Abstract

Poly(vinyl pyrrolidone) (PVP)/La3+/Zr4+ precursor nanofibrous membranes (LZPNM) with various Zr contents were synthesized via a simple electrospinning method. By controlling the Zr incorporation, the tensile properties of precursor membranes dramatically change from 0.77 to 1.73 MPa. Meanwhile, the average diameters of precursor nanofibers increase with the increase of Zr contents (from 283 to 535 nm). In addition, flexible La2O3-ZrO2 nanofibrous membranes (LZNM) were obtained by calcination of corresponding precursor membranes. Furthermore, the structures and morphologies of the precursor membranes were investigated using X-ray powder diffraction analysis (XRD) and field-emission scanning electron microscopy (FE-SEM). The surface functional groups and thermal properties of the precursor membranes were measured via Fourier transform infrared (FTIR) spectroscopy and thermogravimetric analysis (TGA).

1 Introduction

Electrospinning has been widely used to prepare continuous organic, inorganic, or composite fibers (1), (2), (3), (4). This preparation method is simple, versatile, scalable, and relatively inexpensive. Nanofibers possess several attractive properties such as structural flexibility, large surface-area-to-volume ratio, and high length-to-diameter ratio. Particularly, metal-oxide nanofibers have been successfully used in catalysts (5), gas sensors (6), photodetectors (7), (8), electrodes for supercapacitors/lithium-ion batteries (9), (10), dye-sensitized solar cells (11), (12), and lighting devices (13), (14) because of their fascinating characteristics. Hence, various metal-oxide nanofibers have been synthesized via electrospinning in the recent years (15), (16).

La2O3-ZrO2 has attracted much attention because of its superior properties such as high chemical stability, high thermal stability, low thermal conductivity, and nontoxicity. It has been recently used in many interesting industrial applications including thermal barrier coatings (17), (18), nuclear waste encapsulation (19), and luminescent materials (20), (21). La2O3-ZrO2 nanofibers have been prepared by the electrospinning technology (22), (23). However, the metal-oxide nanofibrous membranes are usually fragile, thus significantly limiting their practical applications such as flexible electronic devices, flexible energy storage devices, and filtration/purification devices. Until now, flexible metal-oxide membranes are very limited. Only a few types of flexible inorganic membranes such as SiO2-TiO2 composite fibrous membranes (24), ZrO2 membranes (25), SiO2 membranes (26), Al2O3 membranes (27), TiC membranes (28), and La2O3-ZrO2: Eu2+ membranes (29) have been fabricated by the electrospinning method. Although some flexible metal-oxide membranes have been successfully synthesized, the mechanism of the fabrication of flexible metal-oxide membranes is still not fully understood. To prepare flexible metal-oxide nanofibers by the electrospinning method, the following procedure is used: (i) The precursor membranes containing polymer assistant materials and inorganic constituents are fabricated under appropriate conditions by adjusting the electrospinning parameters. (ii) The precursor nanofibrous membranes are heated at a high temperature to remove the polymers and obtain the metal-oxide nanofibrous membranes by carefully controlling the calcination procedure. Hence, high-quality precursor nanofibrous membranes are crucial to obtain flexible metal-oxide membranes; however, in most cases, the precursor nanofibers have not been studied in detail.

