Renewable, bio-based chemicals

Within the bio-based chemical and plastic industries – and downstream with brand owners – there is excitement about renewable platform chemicals such as levulinic acid, lactic acid or biosuccinic acid. These chemicals offer an alternative to petro-based chemicals and will help open up a wide range of potential applications.

Renewable platform chemicals can be used in a large range of downstream applications and have the potential to open up and help decarbonise new markets. AVA Biochem is producing the renewable platform chemical 5-HMF using its proprietary technology, leading to new, sustainable materials for a wide range of applications and sectors.

Company history

Founded in 2011, AVA Biochem is based in Muttenz, Switzerland. AVA Biochem is a subsidiary of Swiss company AVA-CO2. AVA Biochem began commercially producing 5-HMF in early 2014 thanks to a modified hydrothermal carbonisation (HTC) process initially developed by AVA-CO2.

A versatile, renewable platform chemical

5-Hydroxymethylfurfural (5-HMF) has been identified as a valuable, promising platform chemical by the U.S. Department of Energy. Made using biomass, 5-HMF (CAS 67-47-0) has a wide range of applications (Figure 1). It is able to replace petro-based products in various sectors including chemicals, plastics, food and pharmaceuticals. It is currently being used in the research and development of innovative new materials and products such as biopolymers, resins, coatings, paints, varnishes and additives.

Potential applications for 5-HMF.

The AVA Biochem HTC process is easily-scalable and will allow for 5-HMF bulk scale production in the coming years – a real breakthrough for the bio-based economy. Another advantage is that AVA Biochem can consistently produce 5-HMF at various levels of purity – up to 99.9%.

5-HMF is an outstanding platform chemical because high selectivities have been reported for its preparation, particularly from fructose – comparing it favourably with other platform chemicals such as levulinic acid or bioethanol [1].

The challenge of biomass as a feedstock for chemical compounds is the high oxygen content – it contains too many functional groups with oxygen, i.e., hydroxyl groups. 5-HMF can be derived from biomass by eliminating water from fructose, but it only has two functional groups. This is the optimal case, because for producing polymers the monomers should react ‘at two ends’ and this sets 5-HMF apart from other platform chemicals.

Production

The Biochem-1 plant in Muttenz has a production capacity of 20 tonnes of 5-HMF per year. Through improvements and efficiency gains, capacity at the plant is expected to increase to 40 tonnes per year by the end of 2014.

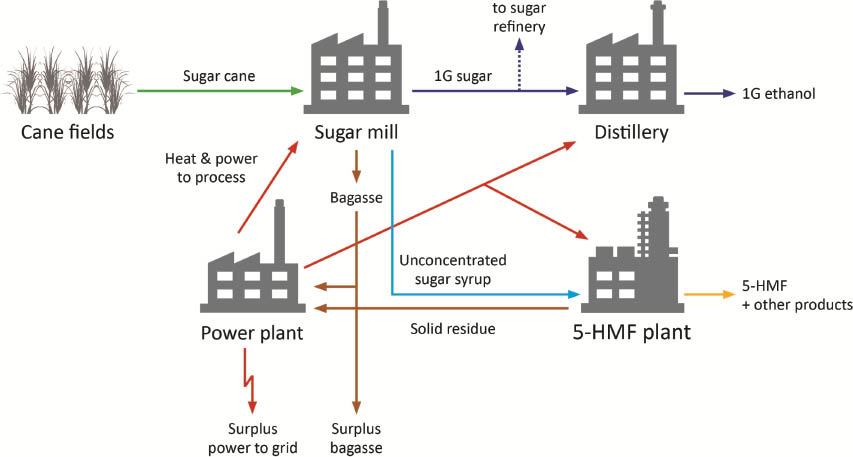

In partnership with the Karlsruhe Institute of Technology, AVA Biochem developed a modified version of AVA-CO2’s HTC technology, which allows for scale-up and efficient use of various biomass streams (Figure 2). Future large-scale 5-HMF production plants will be co-located with food or ethanol production plants to benefit from efficient feedstock supply and other co-location benefits.

Production route for bio-based 5-HMF.

Swiss-made

Biotechnology is key to Switzerland’s competitiveness and sustainability. AVA Biochem is one of around 200 Swiss biotech companies and part of the 5% which focus on industrial biotechnology.

