Abstract

A novel thermo-mechanical pulping (TMP) process has been developed to produce a by-product rich in high-molecular weight (MW) hemicelluloses, a potential raw material for barrier coatings and films. This process uses prehydrolysis to solubilise the hemicelluloses followed by chip compression to separate the soluble material from the wood matrix. The pressate from the chip compression stage was dark-coloured and had a high content of high-MW hemicelluloses and lignin. However, isolating the high-MW material from the pressate directly by ultrafiltration was not feasible because of membrane fouling by dissolved lignin and wood extractives, while coloured impurities are undesirable for many potential applications. To solve these problems the pressate was purified using XAD adsorbent resin to remove low-MW lignin, extractives and colour. Ultrafiltration of the purified pressate yielded lightly coloured high-MW hemicellulose with a low content of lignin and well suited for barrier films and coatings.

1 Introduction

High-molecular weight (MW) hemicelluloses can be used as raw material for barrier coatings (Laine et al. 2013) and films (Jain et al. 2000; Laine et al. 2016; Mikkonen et al. 2015; Peresin et al. 2012). In these investigations high-MW xylan or galactoglucomannan (GGM) from bleached kraft pulps was etherified with an epoxy-functional reagent such as propylene oxide then fabricated into coatings or films. Using kraft pulp as the staring material has the advantage that it is readily available in large quantities and contains high-MW hemicelluloses with good properties for coating and film applications. However, it is also a relatively expensive feedstock. Given this, an alternative source of high-MW hemicelluloses is of interest. One option could be a mechanical pulp biorefinery where wood chips are hydrolysed by water vapour and the dissolved material removed prior to thermo-mechanical pulping (TMP) (Brasch and Free 1965; Lloyd and Murton 2016).

Prehydrolysis of wood chips prior to kraft pulping has been practised commercially for many years to produce dissolving pulp but has not been considered an option for mechanical pulping until recently (Houtman and Horn 2011; Kenealy et al. 2007; Lloyd and Murton 2016). In particular, it has been shown (Lloyd and Murton 2016) that it is possible to produce pulp suitable for newsprint or printing grade paper manufacture while also delivering a hemicellulose-rich by-product without an increase in refining energy (Murton 1996). The flow and composition of this hemicellulose-rich stream varies with process conditions and also includes lignin and extractive material which will need to be removed if used to produce films or coatings.

The hemicelluloses present in softwood TMP and TMP process waters are mainly GGM (Persson et al. 2010; Widsten et al. 2001) which accounts for 15–20% of the softwood mass. The dissolved carbohydrates (hemicelluloses and pectin) can be separated and hydrolysed to monomers for fermentation to ethanol, a biofuel and industrial solvent (Reyes et al. 2013), but there is potential for some of the pre-hydrolysis hemicelluloses to be used for higher value applications. The yield and MW distribution of the dissolved hemicelluloses depends on the severity factor (SF) (Brasch and Free 1965; Lloyd and Murton 2016) which is a function of the pre-heating time and temperature (SF = log[t.exp((T − 100)/(14.75))]) of the wood chips or other raw material. An increase in SF promotes hemicellulose dissolution but may also increase its hydrolysis, reducing its MW and rendering it less suitable for barrier coatings and films. Ideally, hemicelluloses used for barrier coatings or films would be of high MW and contain little strongly chromophoric impurities (mainly lignin oxidation products) (Paulsson and Parkås 2012). High-MW hemicellulose fractions present in pre-hydrolysis TMP water could be recovered by ultrafiltration (UF), while the low-MW hemicellulose fractions in the UF permeate would still be available for fermentation or other uses.

During ultrafiltration of TMP effluent some dissolved lignin fractions (Pranovich et al. 2005) and wood extractives (Puro et al. 2011) will be trapped in the membranes (Puro et al. 2011; Strand et al. 2015), reducing the flow rate or stopping the flow completely. Membrane fouling can be mitigated by an appropriate pre-treatment with polymeric adsorbent material to remove the bulk of the deleterious compounds (Koivula et al. 2013; Puro et al. 2011; Spencer et al. 2010; Willför et al. 2003).

The purpose of this study was to (1) evaluate the auto-hydrolysis conditions required to produce a pressate stream with a high yield of high-MW hemicelluloses and (2) develop an effective treatment method to concentrate the high-MW hemicelluloses and remove material such as lignin, extractives and colour prior to use in film or coating applications.

2 Materials and methods

2.1 Preparation of compression screw pressate (CSP)

Fresh debarked radiata pine (Pinus radiata D. Don) slabwood chips from a sawmill based in Rotorua, New Zealand were steamed at 80 °C for 5 min and then transferred via a compression screw to the preheater, where they were held at 140–170 °C for 20 or 30 min. Preheated chips were then fed through a second compression screw which produced the pressate (CSP) for the study (stored in the dark at 4 °C until needed) (Lloyd and Murton 2016).

2.2 Filtration of CSP

All CSP samples were vacuum-filtered through wet-strength Whatman 113 filter paper to remove suspended solids.

2.3 Washing of XAD resins

Amberlite® resins XAD4, XAD7 and XAD16 were purchased from Sigma-Aldrich. Before use, resins (200–1000 g) were stirred in several litres of Milli-Q water for 30 min to remove the preservative salts and recovered by vacuum filtration through wet-strength Whatman 113 filter paper. The washed resin was then oven-dried at 50 °C.

2.4 Treatment of CSP with XAD resins

Treatments of prefiltered CSP with washed XAD resins were carried out at resin-to-liquid ratios of 0.02–0.08, calculated on washed resin weight. CSP was placed in a 0.5 L or 1 L Schott bottle and the required amount of washed resin was added. The bottle was then shaken at 180 rpm in an orbital shaker for the scheduled length of time (1–3 h) at ambient temperature (ca. 24 °C) or 40 °C, as indicated. After treatment the resin particles were removed by vacuum filtration through wet-strength Whatman 113 filter paper and the filtrate was stored at 4 °C in the dark until needed.

2.5 Regeneration of XAD7 resin

Regeneration of XAD7 resin was performed by desorption of lignin and other adsorbed material with 0.1 M NaOH. Each batch of used XAD7 was stirred magnetically in 1–2 L of 0.1 M NaOH after which the resin particles were removed by vacuum filtration and washed with several litres of distilled water. This process was performed three or four times for each batch until the washings were only lightly yellow coloured.

2.6 Light absorbance measurements

The light absorbance of CSP samples was measured in the ultraviolet (UV) region at 280 nm and/or in the visual region at 457 nm in a quartz cell with a path length of 1 cm using a Shimazdu UV-1800 UV–Vis spectrophotometer. Before measurement samples were diluted with Milli-Q water until the absorbance readings were in the range 0.2–1.0. The results were expressed as the values obtained by multiplying these readings with the corresponding dilution factors.

2.7 Determination of total dissolved solids (TDS)

Total dissolved solids (TDS) in filtered CSP samples were determined gravimetrically after freeze-drying.

2.8 Determination of lignin content

Acid-insoluble (Klason) lignin in freeze-dried CSP was determined in triplicate by a modified method based on TAPPI Standard Methods, T 222 om-88 and acid-soluble lignin in triplicate by a modified TAPPI Useful Method UM 250.