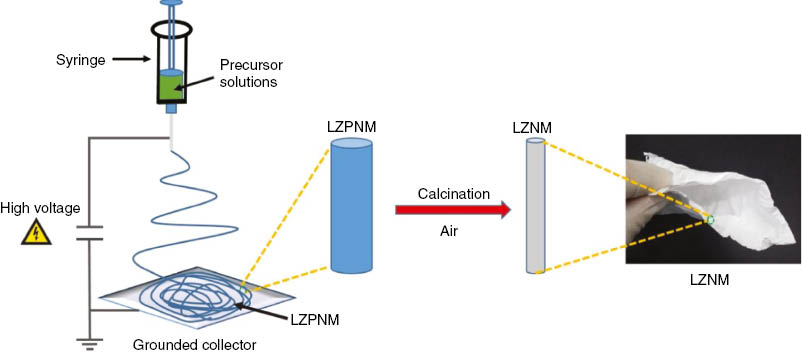

In continuation of our previous studies on flexible La2O3-ZrO2 membranes, we fabricated poly(vinyl pyrrolidone) (PVP)/La3+/Zr4+ precursor membranes doped with different contents of Zr (LZPNM) by the electrospinning and sol-gel techniques. Moreover, flexible La2O3-ZrO2 nanofibrous membranes (LZNM) were obtained via the calcination of the corresponding precursor membranes as shown in Figure 1. We mainly investigated the structures and morphologies of LZPNM by powder X-ray diffraction (XRD) analysis and field-emission scanning electron microscopy (FE-SEM). The surface functional groups and thermal and mechanical properties of the LZPNM were analyzed using a Fourier transform infrared (FTIR) spectrometer, thermogravimetric analyzer (TGA), and tensile tester, respectively.

Schematic diagram illustrating the processing steps in the fabrication of LZPNM and LZMN.

2 Experimental

2.1 Materials

Citric acid and zirconium acetate solution were obtained from Sigma-Aldrich (Seoul, Korea). N,N-dimethylformamide (DMF) was purchased from Samchun Pure Chemical (Daejeon, Korea). PVP (Mw=1,300,000) and lanthanum nitrate hexahydrate were purchased from Aladdin (Shanghai, China). All the chemicals were used as received without further purification. DMF was used as the solvent.

2.2 Fabrication of nanofibrous membranes

The precursor solution was prepared by dissolving different amounts of zirconium acetate solution, citric acid, and lanthanum nitrate hexahydrate in DMF and stirring for 2 h. Then, PVP powder (10 wt%) was added and stirred for 12 h under ambient conditions. The conductivity of precursor solutions were 2.81 (Zr/La: 0 mol%), 3.82 (Zr/La: 70 mol%), and 4.02 m cm-1 (Zr/La: 100 mol%) at 25°C, respectively. After the precursor solution was transferred into a plastic syringe for electrospinning with a flow rate of 1 ml h-1, a high voltage of 20 kV from was applied from a power source (HV30, NanoNc). The nanofibers were collected on a rotating roller (80 rpm), and the needle-to-roller distance was 15 cm. The relative humidity and ambient temperature were 42±3% and 25±2°C, respectively. Thus, the precursor nanofibrous membranes with various Zr contents were obtained. The precursor membranes were named as LZPNM-x [x is the molar proportion (mol%) of Zr/La: 0, 70, and 100, respectively]. Then, the precursor nanofibrous membranes were calcined at 650°C for 4 h under air atmosphere. Various La2O3 nanofibrous membranes doped with different contents of Zr were fabricated, and the La2O3-ZrO2 membranes were named as LZNM-y [y is the molar proportion (mol%) of Zr/La: 0, 70, and 100, respectively].

2.3 Characterization

The morphology and microstructure of the LZPNM and LZNM were analyzed using a FE-SEM (S-4700, Hitachi, Japan). The crystal structure of the precursor membranes was investigated by powder XRD analysis (X’ Pert-PRO, PANalytical, Netherlands) with Cu Kα radiation (λ=0.15405 nm). The surface functional groups of the precursor membranes were measured using an FTIR spectrometer (Varian 1000 FTIR Scimitar Series, PIKE Technologies, USA). The tensile mechanical properties were investigated using a tensile tester (XQ-1C, Instrument Research Center of Donghua-Lipu, China). The thermal properties of the precursor membranes were studied using a TGA (Pyris 1, PerkinElmer, USA).

