Abstract

Perovskite solar cells (PSCs) have garnered significant attention in the photovoltaic community due to their exceptional performance, cost-effective manufacturing, and potential for diverse optoelectronic applications. Despite their promise, maintaining the operational stability of PSCs remains a critical challenge. In recent years, nanostructured materials, particularly two-dimensional (2D), three-dimensional (3D), and their 2D/3D heterojunction combinations, have emerged as innovative solutions to enhance PSCs’ stability and photovoltaic efficiency. This review examines recent advancements in PSCs utilizing these materials. It begins with an introduction to the fundamentals of perovskite-based photovoltaics and progresses to analyzing the role of 2D, 3D, and 2D/3D materials in optimizing PSC components. Key challenges in this field are also highlighted, alongside innovative strategies to overcome them, thus providing insights into the future direction of PSC technology.

1 Introduction

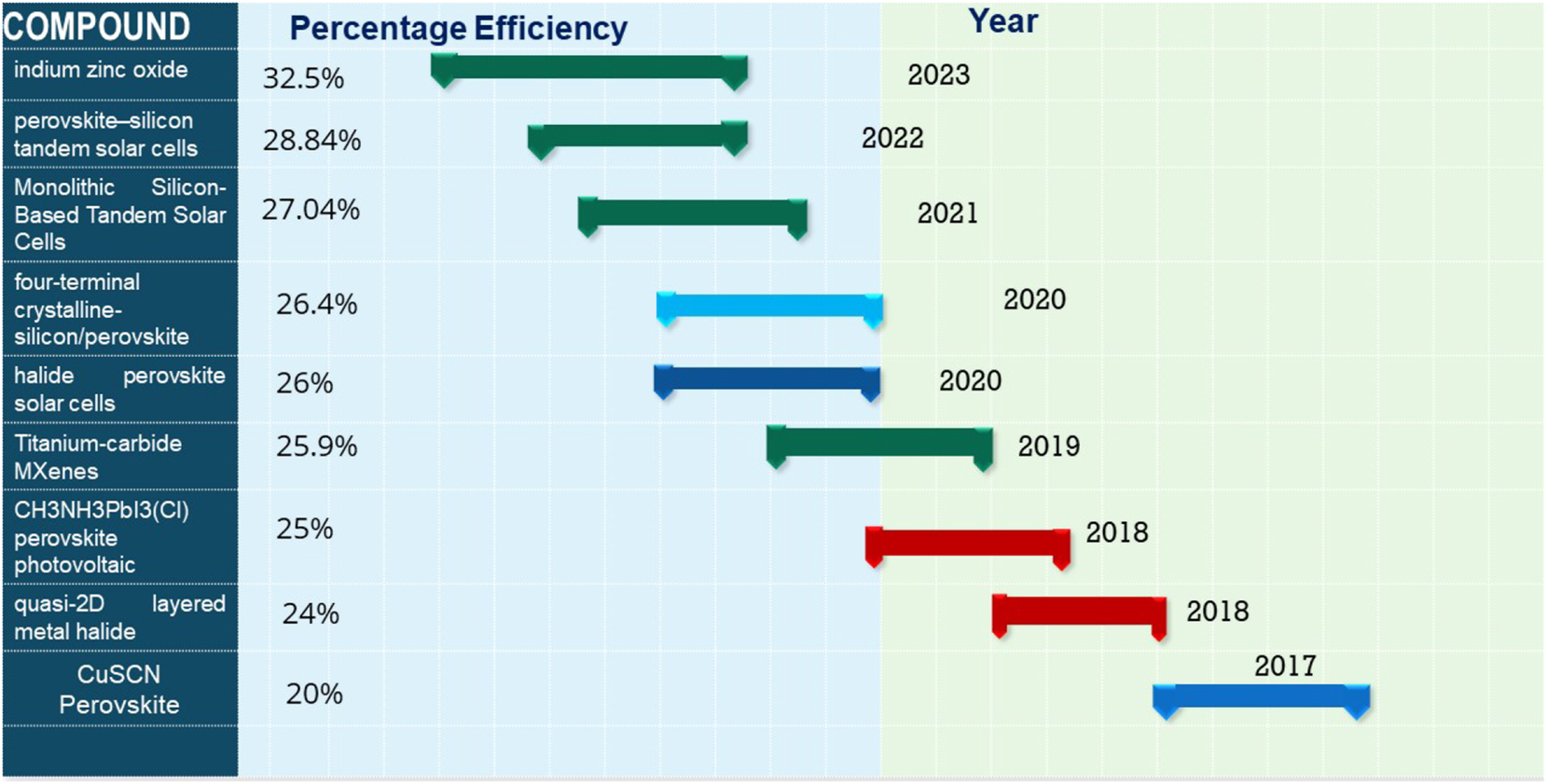

The growing global energy demand and associated environmental crises underscore the urgency of transitioning to sustainable energy solutions. 1 Solar energy, with its unmatched abundance and accessibility, has emerged as a leading candidate to address these challenges. 2 Among the various photovoltaic technologies, perovskite solar cells (PSCs) have garnered significant attention due to their remarkable efficiency, cost-effectiveness, and potential for large-scale implementation. 3 The advancements in PSCs have been transformative, with power conversion efficiencies (PCEs) surpassing 25.2 % for single-junction devices and reaching an unprecedented 32.5 % for tandem configurations in 2023. 4 These breakthroughs are attributed to innovative material engineering, particularly the development of two-dimensional (2D), three-dimensional (3D), and hybrid 2D/3D heterojunctions.