2.9 Determination of extractive content

Quantification of wood extractives in CSP was performed using an earlier published method (McLean et al. 2005; Örsa and Holmbom 1994) but with a partly different selection of internal standards. A 5.0 mL aliquot of each sample, adjusted to pH 3.5 using 1.0 mol L−1 HNO3, and 100 µL of internal standard (0.55 mg mL−1 solution of heptadecanoic acid, betulin, cholesteryl heptadecanoate and 1,3-dipalmitoyl-2-oleoylglycerol (Sigma) in toluene (Merck)) were transferred to a screw cap test tube and extracted into 1.0 mL of methyl tert-butyl ether (MTBE (BDH)). After extraction the MTBE layer was isolated by centrifugation, transferred into gas chromatography (GC) vials and blown to dryness under a nitrogen atmosphere. Samples were silylated with 100 µL of BSA (N,O-bis(trimethylsilyl)-acetamide, Alltech) and 100 µL of pyridine (Merck) at 60 °C for 20 min before cooling to room temperature and making up to 1.0 mL with toluene.

Silylated samples were analysed on an Agilent 6890 N GC FID (flame ionisation detector) instrument with Agilent 7683B autosampler. Samples (1 µL) were injected directly onto a Phenomenex Zebron (ZB-1, 15 m × 0.53 mm × 0.15 µm FT) capillary GC column under a constant pressure (0.21 bar) flow of helium. The injector temperature was held at 90 °C for 30 s after injection before increasing to 325 °C at 100 °C min−1. The column was held at 90 °C for the first 90 s before increasing to 320 °C at 20 °C min−1. The FID was held at 360 °C for a total run time of 60 min. Using a calibration standard of 0.55 mg mL−1 dehydroabietic acid (Helix Biotech), palmitic acid (Aldrich) and triolein (Sigma) in toluene, relative response factors were calculated and used to determine the level of resin acids, fatty acids, sterols, lignans, steryl esters and triglycerides. Samples were analysed in triplicate and the mean and standard deviation reported.

Total dichloromethane (DCM) soluble extractives were determined gravimetrically on freeze dried solids by Soxtec-extraction for 1 h and evaporation to dryness under reduced pressure.

2.10 Determination of mono- and oligo-/polysaccharides

Monosaccharides in liquid samples were determined by ion chromatography before and after acid hydrolysis at Celignis Ltd, University of Limerick, Ireland.

2.11 Determination of MW distributions

Gel permeation chromatography (GPC) was used to determine the MW distribution of freeze-dried CSP samples. GPC was carried out on a Polymer laboratories PL-GPC-50 integrated GPC system with a Knauer K-301 refractive index (RI) detector and a Knauer K-2501 UV detector (280 nm), using two PolarGel-L columns (Varian, 300 × 7.5 mm) connected in series and protected by a guard column (50 × 7.5 mm) of the same material. The system was run at 50 °C with analytical grade DMSO + 0.05 M LiCl as eluent. Flow rate was maintained at 1 mL min−1. The system was calibrated using pullulan saccharide standards (PSS, 180–47,000 MW). Samples were dissolved overnight on a shaker at a concentration of 3 mg mL−1. No filtering was necessary. Injection volume was 100 μL.

2.12 Ultrafiltration

Ultrafiltration (UF) of CSP samples was carried out at the highest feed pressure allowed by the UF system (1.0–1.2 kPa) using a Masterflex ultrafiltration unit (motor model 7553-75; Cole-Parmer) that was equipped with a 10,000 Da polyethersulphone membrane (cylindrical, surface area 0.29 m2) purchased from Smart Membrane Solutions, Rolleston, NZ. Each run was continued until the permeate flow ceased. At this point the run was terminated or distilled water was added to the retentate to continue the ultrafiltration and further concentrate the high-MW fraction. In total, three successive UF runs were performed on the purified CSP 160/20-XAD7.

3 Results and discussion

3.1 Optimal TMP conditions for dissolving high-MW hemicellulose

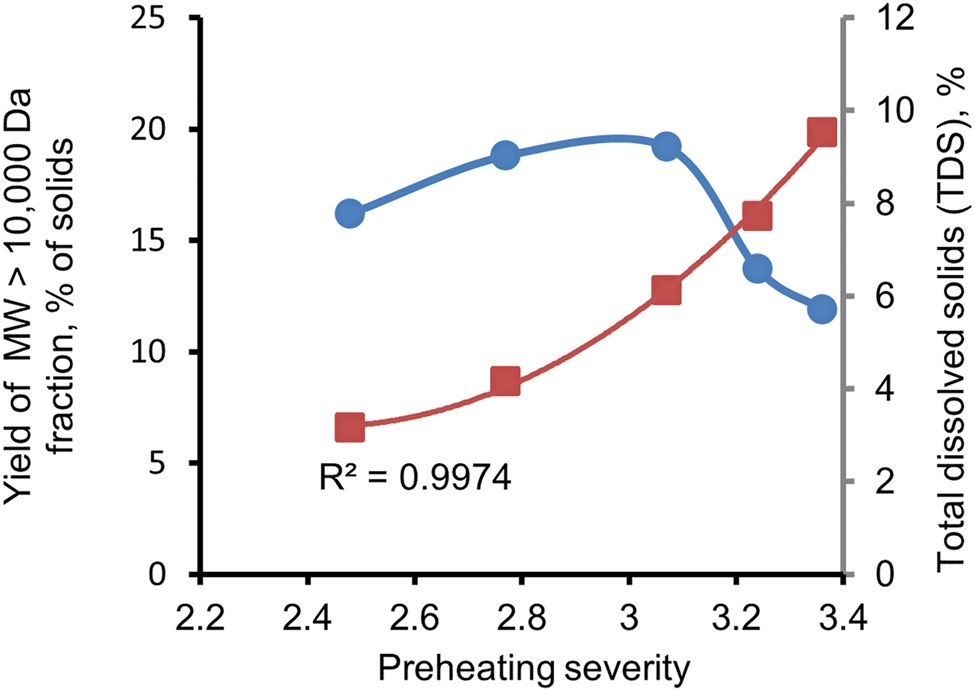

The yield and MW distribution of hemicelluloses in CSP depend on the severity factor which is a function of the chip pre-heating temperature and time (Table 1) (Lloyd and Murton 2016). The amount (yield) of freeze-dried total dissolved solids (TDS) in CSP samples originating from pulping at different severities is shown in Figure 1. It is seen that as severity increased, TDS increased in a logarithmic fashion while the proportion of material of 10,000 Da or larger was at its highest at the middle of the severity range investigated.

Composition of freeze-dried total dissolved solids (TDS) of CSP samples.

| Pre-heating temperature (°C) | Pre-heating time (min) | Severity factor (SF) | TDS (%) | Lignin (%) of TDS | DCM extractives (% of TDS) | Carbohydrates (approximate % of TDS; by difference) | |

|---|---|---|---|---|---|---|---|

| Klason | Acid-soluble | ||||||

| 140 | 20 | 2.48 | 3.16 | 10.4 ± 0.6 | 2.3 ± 0.0 | 1.35 | 85.9 |

| 150 | 20 | 2.77 | 4.15 | 9.1 ± 0.2 | 2.1 ± 0.1 | 0.71 | 88.0 |

| 160 | 20 | 3.07 | 6.12 | 6.4 ± 0.3 | 2.0 ± 0.1 | 0.48 | 91.1a |

| 160 | 30 | 3.24 | 7.72 | 5.3 ± 0.1 | 1.8 ± 0.0 | 0.45 | 92.4 |

| 170 | 20 | 3.36 | 9.53 | 4.9 ± 0.2 | 1.8 ± 0.0 | 0.25 | 93.0 |

-

aValue determined by ion chromatography was 91.4%.

Effect of preheating severity on total dissolved solids (TDS) content of compression screw pressate (CSP, squares) and the percentage of >10,000 Da material in CSP (circles).

