Abstract

This paper presents the features of yarn structure formation on spinning machine, i.e. yarn twist change when winding. It was considered that the twist distribution was one of the reasons for its decrease along the formed yarn. In this paper, based on analysis of changes in thickness and twist due to axial deformation, we consider a yarn moving at constant speed. Moving dynamics of yarn are studied here by using Euler variables. The correspondences of forward and reverse twist waves’ distribution speeds on presented frequency at various vibration forms are obtained. The parameters of Doppler effect for the waves distributed along the yarn are determined.

1 Introduction

Analysis of research literature indicates that the structure of yarn depends on technological and kinematic factors. Structure control, i.e., ways to reduce twist loss and twist distribution along the yarn, and the methods of density regulation are not considered. It is a big problem as characteristics and quality of yarn depend on it. We consider the change in torsion quantity on a ring spinning machine. Formed yarn gets one twist per one turn of the runner. The number of coiled yarn twists changes depending on coil diameter. So, with an increase in diameter of winding, a larger twist occurred. Practice has shown that when twisting the yarn into a coil with a larger and smaller diameters, the difference is about 1% [1]. Twist unevenness also occurs due to vertical movement of the ring bar at a certain distance. So, for example, when lowering the ring strip, a shorter yarn is wound on the package because a part of its length is not wound due to increasing cylinder height. Therefore, in practice, it is used the average twist obtained when the number of torsions in any section of yarn divided by its length. In this case, appearance of twist irregularities is not taken into account, as it is very important for uniform yarn structure. In well-known papers [2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17], the roughness in twist is not analyzed, i.e., the conditions for formation of structure, on which the quality indicators of yarn obtained by the spinning machine are largely dependent, are not taken into account. As noted above, the difference in the number of yarn twist segments leads to appearance of twists in short sections when the annular strip moves up and down. Uniformity of twist distribution in this case depends on the spinning method, i.e., a twist along the yarn is distributed differently. Investigations of these issues are described in papers [2, 5,6,7,8,9,10]. On yarn twist distribution at different spinning methods, the positive results were obtained. A number of works are about the study of twist distribution in OE yarn [11,12,13,14,15]. The issue of twist distribution in the modified yarn was also studied [7]. In all papers, the process of twist wave distribution along the yarn is considered. In this case, the distribution of shear deformations occurs both along the axis of the yarn and along the radial direction. For twist distribution along the yarn, the structural unevenness is important. Twist distribution has been sufficiently investigated, but, as a rule, a structurally uniform and homogeneous product is considered, while the structure of the product is not considered. Therefore, twist distribution with such shortcomings is investigated in this paper.

2 Theory

In paper [5, 6] considered twist distribution of the yarn with structural unevenness where applied the generalized law for Hooke's anisotropic medium, according to which the correspondences between the components of the stress and strain tensors in ax symmetric coordinates are represented by five elastic constants [7].

where σrr, σzz, σθθ, σrz, σzθ, and σrθ are axial, radial, ring, and shear stresses and ɛrr, ɛzz, ɛθθ, ɛrz, ɛzθ, and ɛrθ are corresponding deformations in coordinates r0z, where axis 0z is directed along the axis of the yarn, and axis 0r is perpendicular to it, and the origin of coordinates is at point O (0,0) (Figure 1). Moreover, E1 and E2 correspond the Young's modulus along axial directions 0z and 0r, respectively, and υ12 and υ32 are corresponding Poisson's ratios, characterized by a change in yarn thickness and twist due to axial deformation G-modulus of planar rigidity (zθ).

Scheme of the yarn twisting process.

We denote the angular displacement of yarn arbitrary section by uθ = u(r, z, t) = rθ (r, z, t) and consider the remaining components of the displacement vector to be equal to zero.