The innovative Swiss environment, as well as access to good research and production infrastructure, has been key to AVA Biochem’s success. The company’s location also allows favourable access to chemical and pharmaceutical companies.

Recently, scienceindustries, biotechnet, the Federal Institute of Technology and the Swiss Biotech Association launched a national industrial biotechnology programme. The project, BiocatCH+, is intended to help basic research and technology transfer in biocatalysis in Switzerland.

AVA Biochem is a member of the Swiss business association Chemistry Pharma Biotech and is supported by Switzerland Global Enterprise (SGE) in export promotion.

Future plans

Although a fairly young company, AVA Biochem brings together a pool of international expertise from a range of sectors. We are confident that worldwide production of 5-HMF will rise in the coming years as market demand is created across a range of sectors for various applications. AVA Biochem is actively raising awareness of 5-HMF and its multitude of applications and aims to develop the substance into a bulk chemical in the coming years.

AVA Biochem aims to further strengthen its leadership position in the production of high-quality sustainable 5-HMF made from biomass – a true alternative to petroleum-based chemicals and a positive step towards the decarbonisation of society.

Reference

[1] van Putten RJ, van der Waal JC, de Jong E, Rasrendra CB, Heeres HJ, de Vries JG. Chem. Rev. 2013, 113, 1499–1597.Search in Google Scholar

©2014 by Walter de Gruyter Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- In this issue

- Editorial

- Megatrends – megascience? Part 2

- Feature

- Novel sustainable industrial processes: from idea to commercial scale implementation

- Original articles

- Application of environmental and economic metrics to guide the development of biocatalytic processes

- Synthesis of nanostructured MgO powders with photoluminescence by plasma-intensified pyrohydrolysis process of bischofite from brine

- A solvent free approach for Knoevenagel condensation: facile synthesis of 3-cyano and 3-carbethoxycoumarins

- Green synthesis and characterisations of antibacterial silver-polyvinyl alcohol nanocomposite films for wound dressing

- Company profiles

- AVA Biochem: commercialising renewable platform chemical 5-HMF

- Invenios: micro process technology – chemical process technology of tomorrow

- Conference announcements

- International Conference on Green Chemistry and Sustainable Engineering International (Barcelona, Spain, July 29–31, 2014)

- 7th Annual European Forum for Industrial Biotechnology and the Biobased Economy (Reims, France, September 30–October 2, 2014)

- 19th International Symposium on Homogeneous Catalysis (ISHC-XIX; Ottawa, ON, Canada, July 6–11, 2014)

- 248th American Chemical Society National Meeting and Exposition: Chemistry and Global Stewardship (San Francisco, CA, USA, August 10–14, 2014)

- Conferences 2014–2017

- Book reviews

- Green materials for sustainable water remediation and treatment

- Engineering catalysis

Articles in the same Issue

- Frontmatter

- In this issue

- Editorial

- Megatrends – megascience? Part 2

- Feature

- Novel sustainable industrial processes: from idea to commercial scale implementation

- Original articles

- Application of environmental and economic metrics to guide the development of biocatalytic processes

- Synthesis of nanostructured MgO powders with photoluminescence by plasma-intensified pyrohydrolysis process of bischofite from brine

- A solvent free approach for Knoevenagel condensation: facile synthesis of 3-cyano and 3-carbethoxycoumarins

- Green synthesis and characterisations of antibacterial silver-polyvinyl alcohol nanocomposite films for wound dressing

- Company profiles

- AVA Biochem: commercialising renewable platform chemical 5-HMF

- Invenios: micro process technology – chemical process technology of tomorrow

- Conference announcements

- International Conference on Green Chemistry and Sustainable Engineering International (Barcelona, Spain, July 29–31, 2014)

- 7th Annual European Forum for Industrial Biotechnology and the Biobased Economy (Reims, France, September 30–October 2, 2014)

- 19th International Symposium on Homogeneous Catalysis (ISHC-XIX; Ottawa, ON, Canada, July 6–11, 2014)

- 248th American Chemical Society National Meeting and Exposition: Chemistry and Global Stewardship (San Francisco, CA, USA, August 10–14, 2014)

- Conferences 2014–2017

- Book reviews

- Green materials for sustainable water remediation and treatment

- Engineering catalysis