San Martín et al. (1995) proposed the steam explosion-kraft process for simultaneous production of kraft pulp and ethanol (San Martín et al. 1995). However, the pulp quality was inferior to a standard kraft pulp and the ethanol concentration in the washing filtrate was too low for a meaningful recovery. Martín-Sampedro et al. (2014) reported a better delignification of the mild steam explosion-kraft in comparison to prehydrolysis-kraft for producing dissolving pulp (Martin-Sampedro et al. 2014). Montane et al. (1998) introduced a biorefinery concept based on steam explosion-soda pulping of wheat straw to produce viscose-grade dissolving pulp (Montane et al. 1998).

In general, operating two consecutive high-temperature, energy-intensive stages such as steam explosion and kraft/soda pulping are not favorable for the pulp yield, the process economy and the digestor investment. Therefore, this work investigates the pulping of Finnish silver birch (Betula pendula, one of the most recalcitrant hardwood species) by a mild steam explosion, followed by a mild alkaline extraction and a TCF purification sequence, with the aim of producing a high-quality dissolving pulp with properties comparable to those of commercial PHK pulps for MMCFs applications.

2 Materials and methods

2.1 Materials

Betula pendula (Finnish silver birch) wood chips were provided by Stora Enso, Finland. The chips were screened according to the SCAN-CM 40:01 standard and stored at −20 °C. Some of the chips were air-dried and then ground to sawdust in a Wiley mill (Arthur H. Thomas Co., model No. 2 with screen opening 0.5 mm). Only those wood particles with size smaller than 125 μm were collected for compositional analysis. The chemical composition of the wood was 39.1 % cellulose, 26.7 % xylan, 4.1 % other carbohydrates, 24.9 % total lignin and 2.6 % extractive. Steam explosion experiments were conducted on screened wood chips. Demineralized water was produced on-site with an ion-exchange purification system. O2 was purchased from AGA in liquid state stored in steel cylinder. NaOH (as pellet) and MgSO4 (as powder) was purchased from WVR in technical grade with >95 % purity. O3 was generated on-site from O2. H2O2 (as 30 % solution) was purchased from WVR.

2.2 Production of dissolving wood pulp by StExCell

Fully bleached dissolving pulp was produced from wood chips by steam explosion (SE), followed by caustic extraction (E), two-stage oxygen delignification (OO) and a short TCF bleaching consisting of an ozone (Z) stage and a peroxide (P) stage, with water washing (W) after each stage (Figure 1).

Overview of the StExCell concept for producing dissolving wood pulp (DWP) by steam explosion, caustic extraction (E), oxygen delignification (O) and total-chlorine-free (TCF) bleaching (Z: ozone; P: Peroxide brightening). Water washing (W) is conducted after each stage.

2.2.1 Steam explosion

SE experiment was performed in a pilot reactor system (constructed by the workshop of School of Chemical Engineering, Aalto University Finland) consisting of a 10-L reactor vessel heated by an oil-jacket and connected to a 10-L steam generator (for chip steaming and direct heating) and a 10-L collection tank (for rapid pressure relief, i.e. explosion). A representative steam explosion experiment is illustrated in Figure 2. The reactor system was controlled by the eLabs program from eLabs Oy Engineering, Rauma, Finland. The SE was conducted either uncatalyzed (henceforth referred to as SE) or catalyzed by oxalic acid (henceforth referred to as CSE). A reference vapor-phase prehydrolysis (PH) was also conducted in the same reactor system. The experimental conditions are summarized in Table 1 and 2. Chronologically, the experiments with 5 and 10 min (CSE 1–4, SE 1–3 and SE 7) were conducted as mapping trials to preliminarily investigate the extent of hemicellulose removal and cellulose degradation, based on which the remaining experiments (SE 4–6) were performed to optimize the reaction time.

A representative temperature-intensity (P-factor) profiles of steam explosion and reference prehydrolysis experiments with a P-factor of 1,250. The isothermal time at maximum reaction time for steam explosion (210 °C) was 7 min and for prehydrolysis (170 °C) was 115 min.

Summary of catalyzed and uncatalyzed SE and reference PH experiments.

| Experiment ID | Oxalic acid (% on wood) | L:W (a) | Tmax (°C) | tisothermal at Tmax (min) | P-factor | p (bar) |

|---|---|---|---|---|---|---|

| CSE 1 | 1 | 1.5 | 230 | 5 | 3,100 | 28 |

| CSE 2 | 1 | 1.5 | 230 | 10 | 6,600 | 28 |

| CSE 3 | 1 | 1.5 | 210 | 5 | 950 | 19 |

| CSE 4 | 1 | 1.5 | 210 | 10 | 1,800 | 19 |

| SE 1 | 0 | 1.5 | 230 | 5 | 3,700 | 28 |

| SE 2 | 0 | 1.5 | 230 | 10 | 6,900 | 28 |

| SE 3 | 0 | 1.5 | 210 | 5 | 1,000 | 19 |

| SE 4 | 0 | 1.5 | 210 | 7 | 1,250 | 19 |

| SE 5 | 0 | 1.5 | 210 | 8 | 1,400 | 19 |

| SE 6 | 0 | 1.5 | 210 | 9 | 1,600 | 19 |

| SE 7 | 0 | 1.5 | 210 | 10 | 1,900 | 19 |

| Reference PH | 0 | 1.5 | 170 | 115 | 1,250 | 8 |

-

(a)Liquor-to-wood ratio.

Conditions and chemical charges for the purification of steam-exploded wood.

| Starting pulp | Stage | T (°C) | t (min) | Consistency (%) | O2 (bar) | O3 | NaOH | H2O2 | Mg | H2SO4 |

|---|---|---|---|---|---|---|---|---|---|---|

| kg/t of steam-exploded wood or pulp | ||||||||||

| SE | E | 80 | 60 | 10 | – | – | 100–200 | – | – | – |

| SE-E | O1 | 95 | 30 | 10 | 8 | – | 25 | – | 1 | – |

| SE-E-O1 | O2 | 110 | 60 | 10 | 8 | – | 25 | – | – | – |

| SE-E-O1-O2 | Z | 20 | <10 | 30–35 | – | 3–7 | – | – | – | 11 |

| SE-E–OO–Z | P | 80 | 240 | 10 | – | – | 25 | 15 | 1 | – |

The intensity of the pretreatment (steam explosion or pre-hydrolysis) is expressed by P-factor, which unify the prehydrolysis time and temperature as a single variable in a time-integral computed Arrhenius-type equation using experimentally determined average activation energy and frequency factor for the cleavage of glycosidic bonds of the carbohydrate material in biomass (Sixta 2006a).

In uncatalyzed SE experiment, the frozen birch chips were loaded into the reactor at least 12 h before the reaction for thawing. In oxalic-acid-catalyzed SE, the chips were submerged in 7 L of 1.25 wt.% oxalic acid solution for 3 days with occasional mixing to ensure a homogenous distribution of oxalic acid on the wood. The wood chip suspension was then dewatered by centrifugation to remove the free liquid. The oxalic acid in the entrapped liquid within the chips corresponded to 1 wt.% of the wood chip dry mass (determined by mass balance of a preliminary submerge-dewatering trial, assuming negligible Donnan effect). The acidic wood chips were then loaded into the reactor.

The biomass was heated to reaction temperature with the combination of oil-jacket heating and steam, fed from the steam generator to a liquid-to-wood ratio (L:W) of 1.5 and held for the pre-defined isothermal reaction time before releasing the steam to the receiving tank which was connected via a cooling coil to a bottle at atmospheric pressure for collecting the condensate. Due to inherent hardware limitation, the pressure took 4–6 s to drop from maximum pressure (28 bar at 230 °C and 19 bar at 210 °C) to 4 bar and another 10–20 s to atmospheric pressure, which is slower than a typical industrial steam exploder. However, such pressure relief should still induce sufficient stress to the biomass cell-wall, resulting in more accessible structure for subsequent treatments.

Immediately after the reactor pressure reached atmospheric level, 5 L of ice-cold water was pumped into the reactor from the top, effectively serving as the first washing stage, as well as quenching the reaction. When the reactor temperature reached 70 °C, the raw washing filtrate was drained from the bottom valve and the reactor was opened. The solid residue, henceforth referred to as “steam-exploded wood”, was simultaneously washed and defibrated by disintegrating into an excessive amount of boiling water in a stainless-steel mixer. The washing suspension was then centrifuged to collect the washed steam-exploded wood, which was subsequently homogenized in a dough mixer (Metos Karhu RN20) and stored in sealed plastic bags at 4 °C. The collected centrifuged liquid was combined with the raw washing filtrate and the condensate, henceforth referred to as “SE-filtrate”, and stored at −18 °C.

2.2.2 Total chlorine free purification of steam-exploded wood

Steam-exploded wood produced from experiment SE 4 (uncatalyzed SE at 210 °C for 7 min, equivalent to a P-factor of about 1,250) was further purified by E−, OO-, Z- and P- stages to produce a fully bleached dissolving pulp. The E−, OO- and P-stages were conducted at medium consistency (10 %) in the 2.5-L autoclaves heated in an air-bath reactor (Haato-tuote 16140–538). The Z-stage was conducted at high consistency (>30 %) in a rotary glass reactor connected to the Wedeco GSO30 generator which produced ozone from pure oxygen.

