Abstract

Deep learning (DL) techniques are advancing quickly, which has increased interest in leveraging them to analyze intricate corrosion patterns and forecast corrosion behavior. This offers a huge challenge across multiple industries, resulting in large financial losses and safety risks. It results in the creation of solutions that are more accurate, effective, and proactive to tackle corrosion-related challenges, thereby enhancing the safety, reliability, and sustainability of vital infrastructure systems. This review commences by utilizing deep learning algorithms and its applications in corrosion assessment across various sectors, encompassing corrosion detection, prediction, classification, and material degradation analysis. The goal is to offer insights in current status and future prospects of corrosion management.

1 Introduction

Corrosion is the process by which materials, usually metals, degrade due to their chemical reactions to their surroundings, leading to functional component failures. It not only escalates component costs but also poses risks to life and safety (Harsimran et al. 2021). This natural process affects various sectors such as transportation, infrastructure, production, utilities, and manufacturing (Ibrahimi et al. 2021), with estimated annual costs ranging between 3 % and 4 % of the Gross National Product (GNP) (Nash et al. 2022). Traditional corrosion monitoring methods lack precision and time consuming, hindering effective implementation of corrosion management (Hussein Khalaf et al. 2024).

Deep learning (DL) recent development has created new avenues for addressing complexities of corrosion detection (Petricca et al. 2016), leveraging abundant data and computational power to provide more accurate, proactive, and automated approaches in corrosion research. This review aims to offer a comprehensive overview of deep learning applications in corrosion assessment, by exploring various deep learning architectures and their utility in enhancing safety through corrosion assessment and control strategies.

1.1 Background of deep learning

Warren and McCulloch (1943) proposed the first neural network of the mathematical model, laid the foundation for subsequent research in artificial neural networks (ANNs) and computational neuroscience. In 1960s, neural networks with back propagation algorithms emerged to train multilayer networks (Kelley 1960). Kunihiko Fukushima (1980) introduced Neocognitron for pattern recognition. Hopfield (1982) introduced a type of recurrent neural network as Hopfield network. Ivakhnenko and Ivakhnenko (1995) made a notable contribution to deep learning by developing the first deep learning network with a polynomial activation function. Hochreiter and Schmidhuber (1997) proposed long- and short-term memory intended to solve recurrent neural networks (RNNs) vanishing gradient issue. Yann LeCun et al. (1998) made significant contribution in field of deep learning with their work on gradient-based learning for document recognition.

Jia et al. (2009) play a pivotal role in deep learning research by creating ImageNet datasets at Stanford University. Goodfellow et al. (2020) introduced generative adversarial networks (GANs) as a novel unsupervised learning system. Currently, deep learning stands out as one of the most promising and prominent domains within machine learning, propelled by its remarkable achievements across diverse applications, driving innovation in numerous industries.

2 Deep learning architectures

Deep learning is a contemporary advance in machine learning method that impersonates human brain in decision making. Corrosion detection using deep learning frameworks applied in different neural network models that utilize advanced algorithms to extract features specifically designed to identify and analyze corrosion patterns in images or data and make predictions regarding the presence, severity, or corrosion types. Some common deep learning architectures used in corrosion include convolutional neural networks (CNNs), region convolutional neural networks (R-CNNs), and RNNs. CNNs can automatically learn hierarchical characteristics from image data, which makes them useful for corrosion detection tasks. RCNN segment images identify individual instances of corrosion within images. However, RNNs are suitable for time-series analysis related to corrosion progression. The following sections provide common DL architectures utilized in the field of corrosion detection.

2.1 Convolutional neural networks

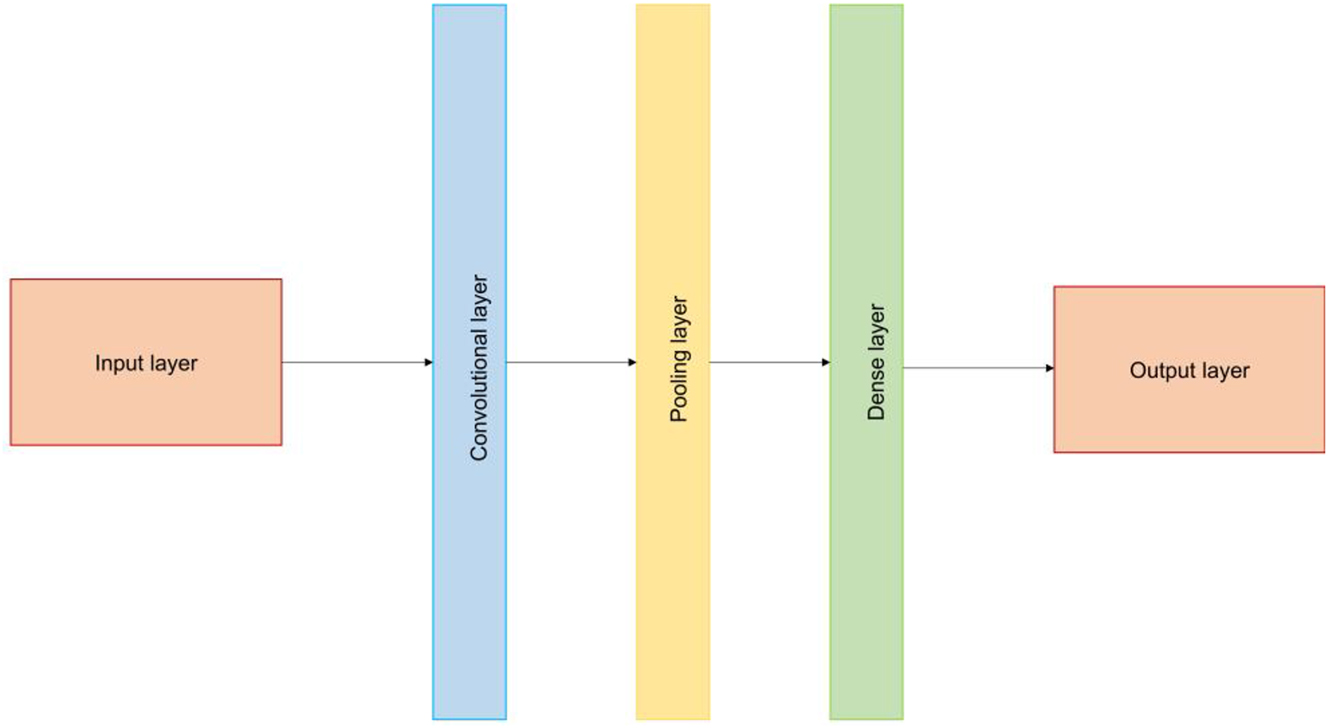

Convolutional neural networks are a type of deep learning model designed to process and analyze image and video by learning spatial feature hierarchies. They are highly effective in tasks such as image recognition, classification, and object detection. As shown in Figure 1, a typical CNN architecture comprises of several layers, including input, convolutional, pooling, and dense layers. Convolutional layers use filters to perform convolution operations on the input for identifying key features. The output is subsequently processed through an activation function, which introduces nonlinearity and allows the model to learn complex features. The pooling layers then reduce the spatial dimensions of feature maps with a defined pool size. Finally, dense layers aggregate the learned features to produce final predictions or classifications.

CNN architecture.

2.1.1 Corrosion detection by color feature using convolutional neural networks

Convolutional neural networks are extensively employed in many industrial applications, including natural language processing, image segmentation, and classification. Comprising multiple layers arranged sequentially, a CNN performs diverse operations on the input data received from preceding layers. Each convolution operation is followed by an activation step, yielding feature maps that exhibit enhanced sensitivity to spatial information within the input. To further enhance this capability, pooling layers are introducing between convolutional layers. These pooling layers employ a sliding two-dimensional array, typically of size 2 × 2, in order to decrease the feature maps’ dimensionality by half. Such reduction helps to create more robust feature maps less dependent on precise positional information. A typical pooling technique called max and average pooling calculates the higher and average value inside every region of feature map.

CNNs can predict the class category even when the precise location of objects within the input is unknown. Object detection involves determining both object localization and categorization of each individual object. The generic object detection identifies and categorizes the items in a picture by assigning them a bounding box, which is usually rectangular and indicates the degree of confidence in the object’s presence.

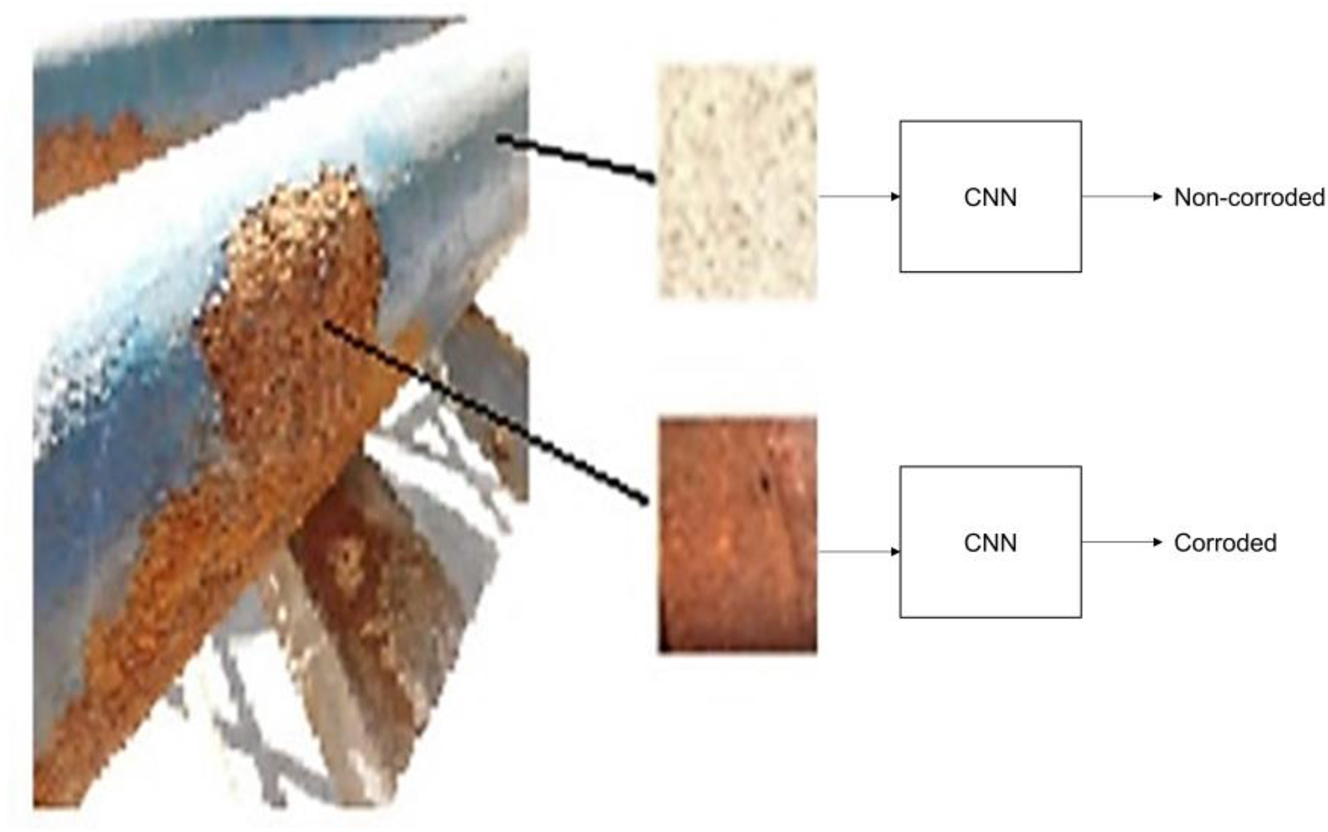

Corrosion, particularly rusting, is a prevalent occurrence. Rust emerges when iron is exposed to high levels of oxygen and water, resulting in the formation of red colored iron oxide. Alternatively, brown colored rust develops in environments with high oxygen and low moisture. When moisture content is high, it leads to the formation of very soluble yellow colored iron oxide rust. The variation in color serves as the primary indicator for visually identifying corroded areas. CNN classifies rusted and not rusted metals based on binary classification (Shirsath et al. 2022b). Figure 2 provides a typical example depicting images of both corroded and noncorroded sections of the pipeline.

Corroded and noncorroded segments of the pipeline.

Conventional computer vision methods primarily rely on rust coloration to detect corrosion on metal surfaces. Open CV, a widely used library in C++ and Python, facilitates object inspection and classification in computer vision applications. However, challenges arise when a red colored background or changes in the surrounding environment near the unaffected structure cause misclassification. Extensive experimental investigations have been conducted to explore the relationship between deep learning techniques and conventional computer vision methods, assessing the accuracy and effectiveness of various test images.