3 Results and discussion

3.1 FE-SEM

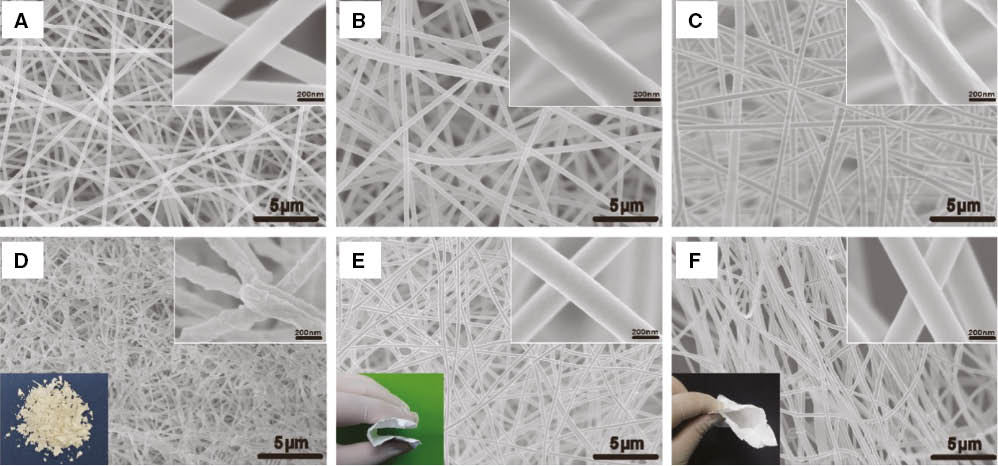

The morphologies of the LZPNM and LZNM were first investigated using FE-SEM. Figure 2A–C show the representative FE-SEM images of LZPNM-0, LZPNM-70, and LZPNM-100, respectively. The diameters of the nanofibers increased from 283±36 nm to 535±94 nm with the increase in the Zr contents. The corresponding FE-SEM images with a higher magnification (Figure 2A–C) show that these randomly oriented nanofibers had a smooth surface and uniform diameters. The diameters of the nanofibers were controlled by the precursor concentration. Figure 2D–F show the FE-SEM images of LZNM-0, LZNM-70, and LZNM-100, respectively. The diameters of the nanofibers increased from 174±29 nm to 286±40 nm. The composition of the nanofibers was controlled by the Zr/La ratio of the precursor. However, as shown in Figure 2D, LZNM-0 consisted of short and fragile nanofibers. The high-magnification FE-SEM images show that the nanofibers had a rough surface (Figure 2D inset). Compared to LZNM-0, LZNM-70 and LZNM-100 showed nanofibers with a smooth surface and robust flexibility during the bending (Figure 2E and F, inset). After the sintering at 650°C, nanofibers with a smooth surface, continuous structure, and almost uniform diameter were obtained. Several process parameters affected the morphology of the electrospun nanofibers, including the operating conditions and intrinsic properties of the precursor solution. The flexibility of LZNM-70 and LZNM-100 depends on the morphology of the nanofibers. To obtain flexible nanofibers with the desired morphology, it is important to optimize the experimental conditions such as the properties of the precursor solution, electrospinning parameters, and calcination conditions.

FE-SEM images of precursor membranes: (A) LZPNM-0, (B) LZPNM-70, (C) LZPNM-100, and inorganic membranes: (D) LZNM-0, (E) LZNM-70, and (F) LZNM-100.

The insets are the digital photograph and magnified FE-SEM images of the corresponding membranes.

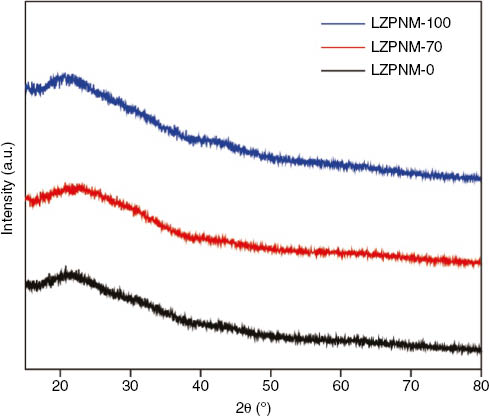

3.2 XRD

The crystalline structure of LZPNM was investigated by XRD. The XRD patterns of LZPNM-0, LZPNM-70, and LZPNM-100 from 20° to 80° are shown in Figure 3. All the samples demonstrated a broad diffraction peak at 2θ≈20°, and sharp crystalline peaks were not observed. This clearly indicates that all the LZPNM materials belong to a completely amorphous state.