After each purification stage, the pulp was washed with excessive hot water in plastic bucket by manual mixing. Following the W2 and W3 stages (post-E and post-O washing, Figure 1), the pulp was screened in a table-top screener (G.A. Serlachius A.B., model 16140–567) with slotted//0.35 mm and//0.17 mm mesh-opening, respectively, for reject removal. The washing suspension was then centrifuged to collect the filtrates (named according to the stages, Figure 1), which was stored at −18 °C, and the washed pulp, which was subsequently homogenized in a kitchen blender (Bosch Multitalent 8) and stored in sealed plastic bags at 4 °C.

The oxygen delignification conditions were adapted from the laboratory knowhows and previous works conducted at Department of Bioproducts and Biosystems, Aalto University (Granatier et al. 2023; Jafari 2015). The caustic extraction and ozone treatment stages were first optimized (Supporting Material 1), from which the selected conditions were applied on a newly produced steam explosion pulp batch with the SE 4 recipe (which is the source of minor deviations in the pulp yield and properties between Table 4, Table 5, Table S1 and Table S2).

Properties of lignin-rich, hemicellulose-lean pulps produced from uncatalyzed and catalyzed steam explosion of Betula pendula wood chips, in reference to a prehydrolysis treatment.

| Experiment ID | Oxalic acid (% on wood) | Tmax (°C) | t (a) (min) | P-factor (b) | p (bar) | Yield (% on wood) | Cellulose | C5 Hemi. (c) | C6 Hemi. (c) | Lignin | η (e) (mL/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| % on pulp (% on wood) (d) | |||||||||||

| Birch wood | – | – | – | – | – | 100.0 | 39.6 | 27.7 | 3.7 | 26.4 | – |

| CSE 1 | 1 | 230 | 5 | 3,100 | 28 | 59.1 | 53.9 (31.9) | 0.3 (0.2) | 0.0 (0.0) | 45.7 (27.0) | 119 |

| CSE 2 | 1 | 230 | 10 | 6,600 | 28 | 56.9 | 50.3 (28.6) | 0.1 (0.1) | 0.0 (0.0) | 49.7 (28.3) | 106 |

| CSE 3 | 1 | 210 | 5 | 950 | 19 | 60.3 | 59.1 (35.6) | 1.5 (0.9) | 0.4 (0.2) | 39.0 (23.5) | 240 |

| CSE 4 | 1 | 210 | 10 | 1,800 | 19 | 60.0 | 57.1 (34.3) | 0.8 (0.5) | 0.1 (0.1) | 42.0 (25.2) | 176 |

| SE 1 | 0 | 230 | 5 | 3,700 | 28 | 62.2 | 60.6 (37.7) | 0.8 (0.5) | 0.0 (0.0) | 38.6 (24.0) | 144 |

| SE 2 | 0 | 230 | 10 | 6,900 | 28 | 62.3 | 49.0 (30.5) | 0.2 (0.1) | 0.1 (0.1) | 50.7 (31.6) | 122 |

| SE 3 | 0 | 210 | 5 | 1,000 | 19 | 67.7 | 58.2 (39.4) | 7.0 (4.8) | 1.3 (0.9) | 33.4 (22.6) | 789 |

| SE 4 | 0 | 210 | 7 | 1,250 | 19 | 66.0 | 59.5 (39.3) | 5.3 (3.5) | 1.0 (0.6) | 34.2 (22.6) | 745 |

| SE 5 | 0 | 210 | 8 | 1,400 | 19 | 64.0 | 59.0 (37.8) | 4.3 (2.7) | 0.0 (0.0) | 36.7 (23.5) | 689 |

| SE 6 | 0 | 210 | 9 | 1,600 | 19 | 62.6 | 58.7 (36.7) | 3.5 (2.2) | 0.0 (0.0) | 37.8 (23.7) | 532 |

| SE 7 | 0 | 210 | 10 | 1,900 | 19 | 64.3 | 53.1 (34.1) | 2.7 (1.7) | 0.4 (0.2) | 43.8 (28.2) | 428 |

| Prehydrolysis | 0 | 170 | – | 1,250 | – | 70.7 | 55.2 (39.0) | 8.8 (6.2) | 0.9 (0.7) | 35.1 (24.8) | – |

-

(a) Isothermal time at maximum reaction temperature (including heat-up). (b) P-factor was rounded to the nearest 50 value (e.g., 1,234 is rounded to 1,250). (c) Hemicellulose. (d) The values in bracket (italic and smaller font) are pulp composition expressed as original wood compound equivalent (% on wood = % on pulp x yield). (e) Lignin-free intrinsic viscosity (correction as demonstrated in Section 2.3.1).

Properties of pulp produced from uncatalyzed steam explosion (210 °C, 7 min, equivalent to a P-factor of about 1,250) of Betula pendula wood chips, followed by caustic extraction (80 °C, 60 min, 100–200 kg NaOH/t of steam-exploded wood) with a reference by prehydrolysis treatment.

| Experiment ID | T (°C) | t (min) | Consistency (%) | NaOH (kg/t) | Yield (% on wood) | Rejects | Cellulose | C5 Hemi. (c) | C6 Hemi. (c) | Lignin | Kappa (number) | η (d) (mL/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % on pulp (% on wood) (d) | ||||||||||||

| Birch wood | – | – | – | – | 100.0 | – | 39.6 | 27.7 | 3.7 | 26.4 | – | – |

| SE(a) | – | – | – | – | 66.0 | – | 59.5 (39.3) | 5.3 (3.5) | 1.0 (0.6) | 34.2 (22.6) | – | 745 |

| SE-E100 | 80 | 60 | 10.0 | 100.0 | 40.1 | 1.7 | 86.5 (34.7) | 4.1 (1.7) | 0.9 (0.4) | 8.5 (3.4) | 45.5 | 838 |

| SE-E150 | 80 | 60 | 10.0 | 150.0 | 40.5 | 0.9 | 87.2 (35.3) | 3.7 (1.5) | 0.7 (0.3) | 8.3 (3.4) | 44.1 | 847 |

| SE-E200 | 80 | 60 | 10.0 | 200.0 | 40.2 | 1.3 | 87.5 (35.2) | 3.5 (1.4) | 0.7 (0.3) | 8.4 (3.4) | 44.5 | 866 |

| PH(b) | – | – | – | – | 70.7 | – | 55.2 (39.0) | 8.8 (6.2) | 0.9 (0.7) | 35.1 (24.8) | – | – |

| PH-E100 | 80 | 60 | 10.0 | 100.0 | 44.1 | 6.1 | 77.8 (34.3) | 7.5 (3.3) | 1.8 (0.8) | 12.9 (5.7) | 64.5 | 1,296 |

| PH-E200 | 80 | 60 | 10.0 | 200.0 | 42.7 | 6.1 | 79.3 (33.9) | 6.4 (2.7) | 1.7 (0.7) | 12.6 (5.4) | 59.8 | 1,306 |

-

(a) Steam explosion with P-factor 1,250 (SE 4 experiment in Table 1). (b) Reference prehydrolysis with P-factor 1,250. (c) Hemicellulose. (d) Lignin-free intrinsic viscosity (correction as demonstrated in Section 2.3.1).

Total chlorine free (TCF) purification of pulp produced from uncatalyzed steam explosion (210 °C, 7 min, equivalent to a P-factor of about 1,250) of Betula pendula wood chips, in reference to the TCF purification of a Visbatch® PHK pulp also from Betula pendula (adapted from Sixta 2006a, chapter 4.2.7.2.3) and a commercial birch PHK pulp.

| Experiment ID | T (°C) | t (min) | Consistency (%) | O2 (bar) | O3 (kg/t pulp) | NaOH | H2O2 | Mg | H2SO4 | Yield (% wood) | Xylan (% pulp) | η (d) (mL/g) | Kappa (number) | Brightness (%ISO) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SE(a) | – | – | – | – | – | – | 0.0 | 0.0 | 0.0 | 66.0 | 5.3 | 745 | – | – |

| SE-E | 80 | 60 | 10.0 | – | – | 100.0 | – | – | – | 41.5 | 4.4 | 825 | 45.5 | 21.1 |

| SE-E-OO | 95/110 | 30/60 | 10.0 | 8/8 | – | 25/25 | – | 1/0 | – | 36.9 | – | 686 | 7.6 | 57.5 |

| SE-E–OO–Z | 20 | – | 33 | – | 6.4 | – | – | – | 11 | 36.6 | – | 537 | – | 80.8 |

| SE-E–OO–Z-P | 80 | 240 | 10 | – | – | 25 | 15 | 1 | – | 35.7 | 3.6 | 425 | – | 89.2 |

| PHK(b) | – | – | – | – | – | – | – | – | – | 31.1 | 4.5 | 654 | 7.7 | 43.3 |

| PHK-O | 110 | 90 | 12 | 7 | – | 25 | – | 1 | – | 30.3 | – | 525 | 2.6 | 70.4 |

| PHK-O-A | 50 | 30 | 2.5 | – | – | – | – | – | 3 | 30.3 | – | 524 | – | 71.6 |

| PHK-O-A-Z | 50 | – | 10 | – | 2.7 | – | – | – | 1 | 30.2 | – | 466 | – | 84.4 |

| PHK-O-A-Z-P | 80 | 180 | 10 | – | – | 11 | 8 | 1 | – | 30.1 | 3.6 | 420 | – | 90.0 |

| Commercial PHK(c) | – | – | – | – | – | – | – | – | – | – | 6.6 | 434 | – | 90.8 |

-

More detailed pulp characterizations are presented in Table S2. (a) Steam explosion with P-factor 1,250 (SE 4 experiment in Table 1). (b) Pre-hydrolysis of B. pendula at 174 °C with P-factor 1,000; kraft cook at 150 °C with H-factor 1,250, 23 % effective alkali charge, 24 % sulfidity. (c) Commercial elemental chlorine free-bleached prehydrolysis kraft dissolving pulp from B. pendula. (d) Lignin-free intrinsic viscosity (correction as demonstrated in Section 2.3.1).