The approximate composition of CSP TDS is shown in Table 1. The ratio of carbohydrates to lignin increased with increasing severity as the rate of hemicellulose hydrolysis increased at a higher rate than that of lignin depolymerisation and solubilisation. This has been reported before for the water soluble portion of TMP produced from Nordic softwoods (Widsten et al. 2001).

The MW distribution of TDS samples is shown in Table 2. Two different GPC detectors were used. The refractive index (RI) detector detects both carbohydrates and lignin while the UV detector detects lignin and any aromatic hemicellulose dehydration products such as furfural and hydroxymethylfurfural (HMF) or pseudolignin. The weight-average MW (Mw) initially increased and then started to decline with an increase in severity, presumably because the rate of secondary depolymerisation reactions was faster than primary hydrolysis reactions at higher severities. Combining the TDS data from Table 1 and the RI detector data from Table 2 shows that the CSP produced by pre-heating at 160 °C for 20 min (hereafter called ‘160/20’) had the highest content of material with MW of 10,000 Da or higher (1.2% of CSP, or 19.2% of its TDS) and was therefore selected for further work.

MW distribution of total dissolved solids (TDS) of filtered CSP samples.

| Pre-heating temperature (°C) | Pre-heating time (min) |

M w | M n | PDI | >10,000 Da (% of CSP TDS) | >10,000 Da (% of CSP) | |

|---|---|---|---|---|---|---|---|

| RI detector | UV detector | RI*TDS/100 | |||||

| 140 | 20 | 6,355 | 317 | 20.0 | 16.2 | 1.2 | 0.5 |

| 150 | 20 | 6,791 | 390 | 17.4 | 18.8 | 3.8 | 0.8 |

| 160 | 20 | 5,110 | 462 | 11.1 | 19.2 | 4.6 | 1.2 |

| 160 | 30 | 3,893 | 366 | 10.6 | 13.7 | 4.1 | 1.1 |

| 170 | 20 | 3,473 | 405 | 8.6 | 11.9 | 3.9 | 1.1 |

-

Mw, weight-average MW; Mn, number-average MW; PDI, polydispersity index.

3.2 Purification of CSP before ultrafiltration

3.2.1 Adsorbent selection

CSP needs to be ultrafiltered to obtain concentrated high-MW hemicellulose solutions suitable for coating and film applications. However, when the 160/20 material was ultrafiltered through a membrane with a 10,000 Da cut-off, the flow rate was very low, and the membrane soon became clogged. Based on earlier investigations it was assumed the membrane fouling was mainly due to lignin and dissolved and colloidal wood extractives (Puro et al. 2011; Strand et al. 2015). To solve this problem, it was decided to investigate the ability of polymeric absorbents to remove the undesirable components. Amberlite® XAD adsorbent resins have shown better ability to remove lignin from water samples than other adsorbent materials such as active carbon and bentonite clay (Strand et al. 2015). However, the resins will also remove some of the carbohydrates (Koivula et al. 2013), which is undesirable if they are of high MW. Given this the present study investigated the ability of XAD resins of different polarities (XAD4, XAD7 and XAD16) to remove lignin and extractives on one hand whilst preserving high-MW hemicelluloses on the other hand. As more lightly coloured raw materials are preferred for coatings or films, a further performance criterion for the resins was their ability to remove dark brownish colour from CSP.