XRD patterns of LZPNM-0, LZPNM-70 and LZPNM-100.

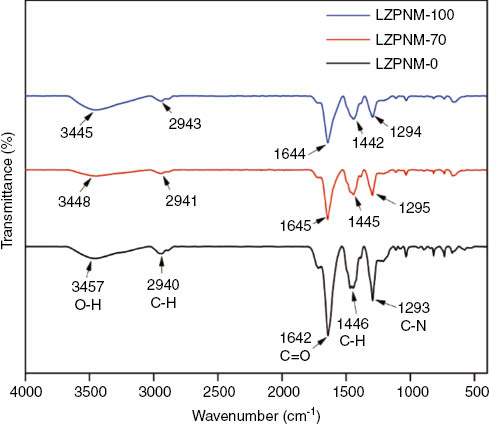

3.3 FTIR

Figure 4 shows the FTIR spectra of LZPNM-0, LZPNM-70, and LZPNM-100 in the wavenumber range 500–4000 cm-1. The broad peaks at ~3450 cm-1 can be assigned to the symmetric stretching vibration of the OH groups of PVP. The peaks at ~1445 cm-1 can be attributed to the CH2 groups of PVP (30). The LZPNM shows characteristic stretching peaks corresponding to the C=O group of PVP (31) at 1642 cm-1, 1645 cm-1, and 1644 cm-1. The peaks at ~1294 cm-1 can be assigned to the absorption of the C-N group of PVP (32). Figure 4 shows no significant change in the position of the peak, and no new peak appeared.

FTIR shows peaks of LZPNM-0, LZPNM-70 and LZPNM-100.

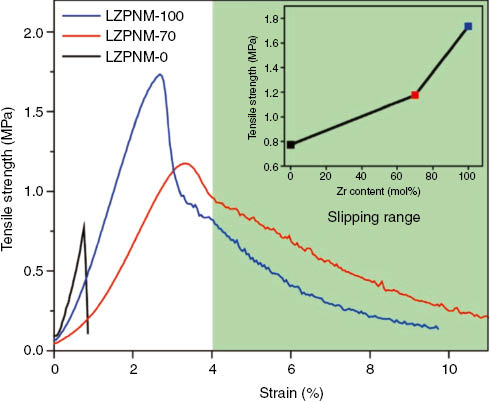

3.4 Tensile strength

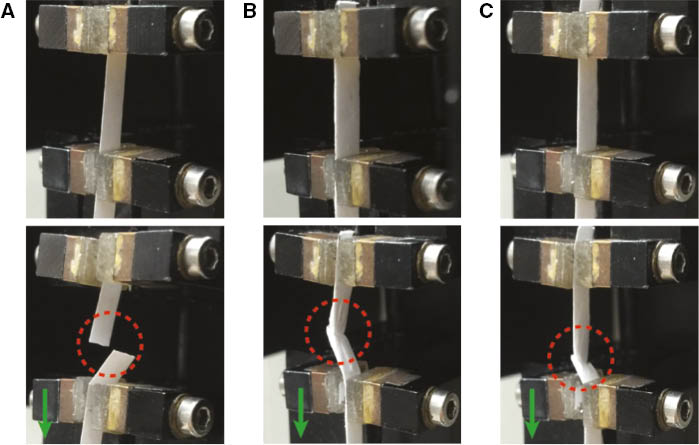

Figure 5 shows the stress-strain curves of the LZPNM. All the stress curves of the samples first showed a significant increase under a stress load. However, LZPNM-0 exhibited an increase until breaking without obvious slipping, because a small fiber diameter has a large packing density. Figure 5 clearly shows the slipping of LZPNM-70 and LZPNM-100. The fractured membranes are marked with red circles (Figure 6). LZPNM-70 and LZPNM-100 with a fiber diameter of 447±61 nm and 535±94 nm, respectively, showed an ultimate stress of 1.18 MPa and 1.73 MPa, respectively, indicating a significant improvement compared to LZPNM-0 (0.77 MPa). The results indicate that LZPNM-70 and LZPNM-100 had a good tensile strength. This can be attributed to the inhibition of fiber breaking by the doped Zr. It is important to obtain flexible inorganic membranes.