2.3 Analytics

2.3.1 Pulp samples

The carbohydrate and lignin contents of the pulp samples were analyzed in accordance with the 2-step sulfuric acid hydrolysis method described in the NREL/TP-510-42618 standard. The hydrolyzed suspension was then filtered through a Robu® glass crucible (porosity 4) to gravimetrically determine the acid insoluble (Klason) lignin fraction. The acid soluble lignin content of filtrate was quantified by measuring the absorbance at 25 °C at the wavelength of 205 nm (Shimadzu UV-2550 spectrophotometer) with an extinction coefficient of 110 L/(g.cm) (Swan 1965). The monosaccharide content in the filtrate was determined by high-performance anion-exchange chromatography (HPAEC) in a Dionex™ ICS-3000 device. The HPAEC system was equipped with an amperometry cell detector and a CarboPac™ PA20 column (3.0 mm × 150 mm). The column and detector were at 22 °C. The eluent was water with a flowrate of 0.37 mL/min. The samples were filtered through a 0.22 μm syringe filter before the analysis. From the amount of neutral monosaccharides, the cellulose and hemicelluloses content in wood and pulp samples was estimated with the Janson formula (Janson 1970).

The pulp samples were analyzed for kappa number and intrinsic viscosity in accordance with the SCAN-C 1:00 and SCAN-CM 15:88 standards, respectively. The intrinsic viscosity of lignin-containing samples is reported as lignin-free intrinsic viscosity, assuming a negligible contribution of lignin to the viscosity of the pulp solution in cupriethylenediamine, calculated by dividing the intrinsic viscosity value obtained from the standard measurement by (100 %-lignin content of the pulp). For validation of the correction calculation, selected lignin-rich pulp samples were bleached with sodium hypochlorite in acetic acid (Wise method) (Wise and D’ Addieco 1946) for the selective removal of lignin before intrinsic viscosity measurement and the values obtained from Wise-treated pulp and untreated pulp with lignin-free correction were reasonably comparable.

The molar mass distribution (MMD) of the pulp samples was determined by size exclusion chromatography (SEC). Prior to the analyses, the samples were subjected to the water/acetone/N,N-dimethylacetamide (DMAc) solvent exchange sequence. The pulp in DMAc was dissolved in 90 g/L LiCl containing DMAc at room temperature and under constant gentle stirring. The samples were then diluted to 9 g/L LiCl/DMAc, filtered with 0.2 μm syringe filters, and fed to a Dionex Ultimate 3000 HPLC system equipped with four PLgel MIXED-A 7.5 × 300 mm columns and a Viscotek/Malvern SEC/MALS 20 multi-angle light-scattering (MALS) detector. The eluent was 9 g/L LiCl/DMAc with a flowrate of 0.75 mL/min. A narrow (low polydispersity index, PDI) polystyrene standard (Mw = 96[thin space (1/6-em)]000 g mol−1, PDI = 1.04) was used to obtain the detector constants for MALS and DRI, whereas a broad polystyrene sample (Mw = 248[thin space (1/6-em)]000 g mol−1, PDI = 1.73) was applied to test the calibration of the detectors. A ∂n/∂c value of 0.136 mL/g was reported for cellulose dissolved in 9 g/L LiCl/DMAc (Potthast et al. 2015). The distribution of the cumulative weight fractions over the entire molar mass range was also evaluated to calculate the weight fractions with degree of polymerization (DP) <100 and DP > 2000.

2.3.2 Liquid samples

The carbohydrate content in the liquid samples were analyzed in accordance with the method described in the NREL/TP-510-42623 standard, by the same HPAEC system described in Section 2.3.1. The monomeric sugar content was determined by direct injection in the HPAEC, while the total sugars content was determined by HPAEC after hydrolysis in 4 % H2SO4 at 121 ± 1 °C for 60 min. The lignin content in the liquid samples was determined by UV-Vis spectrophotometry (Shimadzu UV-2550) at 25 °C by dilution in 50 wt.% ethanol and measuring the absorption at a wavelength of 205 nm, with an extinction coefficient of 110 L/(g.cm) (Swan 1965).

The content of furanic compounds (furfural and hydroxymethylfurfural) and organic acids (formic acid, acetic and levulinic acid) in the liquid samples was determined by high-performance liquid chromatography (HPLC) in a Dionex UltiMate 3,000 system equipped with a UV diode array detector and a HyperREZ XP Carbohydrate Ca+ column (7.7 × 300 mm). The UV detection wavelength was 210 nm and 280 nm for organic acids and furanic compounds, respectively. The column and detectors were at 70 °C and 55 °C, respectively. The eluent was 0.0025 mol/L H2SO4 with a flowrate of 0.5 mL/min. The samples were filtered through a 0.22 μm syringe filter before the analysis.

2.4 Regenerated fibers production and characterization

The bleached StExCell (SE-E–OO–Z-P) pulp and a reference commercial birch PHK pulp were converted to regenerated cellulosic fibers by the Ioncell® process, which is a lyocell-type dry-jet wet spinning technique using ionic liquids (IL) as the direct cellulose solvent (Sixta et al. 2015).

2.4.1 Ionic liquid and cellulosic spinning solution preparation

The [DBNH][OAc] (1,5-diazabicyclo[4.3.0]non-5-ene acetate) was prepared by neutralization of DBN with an equimolar amount of acetic acid (OAc, glacial, 100 %, Merck, Germany) at 75 °C under stirring. The mixture was subsequently stirred for another 30 min to ensure complete conversion.

A 13 wt.% cellulosic spinning solution (dope) was prepared by dissolving the pulp in [DBNH][OAc] in a vertical kneader operating at 75 °C under a vacuum of 10–20 mbar for a duration of 2 h. Subsequently, the dope was filtered using a pre-heated hydraulic press filtration system with a 5–6 µm mesh metal filter fleece to remove the undissolved cellulose fibers at 150–200 bar.

2.4.2 Rheology measurement of the spinning dope

The viscoelastic properties of the cellulose dope were assessed using an Anton Paar MCR 302 rheometer employing a 25 mm plate-plate geometry and 1 mm measuring gap. A dynamic frequency sweep was conducted from 100 to 0.01 s⁻1 to acquire data on the complex viscosity (η*), as well as the dynamic moduli (G′, G″). The frequency sweeps were performed over a temperature range of 50–90 °C, with intervals of 5 °C. The zero-shear viscosity, η°, was determined by fitting the complex viscosity data to the Cross-viscosity model, assuming that the Cox-Mertz rule is valid.

2.4.3 Fiber spinning

2.4.3.1 Single filament spinning

A small amount of dope (approximately 20 g) was placed into a monofilament dry-jet wet spinning unit (manufactured by Fourné Polymertechnik) and heated to the spinning temperature (65 °C for reference pulp and 70 °C for StExCell pulp), determined by dope rheological properties. The dope was then extruded through a capillary with a diameter of 100 µm and length of 200 µm into an air gap where the dope was stretched to reach different draw ratios (DRs) before regeneration in water coagulation bath. The water bath was kept at 5–6 °C. The extrusion velocity was kept constant at 1.3 m/min, while the take-up velocity (the speed of the godets collecting the fibers) was varied to collect fibers at different DRs. The collected filaments were cut into 8 cm long pieces and washed with 80 °C water for 2 h to remove any residual IL.

2.4.3.2 Multi-filament fiber spinning

A large dope (approximately 600 g) was placed into a spinning unit (operating at 65 °C for reference pulp and at 70 °C for StExCell pulp) and then extruded through a 200-hole spinneret with a capillary diameter of 100 µm and length of 20 µm. The spinning bath temperature was kept at approximately 10 °C. The extrusion speed was kept constant at 3.5 m/min. The filaments were mainly collected at DR 6. The collected filaments were cut into 8 cm long pieces and washed with 80 °C water for 2 h to remove any residual IL.