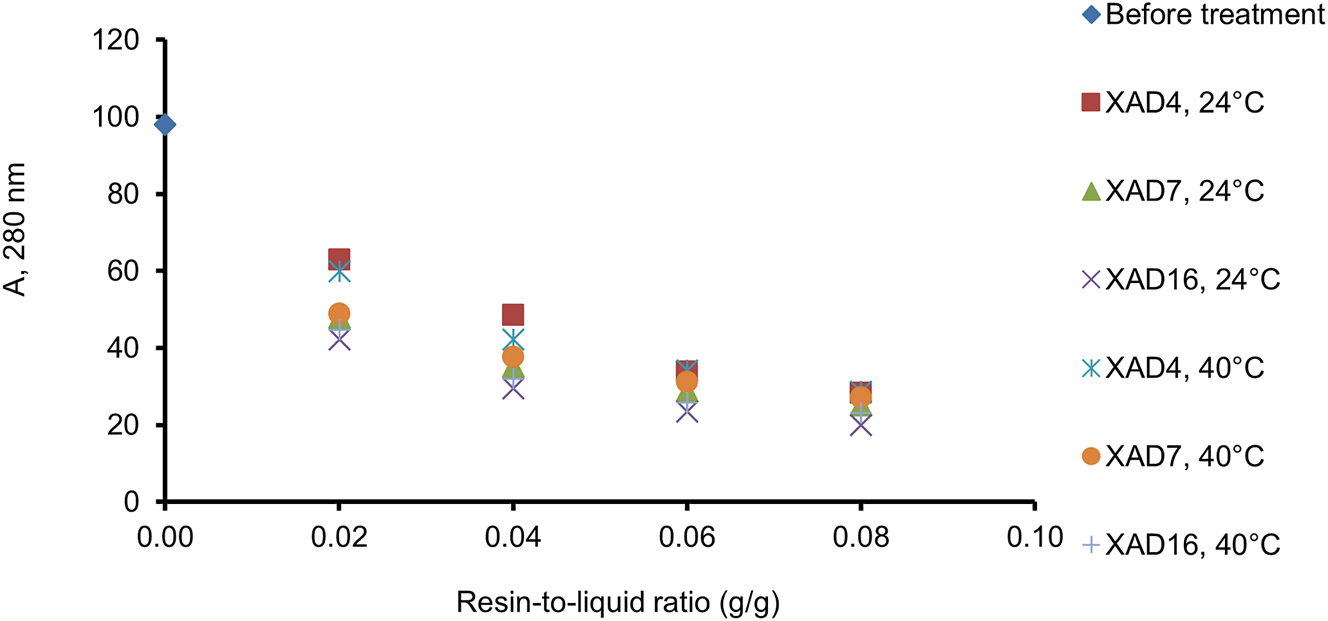

3.2.2 Removal of lignin and other UV-absorbing material

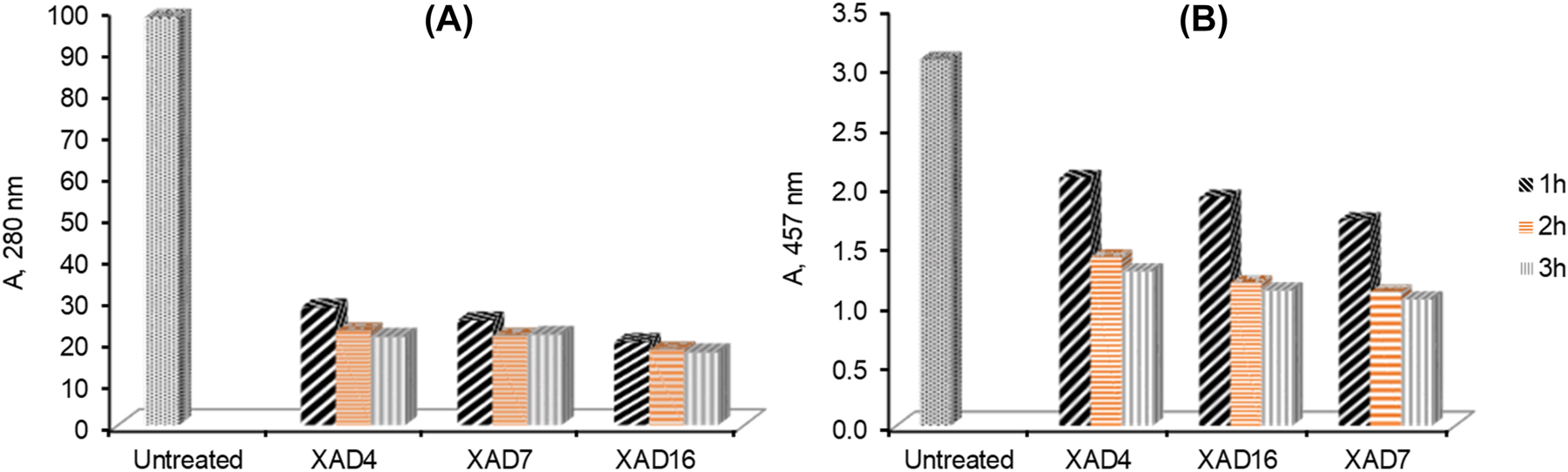

Larger reductions were achieved at greater resin-to-liquid ratios and at the lower (ambient) treatment temperature (Figure 2). Extending the treatment time to 2 h caused a slight further reduction in UV absorption but increasing it to 3 h gave results similar to 2 h (Figure 3a). In general, the ability of the three resins to remove UV-absorbing material decreased in the order XAD16 > XAD7 > XAD4 although the differences were small in relation to the UV absorbance of untreated CSP. The portion of UV-absorbing material that was not removed by the XAD treatments may have been bound to carbohydrates in the form of lignin-carbohydrate complexes (Lawoko et al. 2005) that are not sorbed onto the hydrophobic XAD resins (Westerberg et al. 2012).

Effect of XAD resin type, dose and treatment temperature on UV absorption (280 nm) of pre-hydrolysis TMP water 160/20 (treatment time 1 h).

Effect of XAD resin treatment time on absorption of pre-hydrolysis thermos-mechanical pulping (TMP) water 160/20 in the UV (A) and visible (B) regions. Treatments were done at 24 °C with a resin-to-liquid ratio of 0.08.

All three types of XAD resin were effective at removing UV-absorbing material during 1 h batch treatment of CSP.

For industrial application it is important to be able to regenerate the adsorbent resins used by desorption of the adsorbed material. To investigate the regenerability of XAD7 part of it used in the 3 h treatments was regenerated by stirring it in 0.1 M NaOH (which became dark brown), followed by washing with Milli-Q water and air-drying. Although the dried resin retained a yellowish colour it performed similarly in 3 h treatments (76% of absorbance removed at 280 nm) as the white unused XAD7 resin (78% of absorbance removed at 280 nm) in terms of removing UV-absorbing material from CSP. Regeneration of XAD resin with organic solvents can also be effective (Schwartz and Lawoko 2010).

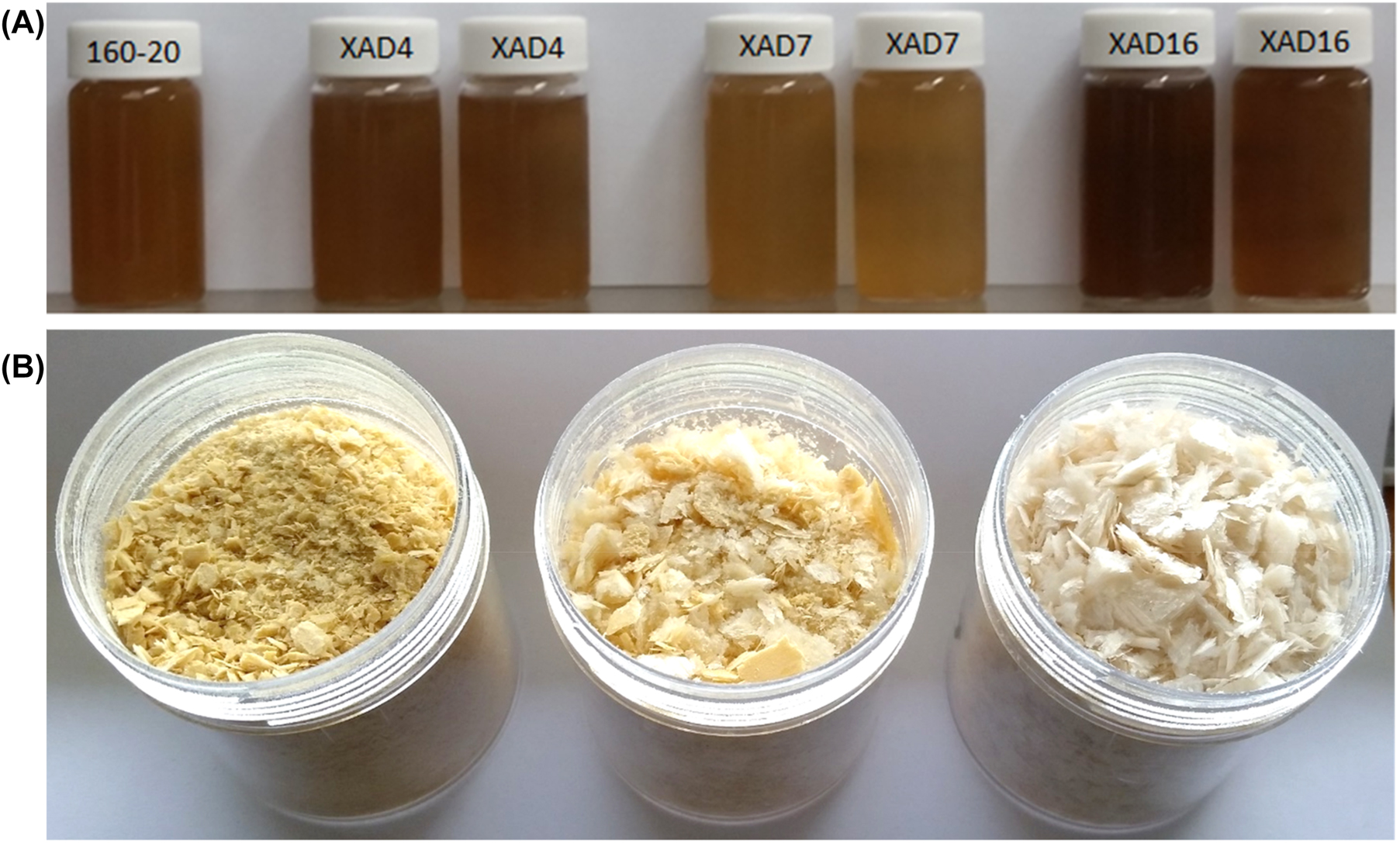

3.2.3 Removal of colour

In terms of colour, all three XAD resins were able to reduce absorbance of CSP 160/20 in the visible region (457 nm) (Figure 3b). Extending the treatment time from 1 h to 2 h reduced absorbance substantially while a further extension to 3 h had little additional effect. Figure 4a shows the effect on colour of two successive 1 h treatments using fresh XAD resins. Samples treated once with XAD16 were darker still than the untreated sample, indicating that the strongly chromophoric material initially became more concentrated in the sample treated with XAD16 before some of it was removed in the second treatment. Most of the dark colour can probably be attributed to lignin oxidation products such as quinonoids (Paulsson and Parkås 2012) that may also absorb light in the UV region and pseudolignin originating from degradation of polysaccharides (Shinde et al. 2018). The visual appearance of the samples was not always in line with the measured light absorbances in the visible region, as is clearly seen by comparing Figures 3b and 4a.