Stress-strain curves for LZPNM-0, LZPNM-70 and LZPNM-100.

The inset is the dependence of its stress and the Zr contents in the LZPNM.

Digital photograph of rupture process by stress-strain test for (A) LZPNM-0, (B) LZPNM-70 and (C) LZPNM-100.

3.5 TGA

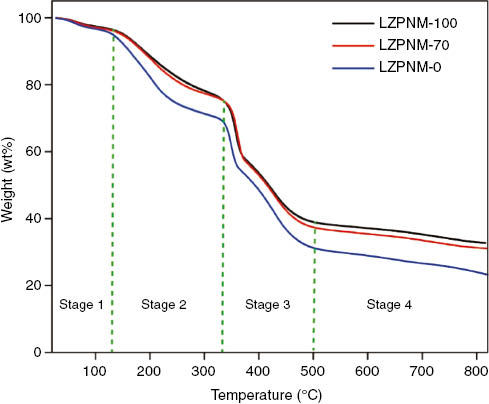

To investigate the thermal decomposition of the precursor membranes, LZPNM was analyzed using a TGA from ambient temperature to 800°C under a heating rate of 10°C min-1 (Figure 7). The calcination process can be divided into four stages from 100°C to 800°C. The first stage occurred from room temperature to 140°C, corresponding to the removal of the residual solvent (DMF) and absorbed water. In the second stage from 140°C to 330°C, the nitrate and side-chain of PVP decomposed, resulting in a large weight loss. In the third stage from 330°C to 500°C, the weight loss can be attributed to the cleavage of the C-C bonds of the PVP. Above 500°C, the TGA curves slightly decreased. This indicates that the water, organic compounds, and nitrate in the composite fibers were removed completely, and pure inorganic oxide nanofibers were obtained.

TGA curves of LZPNM-0, LZPNM-70 and LZPNM-100.

In the design of flexible metal-oxide nanofiber membranes, it is important to determine the change in the structure and properties of the metal-oxide nanofibers with the composition. Hence, flexible LZNM nanofibers were fabricated by careful preparation of the precursors, including the type of metal salt, proportions of metal element, and concentration of polymer. Moreover, the calcination temperature should be optimized. Particularly, after the precursor nanofibers were calcined, the inorganic nanofibers almost automatically shrinked because the polymer template was removed. The nanofibers are usually more brittle because of their thinner section and the internal stress generated by the shrinkage (Figure 2D) (33). Therefore, to prevent the shrinkage of fibers and maintain the morphology of fibers (Figure 2E and F), Zr was incorporated into the fibers during the electrospinning.

4 Conclusions

PVP/La3+/Zr4+ precursor nanofibrous membranes (LZPNM-0, LZPNM-70, and LZPNM-100) were prepared by a facile electrospinning and sol-gel technique. Moreover, the corresponding inorganic nanofibrous membranes (LZNM-0, LZNM-70, and LZNM-100) were obtained by heat treatment. The morphologies and properties of the precursor membranes were studied. The average diameters of the precursor membranes increased with the increase in the Zr contents (from 283 nm to 535 nm). The tensile properties of LZPNM dramatically changed from 0.77 MPa to 1.73 MPa. This study provides a new perspective to analyze and understand the mechanism of flexible LZNM-70 and LZNM-100.

Funding source: National Research Foundation of Korea

Award Identifier / Grant number: NRF-2014R1A1A2008489

Award Identifier / Grant number: 2014R1A4A1008140

Funding source: Korea Institute for Advancement of Technology

Award Identifier / Grant number: A007700075

Funding statement: The authors greatly appreciate the National Research Foundation of Korea (No. NRF-2014R1A1A2008489, No. 2014R1A4A1008140), Industry & Energy (MOTIE) and Korea Institute for Advancement of Technology (KIAT) (Grant/Award Number: ‘No. A007700075’) for financial support.