2.4.4 Testing of regenerated fibers

The mechanical properties of the cellulose fibers were determined by using a Favigraph automatic single-fiber tester (Textechno H. Stein GmbH & Cpo, Germany) based on the ISO 5079:2020 standard (20 mm gauge length, 0.06 cN/tex pretension, 20 mm/min test speed). The fibers were conditioned overnight (20 ± 2 °C, 65 ± 2 % relative humidity) before the testing. For each sample, 10−20 fibers were tested at 20 °C and 65 % relative humidity.

2.4.5 Fiber finishing, yarn spinning and fabric knitting

The air-dried fibers produced from the multi-filament spinning were immersed in an aqueous finishing solution (consisting of Afilan CVS and Leomin PN with a mass ratio of 80:20) at 50 °C for 5 min to reduce the fiber friction and static properties. The targeted amount of spin finish was 0.25 % based on the mass of dry fibers and the sample to liquid ratio was 1:20. The excess water was removed by hand pressing to reach fourfold of its oven-dry weight and was then air-dried. Afterward, the spin-finished fibers were opened with a fiber opener (Trash Analyzer 281C Mesdan Lab, Mesdan S.p.A. Italy).

Yarn spinning was performed as described by Michud et al. (Michud et al. 2016). Firstly, the staple fibres were treated with target amount of 0.25 % m/mfibre of lubricant; 80/20 % of Afilan CVS (ARCHROMA, Switzerland) and Leomin PN (ARCHROMA, Switzerland), respectively. The fibres were submerged into a solution (liquor ratio of 1:20) comprising Afilan CVS (0.677 g L−1) and Leomin PN (0.233 g L−1) and heated at 45 °C for 5 min (manually stirred). Then, the fibres were pressed to reach 300 % pick-up and air dried. Next the fibres were manually opened and left overnight in a conditioned room (65 % relative humidity; 20 °C). The opened fibres were carded (carding machine 337A, Mesdan SpA, Italy) and rolled into sliver using Stiro lab 3,371 (Mesdan SpA, Italy) for roving, stretching and doubling. The sliver was drafted twice, and in the second drafting the sliver was doubled by folding in half. Finally, the doubled sliver was again folded and roving was produced. The roving was then ring spun (Ring Lab 82BA; SER.MA.TES srl, Italy) into a 20-tex yarn (Nm 50, Ne 30). The yarn had Z torsion and the number of twists per meter (TPM) was 700. The calculated twist multiplier expressed in Ne was 3.4. The linear density of the spun yarn was determined from 10-m skeins (n = 10; expressed in tex).

The yarn was plied (without any torsion) for knitting with the jersey pattern by the Lab-knitter 297E (Mesdan SpA, Italy).

3 Results and discussion

3.1 Lignin-rich, hemicellulose-lean pulp produced by steam explosion

Steam explosion has been originally and commonly adapted as a biomass pretreatment method for improving the accessibility of the lignocellulosic structure, thus enhancing the efficiency of the subsequence enzymatic hydrolysis to produce bio-based fuel or platform chemicals. In the applications where biomass was deconstructed and valorized at molecular level, steam explosion was conducted either autocatalyzed at a higher temperature (ca. 250 °C) (Foody 1980; Schultz et al. 1984) or acid-catalyzed at a milder temperature (200–220 °C) (Nunes and Pourquie 1996; Wu et al. 1999). If the steam-exploded pulp is intended for applications at supramolecular level, e.g., rayon-grade dissolving pulp, where the DP of the cellulose fraction is preferably preserved to certain extent, such treatment severity is excessive. Conducting the steam explosion at maximum temperature higher than 210 °C or at 210 °C for longer than 9 min, or in the presence of an acid catalyst would quantitatively remove the hemicellulose, however, at the expense of the cellulose fraction which was degraded to an intrinsic viscosity of less than 250 mL/g (Table 1), rendering the pulp useless for textile application (bleached rayon-grade dissolving pulp typically having an intrinsic viscosity of 400–600 mL/g (Sixta 2006b)). In the more intense treatments (CSE 1, CSE 2, SE 2 and SE 7), the yield of residual lignin in exploded wood was higher than the original lignin in the birch wood raw material. Such discrepancy originated from the “pseudo-lignin”, aromatic material that yields a positive Klason lignin value but not derived from native lignin, which is a typical overestimation in the two-staged acid hydrolysis method for compositional analysis of samples produced from acidic treatments (Hu et al. 2012). Even though the other treatments (CSE 3, CSE 4, SE 1, SE 3–6) did not exhibit a surplus lignin yield, the determined lignin most probably contained a fraction of pseudo lignin.

The extent of hemicellulose removal in the reference vapor-phase prehydrolysis was significantly inferior than experiment SE 4 with comparable intensity (P-factor of 1,250), which is a clear indication of the rupture of the rigid cell wall as a result of the steam explosion, leading to enhanced accessibility (Wang et al. 2015). The cellulose fraction remained relatively well-preserved in the uncatalyzed steam explosion experiment for 7 min at 210 °C (SE 4, Table 3), while at higher intensity, the low residual xylan content (<4 % on wood) no longer provided sufficient protection against the acid hydrolysis of cellulose, which in turn reduced the selectivity (Borrega et al. 2011). Further evidence of better accessibility to the steam-exploded solid residue is discussed in Section 3.2.1.

3.2 Total chlorine free purification of steam-exploded wood

The solid residue from the uncatalyzed steam explosion at 210 °C for 7 min (SE 4), with reasonably low xylan content (5.3 % on pulp) and high enough lignin-free viscosity (745 mL/g) was selected for further purification processes to produce fully bleached dissolving pulp.

3.2.1 Caustic extraction

Caustic extraction of the steam-exploded wood SE 4 at 80 °C and with a moderately low NaOH charge of 100 kg/t of steam-exploded wood (corresponding to a concentration of ca. 11 g NaOH/L) could remove 85 % of the residual lignin, 50 % of the residual hemicelluloses and <5 % of cellulose (the lower molecular weight fraction) from the steam-exploded wood, yielding a pulp with a kappa number about 45 and a lignin-free viscosity over 800 mL/g (Table 4), which is potentially suitable for subsequent oxygen delignification and TCF bleaching. Increasing the alkali charge to 200 kg NaOH/t of steam-exploded wood only slightly improved the hemicellulose extraction without any visible enhancement on delignification. In comparison with steam explosion, caustic extraction with 100 kg NaOH/t on prehydrolyzed wood (170 °C, P-factor 1,250) yielded significantly more rejects (6.1 % vs 1–2 %, Table 4) and a pulp with 50 % more lignin and twice the hemicellulose content. The enhanced porosity and accessibility of the steam-exploded wood evidently facilitated the removal of hydrolyzed component during mild caustic extraction, thus resulting in a substantial decrease in the reject proportion (Table 4). The cellulose yield loss in prehydrolysis-caustic extraction was similar (about 5 %), but the remaining cellulose exhibited a considerably higher DP (intrinsic viscosity of about 1,300 mL/g).

Martín-Sampedro et. al (2014) conducted single- or double-staged steam treatments without explosion (prehydrolysis) and mild steam explosion, all at Tmax = 183 °C, on Eucalyptus globulus, followed by kraft pulping. Even though the cellulose fraction in both pulps (indicated by the intrinsic viscosity) was relatively comparable, due to improved structural accessibility compared to the equivalent non-exploded steam treated-kraft pulp, the delignification on steam-exploded-kraft pulp was progressively enhanced with increasing treatment intensity (Martin-Sampedro et al. 2014). The current study employed a harsher pretreatment (P-factor 1,250 for SE4 and PH experiments versus P-factor 350 for 13 min at 183 °C) and a more violent explosion (19 bar at 210 °C versus 10 bar at 183 °C) so that a proper pulp could be produced by applying a mild alkali extraction after steam explosion. Without a strong nucleophile (Na2S) and higher temperature (160 °C) of a kraft cook, the pretreatment efficiency of steam explosion and a standard vapor-phase prehydrolysis was distinguishably amplified.

The pulp produced from the caustic extraction with 100 kg NaOH/t of steam-exploded wood, denoted as SE-E100, was selected for the subsequence oxygen delignification and TCF bleaching.

3.2.2 Oxygen delignification and total-chlorine-free bleaching

The optimization of the TCF sequence is demonstrated in detail in Supporting Material 1. The rejects collected in the post-oxygen screening (slotted//0.17 mm screen type) was less than 0.1 % on original wood. As expected from the underperformance of prehydrolysis against mild steam explosion with comparable treatment intensity (Table 4), continuation to oxygen delignification after caustic extraction followed similar trend. The PH-E-OO pulp was less degraded (intrinsic viscosity ∼1,050 mL/g versus ∼695 mL/g), less delignified (kappa number ∼14.5 versus ∼7.0) and darker (ISO-brightness ∼37 % versus ∼ 57 %) compared to the equivalent SE-E-OO pulp (Table S1 of Supporting Material 1). Due to such large differences in pulp quality after oxygen delignification, no further bleaching trial was conducted with the PH-E100-OO pulp and the StExCell process was subsequently benchmarked with a Visbatch® kraft pulping process followed by oxygen delignification and Z-P bleaching (Sixta 2006a) (Table 5).