The success of PSCs lies in their unique material properties, including tunable band gaps, superior light absorption, and excellent charge transport characteristics. The integration of 2D materials such as MXenes, graphene, and TiS2 has been instrumental in addressing issues related to stability and efficiency. These materials improve charge carrier dynamics and reduce recombination losses, achieving efficiencies as high as 23.78 % in modified devices. Simultaneously, 3D materials contribute to enhanced structural integrity and mechanical resilience, with hybrid designs combining the advantages of both dimensionalities. For instance, devices incorporating 2D/3D heterojunctions have demonstrated PCEs exceeding 25 %, coupled with improved operational stability under humid and high-temperature conditions.

Because they promise to reduce pollution and generate renewable energy, several solar cells of numerous types have been developed. Experts have been paying close attention to thin-film solar cells like organic solar cells and perovskite solar cells due to their versatility, mobility, and adaptability. Power conversion efficiency (PCEs) peaked at 25.2 % for single-junction PSCs and 17.4 % for OSCs. 5

The Russian Mineralogist L. A. Perovski gave his namesake mineral, perovskite, the explicit valuable stone structure ABX3 (X = halogen, oxygen). The A cation shares a cubo octahedral site with twelve X anions, whereas the B cation acts as a counterion in an octahedral site with just six X anions. Due to their superconductivity or ferroelectricity, oxides are the most cautious perovskites. Less interest was paid to halide perovskites until it was shown that covered organometal halide perovskites transitioned from semiconductor to metal with increasing dimensions. 6

Weber first revealed the production and actual properties of PSCs in 1978; the organometal halide (X = Br, Cl, or I, M = Sn or Pb), which is CH3NH3MX3, is the main element for the PSCs, now receiving tremendous attention. 7 The size of the unit cell border in CH3NH3PbX3 rises from 5.68 Å to 5.92 Å–6.27 Å when the size of the halide increases from X = Cl to Br and I. Mixing halides may significantly alter the lattice parameters in the cubic stage; for example, CH3NH3PbBr2.07I0.93 displayed a = 6.03, CH3NH3PbBr0.45I2.55 showed a = 6.25, and CH3NH3PbBr2.3Cl0.7 displayed a = 5.98. CH3NH3SnBrxl3x (x = 0–3) crystallizes to the cubic perovskite assembly with a = 6.01 (x = 2), a = 6.24 (x = 0), and a = 5.89 (x = 3), In contrast to their lead-based counterparts, several tin-based perovskite compounds have shown electrical conductivity. 8

Large organic cations like C4H9NH3 and phenyl-ethyl ammonium often produce two-dimensional halide perovskite materials. 9 These heavy organic cations are placed into Pb–I octahedron repeat units to create 2D halide perovskites. The 2-dimensional halide perovskite materials are environmentally stable because Vander Waals interactions with the octahedral PbI6 units encapsulate the organic cations (PEA+ and BA+). In addition, the high exciton binding energies, poor charge transport, and wide bandgap of 2D halide perovskite PSCs contribute to their low power conversion efficiency. 10 The problems with two-dimensional halide perovskite have been addressed by combining it with the more traditional three-dimensional lead halide perovskite, a material in which the benefits of both types of perovskite are maximized. Creating a 3D/2D structure not only increases the performance of PSCs but also guarantees the structural integrity of the perovskite crystal phase and leads to long-term stability. 11 For instance, researchers developed a new method for making stable and effective PSCs via perovskite hybridization by constructing 2-dimensional or 3-dimensional perovskite hybrids to combine their merits. 12 Compared to pure 3D perovskite, two-dimensional or three-dimensional perovskite hybrids significantly improved device moisture stability in high humidity (65 %) without encapsulation. Notably, the 2D/3D perovskite hybrid film kept 54 % of its original efficiency after 220 h and exhibited no degradation after 40 days. Researchers successfully produced highly efficient and robust two-dimensional or three-dimensional hybrid perovskite solar cells employing 2-thiophene methylammonium as the spacer cation in 2019. 13

In this study, we detail the research and development that has led to the creation of perovskite solar cells that are both efficient and durable. Employing single-element two-dimensional materials (graphene, antimonene, bismuthine, phosphorene, and borophene), three-dimensional materials, and 2D/3D heterojunction materials for PSCs. Firstly, we will provide a concise introduction to PSCs. Next, the paper showcases the effective use of several elemental 2D, 3D, and 2D/3D materials in various layers of PSCs. The study finishes by emphasizing the significant accomplishments in this rapidly expanding field of research and addressing the issues that need to be addressed.