Unpurified and purified compression screw pressates (CSPs) before and after drying. (A) Compression screw pressate (CSP) 160/20 before (left) and after treatment (XAD samples). In each pair of XAD samples the sample on the left is from a single treatment and the sample on the right from two successive treatments with fresh resin (1 h; resin-to-liquid ratio 0.08; 24 °C). (B) Freeze-dried CSP samples: 160/20 before XAD7 treatment (left), after XAD7 treatment for 3 h at 24 °C (middle) and the high-MW fraction (retentate 2 of Table 3) isolated by ultrafiltration (right).

3.2.4 Removal of extractives

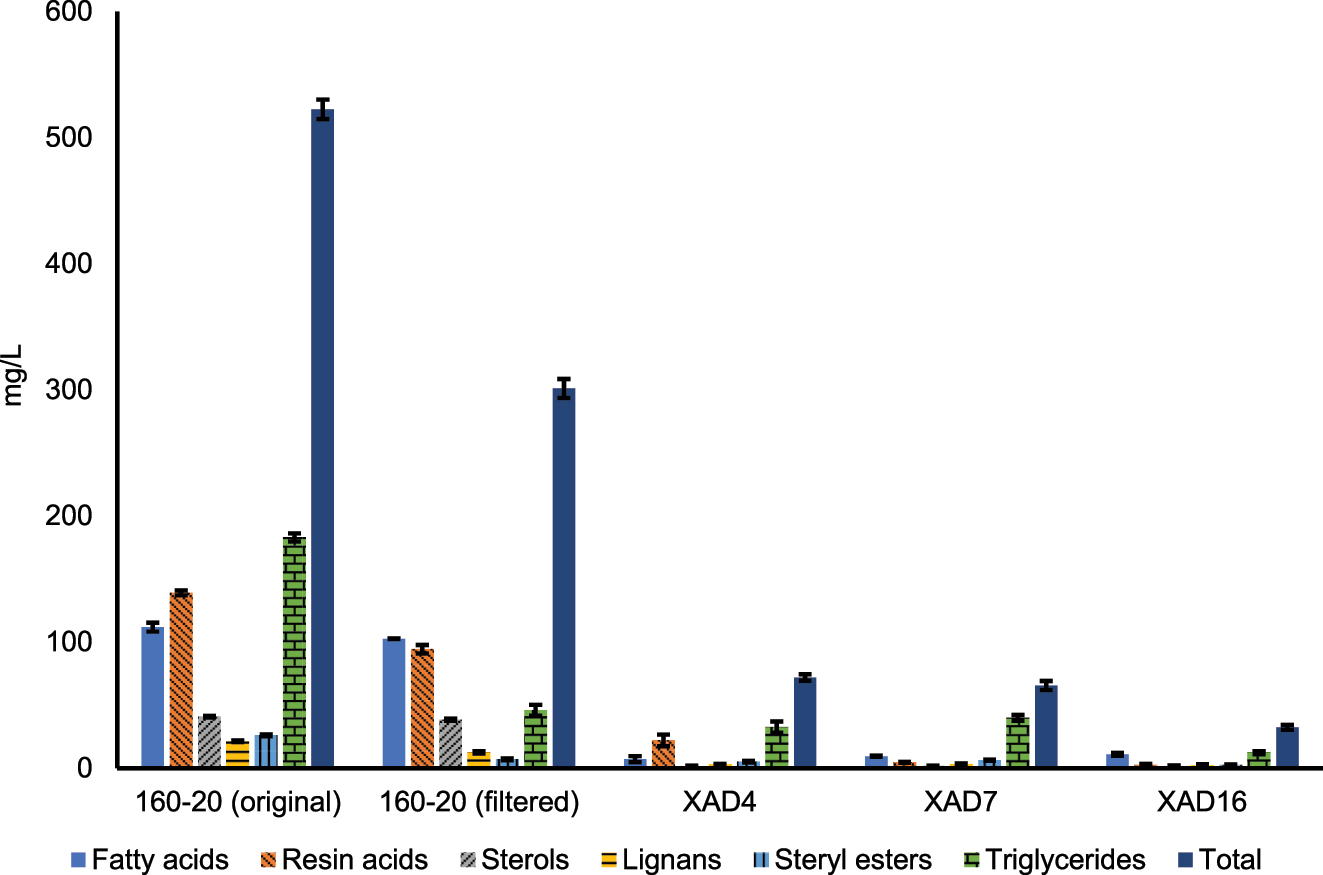

The presence of dissolved and colloidal extractives in CSP is undesirable as they contribute to membrane fouling in ultrafiltration (Puro et al. 2011). The concentration of extractives in CSP 160/20 was reduced by ca. 40% upon passing CSP through filter paper (Figure 5). This reduction in extractives was attributed to the removal of fines material, which is known to contain considerable levels of bound resin (Johnsen et al. 2006). When the filtered CSP was treated with XAD resins the total extractive contents were reduced by 76–89%. Typically, the remaining extractives were mostly triglycerides, with XAD4 also retaining a significant level of resin acids. The removal efficiencies of the three types of resin fell in the same order as seen for UV-absorbing material (XAD16 > XAD7 > XAD4) but the differences were small relative to the amount of extractives found in the original or filtered CSP.

Dissolved and colloidal extractives in compression screw pressate (CSP) 160/20 before and after XAD resin treatments (0.08 resin-to-liquid ratio; 24 °C; 2 h). The filtered (solids-free) CSP 160/20 was used for the XAD treatments. Error bars show standard deviation.