Oxygen delignification of SE-E100 pulp was effective with >80 % κ reduction (Table 5) and an intrinsic viscosity loss of 3.8 mL/g per % brightness gain (Figure 3), which can be attributed to the enhanced accessibility of the pulp produced from steam explosion and presumably a low content of condensed lignin structure. Due to the higher residual lignin content after oxygen delignification (κ = 7.6 of SE–E–OO pulp versus κ = 2.6 of PHK-O pulp), higher chemical charges were required to produce a fully bleached StExCell pulp (Table 5). However, both pathways (PHK–O–Z–P and SE–E–OO–Z–P) arrived at the same pulp specification target of 3.6 % residual xylan, 90 % brightness and approximately 420 mL/g intrinsic viscosity.

Selectivity of total chlorine free purification of pulp produced from uncatalyzed steam explosion (210 °C, 7 min, equivalent to a P-factor of about 1,250) of Betula pendula wood chips, in comparison to a reference Visbatch® PHK pulp (adapted from Sixta 2006a, chapter 4.2.7.2.3). (a) Intrinsic viscosity drop against brightness gain and (b) yield loss against brightness gain. The blue square is the steam explosion route while the red circle is the PHK one. The xylan content of bleached pulps produced from both pathways was 3.6 % on pulp.

The yield of bleached pulp was significantly higher in steam explosion than in PHK treatment (Figure 3, Table 5), which is because alkaline hydrolysis and secondary peeling reactions are insignificant in mild caustic extraction, whereas carbohydrate losses are much more pronounced in a more concentrated alkali environment with a significantly higher treatment temperature, such as in kraft pulping (Sixta 2006a).

Despite similar intrinsic viscosity, the molar mass distribution of the bleached steam-exploded pulp was broader than that of the TCF-bleached Visbatch® PHK pulp and the commercial ECF-bleached PHK pulp, with PDI of 4.4, 3.0 and 2.8, respectively (Figure 4), indicating a higher proportion of degraded (lower molecular weight), or so-called beta-cellulose. However, the bleached Visbatch® pulp were not analyzed by the same SEC system and in the same sequence as the bleached StexCell and bleached commercial PHK pulp, therefore, direct comparison should be assessed with caution.

Molar mass distribution of the bleached steam-exploded pulp (SE–E–OO–Z–P), in reference to the bleached Visbatch® PHK pulp (adapted from Sixta 2006a, chapter 4.2.7.2.3) and a commercial elemental chlorine free-bleached pulp. All the pulps are produced from Betula pendula.

In traditional regenerated cellulosic fibers production by the viscose process, bleached SE pulp would result in lower fiber yield due to the removal of lower Mw carbohydrate fractions during steeping in concentrated NaOH. However, such yield loss does not occur in direct dissolution spinning technologies such as lyocell (NMMO or ionic liquid), but the broader MMD would impair, to certain extent, the mechanical strength of fibers (which is further discussed in Section 3.3).

3.3 Regenerated cellulosic fibers from bleached steam-exploded pulp

The cellulosic spinning solution was prepared by dissolving bleached steam-exploded pulp (SE–E–OO–Z–P) in [DBNH][OAc] at 13 wt.% polymer concentration. To assess the spinning behavior, rheological properties of the SE–E–OO–Z–P spinning solution (StExCell dope) were compared with those of a 13 wt.% standard spinning solution (reference dope), prepared from a commercial birch PHK pulp (the same reference pulp in Table 5 and Figure 4), as a function of temperature (Figure 5).

Rheological properties of the spinning dopes produced from the SE–E–OO–Z–P (StExCell) pulp in comparison with a commercial birch PHK (reference) pulp, both at a concentration of 13 wt.%, as a function of temperature: (a) Complex viscosity, (b) complex moduli at COP, (c) angular frequency at COP.

3.3.1 Rheology of the cellulosic spinning solution

Oscillation measurements revealed the viscoelastic properties of the cellulose solutions in a specific temperature range. A dynamic frequency sweep was performed to measure the time-dependent behavior of the spinning dopes in the angular frequency range of 0.01–100 s−1. In practice, the parameters complex viscosity, complex moduli (G’ = G’) and angular frequency at the cross-over point (COP) proved to be relevant for assessing the viscoelastic properties of the spinning solution.

The complex viscosity of the StExCell dope is higher over the entire temperature range than that of the reference dope, which explains the 5 °C higher spinning temperature of the StExCell dope in order to operate at comparable complex viscosities (23,250 Pa s at 70 °C for StExCell dope versus 22,400 Pa s at 65 °C for the reference dope). The angular frequency at COP is characteristic of the mass-weighted molar mass of the solute. Although the intrinsic viscosity of the SE–E–OO–Z–P pulp (425 mL/g) is slightly lower than that of the reference pulp (434 mL/g), the angular frequency is slightly higher at COP over the entire temperature range, which can be explained by the higher proportion of long molecules (DP > 2000) of SE–E–OO–Z–P pulp (12.8 wt.%) than that of the reference pulp (8.0 wt.%), as demonstrated in Figure 4 and Table S2 of Supporting Material 1. The rheological behavior of polymer solutions is disproportionately determined by the long-chain molecules. Therefore, an increase of spinning temperature by 5 °C would match the angular frequency at COP of the StExCell dope to that of the reference dope.

The complex moduli at COP, G’ = G’ of the StExCell and reference dopes exhibited considerable difference, which can be attributed to the significantly different PDI of the cellulose MMD. The cellulose molecules of the SE–E–OO–Z–P pulp are significantly more widely distributed than those of the reference pulp (Figure 4). At ca. 2,500 Pa, the complex moduli at COP of the StExCell spinning solution was just within the easily spinnable range (Michud et al. 2015). Further optimization shall aim to reduce the PDI of the SE–E–OO–Z–P pulp by avoiding excess degradation of long chains during steam-explosion in order to reach the range of 3,000 Pa for the dynamic modulus in the COP.

3.3.2 Production of Ioncell® fibers

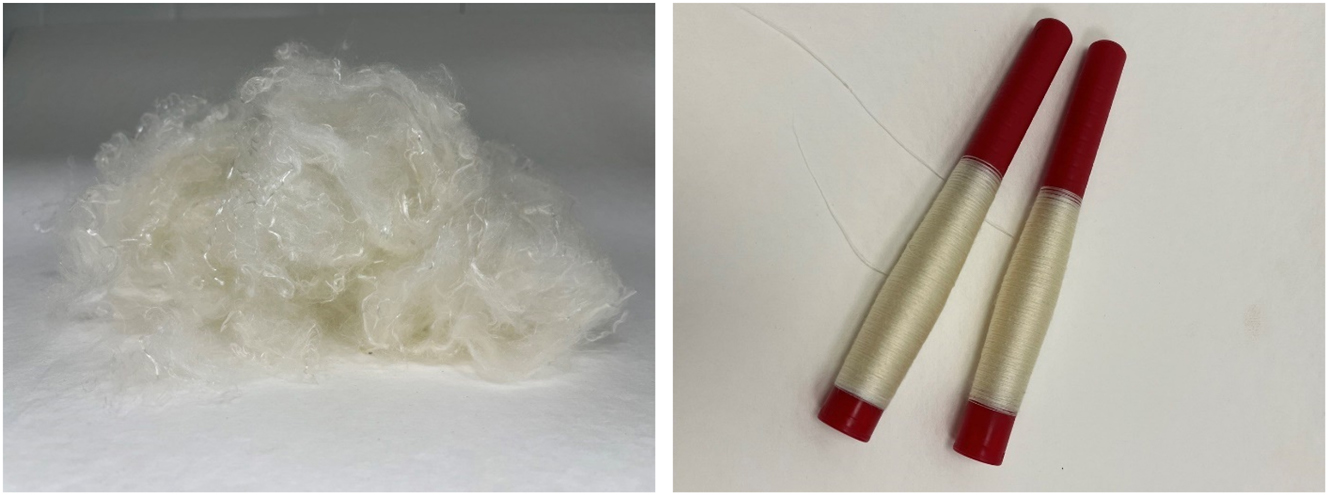

The bleached steam-exploded pulp (SE–E–OO–Z–P) exhibited relatively good spinnability during dry-jet wet spinning. The Ioncell® fibers were successfully produced and subsequently converted into yarns (Figure 6). As the Ioncell® spinning of StExCell pulp was not the focus of this study, but served as a proof-of-concept, only a few spinning trials were conducted, whereby a stable draw ratio of 6 was achieved. The fibers were therefore slightly thicker than standard fibers with a titer of 1.3–1.7 dtex and also exhibited a slightly lower fiber tenacity than the Ioncell® fibres produced from standard PHK pulp, which were, however, still higher than commercial fibers such as lyocell and viscose fibers (Table 6). In a continuation research, the spinning parameters shall be optimized in order to obtain fibers with a standard titer and a slightly higher fiber strength.