2 Perovskites solar cell

2.1 Constructional aspects of PSCs

To comprehensively assess solar cells within their broader context, it is essential to first understand their underlying mechanisms of energy generation. 14 , 15 Photovoltaic cells may be classified into two main configurations, namely inverted (p-i-n) and conventional (n-i-p), depending on the presence of carrier material (either electron or hole) on the outer side of the cell that comes into contact with incoming light first. 16 Furthermore, it is possible to categorize these two collections as mesoscopic or planar cells. In contrast to the exclusively planar architecture seen in mesoscopically fabricated perovskite devices, the planarly created perovskite devices include a mesoporous layer. Furthermore, it has been verified that perovskite devices are capable of operating in the absence of holes or electron transport layers. A considerable body of research has been dedicated to the examination of six specific categories of perovskite solar cells, including mesoscopic n-i-p configurations, planar n-i-p configurations, planar p-i-n configurations, mesoscopic p-i-n conformations, ETL-free structures, and HTL-free structures.

2.2 PSCs history

Perovskite is an inorganic-organic hybrid chemical that makes up the perovskite solar cell. 17 This material is an excellent charge carrier conductor and solar energy collector. The use of perovskite materials in solar cell manufacturing has undergone a dramatic upheaval since 2009. Power conversion efficiencies have improved dramatically and emerged as a hallmark of this revolution. Publications beginning in the early 1990s detail the advent of study into perovskite as a solar absorber.

In 2006, a team of Japanese researchers achieved a remarkable power conversion efficiency of 2.2 percent. This is a significant step forward, and its significance has been generally acknowledged. Dye-sensitized solar cells containing CH3NH3PbBr3 were employed in the experiment. 18 In 2009, CH3NH3PbBr3 was shown to be effective as a disinfectant, making it the first organic halide compound to be discovered. The power conversion efficiency of the CH3NH3PbBr3 device was found to be 3.81 %, whereas that of the CH3NH3PbI3 device was found to be 3.13 %. After further evaluation, the same team found that the CH3NH3PbI3 chemical, in combination with an iodine liquid electrolyte contact and enhanced production conditions, had a PCE value of 6.5 %.

However, the breakdown of perovskite nanocrystals inside the iodine liquid electrolyte was the cause of this PSC’s instability. Since then, many scientists have explored this field to improve the power conversion efficiency of perovskite solar cells. 19 Because of its fundamental photophysical qualities, functioning, and distinguishing traits, this technology has led to several advances in optoelectronic applications. 20 Many interesting electrical properties, such as piezoelectricity, thermoelectricity, superconductivity, and semiconductivity, are found in perovskite materials. The materials utilized determine these characteristics. In light of these positive features, notable experimental findings elucidating the underlying mechanism responsible for these substances’ enhanced power conversion efficiency, diverse techniques used in their production, and a substantial improvement in efficiency above 25 % have been documented within a limited timeframe. Solar state DSSCs were fabricated using the perovskite solar absorber CH3NH3PbI3 and the hole transport material Spiro-OMeTAD, yielding a power conversion efficiency of 9.7 percent. 21 The DSSC has shown significant gains in device stability compared to devices using liquid electrolytes. Researchers have made tremendous progress in solving the problem of device stability, but they still face a significant barrier to commercialization and large-scale production.

To address the problem of low power efficiency, researchers in 2023 used a very thin (5 nm) layer of amorphous indium zinc oxide as the interconnecting transparent conductive oxide. By using thin IZO rear electrodes and enhanced front contact stacks, together with optical improvements, a certified power conversion efficiency of 32.5 % was achieved. This PCE is one of the highest recorded for perovskite/silicon tandems. Ultrathin transparent contact method resulted in a significant reduction of around 80 % in indium usage. 22 The evolution of PSCs over the last few years with maximum power efficiency achieved is shown in Figure 1.

2.3 Addressing energy challenges with perovskite innovations

The global energy landscape faces a dual crisis: escalating energy demand and the adverse environmental impact of fossil fuel dependence. Renewable energy, particularly solar energy, stands out as a sustainable alternative due to its abundant availability and minimal carbon footprint. However, the efficiency, scalability, and affordability of current photovoltaic technologies remain barriers to their widespread adoption. Hybrid perovskite materials have emerged as a transformative solution in the photovoltaic field. Their unique properties, including high power conversion efficiency (PCE), tunable bandgaps, and low-cost fabrication, make them strong contenders for next-generation solar cells. Compared to silicon-based photovoltaics, perovskites enable lighter, flexible, and potentially cheaper devices with comparable or superior efficiencies. Additionally, their adaptability to various structural configurations – such as 2D, 3D, and hybrid 2D/3D – allows researchers to address challenges like long-term stability and environmental resistance. 29

Recent advances in 2D/3D perovskite hybrids represent a significant leap forward in addressing the stability-efficiency trade-off. These hybrid structures combine the superior stability of 2D perovskites with the high efficiency of 3D counterparts. For example, strategies such as defect passivation, enhanced energy-level alignment, and advanced crystallization techniques have resulted in record-breaking efficiencies and improved operational durability. 30

By mitigating challenges such as ion migration, environmental degradation, and charge recombination, hybrid designs are making perovskite solar cells increasingly viable for industrial application. 31 Exploring these advancements provides critical insights into scalable, energy-efficient, and sustainable solar technologies.