3.2.5 Retention of high-MW carbohydrates and lignin

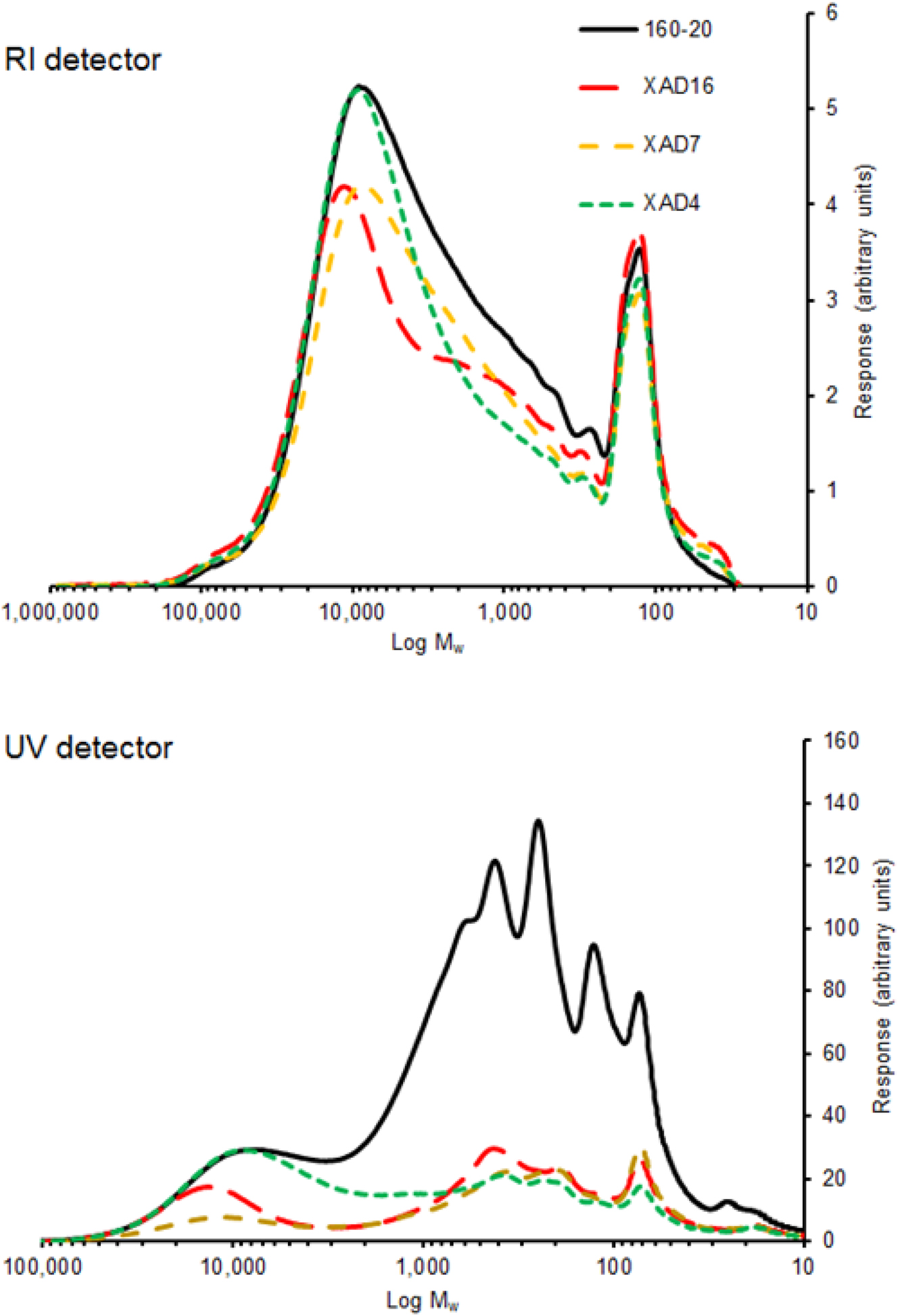

During treatment of CSP with XAD resins it was desirable to preserve high-MW carbohydrates to the highest extent possible while removing lignin and extractive fractions that are detrimental to ultrafiltration. In another investigation (Strand et al. 2015) lignin ranging from 500 to 5,700 Da in size was found to have a significant negative effect on UF flow rate when the membrane used had a cut-off of 5,000 Da, whereas smaller molecules and those larger than 7,400 Da had little negative impact. Determination of MW distribution by GPC with an RI detector showed that the CSP samples treated with XAD resins retained 83–94% of the carbohydrates and lignin of high MW (>10,000 Da) present in untreated CSP (Table 3). In general, the proportion of high-MW carbohydrates was slightly reduced and that of high-MW lignin increased. The resin treatments removed a much larger percentage of the UV-absorbing material of low MW than material with an MW greater than 10,000 Da (Figure 6, UV detector); the largest reductions were seen for the XAD7-treated sample (Figure 6). The fact that XAD7 was the most effective resin in decolouration of CSP and gave the lowest high-MW lignin content (as estimated by GPC with UV detection) suggests that a lot of the dark colour may reside in the high-MW lignin fraction. Thus, although high-MW lignin can potentially be a useful raw material for coating and films if it can be etherified in the same way as hemicellulose, it may be best to avoid accumulating it in the high-MW fraction. From this point of view XAD7 resin is arguably the best choice for purifying CSP intended for coating and film applications.

Percentage of high-MW material (>10,000 Da) in CSP 160/20 before and after XAD resin treatment (0.08 resin-to-liquid ratio; 24 °C; 3 h).

| Sample | Mainly carbohydrates and lignin (RI detector; %) | Mainly lignin (UV detector; %) | ||

|---|---|---|---|---|

| % Of TDS | % In water | % Of TDS | % In water | |

| Untreated | 18.2 | 1.07 | 0.24 | 4.1 |

| XAD4 | 23.2 | 1.09 | 0.74 | 15.7 |

| XAD7 | 18.7 | 0.99 | 0.38 | 7.3 |

| XAD16 | 22.2 | 0.95 | 0.60 | 13.8 |

GPC chromatographs of untreated and resin-treated freeze-dried compression screw pressate (CSP) 160/20 samples.

3.3 Ultrafiltration of CSP 160/20 treated with XAD7 resin

When the XAD resin-treated CSP samples were ultrafiltered using a membrane cut-off of 10,000 Da, the permeates were less coloured than the retentates. CSP 160/20 treated with XAD7 was selected for UF runs due to the superior colour reduction and lower content of high-MW UV-absorbing material (lignin) compared to the CSP samples purified with the other two XAD resins. However, most of its carbohydrates were of low MW (<10,000 Da; Figure 6). To render the material suitable for coatings and films its Mw had to be substantially increased by ultrafiltration. This was possible at a reasonable UF flow rate to isolate high-MW hemicellulose (Table 4). During UF some of the remaining coloured material was also removed as can be seen from the freeze-dried samples in Figure 4b.

Data on ultrafiltration of CSP 160/20 treated with XAD7 resina using a membrane cut-off of 10,000 Da.

| Water sample | Weight (g) | Water added (g) | Yield (g) | TDS (%) | Flow rate (g/m2/h) | Mw (Da) | |

|---|---|---|---|---|---|---|---|

| RI detector | UV detector | ||||||

| 160/20-XAD7 | 3206 | 5.3 | 6,343 | 2,453 | |||

| Retentate 1 | 623 | 2.2 | 12,046 | 4,715 | |||

| Permeate 1 | 2591 | 3.3 | 997 | 2,276 | 384 | ||

| Retentate 2 | 515b | 7722 | 775 | 1.4 | 20,530 | 13,578 | |

| Permeate 2 | 7336 | n/ac | 1779 | 3,206 | 478 | ||

-

aResin-to-liquid ratio 0.06; 24 °C; 3 h. bRetentate 1 with water added before ultrafiltration. cContained material washed off the membrane – no yield could be determined.