We denote the angular displacement of yarn arbitrary section by uθ = u(r, z, t) –, and the remaining components of the displacement vector are assumed to be zero; then, the components of the strain tensor will be expressed by using the following equation:

In Eq. (2), we see that deformation shifts ɛθz and ɛrθ are linearly depend on displacement u(r, z, t) and its derivative. In an adopted scheme, the motion equation is as follows:

after substitution of σzθ and σrθ from Eq. (1), the Eq. (3) takes the following form:

Eq. (4) describes the distribution of twisting waves along the yarn with a structurally heterogeneous property. In this case, the twist changes both along the axis of the yarn and along the radial direction. We consider a yarn with radius r0 and final length l, sliding at constant speed ν on positive direction of axis 0z. It is more convenient to study the dynamics of a moving yarn in Euler variables. Therefore, passing from total time derivatives to a local one, we obtain the following equation:

where

For yarn axis, the displacement roundedness condition is applied:

Yarn initial cross section A in Euler's variable is inactive, i.e.,

Full angular speed of the yarn in a cross section B will be equal to the following equation:

where ω* is the angular speed of the twisting part.

The solution for Eq. (5) satisfying the boundary conditions of Eqs (6) and (7) can be represented as follows:

where function Rn(r) satisfied the following equation

and according to Eqs (9) and (10) the boundary conditions are

The solution of Eq. (11) is represented through the first-order Bessel function, Rn = J1(λnx) λn – equation roots:

Using the condition of orthogonality

where

Eq. (12) for known values of characteristic numbers λn describes the process of monochromatic twist wave distribution along the yarn. The matter of no twist change in a radial direction corresponding to a zero form of fluctuations with λ1 = 0 is considered in the paper [11].

The solution of Eq. (14) is represented as follows:

Function u(r, z, t) has the following form:

where functions yz(z) satisfy the equations

and according to Eqs (7) and (9) satisfy the following conditions

where

We consider the case ν > b and solution for Eq. (16). Taking Eq. (17) into consideration, it will be represented as follows:

where

An = A1n + iA2n is a complex constant, the component of which is determined from conditions of Eq. (18)

Thus, the angular movement of the yarn between sections A and B can be represented as follows:

where

As seen in Eq. (19), the values α1n and α2n are positive (α1n > 0) and negative (α2n < 0) numbers accordingly. They are the wave numbers corresponding to various forms of fluctuations on variable r and describing the wave distribution along positive and negative directions of axis 0z with speeds c1n = − ω / α2n (ω) and c2n = − ω / α1n (ω) accordingly. Here, the speeds of waves depend on frequency ω, which indicates the presence of wave dispersion.

If we do not take into account the twist changes in radial direction, then from Eq. (14), we obtain the expressions for the wave numbers as given in the study by Xu et al [10].

Moreover, the wave numbers k1 and k2 indicate the wave distribution along positive and negative directions of axis 0z, with the speeds b + ν and ν − b, associated with Doppler effect accordingly. From Eq. (19), it is seen that each eigen value λn corresponds to the distribution speeds c1n (ω) and c2n (ω), which depend on frequency ω, i.e., as the wave dispersion effect occurs. For wave distribution speeds, using the dimensionless values χ =ωr0 / b,