3 Large-scale PSC fabrication methods

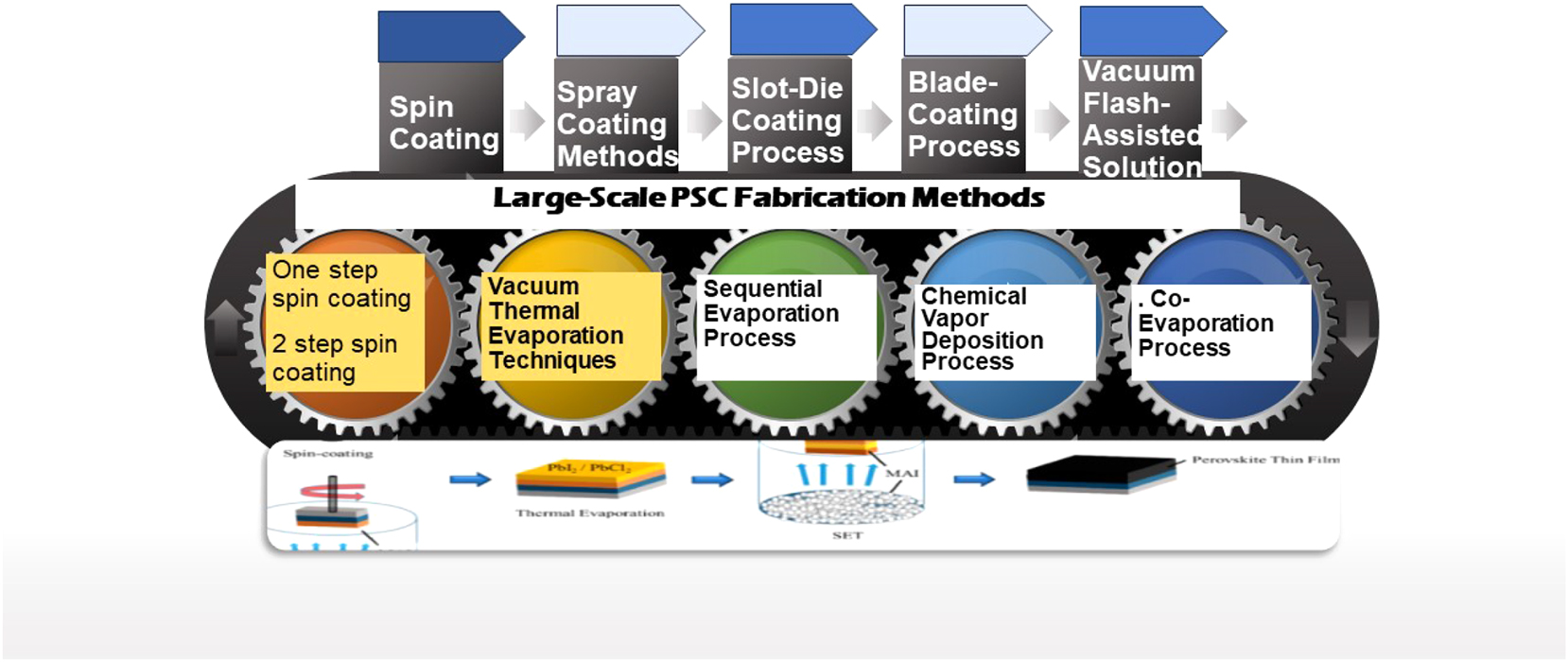

The commercialization of PSCs depends on three factors: performance, cost, and reliability. Because of advancements in device design and manufacturing techniques, photovoltaic solar cells are now on an inexorable ascent (Figure 2). Perovskite solar cells may soon be commercialized due to the establishment of prototype production lines. With these production lines, perovskite photovoltaic devices with suitable performance characteristics may be mass-produced at a reasonable cost while still adhering to time-tested manufacturing practices. However, there are ongoing issues with device stability in the academic and commercial sectors.

Various large-scale PSC fabrication methods.