In 2016, (Petricca et al. 2016) presented CNN model for automated corrosion identification and evaluated its performance against standard computer vision techniques. The study revealed that deep learning methods surpassed standard computer vision technology in real-world scenarios. Specifically, the CNN approach achieved an overall accuracy of 78 %, outperforming the 69 % accuracy of the standard computer vision technique. Notably, the Open CV method demonstrated 89 % accuracy in nonrust classification but only 57 % accuracy in rust detection. Rustseg approach was introduced to automate corrosion detection in images without requiring per-pixel labeled datasets (Burton et al. 2022).

Atha and Jahanshahi (2018) introduced two CNN models, named Corrosion 5 and Corrosion 7, designed for corrosion detection in the YCbCr color space. The datasets are generated by cropping images separately from fully corroded and uncorroded areas using a sliding window approach to locate the corrosion spots. Different sliding window sizes are created by dividing the input image size of 128 × 128 into smaller sizes of 64 × 64 and 32 × 32. The model development process includes training, validation, and testing using a dataset. Various color spaces and window sizes are applied to the existing network to minimize the error rate. The author compared the proposed Corrosion 5 and Corrosion 7 CNN models with the standard ZFNet, VGG 16, and VGG 15 models. The standard architectures, ZFNet, VGG 16, and VGG 15, have more parameters (28,849,104, 65,050,304, and 15,120,164, respectively) compared to Corrosion 5 and Corrosion 7, which have fewer parameters (33,365,792 and 3,067,470, respectively). This leads to a notable decrease in computational time by training the proposed models. The comparison study demonstrates that the proposed CNN models achieve similar accuracy to the standard models when using a window size of 128 × 128 on input images in the RGB color space.

CNNs with the U-Net architecture were used image segmentation tasks (Ronneberger et al. 2015). Y. Zhao et al. (2018) devised a CNN network model incorporating artificial bee colony (ABC) swarm optimization for self-organizing map in the classification of material corrosion levels. Bastian et al. (2019) proposed CNN network extract image features within the RGB color space. The trained network model categorizes images into four classes corresponding to different degrees of low, medium, and high corrosion. Augmentation of data involves flip and rotating operations, employed to expand the amount of data during developmental phase of deep learning network. Additionally, an unsupervised recursive region technique was developed to precisely identify the location of corroded regions. This technique divides the image into four equal zones and identifies corroded areas within these zones. The process iterates until the subregion size reaches 32 × 32, achieving a high precision rate of 98.2 % in identifying rusty areas.

2.2 Corrosion detection using ensemble deep learning model approach

For both structural identification and corrosion feature extraction, two CNN models are combined with an ensemble deep learning technique. The images of corrosion is segmented and separated by algorithm uses grid annotations of the entire image to create numerous rectangular segments, each of which represents a smaller image that the CorrDetector framework uses to offer ground truth information. In order to identify rusty in small drone images, the CNNs primarily learn features associated with corrosion color. A shallow version of the VGG16 model includes five layers in which two fully connected layers that are trained to make multiple prediction decisions at the segment, image, and industrial object levels, and three convolutional layers that extract features from training images (Forkan et al. 2022).

2.3 Region convolutional neural networks

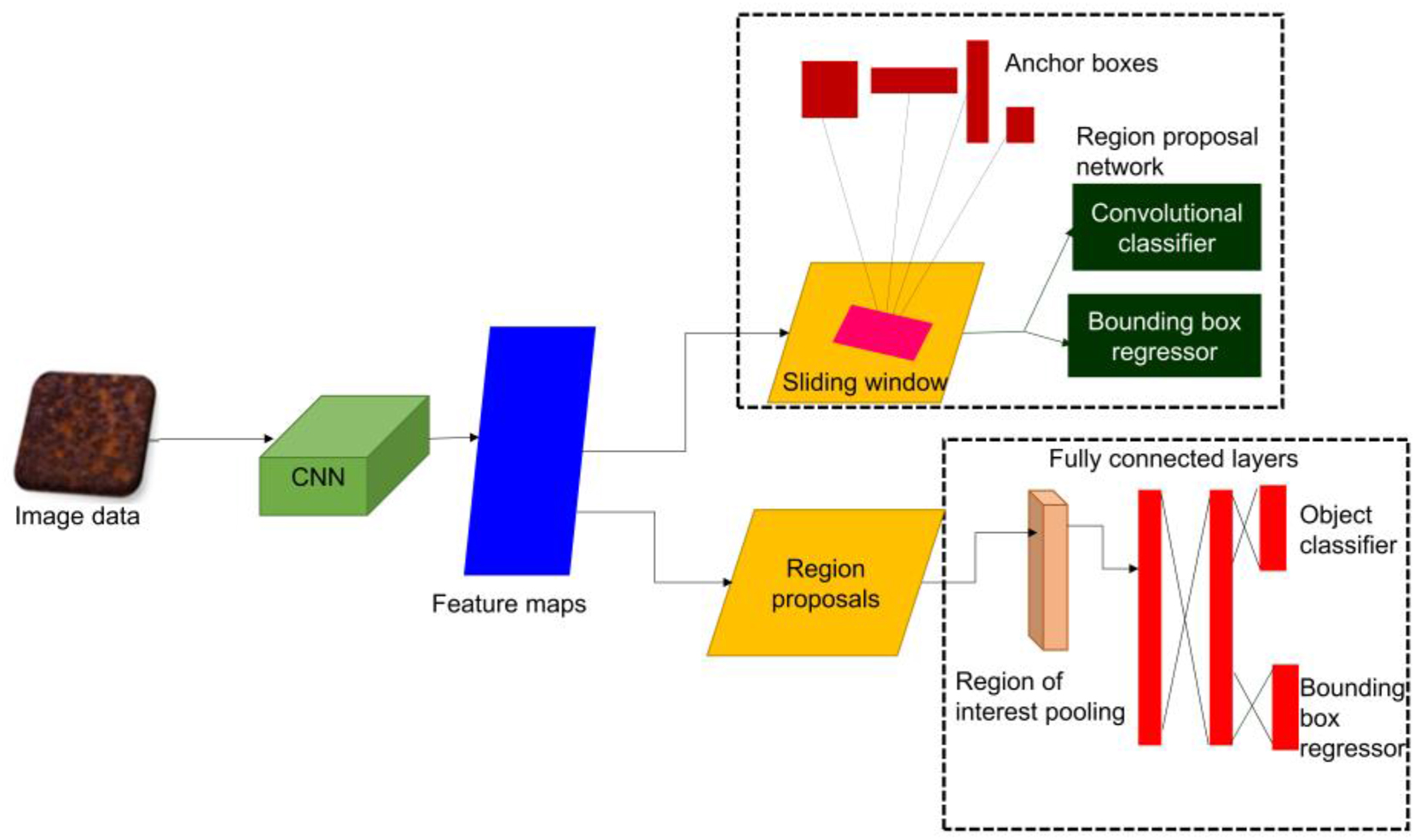

Region convolutional neural networks are used for detecting object as shown in Figure 3. CNNs forward the feature maps to region proposals. These proposals utilize algorithm to extract features from individual regions that contain objects. The extracted features are further refined through region of interest pooling and then passed through fully connected layers, which identify objects within regions and classify them into predefined categories. A bounding box regressor is then applied to fine-tune the object locations by adjusting the bounding box coordinates. On the other hand, the extracted feature map is processed by a sliding window, which varies the size and location of objects within the window, generating anchor boxes. Each region within these anchor boxes extracts features for object detection.

R-CNN architecture.

2.3.1 Corrosion detection using region convolutional neural networks

Object detection entails identifying the bounding box coordinates that encapsulate recognized objects and categorizing them within an image. Deep learning approaches for object detection employ regression/classification techniques for object localization, starting with the generation of region proposals, each accompanied by object scores and classifications.

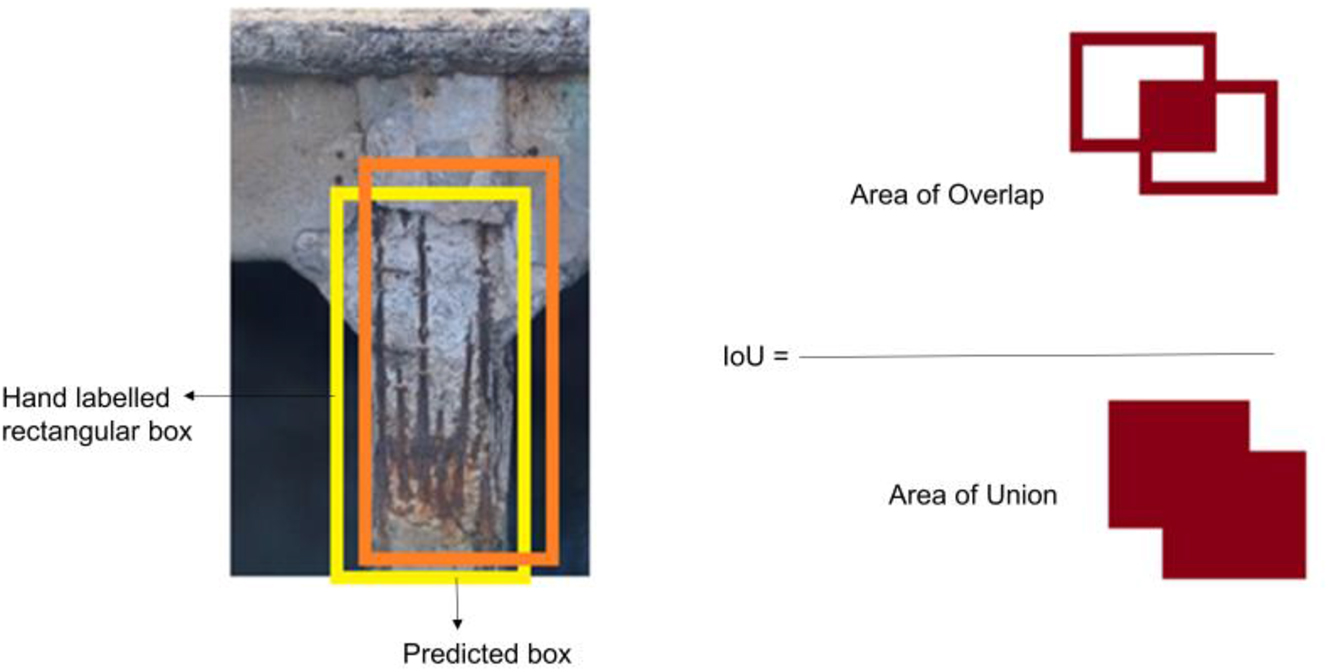

Regression-based object detection networks like the You Only Look Once (YOLO) model are intended to generate predictions in a single pass of forward propagation (Redmon et al. 2016). An m × m grid is created from the divided image, and each cell defines a bounding box and the corresponding confidence scores for conditional classes. The intersection over union (IoU) between the suggested box and the manually labeled rectangular box depicting the corrosion of steel detection in Figure 4 determines the probability of a class per cell, which is represented by these confidence scores. YOLO 2 and YOLO 3 are newer versions that incorporate batch normalization and anchor box algorithms (Redmon and Farhadi 2018). The inclusion of a batch normalization layer between successive hidden layers enhances stability and standardizes the output of activation layers. The single shot detector (SSD) (W. Liu et al. 2016) comprises two components: pretrained image classification network, such as ResNet, VGG-16, etc., that uses to obtain the feature map by removing the classification layer, and a simple convolutional layer attached to the first part, responsible for generating candidate boxes and performing object classification.

IoU-based detection of steel corrosion in concrete.

A selective search technique (Van De Sande et al. 2011) uses RCNN model, pioneered by (Girshick et al. 2014), to produce region proposals. These proposals inputted into CNN network in order to extract vectors of features in each proposed region. After CNN has extracted the features, it passes to support vector machine (SVM) classifier, which has been trained to differentiate between an object’s positive and negative areas.

Training process of the RCNN model involves multiple stages, leading to significant memory usage and computational time. In response to these challenges, (Girshick 2015) introduced the fast RCNN model, which incorporates bounding box regression. Furthermore, (Ren et al. 2017) developed a more advanced object detection system known as faster RCNN to enhance both detection accuracy and computational efficiency. In order to create a feature map, this model combines two pretrained subnetworks, classification and the region proposal network (RPN), reflects conventional fast RCNN model. By traverse the map of feature produced by layer of convolution, RPN computes object probabilities and produces huge anchoring boxes. For detecting object, the following networks use the region proposal technique: feature pyramid network (FPN) (Xiaohan Li et al. 2019), mask region-convolutional neural network (Mask R-CNN) (He et al. 2020), spatial pyramid pooling network (SSP-net) (He et al. 2015), and region-based fully convolutional network (R-FCN) (Dai et al. 2016).