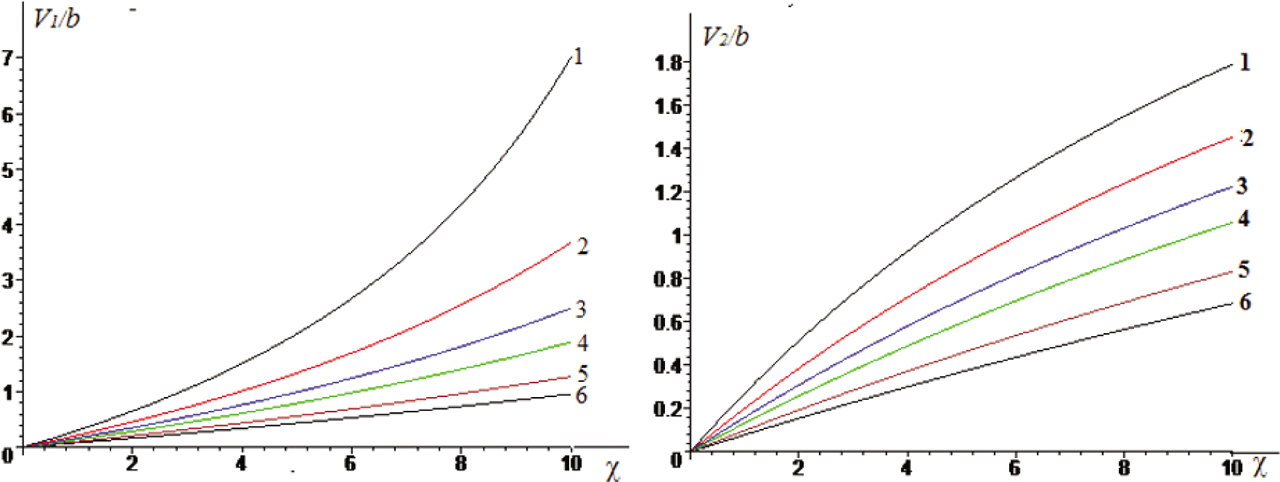

Figure 2 presented the curves of V1n and V2n speed dependence (referred to shear wave speed b) on dimensionless frequency χ = ωr0 / b. The calculations were performed for the following values:

Dependences of backward (a) and direct (b) wave distribution speed on reduced frequency χ at different forms of fluctuations. 1− n = 3, 2 − n = 4, 3− n = 5, 4 − n = 6, 5 − n = 8, 6 − n =10.

The analysis of curves shows that Doppler effect for waves distributing along the yarns is held for each fluctuation form of the yarn by its thickness. In this case, the Doppler effect for the backward wave is stronger than that for the direct one. This is due to the processes of wave's reflection from the axis of the yarn.

4 Conclusion

The conditions for distribution of twist waves for a moving yarn with a constant speed are studied, and the parameters of Doppler effect for waves that are distributed along the yarn are determined. It was found that the Doppler effect for the backward wave is stronger than that for the direct one for 3.5 times. This is due to the processes of wave's reflection from yarn axis.

Acknowledgment

The authors are also highly grateful to technical staff of Art Soft Textile Group LLC. Associate Professor Mr. R. Karimov is acknowledged for his technical support and guidance. (http://www.artsofttex.uz).

Declaration of conflicting interests

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

References

[1] Sevostyanov, A. G. (1989). Mechanical technology of textile materials. p. 512.Search in Google Scholar

[2] Borzunov, I. G. (1982). Spinning of cotton and man-made fibers. M. Light and Food Industry. p. 376.Search in Google Scholar

[3] Chistoborodov, G. I., Avrelkin, V. A., Ronjin, V. I. (2002). Determination of the maximum torsion angle of the product. University News. Textile Technology. Moscow. №2, pp. 40–42.Search in Google Scholar

[4] Maâtouka, I., Msahlia, S., Zidib, M., Sakli, F. (2014). Study of yarn twist angle using numerical simulation. Journal of the Textile Institute, 105(8), 814–820.10.1080/00405000.2013.855378Search in Google Scholar

[5] Van Langenhove, L. (1997). Simulating the mechanical properties of a yarn based on the properties and arrangement of its fibers. Part I: The Finite Element Model, Textile Research Journal, 67(4), 263–268.10.1177/004051759706700405Search in Google Scholar

[6] Van Langenhove, L. (1997). Simulating the mechanical properties of a yarn based on the properties and arrangement of its fibers. Part III: Practical measurements. Textile Research Journal, 67(6), 406–412.10.1177/004051759706700604Search in Google Scholar

[7] Tang, H. B., Xu, B. G., Tao, X. M. (2010). A new analytical solution of the twist wave propagation equation with its application in a modified ring spinning system. Textile Research Journal, 80(7), 636–641.10.1177/0040517509343817Search in Google Scholar

[8] Phillips, D. G. (2008). Torque due to applied tension in ring-spun yarns. Textile Research Journal, 78(8), 671–681.10.1177/0040517508090481Search in Google Scholar

[9] Basu, A., Doraiswamya, I., Gotipamul, R. L. (2003). Measurement of yarn diameter and twist by image analysis. Journal of the Textile Institute, 94(1–2), 37–48.10.1080/00405000308630592Search in Google Scholar

[10] Xu, B. G., Tao, X. M. (2003). Integrated approach to dynamic analysis of yarn twist distribution in rotor spinning part I: Steady state. Textile Research Journal, 79–89.10.1177/004051750307300116Search in Google Scholar

[11] Zhang, H., Chen, D., Wan, Y. (2003). Fiber migration and twist radial distribution in rotor spun yarns. Textile Research Journal, 945–948.10.1177/004051750307301102Search in Google Scholar