Acknowledgments

The authors greatly appreciate the National Research Foundation of Korea (No. NRF-2014R1A1A2008489, No. 2014R1A4A1008140), Industry & Energy (MOTIE) and Korea Institute for Advancement of Technology (KIAT) (Grant/Award Number: ‘No. A007700075’) for financial support.

References

1. Xue J, Niu Y, Gong M, Shi R, Chen D, Zhang L, Lvov Y. Electrospun microfiber membranes embedded with drug-loaded clay nanotubes for sustained antimicrobial protection. ACS Nano. 2015;9:1600–12.10.1021/nn506255eSuche in Google Scholar PubMed

2. Zhu L, Hong M, Ho GW. Hierarchical assembly of SnO2/ZnO nanostructures for enhanced photocatalytic performance. Sci Rep. 2015;5:11609–20.10.1038/srep11609Suche in Google Scholar PubMed PubMed Central

3. Santos LD, Maréchal M, Guillermo A, Lyonnard S, Moldovan S, Ersen O, Sel O, Perrot H, Laberty-Robert C. Proton transport in electrospun hybrid organic-inorganic membranes: an illuminating paradox. Adv Funct Mater. 2015;26:594–604.10.1002/adfm.201504076Suche in Google Scholar

4. Agarwal S, Jiang S. Nanofibers and electrospinning. In: Kobayashi S, Müllen K, editors. Encyclopedia of polymeric nanomaterials. Springer: Berlin, Heidelberg; 2014. pp. 1–15.10.1007/978-3-642-36199-9_370-1Suche in Google Scholar

5. Formo E, Lee E, Campbell D, Xia Y. Functionalization of electrospun TiO2 nanofibers with Pt nanoparticles and nanowires for catalytic applications. Nano Lett. 2008;8:668–72.10.1021/nl073163vSuche in Google Scholar PubMed

6. Yang DJ, Kamienchick I, Youn DY, Rothschild A, Kim ID. Ultrasensitive and highly selective gas sensors based on electrospun SnO2 nanofibers modified by Pd loading. Adv Funct Mater. 2010;20:4258–64.10.1002/adfm.201001251Suche in Google Scholar

7. Tian W, Zhai T, Zhang C, Li SL, Wang X, Liu F, Liu D, Cai X, Tsukagoshi K, Golberg D. Low-cost fully transparent ultraviolet photodetectors based on electrospun ZnO-SnO2 heterojunction nanofibers. Adv Mater. 2013;25:4625–30.10.1002/adma.201301828Suche in Google Scholar PubMed

8. Li X, Gao C, Duan H, Lu B, Wang Y, Chen L, Zhang Z, Pan X, Xie E. High-performance photoelectrochemical-type self-powered UV photodetector using epitaxial TiO2/SnO2 branched heterojunction nanostructure. Small 2013;9:2005–11.10.1002/smll.201202408Suche in Google Scholar PubMed

9. Tang K, Mu X, van Aken PA, Yu Y, Maier J. “Nano-pearl-string” TiNb2O7 as anodes for rechargeable lithium batteries. Adv Energy Mater. 2013;3:49–53.10.1002/aenm.201200396Suche in Google Scholar

10. Li X, Wang G, Wang X, Li X, Ji J. Flexible supercapacitor based on MnO2 nanoparticles via electrospinning. J Mater Chem A 2013;1:10103–6.10.1039/c3ta11727hSuche in Google Scholar

11. Choi SH, Hwang D, Kim DY, Kervella Y, Maldivi P, Jang SY, Demadrille R, Kim ID. Amorphous zinc stannate (Zn2SnO4) nanofibers networks as photoelectrodes for organic dye-sensitized solar cells. Adv Funct Mater. 2013;23:3146–55.10.1002/adfm.201203278Suche in Google Scholar