Zheng and Wu (2019) developed an optimized faster RCNN using k-clustering approach to ascertain the number and size of anchor boxes in sewage pipelines in order to improve convergence time. RPN generated temporary window bounding boxes around objects and refined them using bounding box regression. The model converged more quickly when the k clustering approach was used with a k-value of 5. The coordinates and dimensions of candidate boxes in bounding box regression were fixed by the smooth L1 loss function, while the object present or not in training binary classification was determined using the softmax loss function. Ahuja et al. (2021) proposed residual U-Net combined with Bidirectional Convolutional LSTM for the detection and classification of pitting corrosion. This method was implemented using MATLAB and utilized SEM image datasets.

The corrosion classification task utilized the CNN framework, incorporating Mask R-CNN for segmenting four distinct grades of surface corrosion in metals before blasting, leveraging unsupervised learning and VGG16 transfer learning. This approach yielded mask and bounding box coordinates for each object, accompanied by class labels. This method achieves high accuracy rate of exceeding 93.4 % for identifying corrosion grades across the four defined categories (Ahuja et al. 2019). Metal constructions’ corrosion zones are identified at the pixel level by employing models for deep learning like Mask R-CNN, U-Net, and FCN that are focused on semantic and contour segmentation. These models provide high confidence in finding corroding pixels by effectively identifying oversegmented contours of a region with deep masks (Katsamenis et al. 2020).

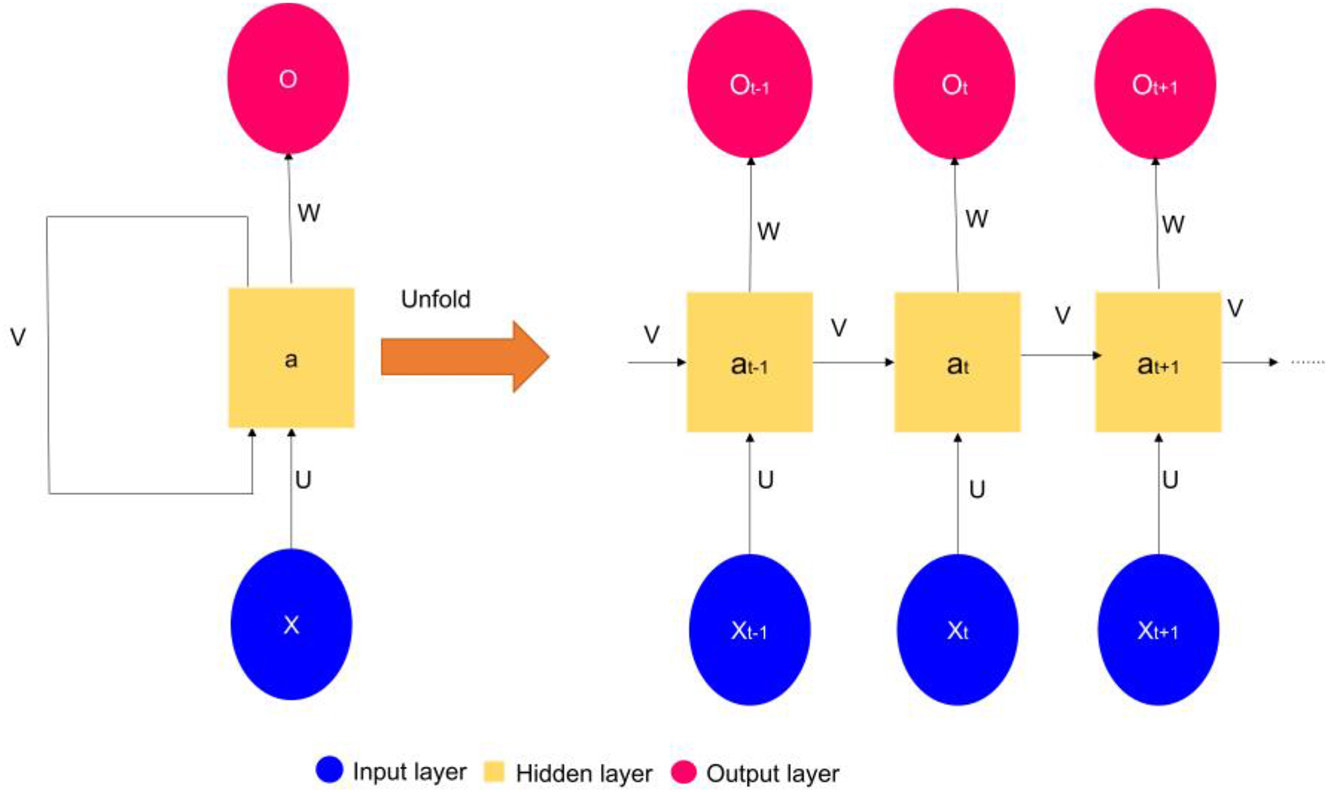

2.4 Recurrent neural networks

Recurrent neural networks are tailored to process sequential data, where the output reliant on both the current input and earlier computations shown in Figure 5. By maintaining a hidden state that is updated at each time step, RNNs effectively handle data in a sequential manner. RNNs are especially useful for tasks like time-series forecasting, natural language processing, and other applications involving sequential patterns because of their capacity to retain information from earlier time steps. To address challenges like learning long-term dependencies in sequences, RNNs leverage advanced architectures like long short-term memory (LSTM) networks, which are made especially to collect and maintain information over extended time intervals.

RNN architecture.

2.4.1 Corrosion prognosis using recurrent neural networks

Due to its ability to deal with sequence inputs, RNNs ideally suited for variety of applications, such as time series forecasting, recognition of speech, and processing of natural languages. An additional internal state parameter that is retained by each hidden layer of RNN is used to indirectly encode information from earlier inputs in the sequence. As a result, the internal states are continuously updated at each step and predict the model output with the current input. Information within RNNs propagated both forward as well as backward through the network via loops. To solve the issue of vanished gradients during training, gradient-based techniques were used to develop LSTM models and gated recurrent units (Lemaréchal 2012).

A small-scale fracture initiates when a material undergoes cyclic loading, gradually becoming more prominent over time. Aircraft, being exposed to cyclic loading are vulnerable to fatigue failure. The presence of a corrosion environment further accelerates the fatigue process, particularly under lower loads and in lesser time. Corrosion fatigue is a common issue faced by aging aircraft fleets due to prolonged exposure to the marine atmosphere. Dourado and Viana (2019) presented neural networks to evaluate aircraft corrosion-fatigue prediction. The proposed model is a hybrid recurrent neural network that computes the hidden state value based on material properties, applied stress range, and corrosion index. It combines data-driven layers with physics-informed layers. According to Equation (1), the hidden states in the RNN model establish a relationship between input at and state of preceding time step at-1.

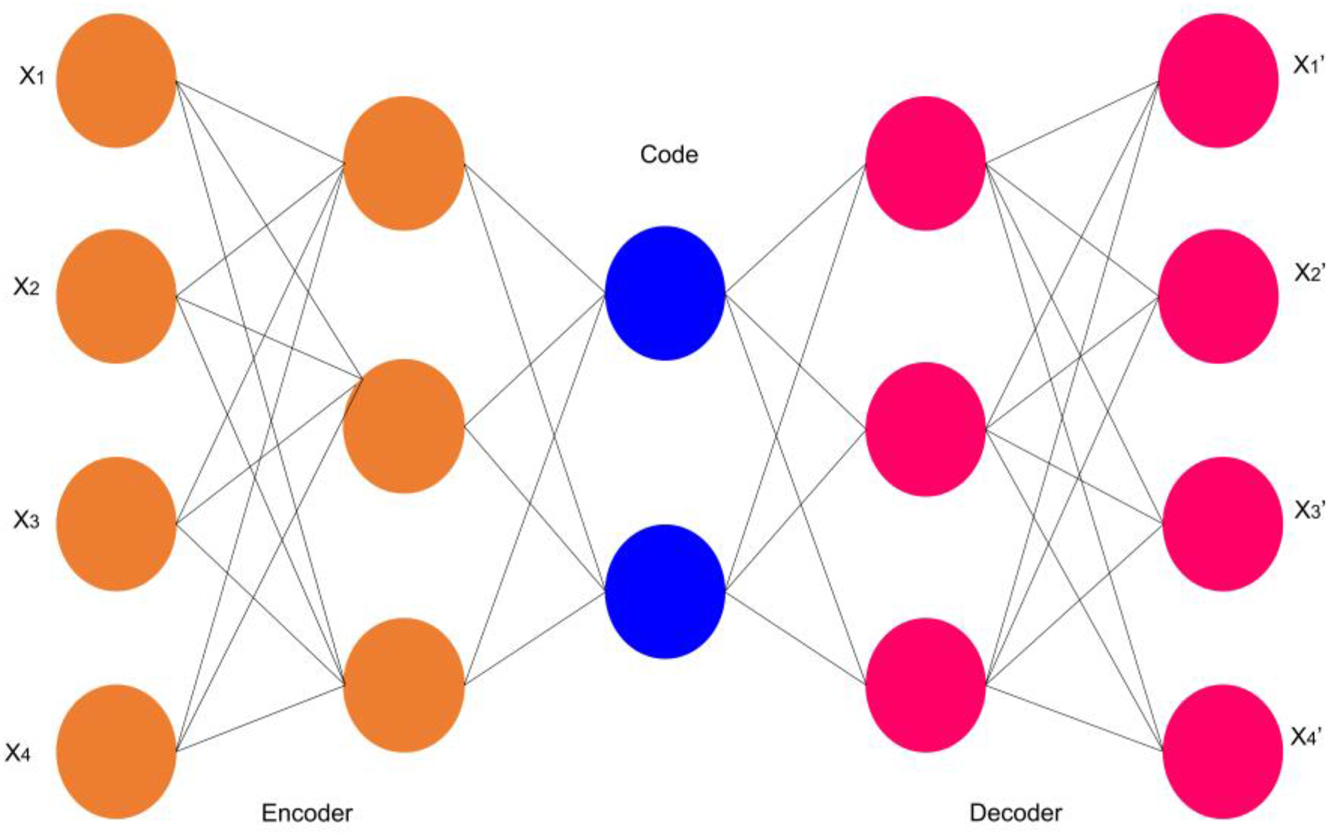

2.5 Autoencoder

Autoencoder network discovered correlations among input features during the training and produced a dimensionally reduced reproduction of the input. An autoencoder converts an unlabeled dataset into code as illustrated in Figure 6, and a decoder uses the code to reconstruct data as closely as possible to the original data. In this case, a feed forward neural network with fully connected controls both encoder and the decoder (Baldi 2012). The node layer of the network decides the degree of data compression. The autoencoder extracts only a valuable feature by limiting the node. Another technique for incorporating Gaussian noise into the original dataset and reconstructing noise-free meaningful features is the denoising autoencoder. Various autoencoders, including sparse (Makhzani and Frey 2014), contractive and variational (Rifai et al. 2011), employ to reduce dataset size.

Autoencoder architecture.

2.5.1 Corrosion detection using autoencoder

Oyama et al. (2021) proposed a method combining variational autoencoders (VAEs) and residual network (ResNet) for detecting rust on the interior surfaces of pipes. The approach utilizes images captured by an inspection robot, where the VAE is trained exclusively on nonrust images. The VAE employs an encoder to reduce dimensionality and extract essential features, followed by a decoder to reconstruct the input images. Rust detection is achieved by comparing the original image to its reconstruction in which substantial discrepancies between the two indicate the presence of potential rust areas.

Valtierra Rodriguez et al. (2024) introduced a novel method that integrates the fractal properties of vibration signals with an autoencoder to detect corrosion damage in bridges. The method utilizes fractal dimension (FD) data representing four corrosion states: healthy, incipient, moderate, and severe. These FD values are transformed into images using specialized algorithms and processed by an autoencoder. In order to evaluate the likelihood of corrosion damage, the autoencoder computes a damage indicator (DI) depending on an error in reconstruction among the input and output images.