Thin films of the spin-coating method have been the standard for producing metal-organic perovskite. That involves applying the material in a solution. This technology might allow for rapid iteration, enhancement, and the discovery of new information. However, this technique cannot accomplish bulk production of solar cells. To make a production process scalable, reducing manufacturing costs is crucial. This entails not only the initial investment in machinery but also the ongoing expenditures of operating the company, such as the cost of electricity, the price of materials, post-production waste treatment expenses, and the cost of quality assurance. 32 , 33 Because of their widespread availability, modern PSC materials are inexpensive. Therefore, investing in gear and equipment is the most expensive element of creating PSCs, although this cost may be lowered by increasing productivity and optimizing procedures. 34 Different substrate materials need different approaches to synthesis, making it necessary to categorize PSCs as either rigid or flexible. Perovskite thin films are typically manufactured by solution processing or vapor deposition techniques. 35

Our findings are based on the two clustering methods in other relevant studies.

The vacuum thermal evaporation process is no longer widely used in industry.

PSC researchers have also reduced blade coating and spray coating.

Ink-jet printing and slot-die coating have become prevalent at PSC research facilities.

Technical obstacles have slowed the commercialization and synthesis of large-area perovskites, but researchers are working to overcome these obstacles.

Some methods of perovskite thin-film production, such as thermal evaporation, have yet to be fully utilized to construct large-area solar cells despite their significant scaling potential.

Recent works have shown the higher power conversion efficiency for large-area PSCs with a slot-die coating, indicating that this coating may play a crucial role in the eventual commercialization of PSCs.

3.1 Spin coating

Spin coating is a batch process where a liquid layer is “pinned” onto a revolving substrate using centrifugal force. The method has been used to create several devices with a width of 1 cm and a surface area of 0.1 cm2. The steps of this method may be classified into two broad categories. The power conversion efficiencies of spin-coated perovskite devices have risen to 9.4 %. 36

The spin coating may make relatively large-area PSCs, as shown by the researchers, 35 , 37 who demonstrated a manufactured perovskite film area of 57 cm2 by carefully managing the solvent evaporation rate. Perovskite deposition is enhanced by a two-step sequential processing strategy instead of a single-step one. Film quality may also be improved by carefully managing post-annealed time and crystal formation. 38 , 39

3.1.1 One-step spin coating process

To experiment, lead halide salts and lead bromide are combined with organic halide salts (formamidinium iodide and methylammonium iodide in a solvent like dimethyl sulfoxide or N, N-dimethylformamide). The absorber and conductive layer (electrons or holes for transport) are doused with the combined precursor solution. Annealing is then conducted, which leads to the creation of perovskite films. 40 , 41

3.1.2 Two-step spin coating process

Isopropanol and dimethylformamide dissolve the halide organic compounds and lead halide salts. After the electron and hole transport layers have been annealed, the lead halide solution is spin-coated onto them. The MAI solution is spin-coated onto a lead halide surface, and then perovskite layers are formed by interdiffusion processes during annealing. Researchers subjected Perovskite solar cells with an area of 1 cm2 to a two-step spin coating procedure and then determined a PCE of 20.1 %. They effectively controlled the leftover PbI2 on the perovskite’s surface. 42

3.1.3 Advantages

Using this method, the chemistry and thickness of the perovskite layer may be manipulated with relative ease. 43 The study demonstrates the utilization of precursor solutions, including solvents with a high boiling point that are polar aprotic, i.e., DMF or DMSO. 44 , 45 This is because when a high rpm is used to spin the substrate, the solvents are often flushed out owing to centrifugal force.

3.1.4 Disadvantages

According to the research, 43 Perovskite films degrade in quality and homogeneity as the spin coating area grows. Controlling stoichiometry and crystallinity in a single phase of solution processing has proven difficult. These difficulties result from the precursor solution’s limited reactivity and the annealing procedure’s inability to complete the reaction fully. According to the results, spin coating is not an appropriate method for producing perovskite films on a big scale and over a wide region. 46 Lead is a necessary ingredient in the solution technique, just as in conventional procedures. However, it has been shown that over 50 % of spin-coating methods used to synthesize perovskite films are useless and must be thrown away. 47 , 48 Nonuniform perovskite films are formed using traditional antisolvents like chlorobenzene in large-area spin coating. 49

3.2 Spray coating methods

Because of its low ink concentration needs, compatibility with large-area technology, and low operating temperature, the spray coating process sees widespread usage in industrial settings. 50 Very scalable methods may be used to fabricate large-area thin perovskite films. The technique used to produce the perovskite layer yields a consistent material across large areas. The process begins with the creation of ink droplets and continues through their deposition into the substrate, their combination into a wet film, and finally, their drying. Spray coating is the most adaptable of the technologies that can be ramped up. The one-step technique and the two-step method are used for depositions now. Aprotic solvents are often used in one-step film deposition solutions. 50 , 51 Aprotic solvents, those without a hydroxyl group, amine groups, or acidic protons, are used in the second phase of a two-step procedure to apply metal salts by spin coating or spray coating. 35 , 52

Spray coating is a popular method for producing scalable substrates because of the speed by which capillary waves may be induced in a fluid. 43 The procedure entails breaking up a fluid into smaller droplets and depositing them onto a surface that can handle them. High-flow gas, ultrasonic stimulation, and ink cavitation are a few methods that may induce atomization. 53 , 54 Scalability is a common feature of atomization, as mentioned above methods.