12. Yang L, Leung WWF. Application of a bilayer TiO2 nanofiber photoanode for optimization of dye-sensitized solar cells. Adv Mater. 2011;23:4559–62.10.1002/adma.201102717Suche in Google Scholar PubMed

13. Hou Z, Yang P, Li C, Wang L, Lian H, Quan Z, Lin J. Preparation and luminescence properties of YVO4: Ln and Y(V, P)O4: Ln (Ln=Eu3+, Sm3+, Dy3+) nanofibers and microbelts by sol-gel/electrospinning process. Chem Mater. 2008;20:6686–96.10.1021/cm801538tSuche in Google Scholar

14. Song H, Yu H, Pan G, Bai X, Dong B, Zhang X, Hark S. Electrospinning preparation, structure, and photoluminescence properties of YBO3: Eu3+ nanotubes and nanowires. Chem Mater. 2008;20:4762–7.10.1021/cm8007864Suche in Google Scholar

15. Li D, McCann JT, Xia Y, Marquez M. Electrospinning: a simple and versatile technique for producing ceramic nanofibers and nanotubes. J Am Ceram Soc. 2006;89:1861–9.10.1002/9780470588246.ch47Suche in Google Scholar

16. Chronakis IS. Novel nanocomposites and nanoceramics based on polymer nanofibers using electrospinning process – a review. J Mater Process Technol. 2005;167:283–93.10.1016/j.jmatprotec.2005.06.053Suche in Google Scholar

17. Vassen R, Cao X, Tietz F, Basu D, Stöver D. Zirconates as new materials for thermal barrier coatings. J Am Ceram Soc. 2000;83:2023–8.10.1111/j.1151-2916.2000.tb01506.xSuche in Google Scholar

18. Cao X, Vassen R, Jungen W, Schwartz S, Tietz F, Stöver D. Thermal stability of lanthanum zirconate plasma-sprayed coating. J Am Ceram Soc. 2001;84:2086–90.10.1111/j.1151-2916.2001.tb00962.xSuche in Google Scholar

19. Boccaccini A, Bernardo E, Blain L, Boccaccini D. Borosilicate and lead silicate glass matrix composites containing pyrochlore phases for nuclear waste encapsulation. J Nucl Mater. 2004;327:148–58.10.1016/j.jnucmat.2004.01.019Suche in Google Scholar

20. Pokhrel M, Brik MG, Mao Y. Particle size and crystal phase dependent photoluminescence of La2Zr2O7: Eu3+ nanoparticles. J Am Ceram Soc. 2015;98:1–10.10.1111/jace.13734Suche in Google Scholar

21. Zhang A, Lü M, Zhou G, Wang S, Zhou Y. Combustion synthesis and photoluminescence of Eu3+, Dy3+-doped La2Zr2O7 nanocrystals. J Phys Chem Solids. 2006;67:2430–4.10.1016/j.jpcs.2006.05.004Suche in Google Scholar

22. Wang J, Dong X, Cui Q, Liu G, Yu W. Preparation and characterization of polycrystalline La2Zr2O7 ultrafine fibres via electrospinning. J Nanosci Nanotechnol. 2011;11:2514–9.10.1166/jnn.2011.3574Suche in Google Scholar PubMed

23. Li J, Dai H, Li Q, Zhong X, Ma X, Meng J, Cao X. Lanthanum zirconate nanofibers with high sintering-resistance. Mater Sci Eng B-Adv Funct Solid-State Mater. 2006;133:209–12.10.1016/j.mseb.2006.04.026Suche in Google Scholar

24. Wen Q, Di J, Zhao Y, Wang Y, Jiang L, Yu J. Flexible inorganic nanofibrous membranes with hierarchical porosity for efficient water purification. Chem Sci. 2013;4:4378–82.10.1039/c3sc51851eSuche in Google Scholar