Ioncell® fibers (left) and yarns (right) produced from the bleached steam-exploded pulp (SE–E–OO–Z–P).

Mechanical properties of dissolving pulp produced from steam explosion and total chlorine free purification of Betula pendula, in reference to Ioncell® fibers from commercial PHK pulp and commercial fibers.

| Fiber ID | Draw ratio | Titer (dtex) | Tenacity (cN/tex) | Elongation (%) |

|---|---|---|---|---|

| Ioncell® SE-E–OO–Z-P | 6 | 2.4 ± 0.5 | 43.2 ± 3.9 | 10.4 ± 1.5 |

| Ioncell® commercial PHK (a) | 8 | 1.7 ± 0.2 | 49.0 ± 3.9 | 13.2 ± 1.9 |

| Commercial lyocell | – | 1.5 ± 0.3 | 38.5 ± 5.0 | 15.5 ± 4.3 |

| Commercial viscose | – | 1.4 ± 0.4 | 25.8 ± 1.5 | 19.7 ± 2.1 |

-

(a) Ioncell® fibers produced from commercial elemental chlorine free -bleached prehydrolysis kraft dissolving pulp from Betula pendula (Table 5).

3.4 Steam explosion as a basis for a sulfur-free and chlorine-free biorefinery

Besides the ability to produce a pulp with adequate properties, the potential of a novel pulping process should be assessed in terms of the chemical usages, the chemical recovery cycle and the valorization of the extracted raw material components.

3.4.1 Chemical usages and chemical recovery cycle

The extremity of the steam explosion treatments resulted in a more accessible fiber structure, thus facilitating a successful subsequent caustic extraction with a relatively low alkali charge. With a higher kappa number, the steam explosion-caustic extraction pulp consumed almost three-fold of bleaching chemical to reach similar dissolving pulp quality. However, due to the lack of a concentrated alkali stage, the overall chemical consumption of StExCell concept is only half of that of a TCF PHK process (Table 7), more notably, no sulfur-containing chemical (such as Na2S) or pulping catalyst (such as anthraquinone) were employed.

Chemical consumption of the StExCell process, in comparison to a total chlorine free prehydrolysis-kraft process (adapted from Sixta 2006a, chapter 4.2.7.2.3) to produce dissolving pulp with comparable purity.

| Chemical (kg/t wood) | StExCell | TCF prehydrolysis kraft(a) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SE | E | OO | Z | P | SUM | PHK | O | A | Z | P | SUM | |

| NaOH | – | 67 | 21 | – | 9 | 97 | 173 | 8 | – | – | 3 | 184 |

| Na2S | – | – | – | – | – | 0 | 58 | – | – | – | – | 58 |

| O3 | – | – | – | 2 | – | 2 | – | – | – | 1 | – | 1 |

| H2SO4 | – | – | – | 4 | – | 4 | – | – | 3 | 1 | – | 4 |

| H2O2 | – | – | – | – | 6 | 6 | – | – | – | – | 2 | 2 |

| Others | – | – | – | – | – | 4 | – | – | – | – | – | 4 |

| Total | 113 | 253 | ||||||||||

-

(a)Total chlorine free prehydrolysis-kraft as described in Table 5.

Even though the chemical recovery of the proposed StExCell process has not been systematically investigated and is therefore not the subject of this article, the lack of a sulphur-based delignification agent and the significantly lower total alkali requirement suggest a simpler and smaller chemical recovery system with significantly lower investment costs.

For example, NaOH recovery could be accomplished with a small soda boiler instead of a capital-intensive kraft recovery boiler system. A fraction of the NaOH can be hypothetically recycled directly into the circuit by ultrafiltration from the E-filtrate and O-filtrate, so that the soda boiler required to recover the remaining NaOH can be even smaller.

3.4.2 Mass balances and potential valorization of the extracted wood components

The yield loss in StExCell process mainly occurred in the steam explosion and caustic extraction stages (Table 5). The identification, quantification, isolation and valorization of those extracted biomass components shall naturally be focused on the filtrates from those two stages. Similar to any other pulping methods, the bleaching filtrates (Z- and P-) are generally too diluted to be recycled beyond treatment in the wastewater treatment plant.

The valorization of the extracted wood components in the SE-filtrate and the E-filtrate is the subject of further research. However, some treatment pathways are speculated and discussed in this chapter.

Unlike kraft pulping, where the concentrated alkali environment and high temperature promote the decompositions of carbohydrates through peeling reaction, alkaline hydrolysis and retro-aldol fragmentation to various hydroxy carboxylic acids and a wide variety of C2 and C3 fragments (Sjöström 1993; Sixta 2006a), which are unrecoverable and combusted in the recovery boiler, the degraded and extracted carbohydrates in StExCell were relatively well detected with over 80 % of the original wood hemicelluloses collected as furfural, monomeric and oligomeric sugars in the SE-filtrate (Figure 7). A small fraction of wood lignin was removed into the SE-filtrate, most probably as low Mw and sticky lignin, similar to that of prehydrolysis stage (Leschinsky et al. 2008a,b), and should be removed before valorizing the extracted carbohydrate-based components, for example by activated carbon adsorption (Gütsch and Sixta 2011). The remaining carbohydrates (mainly xylose and xylan) can be isolated by quantitative hydrolysis to monomeric forms followed by crystallization (Granatier et al. 2023) or catalytic conversion into furfural, which can be distilled for purification (Karinen et al. 2011; Metkar et al. 2015).

Extracted (calculated from the composition of the pulp) and recoverable (quantified by the analyses of the liquids) fractions of the steam explosion and caustic extraction stages.

Most of the extracted lignin was collected in the E-filtrate, which can be valorized as sulfur-free lignin precipitate via the ultrafiltration route and as energy recovered by a soda boiler as discussed in Section 3.4.1.

4 Conclusions

A rayon-grade dissolving pulp was successfully produced from Betula pendula by the novel sulfur- and chlorine-free StExCell process, consisting of mild steam explosion and mild caustic extraction followed by oxygen delignification and a short total-chlorine-free bleaching sequence. Compared to the classical PHK process, StExCell offers clear advantages in the pulp yield, the elimination of sulphur chemicals, a significant reduction in overall chemical demand. Due to the rapid nature of the steam explosion process and the shorten reaction time in mild caustic extraction, the large, pressurized pulping digesters for PHK can be replaced with a smaller steam exploder followed by an unpressurised vessel for alkali extraction, combining with a simpler chemical recovery systems (as discussed in Section 3.4.1), which would substantially reduce the investment cost. Steam explosion is a highly energy intensive process, demanding significantly higher medium pressure steam compared to classical prehydrolysis, however, the subsequent caustic extraction performed at sub-100 °C could potentially compensate for the overall process energy demand. The energy consumption and energy recovery balance of a StExCell mill, versus a PHK mill, is an obvious future research topic.

The bleached StExCell pulp resembled the properties of a commercially available prehydrolysis kraft pulp and could be spun into high-quality Ioncell® fibers using the dry-jet wet spinning process, which were then successfully processed into yarns and fabrics for demonstration purposes. The chemical recovery and valorization of the isolated wood components (hemicelluloses and lignin) shall be the topic of further StExCell development research.

Acknowledgments

The authors would like to thank Ms. Rita Hataka and Dr. Leena Pitkänen for the support with the chromatographic analyses and Ms. Senni Heimala for the support with yarn spinning and fabric production.

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: Huy Quang Lê: Study conception and design, experiment execution, data collection, analysis and interpretation of results, manuscript preparation. Jialin She: experiment execution, data collection. Wenwen Fang: experiment execution, data collection. Herbert Sixta: study conception and design, analysis and interpretation of results, manuscript preparation. The authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interests: The authors state no conflict of interest.

-

Research funding: None declared.

-

Data availability: The raw data can be obtained on request from the corresponding author.