Modern technical advancements in ultrasonic spray coaters have efficiently produced various functional thin films for solar cells. 54 Many different goals have motivated liquid thin-film coating technology research and development.

Organic salts may be deposited on a substrate using either a covering with a spray or soaking in alcohol. Isopropanol is used as a solvent in this process. 55 There is a noticeable variation in the outcomes depending on the method used to deposit the perovskite solutions. Many different mixtures of methylammonium iodide, lead iodide, and iodide chloride have been synthesized using a single-step deposition method. 56 , 57 The experiment used DMSO, GBL-DMSO, DMF-DMSO, DMF, and GBL as solvents. Hydrogen iodide and other processing additives were also used in some studies. For perovskite films made using this method, the highest power conversion efficiency was 18.1 percent for small-area specimens and 15.5 percent for the most extensive device area of 40 cm2. 58

No ultrasonic spray coater was used in the research, but they could determine the area of the device with the highest efficiency and most preferable form. 52 Perovskite was created by spraying a single-cation mixed halide over a preheated substrate, according to the study authors. Previous research 53 showed that this method yielded a favorable crystallization shape. Several scientific applications rely heavily on ultrasonic atomization, including temperature control, metal polyhalide complex, nucleation processes, solution optimization, and synthesis.

Since spray coating with nanoparticles is a simple manufacturing technology, it has been given much attention as a possible approach for advancing semi-transparent electronics. Researchers have used carbon nanotubes, silver nanowires, and spray-coated electrodes for transparency and their equivalent composites to produce tiny photovoltaic devices with a surface area of 0.25 cm2. Translucent in appearance, these devices were constructed completely using solution-based methods. Additionally, PCEs of greater than 10 % were obtained. 59 , 60 , 61

3.2.1 Advantages

There is potential for rapid, low-waste, and large-scale production of PSC devices. 50 Improved droplet size homogeneity, increased airflow, and more precise control over spray cone dispersion are only some of the hallmarks of modern ultrasonic spray coaters. 54 Uniform nucleation, faster supersaturation, reduced antisolvent consumption, faster antisolvent dispersion, and better homogeneity across a large surface area are some of the additional benefits of spray coating over conventional antisolvent dropping technique.

3.2.2 Disadvantages

Perovskite solar cells made using spray coating often have worse photovoltaic performance than PSCs made using blade or slot-die coating. As a result, refining the spray coating method for producing large-area perovskite films is crucial. 49

Single-step experiments frequently yield low-quality perovskite films, with architectures characterized by non-uniform crystallization, mostly dendritic structures, and insufficient coverage of the underlying transport layer. 35 This results in lower open-circuit voltages, short-circuit currents, and fill factors for photovoltaic cell devices compared to spin-coated devices. Low shunt resistance might be to blame for this discrepancy. 53 , 62 Particle dispersion, surface defects beyond the desired region, and ineffective regulation of the thickness of the applied layer are some additional issues with this method. 63

3.3 Slot-die coating process

Microfluidic metal dies are used in slot-die coating, a manufacturing technique to regulate the flow of ink precisely. Ink is spread over a moving substrate surface using a machine-shaped die with a narrow channel. 64

A plastic or other malleable substrate is often used for the surface. During high-speed coating, the head is usually mounted horizontally on a roller to decrease the effects of gravity on the fluid inside the head and to control the creation of wet film. Geometry, web speeds, and fluid feed rates are only some of the variables that affect the formation of a wet film. Thus, the geometry of the film affects not only the coating processes but also the thickness of the wet film, its chemical composition, and the stability of the microfluidic boundary conditions. 65 Historically, slot-die coating has been extensively employed in the organic photovoltaic area because of its many benefits, including its non-viscous nature and low boiling point. The entirely confined nature of the environmental deposition process is directly responsible for these qualities. It is possible to lessen the effects of compositional shifts due to solvent evaporation loss. The action of copying data or information from one page to another. Non-contact deposition of a precursor solution onto a die with a clear separation is the fundamental principle of the film synthesis technique. The substrate is coated evenly using a continuous ink reservoir with a tiny hole, a process known as slot-die coating. The thickness of the resulting film may be accurately controlled using this method. 66 , 67

3.3.1 Advantages

Using high-precision materials, film can potentially reduce solvent evaporation loss, making manufacturing perovskite solar cells at a large scale more possible production. Coating for slot can be used for the last step of processing PSC devices with high replication efficiency in normal circumstances. 68 Slot-die coating’s deposition procedures are fast and flexible enough to apply over large, precisely controlled surfaces with little solution waste. These techniques also work using equipment that rolls continuously. As such, the slot-die coating is particularly advantageous for making thick perovskite thin films. 69