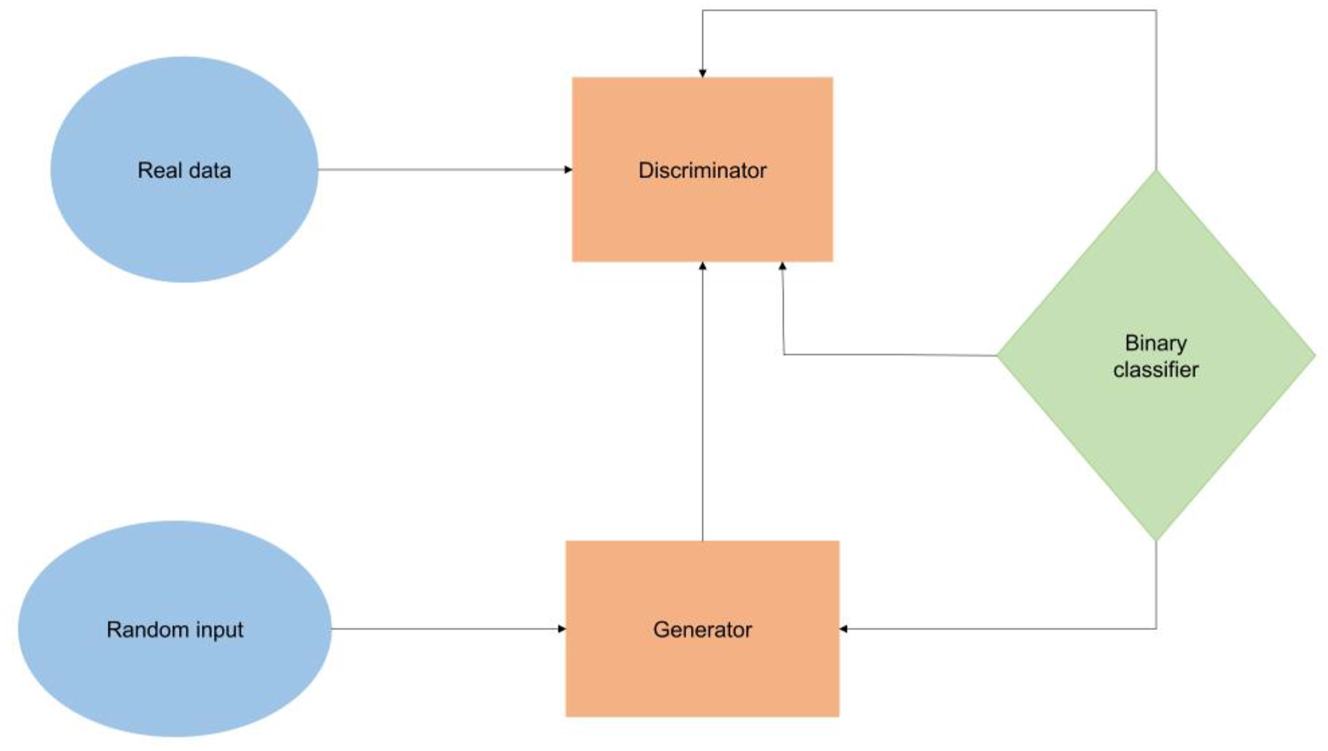

2.6 Generative adversarial network

Generative adversarial network comprises two rival models: generator produces realistic samples and classifier must differentiate the generated data from actual (Aggarwal et al. 2021). Typically, the GAN model illustrated in Figure 7, in which the generator simulates data starting from the random. A binary classifier serves as the discriminator to check probability distribution of generated data and find the discrepancy with the actual data. Probability range of data input is learned by GAN network through parallel training of both modules.

Generative adversarial network framework.

2.6.1 Anomaly detection and corrosion visualization using generative adversarial network

Yumoto et al. (2023) introduced a GAN-based anomaly detection method for identifying defects in piping systems. The approach combines f-AnoGAN and lightweight GAN models, trained exclusively on nondefective images. Anomalies are detected by comparing input images with GAN-generated images, with the subtraction revealing potential defect locations.

Von Zuben et al. (2020) developed a technique for visualizing automobile corrosion using GANs. By extending the capabilities of GANs to handle multiple classes, their model was able to transform images between various domains. In their application, the model converted images of corrosion-free cars into versions exhibiting different corrosion levels – ranging from none to mild, moderate, or severe corrosion.

2.7 Transfer learning models

As a deep learning technique, transfer learning uses pretrained models to solve problems instead than building from scratch (Pratt 1993). Table 1 provides a summary of existing architectures, including GoogLeNet (Szegedy et al. 2015), ResNet (He et al. 2016), ZF Net (Zeiler and Fergus 2014), VGG Net (Simonyan and Zisserman 2015), and AlexNet (Krizhevsky et al. 2017).

Summary of the pretrained CNN models.

| Architecture | Developer | No. of layers | No. of parameters | Error rate (%) |

|---|---|---|---|---|

| LeNet-5 | Yann LeCun | 7 | 60,000 | 3.6 |

| AlexNet | Alex Krizhevsky | 8 | 61 million | 15.3 |

| ZF net | Zeiler MD, Fergus R | 14.8 | ||

| VGG net | Simonyan, Zisserman | 16 to 19 | 138 million | 7.3 |

| GoogLeNet | Szegedy | 22 | 7 million | 6.67 |

| ResNet-50 | Kaiming He | 50 | 44.6 million | 3.57 |

2.7.1 Corrosion assessment using transfer learning models

Ziheng Zhao et al. (2024) explores various CNN-based architectures, including the base CNN, ResNet, MobileNet, and DenseNet models, to enhance corrosion detection. It highlights the advantages of the latter three models: ResNet leverages residual blocks to mitigate the vanishing gradient problem, MobileNet employs depthwise separable convolutions for improved computational efficiency, and DenseNet utilizes dense blocks to reduce training loss. The proposed approach integrates transfer learning, significantly reducing execution time and providing an efficient framework for corrosion classification.

Zhao et al. (2022) proposed an enhanced VGG16 model is proposed for classifying patterns of corrosion on water supply pipes in interior walls. The model incorporates the squeeze-and-excitation (S.E.) attention mechanism to prioritize critical channels of the feature map, reweighting them using channel attention that is globally calculated. Additionally, a joint-loss-function method combining central loss and cross-entropy loss improves classification performance by increasing interclass separability and reducing intraclass variation. According to experimental findings, the model’s accuracy is 95.27 %, surpassing traditional VGG and AlexNet models. This enhanced VGG16 effectively focuses on corrosion-relevant features while suppressing irrelevant information, ensuring robust pattern identification.

Papamarkou et al. (2021) propose using ResNets for real-time detection of corrosion types such as iron oxide discoloration, pitting, and stress corrosion cracking in stainless steel canisters used for nuclear fuel storage. The method involves segmenting canister images into smaller tiles, training a ResNet on these tiles, and classifying the entire image based on the count of tiles identified as corroded. The results demonstrate high accuracy in detecting corrosion loci and determining overall image status, enabling faster, automated inspections while reducing costs and minimizing radiation exposure to personnel. The algorithm optimizes hyperparameters using a validation set and aggregates tile predictions for whole-image inference.

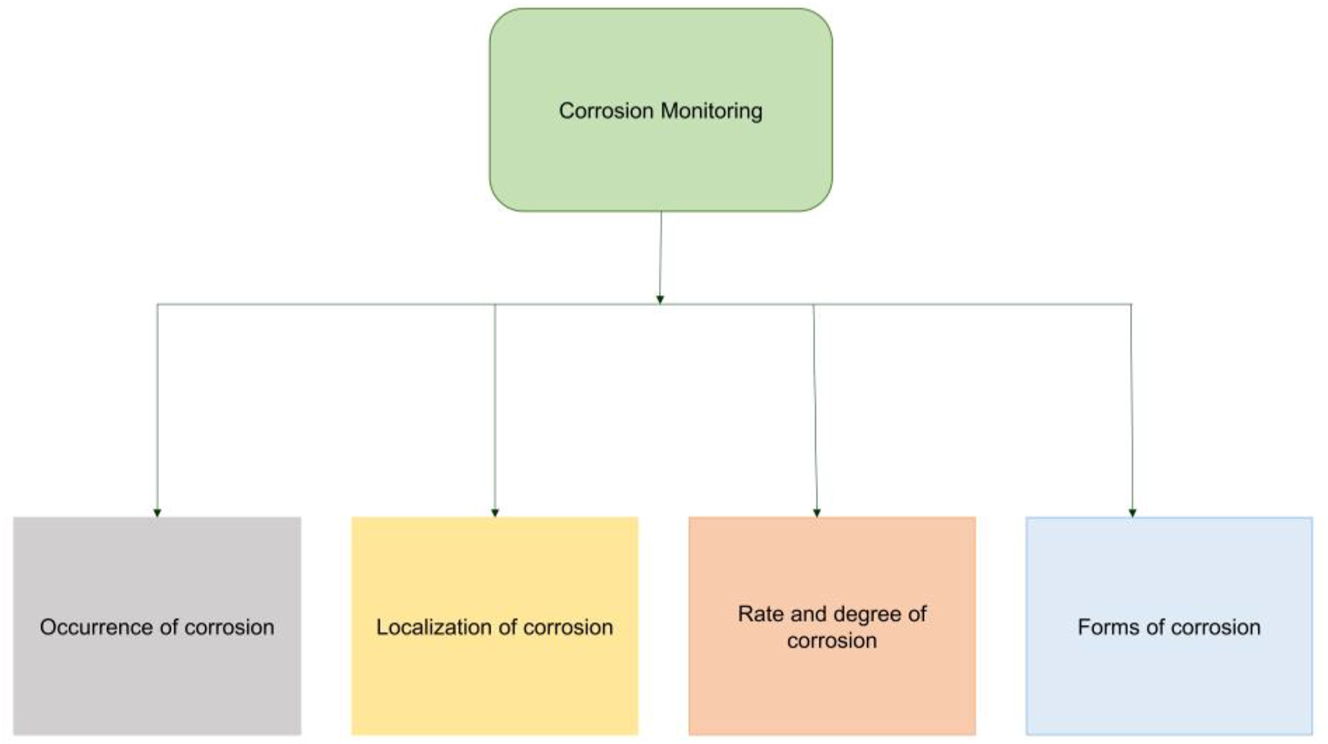

3 Deep learning in corrosion monitoring and control

3.1 Corrosion monitoring

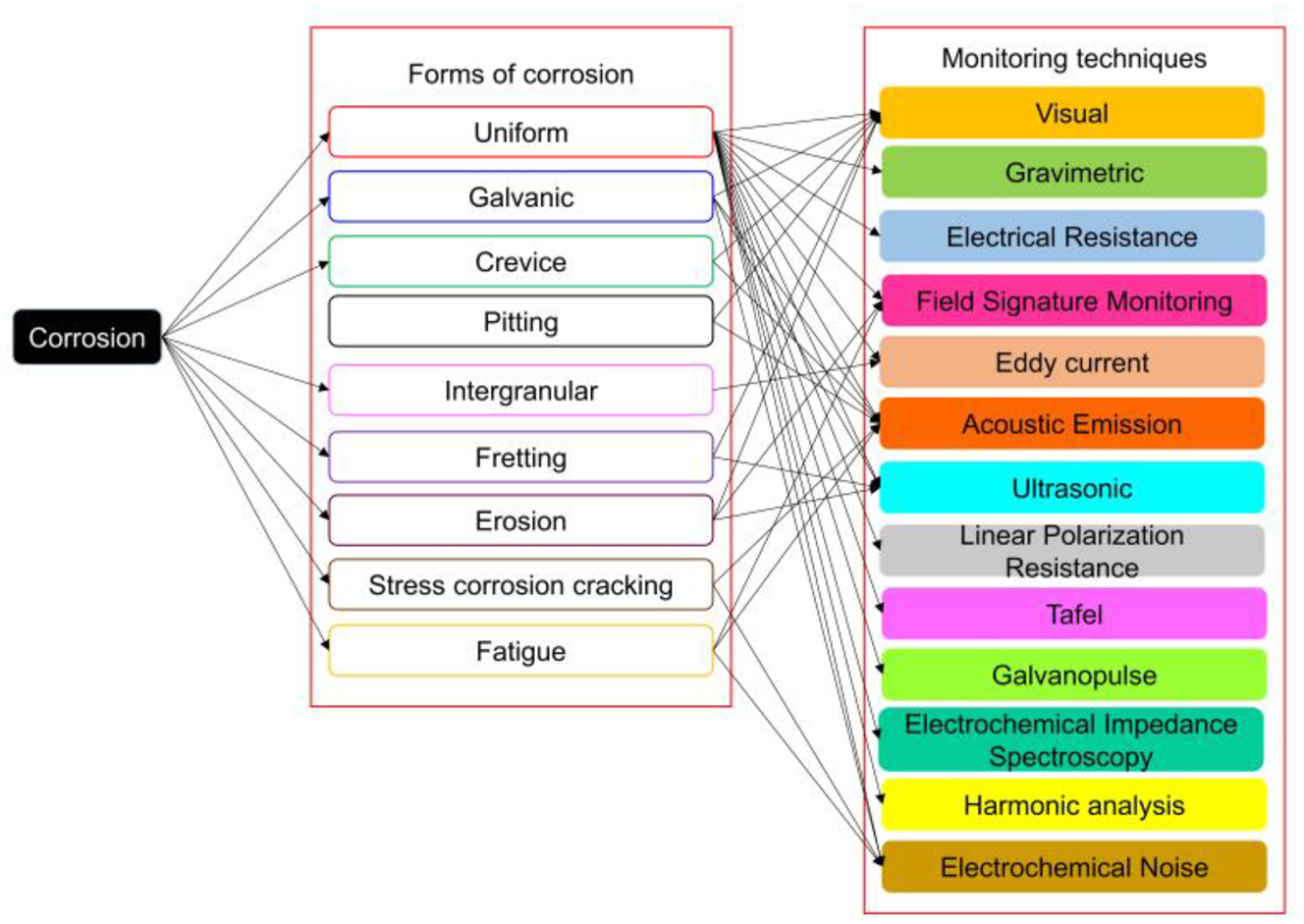

Corrosion monitoring involves systematically measuring the corrosion rate of materials to diagnose and control corrosion. It is essential in preventing major equipment and material failures, ensuring the safety of structures across various industries. Figure 8 illustrates various process used in corrosion monitoring to ascertain initiation time, corrosion rate, and corrosion types, with environmental conditions and constituents influencing corrosion and its forms (Alves et al. 2017; Jian et al. 2013), as depicted in Figure 9.