References

Alonso, D.M., Wettstein, S.G., Mellmer, M.A., Gurbuz, E.I., and Dumesic, J.A. (2013). Integrated conversion of hemicellulose and cellulose from lignocellulosic biomass. Energy Environ. Sci. 6: 76–80, https://doi.org/10.1039/c2ee23617f.Suche in Google Scholar

Babcock, L.W. (1932). Method of producing fermentable sugars and alcohol from wood, US patent application no. US1855464A.Suche in Google Scholar

Borrega, M., Nieminen, K., and Sixta, H. (2011). Degradation kinetics of the main carbohydrates in birch wood during hot water extraction in a batch reactor at elevated temperatures. Bioresour. Technol. 102: 10724–10732, https://doi.org/10.1016/j.biortech.2011.09.027.Suche in Google Scholar PubMed

Carpenter, J., Felsot, A., Goode, T., Hammig, M., Onstad, D., and Sankula, S. (2002). Comparative environmental impacts of biotechnology-derived and traditional soybean, corn, and cotton crops. Council for Agricultural Science and Technology, Ames, Iowa.Suche in Google Scholar

Chanzy, H., Paillet, M., and Peguy, A. (1986). Spinning of exploded wood from amine oxide solutions. Polym. Commun. (Guildford) 27: 171–172.Suche in Google Scholar

Chen, W.-H., Tsai, C.-C., Lin, C.-F., Tsai, P.-Y., and Hwang, W.-S. (2013). Pilot-scale study on the acid-catalyzed steam explosion of rice straw using a continuous pretreatment system. Bioresour. Technol. 128: 297–304, https://doi.org/10.1016/j.biortech.2012.10.111.Suche in Google Scholar PubMed

Foody, P. (1980). Optimization of steam explosion pretreatment. Iotech Corp., Ottawa, Ontario, Canada, Final Report to DOE.10.2172/5170904Suche in Google Scholar

García-Aparicio, M., Parawira, W., Van Rensburg, E., Diedericks, D., Galbe, M., Rosslander, C., Zacchi, G., and Görgens, J. (2011a). Evaluation of steam-treated giant bamboo for production of fermentable sugars. Biotechnol. Prog. 27: 641–649, https://doi.org/10.1002/btpr.580.Suche in Google Scholar PubMed

García-Aparicio, M.P., Oliva, J.M., Manzanares, P., Ballesteros, M., Ballesteros, I., González, A., and Negro, M.J. (2011b). Second-generation ethanol production from steam exploded barley straw by Kluyveromyces marxianus cect 10875. Fuel 90: 1624–1630, https://doi.org/10.1016/j.fuel.2010.10.052.Suche in Google Scholar

Granatier, M., Lê, H.Q., Ma, Y., Rissanen, M., Schlapp-Hackl, I., Diment, D., Zaykovskaya, A., Pokki, J.-P., Balakshin, M., Louhi-Kultanen, M., et al.. (2023). Gamma-valerolactone biorefinery: catalyzed birch fractionation and valorization of pulping streams with solvent recovery. Heliyon 9, https://doi.org/10.1016/j.heliyon.2023.e17423.Suche in Google Scholar PubMed PubMed Central

Gunarathne, D.S., Mueller, A., Fleck, S., Kolb, T., Chmielewski, J.K., Yang, W., and Blasiak, W. (2014). Gasification characteristics of steam exploded biomass in an updraft pilot scale gasifier. Energy 71: 496–506, https://doi.org/10.1016/j.energy.2014.04.100.Suche in Google Scholar

Gütsch, J.S. and Sixta, H. (2011). The hitac-process (high temperature adsorption on activated charcoal) new possibilities in autohydrolysate treatment. Lenzinger Ber. 89: 142–151.Suche in Google Scholar

Horn, S.J., Nguyen, Q.D., Westereng, B., Nilsen, P.J., and Eijsink, V.G.H. (2011). Screening of steam explosion conditions for glucose production from non-impregnated wheat straw. Biomass Bioenergy 35: 4879–4886, https://doi.org/10.1016/j.biombioe.2011.10.013.Suche in Google Scholar

Hu, F., Jung, S., and Ragauskas, A. (2012). Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresour. Technol. 117: 7–12, https://doi.org/10.1016/j.biortech.2012.04.037.Suche in Google Scholar PubMed

Jafari, V. (2015). Extended oxygen delignification of high kappa softwood pulp in a flow-through reactor. Doctor of Science (Technology), Aalto University, Espoo.Suche in Google Scholar

Janson, J. (1970). Calculation of the polysaccharide composition of wood and pulp. Paperi ja Puu 52: 323–329.Suche in Google Scholar

Jeoh, T. (1998). Steam explosion pretreatment of cotton gin waste for fuel ethanol production. Virginia Tech, Blacksburg, Virginia.Suche in Google Scholar

Karinen, R., Vilonen, K., and Niemelä, M. (2011). Biorefining: heterogeneously catalyzed reactions of carbohydrates for the production of furfural and hydroxymethylfurfural. ChemSusChem. 4: 1002–1016, https://doi.org/10.1002/cssc.201000375.Suche in Google Scholar PubMed

Kleinert, T.N. (1971). Organosolv pulping and recovery process, USA patent application no. US3585104A.Suche in Google Scholar

Kleinert, T.N. and Tayenthal, K. (1931). Process of decomposing vegetable fibrous substances for the purpose of obtaining simultaneously the cellulose and the incrusting ingredients. US patent application no. US1856567A.Suche in Google Scholar

Kumar, L., Chandra, R., Chung, P.A., and Saddler, J. (2010). Can the same steam pretreatment conditions be used for most softwoods to achieve good, enzymatic hydrolysis and sugar yields? Bioresour. Technol. 101: 7827–7833, https://doi.org/10.1016/j.biortech.2010.05.023.Suche in Google Scholar PubMed

Lê, H.Q., Ma, Y., Borrega, M., and Sixta, H. (2016). Wood biorefinery based on gamma-valerolactone/water fractionation. Green Chem. 18: 5466–5476, https://doi.org/10.1039/c6gc01692h.Suche in Google Scholar

Leschinsky, M., Zuckerstätter, G., Weber, H.K., Patt, R., and Sixta, H. (2008a). Effect of autohydrolysis of Eucalyptus globulus wood on lignin structure. Part 1: comparison of different lignin fractions formed during water prehydrolysis. Holzforschung 62: 645–652, https://doi.org/10.1515/hf.2008.117.Suche in Google Scholar

Leschinsky, M., Zuckerstätter, G., Weber, H.K., Patt, R., and Sixta, H. (2008b). Effect of autohydrolysis of Eucalyptus globulus wood on lignin structure. Part 2: influence of autohydrolysis intensity. Holzforschung 62: 653–658, https://doi.org/10.1515/hf.2008.133.Suche in Google Scholar

Li, J., Henriksson, G., and Gellerstedt, G. (2007). Lignin depolymerization/repolymerization and its critical role for delignification of aspen wood by steam explosion. Bioresour. Technol. 98: 3061–3068, https://doi.org/10.1016/j.biortech.2006.10.018.Suche in Google Scholar PubMed

Luterbacher, J.S., Rand, J.M., Alonso, D.M., Han, J., Youngquist, J.T., Maravelias, C.T., Pfleger, B.F., and Dumesic, J.A. (2014). Nonenzymatic sugar production from biomass using biomass-derived γ-valerolactone. Science 343: 277–280, https://doi.org/10.1126/science.1246748.Suche in Google Scholar PubMed

Martin-Sampedro, R., Eugenio, M.E., Moreno, J.A., Revilla, E., and Villar, J.C. (2014). Integration of a kraft pulping mill into a forest biorefinery: pre-extraction of hemicellulose by steam explosion versus steam treatment. Bioresour. Technol. 153: 236–244, https://doi.org/10.1016/j.biortech.2013.11.088.Suche in Google Scholar PubMed

Mason, W.H. (1926a). Low-temperature explosion process of disintegrating wood and the like, US patent application.Suche in Google Scholar

Mason, W.H. (1926b). Process and apparatus for disintegration of wood and the like. US patent application.Suche in Google Scholar

Mason, W.H. (1928). Apparatus for and process of explosion fibration of lignocellulose material, US patent application no. US1655618A.Suche in Google Scholar

Metkar, P.S., Till, E.J., Corbin, D.R., Pereira, C.J., Hutchenson, K.W., and Sengupta, S.K. (2015). Reactive distillation process for the production of furfural using solid acid catalysts. Green Chem. 17: 1453–1466, https://doi.org/10.1039/c4gc01912a.Suche in Google Scholar

Michud, A., Hummel, M., and Sixta, H. (2015). Influence of molar mass distribution on the final properties of fibers regenerated from cellulose dissolved in ionic liquid by dry-jet wet spinning. Polymer 75: 1–9, https://doi.org/10.1016/j.polymer.2015.08.017.Suche in Google Scholar

Michud, A., Tanttu, M., Asaadi, S., Ma, Y., Netti, E., Pirjo, K., Persson, A., Berntsson, A., Hummel, M., and Sixta, H. (2016). Ioncell-f: ionic liquid-based cellulosic textile fibers as an alternative to viscose and lyocell. Text. Res. J. 86: 543–552, https://doi.org/10.1177/0040517515591774.Suche in Google Scholar

Monavari, S., Galbe, M., and Zacchi, G. (2009). Impact of impregnation time and chip size on sugar yield in pretreatment of softwood for ethanol production. Bioresour. Technol. 100: 6312–6316, https://doi.org/10.1016/j.biortech.2009.06.097.Suche in Google Scholar PubMed

Monavari, S., Bennato, A., Galbe, M., and Zacchi, G. (2010). Improved one-step steam pretreatment of so2-impregnated softwood with time-dependent temperature profile for ethanol production. Biotechnol. Prog. 26: 1054–1060, https://doi.org/10.1002/btpr.421.Suche in Google Scholar PubMed

Montane, D., Farriol, X., Salvadó, J., Jollez, P., and Chornet, E. (1998). Application of steam explosion to the fractionation and rapid vapor-phase alkaline pulping of wheat straw. Biomass Bioenergy 14: 261–276, https://doi.org/10.1016/s0961-9534(97)10045-9.Suche in Google Scholar