25. Chen Y, Mao X, Shan H, Yang J, Wang H, Chen S, Tian F, Yu J, Ding B. Free-standing zirconia nanofibrous membranes with robust flexibility for corrosive liquid filtration. RSC Adv. 2014;4:2756–63.10.1039/C3RA45043KSuche in Google Scholar

26. Si Y, Mao X, Zheng H, Yu J, Ding B. Silica nanofibrous membranes with ultra-softness and enhanced tensile strength for thermal insulation. RSC Adv. 2015;5:6027–32.10.1039/C4RA12271BSuche in Google Scholar

27. Wang Y, Li W, Xia Y, Jiao X, Chen D. Electrospun flexible self-standing γ-alumina fibrous membranes and their potential as high-efficiency fine particulate filtration media. J Mater Chem A 2014;2:15124–31.10.1039/C4TA01770FSuche in Google Scholar

28. Zhou G, Xiong T, Jiang S, Jian S, Zhou Z, Hou H. Flexible titanium carbide-carbon nanofibers with high modulus and high conductivity by electrospinning. Mater Lett. 2016;165:91–4.10.1016/j.matlet.2015.11.119Suche in Google Scholar

29. Han W, Ding B, Park M, Cui F, Ghouri ZK, Saud PS, Kim H. Facile synthesis of luminescent and amorphous La2O3–ZrO2: Eu3+ nanofibrous membranes with robust softness. Nanoscale 2015;7:14248–53.10.1039/C5NR02173ASuche in Google Scholar

30. Li C, Chen R, Zhang X, Shu S, Xiong J, Zheng Y, Dong W. Electrospinning of CeO2–ZnO composite nanofibers and their photocatalytic property. Mater Lett. 2011;65:1327–30.10.1016/j.matlet.2011.01.075Suche in Google Scholar

31. Yu D-G, Williams GR, Yang J-h, Wang X, Qian W, Li Y. Chitosan nanoparticles self-assembled from electrospun composite nanofibers. J Textil Sci Eng. 2012;2:1–5.Suche in Google Scholar

32. Deniz AE, Vural HA, Ortaç B, Uyar T. Gold nanoparticle/polymer nanofibrous composites by laser ablation and electrospinning. Mater Lett. 2011;65:2941–3.10.1016/j.matlet.2011.06.045Suche in Google Scholar

33. Horzum N, Muñoz-Espí R, Glasser G, Demir MM, Landfester K, Crespy D. Hierarchically structured metal oxide/silica nanofibers by colloid electrospinning. ACS Appl Mater Interfaces 2012;4:6338–45.10.1021/am301969wSuche in Google Scholar PubMed

©2017 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Artikel in diesem Heft

- Frontmatter

- In this Issue

- Guest editorial

- Electrospinning, fibers and textiles: a new driving force for global development

- Full length articles

- Study on uniformity of a melt-blown fibrous web based on an image analysis technique

- Structure and properties of polytetrafluoroethylene (PTFE) fibers

- Modeling of braiding parameter impact on pore size and porosity in a tubular braiding fabric

- Optimization design of a flexible absorption device for solar energy application

- Synthesis and structure analysis of polyesteramides modified with bio-based diaminopentane hexanedioic salt

- Insight into the precursor nanofibers on the flexibility of La2O3-ZrO2 nanofibrous membranes

- Fabrication of superhydrophobic nanofiber fabric with hierarchical nanofiber structure

Artikel in diesem Heft

- Frontmatter

- In this Issue

- Guest editorial

- Electrospinning, fibers and textiles: a new driving force for global development

- Full length articles

- Study on uniformity of a melt-blown fibrous web based on an image analysis technique

- Structure and properties of polytetrafluoroethylene (PTFE) fibers

- Modeling of braiding parameter impact on pore size and porosity in a tubular braiding fabric

- Optimization design of a flexible absorption device for solar energy application

- Synthesis and structure analysis of polyesteramides modified with bio-based diaminopentane hexanedioic salt

- Insight into the precursor nanofibers on the flexibility of La2O3-ZrO2 nanofibrous membranes

- Fabrication of superhydrophobic nanofiber fabric with hierarchical nanofiber structure