Multifaceted corrosion monitoring.

Forms of corrosion.

Monitoring techniques are classified as destructive and nondestructive examinations, with destructive involves electric resistance and polarization probe methods. The gravimetric/weight-loss method is the simplest direct approach for quantifying the corrosion rate of metal loss, suitable for both laboratory and industrial environments. Numerous electrochemical techniques, such as electrochemical impedance (Hamdy et al. 2006), harmonic analysis (Vedalakshmi et al. 2009), galvano pulse (Sathiyanarayanan et al. 2006), Tafel extrapolation, linear polarization resistance (Kelly et al. 2002), and electrochemical noise techniques (Calabrese et al. 2015), have been implemented for corrosion assessment in various structures like metallic pipelines, offshore platforms, and bridges. Similarly, nondestructive techniques (NDTs) like acoustic emission (Tang et al. 2019) and ultrasonic methods (Qi et al. 2010) operate in field environments for early detection of various corrosion forms, as shown in Figure 10.

Corrosion forms and its monitoring techniques.

Visual inspection, the most direct method for corrosion detection, can prove to be time-consuming, especially in industrial environments where access to all locations may be restricted. Moreover, relying solely on visual inspection for damage assessment can lead to subjective interpretations, resulting in inconsistent outcomes and requiring significant time and resources. To overcome these challenges, corrosion monitoring is moving toward real-time data acquisition using intelligent sensors and visual inspection facilitated by unmanned aerial vehicles (UAV). The integration of computer vision and image processing into robotic systems enables the development of fully autonomous inspection capabilities (Ortiz et al. 2010). Deep learning technology has recently been introduced by computer science advances, specifically in object classification and detection. By integrating deep learning techniques into corrosion assessment processes, the efficiency of corrosion risk management systems is enhanced, allowing for the detection of various forms of corrosion and defect areas using computer vision techniques (Ejimuda and Ejimuda 2018). In order to detect flaws in the ballast tanks of maritime vessels using real-time inspection by UAV, a recent study developed an autonomous inspection system that makes use of deep learning architectures (Andersen et al. 2020). Furthermore, concrete corrosion damage in civil constructions can be identified automatically by computer vision, YOLO object detection techniques like YOLOv3, YOLOv5s, and YOLOv7 (Nabizadeh and Parghi 2023).

You Only Look Once v3 tiny (YOLO v3-tiny) is a newly developed deep learning system called accurate metallic corrosion detector (AMCD) that allows micro aerial vehicles (MAVs) with limited computing resources to conduct visual inspections in real-time. Inspection dataset of images in field labeled with four corrosion kinds: bar, exfoliation, nubby, and fastener corrosion is used to train and test AMCD. To accomplish effective corrosion detection, this system includes depthwise separable convolution (DSConv) layers for the automated identification and categorization of steel bridge corrosion on both surface and subsurface (Yu et al. 2023). This method uses a hybrid inspection system (HIS) and a quicker convolutional neural network based on regions used to merge vision and thermographic pictures. Mukhti et al. (2023) examined the viability of employing the measurement of ultrasonic pulse waves to detect initial concrete damage identification caused by corrosion. The development of model for classifying the initial identification of damage in concrete caused by rebar corrosion involves application of techniques in deep learning, particularly, three models of recurrent neural network (RNN), which includes bidirectional long short-term memory, long short-term memory, and gated recurrent unit performed better than conventional ultrasonic testing parameters. Furthermore, convolutional neural network (CNN) was suggested by (Homborg et al. 2024) for the classification of pitting and uniform corrosion of time-frequency transient data by electrochemical noise technique.

Acoustic emission (AE) serves as nondestructive technique (NDT) specifically applied in detecting corrosion phenomena like fatigue, stress corrosion cracking (SCC), pitting, and intergranular corrosion (IGC). AE parameters used for corrosion detection include amplitude, number of hits, and time. The location of the corroding spot is typically determined based on the velocity of acoustic wave propagation measured using a piezoelectric sensor. As AE signals traverse structural components, they undergo multiple reflections and reverberations at edges and joints, allowing for the identification of AE spots from sensor measurements at different locations simultaneously. Ebrahimkhanlou et al. (2019) explored two deep learning methods, stacked autoencoder, CNN, for defect localization by AE data using single piezoelectric sensor.

Stress corrosion, which occurs when susceptible materials fail under tensile stress in corrosive environments, is particularly prevalent in cooling water systems, which include heat exchanger and condenser tubes found in chemical and power plants. In nuclear reactors, periodic inspections are conducted using the eddy current technique to detect stress corrosion cracking. Eddy current testing (ECT) inspections can estimate the presence, length, and depth of cracks, but determining the shape of the crack is computationally intensive. The potential of deep learning techniques to identify the geometries of condenser tube cracks was examined by (Demachi et al. 2020). The survey was conducted perpendicular to the crack’s direction to generate images from the ECT data. CNN was trained on 2D array data to determine model parameters, and in testing, the proposed model accurately calculated the unknown depth of the cracks. Chun et al. (2019) proposed CNN to measure the appropriate thickness of corroded components.

3.2 Corrosion control

Corrosion of metals occur when they come into contact with a corrosive environment. There are various corrosion control methods that can be prevented by either altering the metal in terms of alloying and composition or altering the environment by adding inhibitors. In addition to it, the metal potential changes with help of cathodic and anodic protection.

3.2.1 Inhibitors and coatings using deep learning

Corrosion inhibitors are chemical substances added to the corroding systems to control internal corrosion by lowering the rate of corrosion. They lessen the corrosion by functioning as a barrier or creating an adsorbed layer to impede the anodic or cathodic process. There are various forms of inhibitors in which it gets oxidized, adsorbed, film forming, and vapor phase. Electrochemical corrosion testing methods are typically employed to assess their inhibiting surface effectiveness examined using optical or scanning electron microscopy. Stoean et al. (2018) proposed an automated approach for evaluating the effectiveness of inhibitors across the surfaces of copper and steel laminas using CNNs. Despite the limited number of samples available from electrochemical experiments, provided as microscopic slides, the study effectively employed data augmentation to enhance the dataset. The CNN model, comprising two layers, successfully classified three distinct corrosion states, demonstrating its ability to accurately identify inhibitor performance on metal surfaces.

Coatings can suffer from premature failures and initiate corrosion defects due to many potential factors. Protective coatings are effective in mitigating corrosion by shielding the metal from direct exposure to corrosive environments. The adhesion of coating is manually tested by scratch, to assess the adhesion resistance of coatings. Zhang et al. (2022) proposed an automated approach for crosscut testing of coatings using CNNs and image segmentation. Crosscut images are used to assess the adhesion strength, with the CNN model, consisting of two layers, performing classification and image recognition tasks. By employing data augmentation, the model effectively detects defects by comparing the differences between intact surfaces and ablations in the images. The results were then compared to traditional human expert classifications. This method of automated testing and image recognition can be extended to quality control in manufacturing processes, particularly in the context of Chemistry 4.0.

Liu et al. (2019) proposed a deep learning-based object detection method for assessing coating breakdown and corrosion in marine and offshore industries. The approach utilizes transfer learning on a convolutional activation feature network (TLCAF) to identify regions of interest related to different types of coating failures for coating breakdown class (CBC) feature extraction. CNN feature extraction is performed using RCNN and VGG16 models, which extract a total of 12,184 features across three categories: edge CBC, non-CBC, and surface CBC. A linear classifier is then employed for feature classification. The system achieved a recognition accuracy of 89.54 %. This automated coating assessment method effectively identifies coating failure features, such as corrosion on surfaces, edges, or welds, making it suitable for industries struggling with inefficient coating inspections.

Research into protective coatings utilizing two-dimensional materials like graphene has shown promise in combating microbiologically influenced corrosion (MIC). In order to create synthetic data for developing MIC-resistant 2D coatings, (Allen et al. 2022) explored the efficacy of protective coatings made of few-layered graphene applied onto copper surfaces using deep generative models like the VAE and GAN. It generates synthetic data for expanding limited experimental datasets on discrete corrosion rates. These datasets focus on failed and effective coatings for corrosion resistance classification in the development of MIC-resistant 2D materials. The VAE model outperformed the GAN, achieving 90 % accuracy when paired with an eXtreme boost gradient (XGBoost) classifier.

3.2.2 AI-assisted cathodic protection

Cathodic protection (CP) provides one of best methods for external corrosion prevention in conjoint with coatings, which it either sacrifices with the help of anode or protects from external supply. It’s widely used in buried structures especially in oil and gas industries, storage tanks, etc. Most of the industries prefer impressed current system for a longer lifetime in cathodic protection, which is performed by providing an electric current to the pipes to be protected from external source (Harsimran et al. 2021). Cathodically protected pipeline should maintain the protection criteria of CP, which the industries manually monitor the measurements periodically. Therefore, it leads to human error and the system that is not protected appears to be protected in real scenario.

To avoid such circumstances, artificial intelligence (AI) evaluates CP readings considerably, which lowers the time and labor needed for routine review of remote monitoring data. It provides solutions related to the pipeline's integrity, which would not be possible without AI. Mathias Muller (2024) proposed the application of artificial intelligence (AI) to assess cathodic protection (CP) measurements by significantly reducing the time and labor required for regular evaluations of remote monitoring data. This approach enables the assessment of pipeline coating integrity in ways that would not be possible without AI. As a result, it opens up new possibilities for detecting and locating hazardous third-party interference with pipelines.

Kadhim and Al-Shareefi (2009) developed an artificial neural network (ANN) model to assess the cathodic protection (CP) system, predicting potential and corrosion rates based on experimental data. The model consists of one input layer, two hidden layers, and one output layer. The accuracy of the predictions improves as more experimental data becomes available, allowing for more reliable forecasts of future damage levels. The ANN model helps control pipeline corrosion and predicts corrosion rates in impressed current cathodic protection (ICCP) systems. For future validation and testing, new datasets from various pipeline environments are used to train the model. From the literatures, the authors suggest that the reliable prediction of CP can be done by incorporating more data into the deep learning structured model to predict future damages in controlling corrosion.

3.2.3 Corrosion-resistant materials discovery using artificial intelligence

Metals can achieve significantly enhanced corrosion resistance through modifications in their microstructure, the elimination of tensile stresses, and by purifying or alloying. Yin et al. (2023) designed AI-based digital platform to assess corrosion by pattern recognition and corrosion rate classification. It supports the discovery of metallic materials with superior corrosion-resistant properties promising to improve global safety. Table 2 illustrates the corrosion-resistant materials design facilitated by AI methods. Future studies employ additive manufacturing techniques to customize the printed alloys microstructure, enabling the prediction for their corrosion resistance and the exploration of the potential impacts of these modifications.