Moreno, A.D., Ibarra, D., Ballesteros, I., González, A., and Ballesteros, M. (2013). Comparing cell viability and ethanol fermentation of the thermotolerant yeast Kluyveromyces marxianus and Saccharomyces cerevisiae on steam-exploded biomass treated with laccase. Bioresour. Technol. 135: 239–245, https://doi.org/10.1016/j.biortech.2012.11.095.Suche in Google Scholar PubMed

Nunes, A.P. and Pourquie, J. (1996). Steam explosion pretreatment and enzymatic hydrolysis of eucalyptus wood. Bioresour. Technol. 57: 107–110, https://doi.org/10.1016/0960-8524(96)00019-3.Suche in Google Scholar

Öhgren, K., Bura, R., Saddler, J., and Zacchi, G. (2007). Effect of hemicellulose and lignin removal on enzymatic hydrolysis of steam pretreated corn stover. Bioresour. Technol. 98: 2503–2510, https://doi.org/10.1016/j.biortech.2006.09.003.Suche in Google Scholar PubMed

Park, J.-Y., Kang, M., Kim, J.S., Lee, J.-P., Choi, W.-I., and Lee, J.-S. (2012). Enhancement of enzymatic digestibility of Eucalyptus grandis pretreated by naoh catalyzed steam explosion. Bioresour. Technol. 123: 707–712, https://doi.org/10.1016/j.biortech.2012.07.091.Suche in Google Scholar PubMed

Peter, W. and Hoglinger, O. (1986). Herstellung von Kunstfaserzellstoff nach dem Organosolv-aufschlussverfahren. Lenzinger Ber 61: 12–16.Suche in Google Scholar

Potthast, A., Radosta, S., Saake, B., Lebioda, S., Heinze, T., Henniges, U., Isogai, A., Koschella, A., Kosma, P., Rosenau, T., et al.. (2015). Comparison testing of methods for gel permeation chromatography of cellulose: coming closer to a standard protocol. Cellulose 22: 1591–1613, https://doi.org/10.1007/s10570-015-0586-2.Suche in Google Scholar

Pye, E.K. and Lora, J.H. (1991). The alcell process: a proven alternative to kraft pulping. Tappi J. 74: 113–118.Suche in Google Scholar

San Martín, R., Perez, C., and Briones, R. (1995). Simultaneous production of ethanol and kraft pulp from pine (pinus radiata) using steam explosion. Bioresour. Technol. 53: 217–223, https://doi.org/10.1016/0960-8524(95)00056-3.Suche in Google Scholar

Sassner, P., Mårtensson, C.-G., Galbe, M., and Zacchi, G. (2008). Steam pretreatment of h2so4-impregnated salix for the production of bioethanol. Bioresour. Technol. 99: 137–145, https://doi.org/10.1016/j.biortech.2006.11.039.Suche in Google Scholar PubMed

Schultz, T.P., Templeton, M.C., Biermann, C.J., and Mcginnis, G.D. (1984). Steam explosion of mixed hardwood chips, rice hulls, corn stalks, and sugar cane bagasse. J. Agric. Food Chem. 32: 1166–1172, https://doi.org/10.1021/jf00125a058.Suche in Google Scholar

Sharazi, A.M. and Van Heiningen, A. (2017). Ethyl xylosides formation in sew (avap®) fractionation of sugarcane straw; implications for ethanol and xylose recovery. Holzforschung 71: 951–959, https://doi.org/10.1515/hf-2017-0041.Suche in Google Scholar

Sixta, H. (1986). Cellulose preparation and recycling of raw materials and auxiliaries by the lenzinger magnesium bisulfite process. Lenzinger Berichte 61: 5–11.Suche in Google Scholar

Sixta, H. (2006a) Chemical pulping processes. In: Sixta, H., Potthast, A., and Krotschek, A.W. (Eds.). Handbook of pulp. Wiley-VCH Verlag GmbH and Co. KGaA, Weinheim.Suche in Google Scholar

Sixta, H. (2006b) Pulp properties and applications. In: Sixta, H. (Ed.). Handbook of pulp. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.10.1002/9783527619887Suche in Google Scholar

Sixta, H., Michud, A., Hauru, L., Asaadi, S., Ma, Y., King, A.W.T., Kilpelainen, I., and Hummel, M. (2015). Ioncell-f: a high-strength regenerated cellulose fibre. Nord. Pulp Paper Res. J. 30: 43–57, https://doi.org/10.3183/npprj-2015-30-01-p043-057.Suche in Google Scholar

Sjöström, E. (1993). Wood chemistry: fundamentals and applications. Academic Press, San Diego.Suche in Google Scholar

Swan, B. (1965). Isolation of acid-soluble lignin from the klason lignin determination. Svensk Papperstidn. 68: 791–795.Suche in Google Scholar

Textile-Exchange (2021). Textile exchange: preferred fiber & materials - market report 2021.Suche in Google Scholar

Textile-School (2018). History of textile fabrics, [Online]. Available: https://www.textileschool.com/130/history-of-textile-fabrics/(Accessed web page 2024.Suche in Google Scholar

The-Fiber-Year (2023). The fiber year: world survey on textiles and nonwovens. Speicher, Switzerland, The Fiber Year GmbH.Suche in Google Scholar

Wang, K., Chen, J., Sun, S.-N., and Sun, R.-C. (2015) Chapter 6: steam explosion. In: Pandey, A., Negi, S., Binod, P., and Larroche, C. (Eds.). Pretreatment of biomass. Elsevier, Amsterdam.10.1016/B978-0-12-800080-9.00006-2Suche in Google Scholar

Wise, L.E.M.M. and D’ Addieco, A.A. (1946). Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Tech. Assoc. Pap. 29: 210–218.Suche in Google Scholar

Wu, M.M., Chang, K., Gregg, D.J., Boussaid, A., Beatson, R.P., and Saddler, J.N. (1999). Optimization of steam explosion to enhance hemicellulose recovery and enzymatic hydrolysis of cellulose in softwoods. Appl. Biochem. Biotechnol. 77: 47–54, https://doi.org/10.1385/abab:77:1-3:47.10.1007/978-1-4612-1604-9_5Suche in Google Scholar

Yamamoto, M., Kankaanpaa, A., Jarvelainen, I., and Granström, T. (2020) Proceedings of SBFC2020 symposium on biomaterials, fuels and chemicals, April 25-29, 2020: New Orleans: st1 cellunolix™ process is producing multiple products from softwood sawdust with potentially high market value. Society for Industrial Microbiology and Biotechnology.Suche in Google Scholar

Supplementary Material

This article contains supplementary material (https://doi.org/10.1515/hf-2024-0065).

© 2024 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Frontmatter

- Wood Growth/Morphology

- Among-family variations of wood-color parameters, decay resistance, total phenol, and total flavanol content in the heartwood of the third-generation Acacia mangium in Indonesia

- Wood Chemistry

- Structure and bioactivity of tannin extracts from Taxodium ‘Zhongshanshan’

- Wood Physics/Mechanical Properties

- Mechanical properties of beech wood treated with malic acid-based polyester

- Micro-mechanical tests on tissue slices of Norway spruce: tensile and shear performance

- Wood Technology/Products

- StExCell: novel steam-explosion-based biorefinery concept for dissolving pulp production

- Acetylation of wood: understanding the risk of de-acetylation during exposure to elevated temperature

- Production of phenolic-rich slow pyrolysis liquid extracts by supercritical carbon dioxide fractionation

- Esterification of wood with citric acid and sorbitol: effect of the copolymer on the properties of the modified wood. Part 1: macroscopic changes, fixation of chemicals and impact bending properties

- Application of gas grafting with palmitoyl chloride to manufacture hydrophobic decorative wood veneer

- Wood Science – Non-Tree Plants

- Structural and anatomical analysis of rattan (Calamus balansaeanus Becc.)

- Thermal modification of Lantana camara stalks and its characterization

Artikel in diesem Heft

- Frontmatter

- Wood Growth/Morphology

- Among-family variations of wood-color parameters, decay resistance, total phenol, and total flavanol content in the heartwood of the third-generation Acacia mangium in Indonesia

- Wood Chemistry

- Structure and bioactivity of tannin extracts from Taxodium ‘Zhongshanshan’

- Wood Physics/Mechanical Properties

- Mechanical properties of beech wood treated with malic acid-based polyester

- Micro-mechanical tests on tissue slices of Norway spruce: tensile and shear performance

- Wood Technology/Products

- StExCell: novel steam-explosion-based biorefinery concept for dissolving pulp production

- Acetylation of wood: understanding the risk of de-acetylation during exposure to elevated temperature

- Production of phenolic-rich slow pyrolysis liquid extracts by supercritical carbon dioxide fractionation

- Esterification of wood with citric acid and sorbitol: effect of the copolymer on the properties of the modified wood. Part 1: macroscopic changes, fixation of chemicals and impact bending properties

- Application of gas grafting with palmitoyl chloride to manufacture hydrophobic decorative wood veneer

- Wood Science – Non-Tree Plants

- Structural and anatomical analysis of rattan (Calamus balansaeanus Becc.)

- Thermal modification of Lantana camara stalks and its characterization