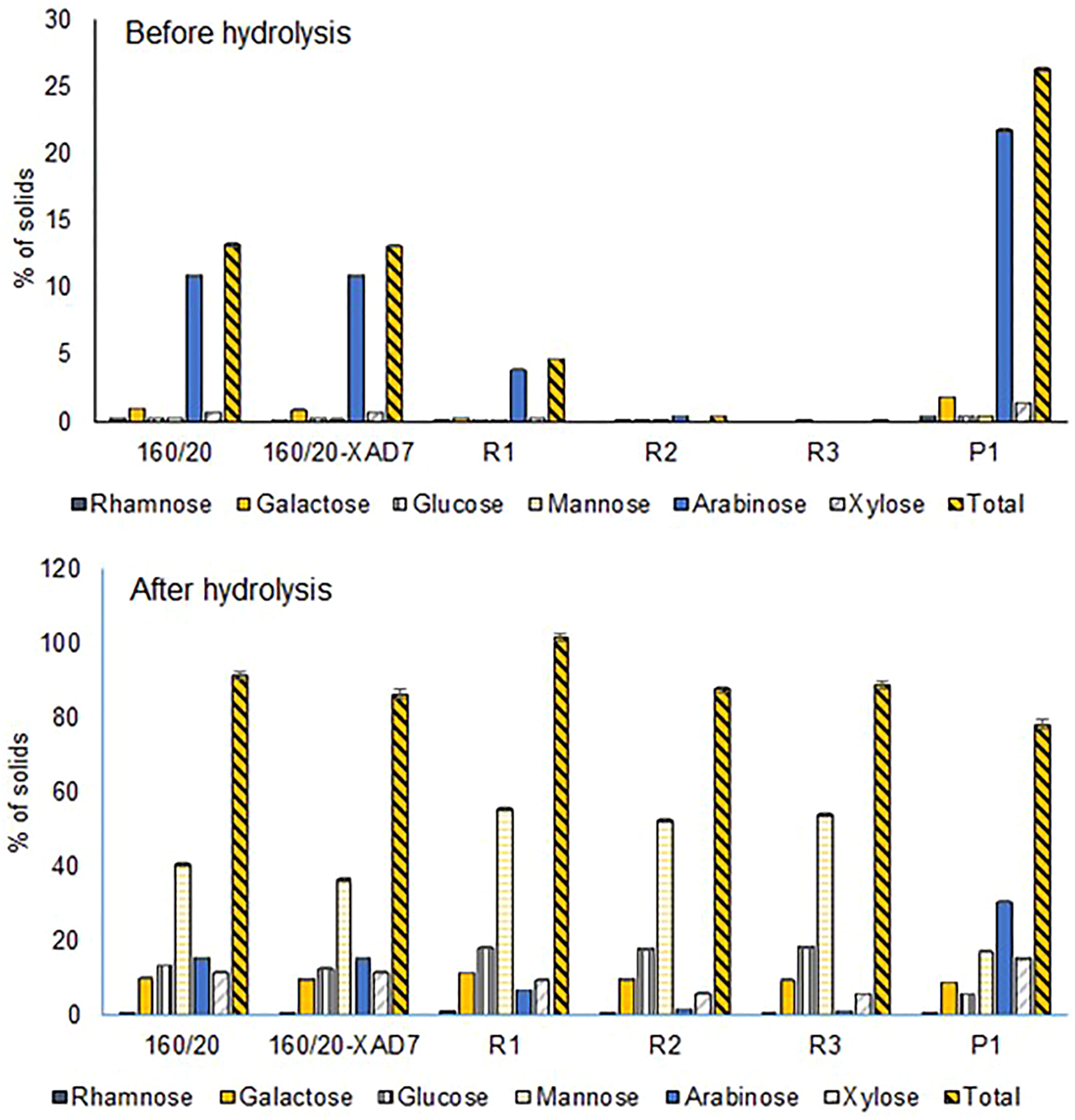

The monosaccharide distribution of post-hydrolysis 160/20 (Figure 7) reflects the reported composition of non-cellulosic polysaccharides in radiata pine wood, dominated by GGM and xylan (Smelstorius 1974), except for the large amount of arabinose that probably originates from arabinoxylans and arabinogalactans (Smelstorius 1974). 13% of pre-hydrolysis 160/20 solids were monosaccharides (mostly arabinose), increasing to 91% after acid hydrolysis of oligo- and polysaccharides (this includes the mass of water added on hydrolysis). Regarding the UF of 160/20-XAD7 (Figure 7), the monosaccharides (almost all of them arabinose) were almost completely removed already during the first run. The second and third UF runs did not change the composition of the hemicelluloses but increased the molar mass of the retentate solids that includes UV-absorbing material such as lignin (possibly as LCCs, lignin-carbohydrate complexes) or pseudolignin in addition to the high-MW hemicelluloses (Table 4). The hemicellulose content of the final retentate (R3) at 89% of total solids was similar to that of 160/20 (91%) and 160/20-XAD7 (86%), indicating that they were well retained in the UF process (Figure 7).

Monosaccharide content of 160/20, 160/20-XAD7 and the retentates and permeates from ultrafiltration of resin-purified compression screw pressate (CSP) 160/20-XAD7 before and after acid hydrolysis (dry matter basis). Error bars show standard deviation. R1-R3 denote retentates from successive UF runs and P1 the permeate from the first run.

4 Conclusions

This study has shown that auto-hydrolysis of radiata pine chips using 160 °C for 20 min produces a pressate stream with a high yield of high-MW hemicelluloses. This pressate stream can be purified further using XAD resin to remove lignin, extractives and colour followed by ultrafiltration to isolate the high MW hemicelluloses for use in film or coating applications. In particular:

The yield and average molecular weight of hemicelluloses in compression screw pressate can be optimised by adjusting the chip preheating severity

Compression screw pressate cannot be ultrafiltered until most of the dissolved low-MW lignin/pseudolignin and extractives have been removed. Amberlite XAD resins are effective at removing these deleterious compounds.

XAD7 resin removes more of the undesirable colour than XAD4 and XAD16 resins. It can be regenerated using dilute sodium hydroxide.

High-MW and light-coloured hemicellulose with a molar mass of >10,000 Da and consisting mainly of GGM can be isolated from compression screw pressate purified with XAD7 resin in high yield and purity by ultrafiltration.

-

Author contributions: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: None declared.

-

Conflict of interest statement: The authors declare no conflicts of interest regarding this article.

References

Brasch, D.J. and Free, K.W. (1965). Prehydrolysis-Kraft pulping of Pinus radiata grown in New Zealand. TAPPI (Tech. Assoc. Pulp Pap. Ind.) 48: 245–248.Search in Google Scholar

Houtman, C. and Horn, E. (2011). Pilot trials of hemicelluloses extraction prior to thermomechanical pulp production: Part 1. Tappi J. 10: 21–28, https://doi.org/10.32964/tj10.5.21.Search in Google Scholar

Jain, R.K., Sjöstedt, M., and Glasser, W.G. (2000). Thermoplastic xylan derivatives with propylene oxide. Cellulose 7: 319–336, https://doi.org/10.1023/A:1009260415771.10.1023/A:1009260415771Search in Google Scholar

Johnsen, I.A., Stenius, P., Tammelin, T., Österberg, M., Johansson, L.-S., and Laine, J. (2006). The influence of dissolved substances on resin adsorption to TMP fine material. Nord. Pulp Pap Res. J. 21: 629–637, https://doi.org/10.3183/npprj-2006-21-05-p629-637.Search in Google Scholar

Kenealy, W.R., Houtman, C.J., Laplaza, J., Jeffries, T.W., and Horn, E.G. (2007). Pretreatments for converting wood into paper and chemicals. ACS (Am. Chem. Soc.) Symp. Ser., https://doi.org/10.1021/bk-2007-0954.ch025.Search in Google Scholar

Koivula, E., Kallioinen, M., Sainio, T., Antón, E., Luque, S., and Mänttäri, M. (2013). Enhanced membrane filtration of wood hydrolysates for hemicelluloses recovery by pretreatment with polymeric adsorbents. Bioresour. Technol. 143: 275–281, https://doi.org/10.1016/j.biortech.2013.05.129.Search in Google Scholar PubMed

Laine, C., Harlin, A., Hartman, J., Hyvärinen, S., Kammiovirta, K., Krogerus, B., Pajari, H., Rautkoski, H., Setälä, H., Sievänen, J., et al.. (2013). Hydroxyalkylated xylans – their synthesis and application in coatings for packaging and paper. Ind. Crop. Prod. 44: 692–704, https://doi.org/10.1016/j.indcrop.2012.08.033.Search in Google Scholar

Laine, C., Asikainen, S., Talja, R., Stépán, A., Sixta, H., and Harlin, A. (2016). Simultaneous bench scale production of dissolving grade pulp and valuable hemicelluloses from softwood kraft pulp by ionic liquid extraction. Carbohydr. Polym. 136: 402–408, https://doi.org/10.1016/j.carbpol.2015.09.039.Search in Google Scholar PubMed

Lawoko, M., Henriksson, G., and Gellerstedt, G. (2005). Structural differences between the lignin-carbohydrate complexes present in wood and in chemical pulps. Biomacromolecules 6: 3467–3473, https://doi.org/10.1021/bm058014q.Search in Google Scholar PubMed