AI models employed in corrosion-resistant materials design.

| References | Input | AI model | Output | Evaluation metrics |

|---|---|---|---|---|

| Ji et al. (2024) | Elemental composition, mechanical properties, heat treatment, and corrosion data of AlMgZn alloy | Reinforcement learning neural network | Elongation prediction of corrosion-resistant Al alloy in NaCl environment | R2 = 0.92 |

| Zeng et al. (2024) | High-entropy alloy compositions of AlCrFeCoNi | Random forest | Binary classification: Formable versus. nonformable compositions based on single-phase structure | Accuracy = 0.88 |

| Roy et al. (2022) | pH, halide concentration, composition of elements with minimum reduction potential | Gradient boost regressor | Predicts corrosion resistance of multiprincipal element alloys in aqueous environments | R2 = 0.93 |

| Sasidhar et al. (2022) | Chemical composition and environmental conditions of pH, halide concentration of Fe, Al, Ni–Cr, high entropy alloys and passivating alloys | Deep neural network | Predicts pitting potential of corrosion-resistant alloys | R2 = 0.61 |

| Sasidhar et al. (2023) | Elemental physical/chemical property-based numerical descriptors of Fe-based alloys, Ni–Cr-based alloys, Al-based alloys, and high-entropy alloys | Deep neural network | Predicts pitting potential based on corrosion resistance alloy composition in electrochemical test environments | R2 = 0.84 |

| Wang et al. (2022) | 15-Dimensional vector of physical descriptors (Fe/Mn ratio, Gibbs free energy, self-diffusivity, Mn, Fe, Ni activities, work function, and surface energy | Random forest regressor | Model predicts corroded Mn and Fe concentrations of high temperature molten salt for corrosion-resistant alloy | R2 = 0.89 for Mn R2 = 0.79 for Fe |

| Taylor and Tossey (2021) | High-temperature parabolic oxidation rate constants of 75 corrosion-resistant alloys of product thickness in different environmental conditions | Random forest | Predicts oxidation behavior of corrosion-resistant alloy elements | Mean-squared error = 2.09 Root mean-squared error = 1.45 Mean absolute error = 0.95 R2 = 0.92 |

3.2.4 AI-based zinc galvanizing by hot dip method

Zinc hot dip galvanizing is one of the earliest techniques for preventing corrosion (Cerny et al. 2024). A hot dip galvanized coating that submerges steel in molten zinc to control corrosion on steel structures (Lu et al. 2021). In harsh environments, the galvanized covering acts as a barrier, which provides protection against corrosive substances. According to (Najafabadi et al. 2021), it can extend 50 years of life for steel structures. The authors suggest that the future studies should handle complexities of galvanizing process with high-quality data using deep learning models that achieve better corrosion control.

4 Deep learning in corrosion applications

In the subsequent section of the review article, the adaptability of deep learning neural networks in corrosion assessment across diverse sectors, such as pipeline systems, photovoltaic modules, electrical insulators, and civil structures, is elucidated.

4.1 Pipelines

Most forms of transportation rely on pipelines for the conveyance of various substances such as petroleum products, drinking water, and cooling water. Corrosion posed a serious risk to both the external and internal surfaces of pipelines, because of the existence of corrosive ions in surrounding environment. External corrosion results from exposure to air, moisture, temperature fluctuations, and air pollutants like sulfur dioxide and chlorides. On the other hand, number of factors, including as the nature of substances being transported and the metallurgical composition of the pipe, affect internal corrosion. In wastewater pipelines, corrosion causes due to the presence of sulfur-reducing bacteria (SRB) and corrosive agents such as hydrogen sulfide, carbon dioxide, ammonia, nitrogen, oxygen, carbon dioxide, ammonia, phosphorus, sulfuric acids, and alkalies. The hydrocarbon fluid in oil and gas pipeline systems frequently experiences corrosion acceleration by CO2 and H2S presence. Modern techniques for imaging the internal surface of pipelines include automated digital cameras, magnetic flux leakage, ultrasonic testing, and pipeline inspection gauge (PIG).

Steam flowing at high temperatures and pressures can cause corrosion in thermoelectric pipelines. Flow-assisted corrosion (FAC) can occur when the water carries solid particles or promotes flow corrosion, leading to metal loss on the inner surface of the pipe. This metal loss is reflected in the texture pattern of images captured from the inner surface of the pipe using an automated imagery system. However, the images obtained from the video stream often exhibit variations in brightness and blurred spots due to the confined space inside the pipe. To address this challenge, (Vriesman et al. 2019) created an AlexNet-based CNN model extract texture features in images by employing data augmentation techniques in which synthetic images were generated and trained with accuracy rate of 99.20 % in order to distinguish between three corrosion levels on internal surface of thermoelectric pipe walls: aggravated corrosion (AC), nondefective (ND), and medium corrosion (MC).

Nguyen et al. (2018) developed a corrosion identification system using U-Net architecture for the penstock pipeline located in the U.S. state of Tennessee. This U-Net model was trained for multiclass semantic segmentation to detect various objects within the input image, including regular, wet, corroded, rivet, water, and other corroded spots. Experimental datasets were collected using a micro aerial vehicle equipped with a digital camera flying inside the penstock. Upon image acquisition, preprocessing was performed using histogram equalization in open CV’s contrast-limited adaptive histogram equalization (CLAHE) module. Class imbalance, a common issue in deep learning classification, was addressed by incorporating class weights into different loss functions such as weighted focal loss function, softmax cross-entropy (SCE), focal, and weighted softmax cross-entropy (W-SCE). It was observed that adjusting class weights effectively controlled class imbalance and enhanced the U-Net model performance, especially when utilizing weighted focal loss function.

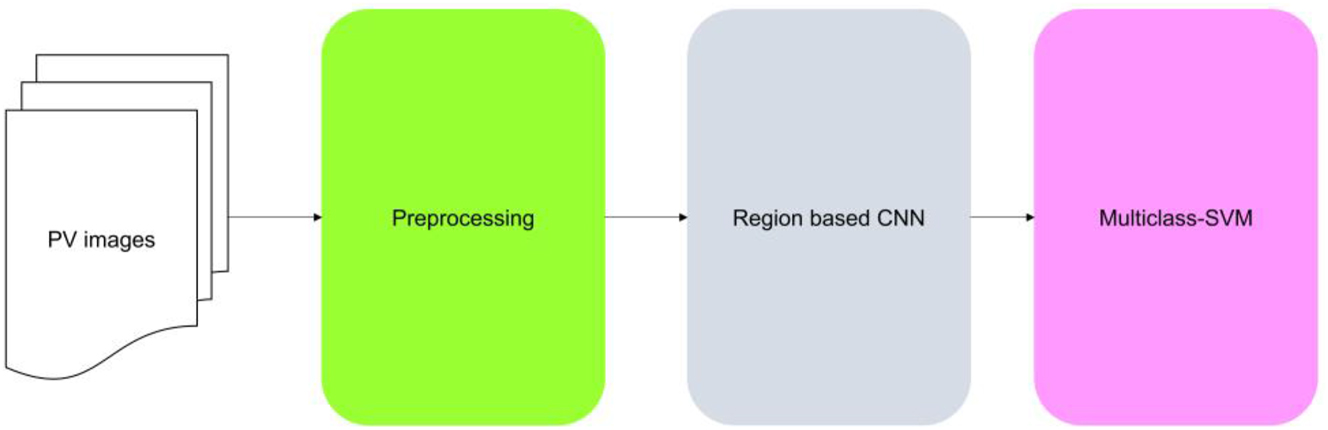

4.2 Photovoltaic modules

In recent years, both domestic and industrial sectors have increasingly turned to solar arrays to address power shortages and promote green energy initiatives, aiming to mitigate environmental challenges. As photovoltaic (PV) plants are often installed in remote and harsh environments, regular inspections are imperative to maintain uninterrupted power generation and ensure optimal performance. Common issues encountered in PV arrays include gridline corrosion, dust shading, and encapsulant deterioration. Owing to the labor-intensive nature of manual inspections, PV arrays are captured by unmanned aerial vehicles that are equipped with digital cameras. In response, CNN model with three phases featuring has been suggested for defect identification in PV images, as illustrated in Figure 11. In the preprocessing algorithm, a bounding box find defects within region of interest (ROI), background elimination, interference removal, and Kirsch edge detection are among the processes that are involved. The ROI’s features extracted by R-CNN model. The final classification layer employs a multiclass-support vector machine (MC-SVM), achieving an accuracy rate of 95.03 % in classifying PV module defects (Xiaoxia Li et al. 2020).

Schematic representation of detecting PV.

4.3 Electrical insulator

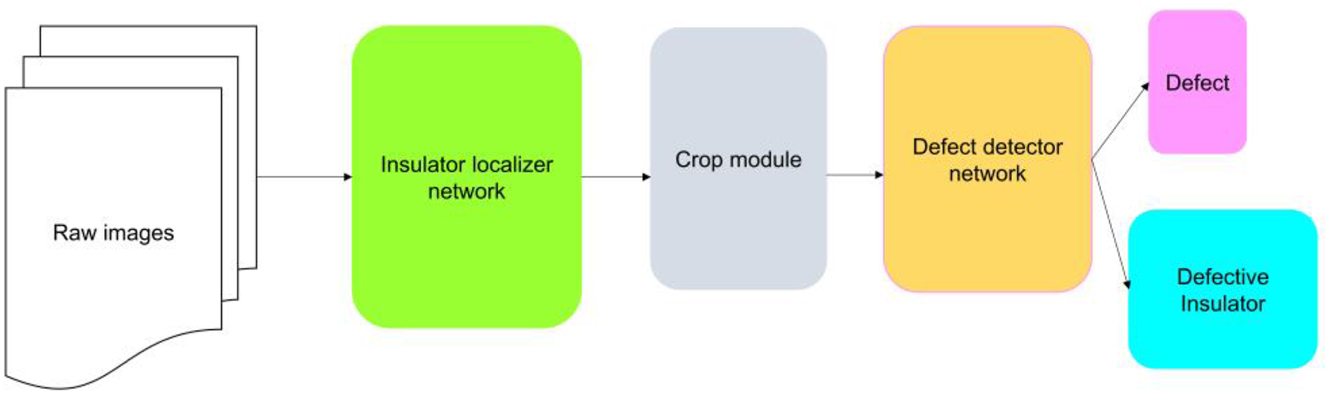

The transmission line’s electrical insulators face the risk of bunch-drop failure, potentially disrupting the power distribution network. Porcelain insulators with cap and pin constructions are prone to electrolytic corrosion, especially at metal/nonmetal contact points, due to leakage current and crevice deterioration in moist conditions. The main challenge for deep learning models is localizing insulators against complex backgrounds, which can vary depending on the season, and then identifying insulator defects.

A novel CNN model combining the orientation angle detection and binary shape prior knowledge (OAD-BSPK) algorithm was presented by (Zhao et al. 2016). Line segments on the image contour provide the orientation angle, which is then used along with the binary shape of insulators to identify the location of insulators. The dataset is enlarged through data augmentation, and a multipatch CNN initialized with parameters from the pretrained Alex-Net CNN on the ImageNet dataset achieves an accuracy of 98.0678 % with classifier of SVM using radial basis function (RBF) kernel.

Tao et al. (2020) developed two cascading CNN architectures: insulator localizer and a defect detection network depicted in Figure 12. The input image processed by VGG-16 network creates feature map, which is bounding boxed by RPN. The DDN, designed with two ResNet models with fewer convolution layers than VGG-16, employs RPN and region of interest pooling layers to construct bounding boxes on cropped insulator images. Synthetic data are generated through data augmentation, simulating various experimental conditions to account for potential variations in accurate data. According to the experimental data, accuracy and recall are 0.91 and 0.96, respectively.

Cascaded CNN model for defect detection in insulator.

A second-order convolutional network was created by (Chen et al. 2019a) to identify faults in insulators from aerial images with complex backgrounds. The resulting output heat maps are upsampled eight times to improve semantic segmentation. During each two-fold upsampling, the output is combined with the results of pooling layers 4, 3, 2, and 1. The initial fully connected network (FCN) segmentation results are reconstructed using morphological filters to obtain insulator images. To eliminate background interference, the insulator image is multiplied with the original image, and their outputs, along with label images, are used to train the second FCN for insulator fault detection. The second-order FCN (SOFCN) method achieves 99.91 % accuracy in detecting faults in ceramic insulators. Jalil et al. (2019) proposed R-CNN model of detecting faults in power line insulators. The proposed model achieves 97.3 % accuracy using a dataset collected from drones flying over power lines at a distance of 10 m. Mohamed et al. (2019) proposed the YOLO-based algorithm for object detection to facilitate localization of insulators and detect bunch-drop occurrences.

4.4 Concrete structures

Corrosion stands as the primary cause behind structural failure in concrete reinforced structures. The alkalinity of the concrete is decreased when CO2 from the atmosphere infiltrates into the concrete pores and reacts with the pore solution to produce calcium carbonates. The creation of a passive layer on reinforcement steel bars is hindered when the pH drops below 8.6, which promotes corrosion of the reinforcement. Similarly, the concrete cover is penetrated by chloride ions from marine environments, which break the passive coating on the steel and cause corrosion (Apostolopoulos et al. 2013). Rust accumulation around steel bars causes them to expand in volume, exerting pressure on the surrounding concrete and leading to cracks and spalling. Regular condition surveys are vital for civil infrastructure to ensure timely maintenance and prevent major failures. With the development of deep learning, numerous research groups have created a variety of neural network models, as summarized in Table 3, to assess concrete structures’ condition, particularly for crack detection in civil infrastructure.