[12] Guo, B., Tao, X., Lo, T. (2000). A mechanical model of yarn twist blockage in rotor spinning, Textile Research Journal, 70(1), 11–17.10.1177/004051750007000103Search in Google Scholar

[13] Ba, T., Huang, X. (2000). Modeling the twist level at the peeling point in rotor spinning. Textile Research Journal, 390–395.Search in Google Scholar

[14] Xu, B. G., Tao, X. M. (2003). Integrated approach to dynamic analysis of yarn twist distribution in rotor spinning part I: Textile Research Journal.10.1115/IMECE2002-39488Search in Google Scholar

[15] Zhang, H., Chen, D., Wan, Y. (2003). Fiber migration and twist radial distribution in rotor spun yarns. Textile Research Journal.Search in Google Scholar

[16] Idzik, M. (2019). Analysis of changes in fiber density distribution in a cotton combed spinning system using modified regulation of the sliver draft. Autex Research Journal, 19(1), 54–59.10.1515/aut-2018-0022Search in Google Scholar

[17] Lu, Y., Wang, Y., Gao, W. (2019). Wicking behaviors of ring and compact-siro ring spun yarns with different twists. Autex Research Journal, 19(1), 68–73.10.1515/aut-2018-0031Search in Google Scholar

© 2021 Sh. Shukhratov et al., published by Sciendo

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Durable Wash-Resistant Antimicrobial Treatment of Knitted Fabrics

- Estimation of Seams in Paraglider Wing

- Conductive Heat Transfer Prediction of Plain Socks in Wet State

- Fabrication and Characterization of Fibrous Polycaprolactone Blended with Natural Green Tea Extracts Using Dual Solvent Systems

- Preliminary Experimental Investigation of Cut-Resistant Materials: A Biomimetic Perspective

- Effect of Lycra Weight Percent and Loop Length on Thermo-physiological Properties of Elastic Single Jersey Knitted Fabric

- Experimental Investigation of the Wettability of Protective Glove Materials: A Biomimetic Perspective

- Mechanical Properties of Composites Reinforced with Technical Embroidery Made of Flax Fibers

- Approach to Performance Rating of Retroreflective Textile Material Considering Production Technology and Reflector Size

- A Fabric-Based Integrated Sensor Glove System Recognizing Hand Gesture

- Influence of Multilayer Interlocked Fabrics Structure on Their Thermal Performance

- Texture Representation and Application of Colored Spun Fabric Using Uniform Three-Structure Descriptor

- Investigation of Twist Waves Distribution along Structurally Nonuniform Yarn

- Smart Textile for Building and Living

- Determination of Sewing Thread Consumption for 602, 605, and 607 Cover Stitches Using Geometrical and Multi-Linear Regression Models

Articles in the same Issue

- Durable Wash-Resistant Antimicrobial Treatment of Knitted Fabrics

- Estimation of Seams in Paraglider Wing

- Conductive Heat Transfer Prediction of Plain Socks in Wet State

- Fabrication and Characterization of Fibrous Polycaprolactone Blended with Natural Green Tea Extracts Using Dual Solvent Systems

- Preliminary Experimental Investigation of Cut-Resistant Materials: A Biomimetic Perspective

- Effect of Lycra Weight Percent and Loop Length on Thermo-physiological Properties of Elastic Single Jersey Knitted Fabric

- Experimental Investigation of the Wettability of Protective Glove Materials: A Biomimetic Perspective

- Mechanical Properties of Composites Reinforced with Technical Embroidery Made of Flax Fibers

- Approach to Performance Rating of Retroreflective Textile Material Considering Production Technology and Reflector Size

- A Fabric-Based Integrated Sensor Glove System Recognizing Hand Gesture

- Influence of Multilayer Interlocked Fabrics Structure on Their Thermal Performance

- Texture Representation and Application of Colored Spun Fabric Using Uniform Three-Structure Descriptor

- Investigation of Twist Waves Distribution along Structurally Nonuniform Yarn

- Smart Textile for Building and Living

- Determination of Sewing Thread Consumption for 602, 605, and 607 Cover Stitches Using Geometrical and Multi-Linear Regression Models