Lloyd, J.A. and Murton, K.D. (2016). Preparation of prehydrolysis-TMPs with different severity factors and analysis of the pulps and byproducts. Holzforschung 70: 1003–1013, https://doi.org/10.1515/hf-2015-0216.Search in Google Scholar

McLean, D.S., Stack, K.R., and Richardson, D.E. (2005). The effect of wood extractives composition, pH and temperature on pitch deposition. Appita J. 58: 52–55.Search in Google Scholar

Mikkonen, K.S., Laine, C., Kontro, I., Talja, R.A., Serimaa, R., and Tenkanen, M. (2015). Combination of internal and external plasticization of hydroxypropylated birch xylan tailors the properties of sustainable barrier films. Eur. Polym. J. 66: 307–318, https://doi.org/10.1016/j.eurpolymj.2015.02.034.Search in Google Scholar

Murton, K.D. (1996). The effect of chip compression on TMP pulp properties. Appita J. 49: 313–318.Search in Google Scholar

Örsa, F. and Holmbom, B. (1994). Convenient method for the determination of wood extractives in papermaking process waters and effluents. J. Pulp Pap. Sci. 20: 159–175.Search in Google Scholar

Paulsson, M. and Parkås, J. (2012). Review: light-induced yellowing of lignocellulosic pulps – mechanisms and preventive methods. Bioresources 7: 5995–6040, https://doi.org/10.15376/biores.7.4.5995-6040.Search in Google Scholar

Peresin, M.S., Kammiovirta, K., Setälä, H., and Tammelin, T. (2012). Structural features and water interactions of etherified xylan thin films. J. Polym. Environ. 20: 895–904, https://doi.org/10.1007/s10924-012-0469-7.Search in Google Scholar

Persson, T., Krawczyk, H., Nordin, A.-K., and Jönsson, A.-S. (2010). Fractionation of process water in thermomechanical pulp mills. Bioresour. Technol. 101: 3884–3892, https://doi.org/10.1016/j.biortech.2009.12.142.Search in Google Scholar PubMed

Pranovich, A.V., Reunanen, M., Sjöholm, R., and Holmbom, B. (2005). Dissolved lignin and other aromatic substances in thermomechanical pulp waters. J. Wood Chem. Technol. 25: 109–132, https://doi.org/10.1080/02773810500191575.Search in Google Scholar

Puro, L., Kallioinen, M., Mänttäri, M., and Nyström, M. (2011). Evaluation of behavior and fouling potential of wood extractives in ultrafiltration of pulp and paper mill process water. J. Membr. Sci. 368: 150–158, https://doi.org/10.1016/j.memsci.2010.11.032.Search in Google Scholar

Reyes, P., Mendonça, R.T., Aguayo, M.G., Rodríguez, J., Vega, B., and Fardim, P. (2013). Extraction and characterization of hemicelluloses from Pinus radiata and its feasibility for bioethanol production | Extração e caracterização de hemiceluloses de pinus radiata e sua viabilidade para a produção de bioetanol. Rev. Árvore 37: 175–180, https://doi.org/10.1590/S0100-67622013000100018.Search in Google Scholar

Schwartz, T.J. and Lawoko, M. (2010). Removal of acid-soluble lignin from biomass extracts using Amberlite XAD-4 resin. Bioresources 5: 2337–2347.Search in Google Scholar

Shinde, S.D., Meng, X., Kumar, R., and Ragauskas, A.J. (2018). Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. Green Chem. 20: 2192–2205, https://doi.org/10.1039/c8gc00353j.Search in Google Scholar

Smelstorius, J.A. (1974). Chemical composition of wood of Australian-grown pinus radiata D. Don. II. Polysaccharides | Die chemische Zusammensetzung des Holzes von in Australien gewachsener Pinus radiata D. Don. II. Polysaccharide. Holzforschung 28: 67–73, https://doi.org/10.1515/hfsg.1974.28.2.67.Search in Google Scholar

Spencer, R.G.M., Aiken, G.R., Dyda, R.Y., Butler, K.D., Bergamaschi, B.A., and Hernes, P.J. (2010). Comparison of XAD with other dissolved lignin isolation techniques and a compilation of analytical improvements for the analysis of lignin in aquatic settings. Org. Geochem. 41: 445–453, https://doi.org/10.1016/j.orggeochem.2010.02.004.Search in Google Scholar

Strand, E., Kallioinen, M., Reinikainen, S.-P., Arkell, A., and Mänttäri, M. (2015). Multivariate data examination in evaluation of the effect of the molecular mass of lignin and hemicelluloses on ultrafiltration efficiency. Separ. Purif. Technol. 144: 146–152, https://doi.org/10.1016/j.seppur.2015.02.013.Search in Google Scholar

Westerberg, N., Sunner, H., Helander, M., Henriksson, G., Lawoko, M., and Rasmuson, A. (2012). Separation of galactoglucomannans, lignin, and lignin-carbohydrate complexes from hot-water-extracted Norway spruce by cross-flow filtration and adsorption chromatography. Bioresources 7: 4501–4516, https://doi.org/10.15376/biores.7.4.4501-4516.Search in Google Scholar

Widsten, P., Laine, J.E., Qvintus-Leino, P., and Tuominen, S. (2001). Effect of high-temperature fiberization on the chemical structure of softwood. J. Wood Chem. Technol. 21: 227–245, https://doi.org/10.1081/WCT-100105374.Search in Google Scholar

Willför, S., Rehn, P., Sundberg, A., Sundberg, K., and Holmbom, B. (2003). Recovery of water-soluble acetylgalactogluco-mannans from mechanical pulp of spruce. Tappi J. 2: 27–32.Search in Google Scholar

© 2023 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Wood Chemistry

- Native state of wood cellulose: evidence that further supports its non-crystalline nature

- The influence of transition metal ions on the oxidation of kraft pulp using hydrogen peroxide under mildly acidic conditions

- Wood Technology/Products

- Building machine learning models to identify wood species based on near-infrared spectroscopy

- Isolation and purification of high-molecular weight hemicelluloses from radiata pine wood chips prior to thermo-mechanical pulp (TMP) production

- Effect of pressurized hot water extraction on the resistance of Scots pine sapwood against mould fungi

- Wood color modification with iron salts aqueous solutions: effect on wood grain contrast and surface roughness

- Wood Science — Non-Tree Plants

- 3D characterization of vascular bundle in moso bamboo node and its effect on compressive properties

- Wood Biochemistry

- Durability of Hinoki (Chamaecyparis obtusa) stained wood following Anaglyptus subfasciatus infestation

Articles in the same Issue

- Frontmatter

- Wood Chemistry

- Native state of wood cellulose: evidence that further supports its non-crystalline nature

- The influence of transition metal ions on the oxidation of kraft pulp using hydrogen peroxide under mildly acidic conditions

- Wood Technology/Products

- Building machine learning models to identify wood species based on near-infrared spectroscopy

- Isolation and purification of high-molecular weight hemicelluloses from radiata pine wood chips prior to thermo-mechanical pulp (TMP) production

- Effect of pressurized hot water extraction on the resistance of Scots pine sapwood against mould fungi

- Wood color modification with iron salts aqueous solutions: effect on wood grain contrast and surface roughness

- Wood Science — Non-Tree Plants

- 3D characterization of vascular bundle in moso bamboo node and its effect on compressive properties

- Wood Biochemistry

- Durability of Hinoki (Chamaecyparis obtusa) stained wood following Anaglyptus subfasciatus infestation