Deep learning models employed in structural health monitoring.

| References | Deep learning model | Application in structural health monitoring |

|---|---|---|

| Cha et al. (2017) | Convolutional neural network | Crack damage detection in civil infrastructure |

| Lin et al. (2017) | Convolutional neural network | Structural damage detection |

| Dung et al. (2019) | Deep convolutional neural network | Crack detection in steel bridges |

| Cha et al. (2018) | Faster region convolutional neural network | Structural damage detection |

| Liu et al. (2017) | Faster region convolutional neural network | Building quality assessment |

| Zheng and Wu (2019) | Mask region convolutional neural network | Structural defect identification |

| Chen et al. (2019b) | Faster region convolutional neural network | Corrosion detection in structural components |

| Xu et al. (2018) | Restricted Boltzmann machine | Crack identification on steel structure |

| Ameli et al. (2024) | Mask RCNN and YOLOv8 | Corrosion detection on steel bridge |

| Guzman Torres et al. (2023) | YOLO v3 | Corrosion damage detection on steel-reinforced concrete structure |

5 Deep learning for corrosion prediction and reliability enhancement

The integrity of industrial assets often fails to provide accurate predictions of remaining useful life (RUL), particularly components like heat exchangers in oil and gas industry by using conventional methods. This is primarily due to the limited corrosion data availability in inspection records, which are costly to obtain and may not cover all areas of the assets. As a result, there is a lack of comprehensive inspection data necessary for traditional statistical tools to accurately assess corrosion rates and estimate RUL. As a result, there is increasing interest in using AI methods to better accurately anticipate the RUL of corroded industrial assets. In order to tackle this challenge, a novel approach that focuses on generalized corrosion specifically uses bootstrap method and Weibull function to categorize the process of corrosion and 1D-CNN model predict RUL in oil and gas industries (Belonsi et al. 2023). Meanwhile, (Wu et al. 2023) forecast and analyze the time-dependent chloride transport in concrete exposed to coastal conditions using deep learning techniques as CNN, bidirectional LSTM, LSTM, and gated recurrent unit. Whereas (Ao et al. 2022) present deep learning approach for predicting the behavior of corrosion and mechanical properties of Al–Zn–Mg alloys with various surface microstructures, accurately correlating metallographic images, corrosion behavior, and mechanical properties, (Sasidhar et al. 2023) propose enhancing deep learning frameworks for predicting potential of pitting corrosion-resistant alloys. This correlation can offer theoretical backing for innovative and nondestructive methods of testing to mitigate unanticipated material failures.

Contemporary modeling approaches, including physical and data-driven models, struggle to adequately address the complex nature of stress corrosion cracking. To overcome these limitations, reliability model using deep learning is developed for oil and gas pipelines. First order reliability techniques and finite element simulations are used to obtain the dataset. This model seeks to predict pipeline reliability in terms of failure probability, offering a more efficient alternative to traditional modeling methods (Soomro et al. 2021).

6 Deep learning in corrosion challenges and future directions

Deploying deep learning for material degradation presents a significant challenge, primarily stemming from the scarcity of high-quality training data rather than computing power or model architecture (Nash et al. 2018). Table 4 reviewed the different deep learning methods utilized for corrosion data and its applications. The computational complexity becomes crucial, especially when inspecting large-scale infrastructures, where the risk of erroneous segmentation is heightened due to image interference, necessitating enhancements in accuracy. Detecting the precise location of defects poses a formidable challenge. For future applications, the categorization of various forms of corrosion is intended to automate real-life scenario identification and quantification in the future. Additionally, analyzing corrosion growth and quantifying the corroded region in images can aid inspectors in reducing the cost as well as time of inspecting oil & gas pipelines and civil structures. The model’s utility extends to maintenance planning decision-making. In future research, to account for the complexities of real-word scenarios, incorporating corroded images of steel with diverse difficulties, by different view angles or illuminations, can enhance model performance. Improving accuracy of corrosion condition rating model involves obtaining more images varied with different severity levels of corrosion, lighting conditions, and backgrounds. Furthermore, future work should focus on characterizing different localized corrosion processes, including distinguishing between crevice and pitting corrosion within same system, various stages of microbiologically influenced corrosion, pitting, and inhibition or reactivation of corrosion inhibited processes.

Different deep learning methods for corrosion applications.

| References | Deep learning model | Input type | Dataset size | Corrosion applications |

|---|---|---|---|---|

| Belonsi et al. (2023) | Convolutional neural network and bootstrap method | 1D corrosion data | 20, 564 | Remaining useful life prediction for heat exchanger in oil and gas refineries |

| Zhang et al. (2021) | CNN with squeeze-and-excitation network | Corrosion images | 119,081 | Metallic corrosion in civil structures |

| Yu et al. (2023) | Depthwise separable convolutional neural network | Images | 27,039 | Corrosion detector in micro aerial vehicle on-board platform |

| Mukhti et al. (2023) | Bi-directional recurrent neural network | Ultrasonic pulse waves | 386 data | Early detection of rebar corrosion in reinforced concrete damages |

| Bolton et al. (2023) | ResNet50 (ImageNet) | Images | 39,600 | Corrosion detection in metal structures |

| Homborg et al. (2024) | Convolutional neural network | Images | 480 | Pitting corrosion detection of aluminum alloys |

| Guzman Torres et al. (2023) | YOLOv3 | Images | 790 | Corrosion damage on steel reinforced concrete structures |

| Shirsath et al. (2022a) | Convolutional neural network (ResNet50) | Images | 9,760 | Corrosion detection of bulk carriers’ compartments |

| Wu et al. (2023) | Convolutional neural network, LSTM, GRU, and Bi-LSTM | Images | 300 | Chloride corrosion in concrete structure |

| Ameli et al. (2024) | Mask RCNN and YOLOv8 | Images | 514 | Corrosion in steel bridge components |

| Oyama et al. (2021) | Variational autoencoder and ResNet50 | Images | 31,000 | Corrosion in pipe |

| Andersen et al. (2020) | Faster region convolutional neural network + YOLO | Images | 1,314 | Corrosion in marine vessels |

| Forkan et al. (2022) | Convolutional neural network | Drone images | 146,688 | Structural corrosion detection |

| Ahuja et al. (2019) | Convolutional neural network | Images | 862 | Surface corrosion of steel |

| Katsamenis et al. (2020) | Fully connected network, U-net, and mask region convolutional neural network | Steel grade images | 116 | Corrosion detection on metal structures |

7 Conclusions

In conclusion, DL techniques integrate in corrosion assessment, and control represents a significant advancement with promising implications for various industries, which offers unprecedented capabilities in corrosion detection and mitigation. This review has revealed several key findings and exhibits remarkable performance in identifying corrosion patterns and anomalies from large datasets, surpassing traditional methods in accuracy and efficiency. This capability enables early detection of corrosion-related issues, facilitating timely intervention and preventive maintenance. In summary, the review underscores the transformative impact of DL on corrosion assessment and control, paving the way for more proactive, data-driven approaches to asset integrity management. By harnessing the power of DL, industries can enhance safety, reliability, and sustainability while minimizing costs and maximizing operational efficiency in the face of corrosive challenges.

Acknowledgments

The authors express their gratitude for the support and encouragement provided by CSIR-CECRI, Karaikudi, and NIT, Trichy. The CSIR-CECRI reference number is CECRI/PESVC/Pubs/2022-154.

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: The authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: The authors state no conflict of interest.

-

Research funding: None declared.

-

Data availability: Not applicable.

References

Aggarwal, A., Mittal, M., and Battineni, G. (2021). Generative adversarial network: an overview of theory and applications. Int. J. Inf. Manag. Data Insights. 1: 1–9, https://doi.org/10.1016/j.jjimei.2020.100004.Search in Google Scholar

Ahuja, S.K., Shukla, M.K., and Ravulakollu, K.K. (2019). Surface corrosion grade classification using convolution neural network. Int. J. Recent Technol. Eng. 8: 7645–7649.10.35940/ijrte.C6196.098319Search in Google Scholar

Ahuja, S.K., Shukla, M.K., and Ravulakollu, K.K. (2021). Optimized deep learning framework for detecting pitting corrosion based on image segmentation. Int. J. Performability Eng. 17: 627–637, https://doi.org/10.23940/ijpe.21.07.p7.627637.Search in Google Scholar

Allen, C., Aryal, S., Do, T., Gautum, R., Hasan, M.M., Jasthi, B.K., Gnimpieba, E., and Gadhamshetty, V. (2022). Deep learning strategies for addressing issues with small datasets in 2D materials research: microbial corrosion. Front. Microbiol. 13: 1–11, https://doi.org/10.3389/fmicb.2022.1059123.Search in Google Scholar PubMed PubMed Central

Alves, L.M., Cotta, R.A., and Ciarelli, P.M. (2017). Proceedings of the 6th International Conference on Pattern Recognition Applications and Methods, January, 2017: identification of types of corrosion through electrochemical noise using machine learning techniques. ICPRAM.Search in Google Scholar

Ameli, Z., Nesheli, S.J., and Landis, E.N. (2024). Deep learning-based steel bridge corrosion segmentation and condition rating using Mask RCNN and YOLOv8. Infrastructures 9: 1–16, https://doi.org/10.3390/infrastructures9010003.Search in Google Scholar

Andersen, R., Nalpantidis, L., Ravn, O., and Boukas, E. (2020). Investigating deep learning architectures towards autonomous inspection for marine classification. IEEE Intern Symposium Saf. Security Rescue Robotics. SSRR: 197–204, https://doi.org/10.1109/ssrr50563.2020.9292621.Search in Google Scholar

Ao, M., Ji, Y., Sun, X., Guo, F., Xiao, K., and Dong, C. (2022). Image deep learning assisted prediction of mechanical and corrosion behavior for Al-Zn-Mg alloys. IEEE Access 10: 35620–35631, https://doi.org/10.1109/access.2022.3161519.Search in Google Scholar

Apostolopoulos, C.A., Demis, S., and Papadakis, V.G. (2013). Chloride-induced corrosion of steel reinforcement - mechanical performance and pit depth analysis. Constr. Build. Mater. 38: 139–146, https://doi.org/10.1016/j.conbuildmat.2012.07.087.Search in Google Scholar

Atha, D.J. and Jahanshahi, M.R. (2018). Evaluation of deep learning approaches based on convolutional neural networks for corrosion detection. Struct. Heal. Monit. 17: 1110–1128, https://doi.org/10.1177/1475921717737051.Search in Google Scholar

Baldi, P. (2012). Proceedings of ICML Workshop on Unsupervised and Transfer Learning, July 2, 2011: Autoencoders, Unsupervised Learning, and Deep Architectures.Search in Google Scholar

Bastian, B.T., N, J., Ranjith, S.K., and Jiji, C.V. (2019). Visual inspection and characterization of external corrosion in pipelines using deep neural network. NDT E Int. 107: 1021, https://doi.org/10.1016/j.ndteint.2019.102134.Search in Google Scholar

Belonsi, M.H., De Lima, A.M.G., Duarte, M.A.V., Ferraresi, R.N., and Da Silva, W.C.D. (2023). A methodology based on 1D-CNN and bootstrap method to estimate the remaining useful life of industrial assets suffering from generalized corrosion. Math. Probl. Eng.: 1–12, https://doi.org/10.1155/2023/4203541.Search in Google Scholar

Bolton, T., Bass, J., and Gaber, T. (2023). Proceedings of the 8th International Conference on Advanced Intelligent Systems and Informatics, November 18, 2022: A Comparison of Deep Learning Techniques for Corrosion Detection.10.1007/978-3-031-20601-6_18Search in Google Scholar

Burton, B., Nash, W.T., and Birbilis, N. (2022). RustSEG: automated segmentation of corrosion using deep learning. Comput. Vis. pattern Recognit: 1–30.Search in Google Scholar

Calabrese, L., Bonaccorsi, L., Galeano, M., Proverbio, E., Di Pietro, D., and Cappuccini, F. (2015). Identification of damage evolution during SCC on 17-4 PH stainless steel by combining electrochemical noise and acoustic emission techniques. Corros. Sci. 98: 573–584, https://doi.org/10.1016/j.corsci.2015.05.063.Search in Google Scholar

Cerny, D., Kuchar, J., Kania, H., and Saternus, M. (2024). Verification of the properties of zinc hot-dip galvanized steel samples. In: Bartosz, G., Olaf, C., Vitalii, I., and Jose Mendes, M. (Eds.). Advances in manufacturing IV. Springer, Switzerland, pp. 195–205.10.1007/978-3-031-56463-5_15Search in Google Scholar

Cha, Y.J., Choi, W., and Büyüköztürk, O. (2017). Deep learning-based crack damage detection using convolutional neural networks. Comput. Civ. Infrastruct. Eng. 32: 361–378.10.1111/mice.12263Search in Google Scholar

Cha, Y.J., Choi, W., Suh, G., Mahmoudkhani, S., and Büyüköztürk, O. (2018). Autonomous structural visual inspection using region-based deep learning for detecting multiple damage types. Comput. Civ. Infrastruct. Eng. 33: 731–747, https://doi.org/10.1111/mice.12334.Search in Google Scholar