3.3.2 Disadvantages

Substrates heated to 90 °C are subjected to precursor solutions, and perovskite films with a specific crystalline structure and a black color are rapidly generated. Perovskite films made with slot-die coating have been proven to be significantly rough. 70 When the substrate was heated to more than 110 degrees C, the performance of the metal-organic halide perovskite decreased, as found by the researchers. Perovskite solar cells manufactured at these high temperatures were reported to have lower power conversion efficiencies. 71 Partially delaminating from the TiO2 blocking layer is more common in perovskite films than in spin-coated films. 71 Therefore, this method is not recommended for altering the active region. 72 , 73

3.4 Blade-coating process

When a blade is used to move over a surface, or when a surface moves over a blade, as in roll-to-roll coating, the process is called “blade coating”. 64 Doctor-blading and knife-over-edge coating are two other common names for this technique. The blade aids in distributing measured amounts of ink, which is then shaped into a thin liquid layer. After exposure to air, the film shrinks and bonds together, becoming thin. It is generally accepted that the synthesis technique is the most often employed approach for producing perovskite films on a big scale. Cells with surface areas more significant than 10 cm2 have been successfully fabricated using this method in several studies of photovoltaic solar cells. Several studies 74 , 75 have demonstrated that processing temperatures may affect perovskite film quality. Lately, additives have created compact perovskite films with desirable properties such as small pinholes and a consistent crystal structure. 76 , 77 Blade coating, a straightforward technique for depositing perovskite sheets, has become more common. 78 , 79 Recent applications include the production of perovskite photovoltaics employing a scalable solution technique with enviable efficiencies approaching 20 %. 80 , 81 , 82

3.4.1 Advantages

The treatment temperature and the distance between the blade and the substrate may be precisely controlled using this method. Compared to alternative one-directional coating methods, the method outlined here is simpler. The method reported here is low-cost for producing PSCs in small batches, with extensive film-deposition tuning for specific uses. 83 Coated blades produce perovskite films that are homogeneous, defect-free, and polycrystalline. These films also exhibit persistent photoluminescence. 84 , 85

3.4.2 Disadvantages

The lack of consistency in the quality of the blade coating is said to be a major problem for the technology under consideration. In contrast to other solution processing methods, the simplest implementation of blade coating does not include a hermetically sealed ink reservoir. Since ink’s chemical composition may change over time, nucleation temperature, crystallization temperature, and improving grain growth require careful management of the solution chemistries. 35 , 86

3.5 Vacuum flash-assisted solution

The VAS method, or vacuum flash-aided solution, makes quick and accurate solvent extraction possible. By going through this procedure, the perovskite precursor phase may be formed quickly. 87 Spin-coating was used to apply the perovskite precursor solution, which consisted of DMSO and MA0.15 Br0.45FA0.81PbI2.51 with a one-to-one ratio of Pb to DMSO, onto a mesoporous TiO2 film. 88

Large-area, high-efficiency perovskite solar cells have been made possible using a visual analog scale method. Perovskite films are made by vacuum flash-assisted solution processing, initial nucleation, and subsequent stages. Perovskite films were made, containing crystals greater than those made with regular solution processing procedures. According to the study, this allowed the photovoltaic solar cells to achieve a maximum efficiency of 20.5 % in converting light to usable energy for a 1 cm2 area. 89

3.5.1 Advantages

Thermal annealing transforms The precursor phase into well-aligned, crystalline perovskite films. The electrical characteristics of these films are remarkable, and they may be grown on a wide variety of substrates. The VAS method efficiently eliminates hysteresis in J–V curves 90 , 91 and can be readily scaled up to industrial levels. The flexibility of the VAS method regarding precursor components and changes in perovskite composition. 89 Vacuum methods for perovskite film deposition provide fine control over film thickness and fabrication on low-temperature substrates, in addition to the inherent purity of sublimed materials. Perovskite technology relies on the availability of plastic electronics, which is necessary for tandem devices made using standard inorganic solar cells, allowing for the fabrication of lightweight, flexible electronics. In addition, a significant benefit of perovskite solution processing is that it does not need the use of harmful solvents.

3.5.2 Disadvantages

This process yields perovskite films with subpar crystalline structures or amorphous properties, reducing charge-carrier transport. 92 Although large-area perovskite solar cells manufactured using this approach have advantageous power conversion efficiencies, they are not sufficiently stable.

3.6 Chemical vapor deposition process

The use of gaseous chemicals in a process called chemical vapor deposition has shown to be a reliable, low-cost, and highly successful method for manufacturing a wide variety of semiconductor materials. Chemical vapor deposition technology, as opposed to the spin coating method used in the fabrication process of the PSC device, results in dramatically improved device performance. Chemical vapor deposition uses several different processes, including dual-source evaporation, 91 the vapor-assisted approach, 92 and vapor-solid interaction; 93 researchers used a dual-source co-evaporation method to create uniform and high-quality perovskite films. This method requires high temperatures and a very low vacuum. Researchers used the aforementioned method on a 64-cm2 photovoltaic device in their research. Across an active area of 1.5 cm2, the results indicated a mean PCE of 6.0 %. 93