Chen, J., Xu, X., and Dang, H. (2019a). Fault detection of insulators using second-order fully convolutional network model. Math. Probl. Eng.: 1–10, https://doi.org/10.1155/2019/6397905.Search in Google Scholar

Chen, Q., Wen, X., Lu, S., and Sun, D. (2019b). Corrosion detection for large steel structure base on UAV integrated with image processing system. IOP Conf. Ser. Mater. Sci. Eng. 608, https://doi.org/10.1088/1757-899x/608/1/012020.Search in Google Scholar

Chun, P.J., Yamane, T., Izumi, S., and Kameda, T. (2019). Evaluation of tensile performance of steel members by analysis of corroded steel surface using deep learning. Metals 9: 1–15, https://doi.org/10.3390/met9121259.Search in Google Scholar

Dai, J., Li, Y., He, K., and Sun, J. (2016). Proceedings of the 30th International Conference on Neural Information Processing Systems, December, 2016: R-FCN: Object detection via region-based fully convolutional networks. NIPS.Search in Google Scholar

Demachi, K., Hori, T., and Perrin, S. (2020). Crack depth estimation of non-magnetic material by convolutional neural network analysis of eddy current testing signal. J. Nucl. Sci. Technol. 57: 401–407, https://doi.org/10.1080/00223131.2019.1691076.Search in Google Scholar

Dourado, A., and Viana, F.A.C. (2019). Annual Conference of the Prognostics and Health Management Society, September, 2019: Physics-informed neural networks for corrosion-fatigue prognosis. PHM.10.36001/phmconf.2019.v11i1.814Search in Google Scholar

Dung, C.V., Sekiya, H., Hirano, S., Okatani, T., and Miki, C. (2019). A vision-based method for crack detection in gusset plate welded joints of steel bridges using deep convolutional neural networks. Autom. Constr. 102: 217–229, https://doi.org/10.1016/j.autcon.2019.02.013.Search in Google Scholar

Ebrahimkhanlou, A., Dubuc, B., and Salamone, S. (2019). A generalizable deep learning framework for localizing and characterizing acoustic emission sources in riveted metallic panels. Mech. Syst. Signal Process. 130: 248–272, https://doi.org/10.1016/j.ymssp.2019.04.050.Search in Google Scholar

Ejimuda, C.C., and Ejimuda, C.M. (2018). SPE western regional meeting, April 22, 2018: Using deep learning and computer vision techniques to improve facility corrosion risk management systems.10.2118/190036-MSSearch in Google Scholar

Forkan, A.R.M., Kang, Y. Bin, Jayaraman, P.P., Liao, K., Kaul, R., Morgan, G., Ranjan, R., and Sinha, S. (2022). CorrDetector: a framework for structural corrosion detection from drone images using ensemble deep learning. Expert Syst. Appl. 193, https://doi.org/10.1016/j.eswa.2021.116461.Search in Google Scholar

Girshick, R., Donahue, J., Darrell, T., and Malik, J. (2014). IEEE Computer Society Conference on Computer Vision and Pattern Recognition, June 23-28, 2014: Rich feature hierarchies for accurate object detection and semantic segmentation.10.1109/CVPR.2014.81Search in Google Scholar

Girshick, R. (2015). IEEE International Conference on Computer Vision, December 7-13, 2015: Fast R-CNN. ICCV.10.1109/ICCV.2015.169Search in Google Scholar

Goodfellow, I., Pouget-Abadie, J., Mirza, M., Xu, B., Warde-Farley, D., Ozair, S., Courville, A., and Bengio, Y. (2020). Generative adversarial networks. Commun. ACM. 63: 139–144, https://doi.org/10.1145/3422622.Search in Google Scholar

Guzman-Torres, J.A., Domínguez-Mota, F.J., Martínez-Molina, W., Naser, M.Z., Tinoco-Guerrero, G., and Tinoco-Ruíz, J.G. (2023). Damage detection on steel-reinforced concrete produced by corrosion via YOLOv3: a detailed guide. Front. Built Environ. 9: 1–16, https://doi.org/10.3389/fbuil.2023.1144606.Search in Google Scholar

Hamdy, A.S., El-Shenaw, E., and El-Bitar, T. (2006). Electrochemical impedance spectroscopy study of the corrosion behavior of some niobium bearing stainless steels in 3.5% NaCl. Int. J. Electrochem. Sci. 1: 171–180.10.1016/S1452-3981(23)17147-1Search in Google Scholar

Harsimran, S., Santosh, K., and Rakesh, K. (2021). Overview of corrosion and its control: a critical review. Proc. Eng. Sci. 3: 13–24, https://doi.org/10.24874/pes03.01.002.Search in Google Scholar

He, K., Zhang, X., Ren, S., and Sun, J. (2015). Spatial pyramid pooling in deep convolutional networks for visual recognition. IEEE Trans. Pattern Anal. Mach. Intell. 37: 1904–1916, https://doi.org/10.1109/tpami.2015.2389824.Search in Google Scholar PubMed

He, K., Zhang, X., Ren, S., and Sun, J. (2016). Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, December, 2016: Deep residual learning for image recognition.10.1109/CVPR.2016.90Search in Google Scholar

He, K., Gkioxari, G., Dollár, P., and Girshick, R. (2020). Mask R-CNN. IEEE Trans. Pattern Anal. Mach. Intell. 42: 386–397, https://doi.org/10.1109/tpami.2018.2844175.Search in Google Scholar

Hochreiter, S. and Schmidhuber, J. (1997). Long short-term memory. Neural Comput 9: 1735–1780, https://doi.org/10.1162/neco.1997.9.8.1735.Search in Google Scholar PubMed

Homborg, A., Mol, A., and Tinga, T. (2024). Corrosion classification through deep learning of electrochemical noise time-frequency transient information. Eng. Appl. Artif. Intell. 133, https://doi.org/10.1016/j.engappai.2024.108044.Search in Google Scholar

Hopfield, J.J. (1982). Neural networks and physical systems with emergent collective computational abilities. Proc. Natl. Acad. Sci. U. S. A. 79: 2554–2558, https://doi.org/10.1073/pnas.79.8.2554.Search in Google Scholar PubMed PubMed Central

Hussein Khalaf, A., Xiao, Y., Xu, N., Wu, B., Li, H., Lin, B., Nie, Z., and Tang, J. (2024). Emerging AI technologies for corrosion monitoring in oil and gas industry: a comprehensive review. Eng. Fail. Anal. 155, https://doi.org/10.1016/j.engfailanal.2023.107735.Search in Google Scholar

Ibrahimi, B.E L, Nardeli, J.V., and Guo, L. (2021). An overview of corrosion. ACS Symp. Ser. 1403: 1–19, https://doi.org/10.1021/bk-2021-1403.ch001.Search in Google Scholar

Ivakhnenko, A. and Ivakhnenko, G. (1995). The review of problems solvable by algorithms of the group method of data handling (GMDH). Pattern Recognit. Image Anal. 5: 527–535.Search in Google Scholar

Jalil, B., Leone, G.R., Martinelli, M., Moroni, D., Pascali, M.A., and Berton, A. (2019). Fault detection in power equipment via an unmanned aerial system using multi modal data. Sensors 19: 1–15, https://doi.org/10.3390/s19133014.Search in Google Scholar PubMed PubMed Central

Ji, Y., Fu, X., Ding, F., Xu, Y., He, Y., Ao, M., Xiao, F., Chen, D., Dey, P., Qin, W., et al.. (2024). Artificial intelligence combined with high-throughput calculations to improve the corrosion resistance of AlMgZn alloy. Corros. Sci. 233: 1–15, https://doi.org/10.1016/j.corsci.2024.112062.Search in Google Scholar

Jia, D., Dong, W., Socher, R., Jia Li, L., Li, K., and Fei, L.F. (2009). IEEE Conference on Computer Vision and Pattern Recognition, June 20-25, 2009: ImageNet: A large-scale hierarchical image database.Search in Google Scholar

Jian, L., Weikang, K., Jiangbo, S., Ke, W., Weikui, W., Weipu, Z., and Zhoumo, Z. (2013). Determination of corrosion types from electrochemical noise by artificial neural networks. Int. J. Electrochem. Sci. 8: 2365–2377, https://doi.org/10.1016/s1452-3981(23)14315-x.Search in Google Scholar

Kadhim, H. and Al-Shareefi, M. (2009). Neural network corrosion control by impressed cathodic protection. M.S.thesis. University of Technology, Iraq.Search in Google Scholar

Katsamenis, I., Protopapadakis, E., Doulamis, A., Doulamis, N., and Voulodimos, A. (2020). Pixel-level corrosion detection on metal constructions by fusion of deep learning semantic and contour segmentation. In: George, B., Zhaozheng, Y., and Edward, Y. (Eds.). Advances in visual computing. Springer, San Diego, pp. 160–169.10.1007/978-3-030-64556-4_13Search in Google Scholar

Kelley, H.J. (1960). Gradient theory of optimal flight paths. ARS J 30: 947–954, https://doi.org/10.2514/8.5282.Search in Google Scholar

Kelly, R.G., Scully, J.R., Shoesmith, D., and Buchheit, R.G. (2002). Electrochemical techniques in corrosion science and engineering. CRC Press, Boca Raton, FL.10.1201/9780203909133Search in Google Scholar

Krizhevsky, A., Sutskever, I., and Hinton, G.E. (2017). ImageNet classification with deep convolutional neural networks. Commun 60: 84–90, https://doi.org/10.1145/3065386.Search in Google Scholar

Kunihiko Fukushima, S.M. (1980). Neocognitron: a self-organizing neural network model for a mechanism of pattern recognition unaffected by shift in position. Biol. Cybern. 36: 193–202, https://doi.org/10.1007/bf00344251.Search in Google Scholar PubMed

LeCun, Y., Bottou, L., Bengio, Y., and Haffner, P. (1998). Gradient-based learning applied to document recognition. Proc. IEEE. 86: 2278–2324, https://doi.org/10.1109/5.726791.Search in Google Scholar

Lemaréchal, C. (2012). Cauchy and the gradient method. In: Grotschel, M. (Ed.). Documenta mathematica series. EMS Press, Zurich, pp. 251–254.10.4171/dms/6/27Search in Google Scholar

Li, X., Lai, T., Wang, S., Chen, Q., Yang, C., and Chen, R. (2019). IEEE International Conference on Parallel and Distributed Processing with Applications, Big Data and Cloud Computing, Sustainable Computing and Communications, Social Computing and Networking, December 16-18, 2019: Weighted feature pyramid networks for object detection.10.1109/ISPA-BDCloud-SustainCom-SocialCom48970.2019.00217Search in Google Scholar

Li, X., Li, W., Yang, Q., Yan, W., and Zomaya, A.Y. (2020). An unmanned inspection system for multiple defects detection in photovoltaic plants. IEEE J. Photovoltaics. 10: 568–576, https://doi.org/10.1109/jphotov.2019.2955183.Search in Google Scholar

Lin, Y.Z., Nie, Z.H., and Ma, H.W. (2017). Structural damage detection with automatic feature-extraction through deep learning. Comput. Civ. Infrastruct. Eng. 32: 1025–1046, https://doi.org/10.1111/mice.12313.Search in Google Scholar

Liu, W., Anguelov, D., Erhan, D., Szegedy, C., Reed, S., Fu, C.Y., and Berg, A.C. (2016). SSD: single shot multibox detector. In: Bastian, L., Jiri, M., Nicu, S., and Max, W. (Eds.). Lecture notes in computer science. Springer, The Netherlands, pp. 21–37.10.1007/978-3-319-46448-0_2Search in Google Scholar

Liu, L., Yan, R.J., Maruvanchery, V., Kayacan, E., Chen, I.M., and Tiong, L.K. (2017). Transfer learning on convolutional activation feature as applied to a building quality assessment robot. Int. J. Adv. Robot. Syst. 14: 1–12, https://doi.org/10.1177/1729881417712620.Search in Google Scholar

Liu, L., Tan, E., Yin, X.J., Zhen, Y., and Cai, Z.Q. (2019). Proceedings of 3rd high performance computing and cluster technologies conference, June, 2019: Deep learning for coating condition assessment with active perception.10.1145/3341069.3342966Search in Google Scholar

Lu, Z., Liu, Y., and Zhong, S. (2021). 33rd Chinese Control and Decision Conference, May, 2021: Research on Zinc Layer Thickness Prediction Based on LSTM Neural Network.10.1109/CCDC52312.2021.9602402Search in Google Scholar

Makhzani, A., and Frey, B. (2014). International Conference on Learning Representations, March 22, 2014: k-Sparse autoencoders. ICLR.Search in Google Scholar

Muller, M. (2024). 20th Pipeline Technology Conference, April, 2024: Practical application of AI in the condition assessment of pipelines and the role of cathodic corrosion protection.Search in Google Scholar