3.6.1 Benefits

The present technique can make films that are consistently thick over a large surface area. This strategy has considerable economic potential for increasing the efficiency of perovskite solar cells in fabricating films with complex perovskite compositions. 35 The coating and semiconductor industries widely acknowledge and utilize vapour-based approaches. 94 Multizone Chemical Vapour Deposition permits fine-grained control over a wide range of process parameters, including gas flow rate, substrate temperature, and pressure, which considerably improves the repeatability of the operation. 95 One unique feature of the CVD technique is that air at standard atmospheric pressure can be used as the carrier gas, which has practical applications in manufacturing. 96 This is primarily because it allows for in situ annealing in an organic vapor environment, which improves crystallization kinetics. 97

3.6.2 Drawbacks

The method used to create the perovskite films in this research yields amorphous films with a flawed crystalline structure. Similar to perovskite films made using the vacuum flash-assisted solution approach, 98 the poor efficiency of charge-carrier transport results from these defects. Precision vacuum pressures are required for vapor deposition processes, driving up operating costs. 48

3.7 Sequential evaporation process

Vapor deposition was used to create several film layers, which were subsequently exposed to diffusion and recrystallization to induce diverse modifications in this experiment. An organic halide layer is added after a layer of metal halide has been placed on the conductive glass substrate. The successive deposition of MAPbI perovskite films in an experimental setup suggested a drastically reduced small-scale power conversion efficiency of 5.4 % in a device without a layer for carrying holes. 99 However, this strategy may not be ideal for maximizing financial scalability, resulting in reduced material utilization because of intrinsic throughput limits and the intermittent nature of evaporation. Up to 17.6 percent efficiency was attained in small-area devices constructed from perovskite and treated with sequential evaporation. To do this, the system’s internal pressures were fine-tuned to maximize evaporation efficiency, which significantly impacted the geometry of the cells. 100

3.7.1 Advantages

An experiment 97 , 101 demonstrated that this method can provide high-performance perovskite solar cells with an efficiency of 15.4 % for small-area devices with further optimization. Vacuum evaporation is used because it produces homogenous and dense films that are easy to replicate and manipulate in thickness. Heterojunction devices with superior performance may be fabricated using this method because multilayer films can be produced without modifying the primary layers chemically. 102 By protecting the layers underneath the perovskite film from the harmful effects of solvents, this method also proved useful in fabricating tandem cell architecture. 49

3.7.2 Disadvantages of the sequential evaporation method

The economic feasibility of this approach may be impeded by limitations in throughput and the impact of alternating evaporation on material usage. Like other systems that rely on a vacuum, vapor technology is associated with high costs. 48

3.8 Co-evaporation process

The aforementioned technique is often considered the best vacuum-based method for various uses. A shallow pressure of around 105–106 mbar is required to create the perovskite films. Individual crucibles heat the precursor solutions to a high enough temperature to cause sublimation. 97 Perovskite solar cell sheets made using co-vapour deposition have a smooth, flat surface, demonstrating high homogeneity. The power conversion efficiencies of these films may reach 16.5 percent. 90 This method is also fully multilayer film creation and works with existing semiconductor manufacturing techniques.

3.8.1 Advantages

Adopting this method helps achieve smoother films by significantly decreasing the size of perovskite crystallite grains. Utilizing the pristine nature of sublimated chemicals, co-evaporation permits fine-grained control over layer thickness and chemical composition in perovskite materials. 90 If the stoichiometry between the inorganic and organic precursors is correct, the complete perovskite layer may be synthesized without the requirement for heat treatment. This equilibrium is significant when dealing with temperature-sensitive substrates like plastic foils. Perovskite solution may be used in any molecular transport medium without needing an annealing step. When compared to films created by spin-coating, the uniformity and substrate adherence of perovskite films prepared using this process are much greater. Denser and pore-free materials are better suited for use with flat solar panels. 46

3.8.2 Disadvantages

It has a high vapor pressure because controlling the pace at which MAI evaporates is challenging. Regular calibrations of the precursor ratio and deposition rate are required to keep the slow process running smoothly. As was previously said, hoover technology might come with hefty fees that add up to a pricey process. 48 The insufficient condensing of organic cation precursors beyond the evaporation cone region is attributed to their considerably higher vapor pressure. 97 Due to the complex infrastructure requirements, vapor-based approaches are not yet widely used in the production of commercial perovskite optoelectronics. Precursor stoichiometry control is further complicated by the process’s utilization of a wide variety of vapors. 102

3.9 Vacuum thermal evaporation techniques

Sublimation occurs in a vacuum during this process (at pressures of 106 Pa) before their vapor is condensed onto a cooled substrate. 35 In conditions of severe vacuum, the particles expand. Particles that have sublimated travel in a conical pattern away from the source of heat pattern and eventually settle on the substrate. How uniformly a film is deposited depends on how far the evaporation source is from the substrate. Parasitic condensation on the vacuum chamber’s walls reduces material production, leading to the trade-off. 35 Using a linear deposition source and an extended evaporation cone, a substrate may be moved in an orthogonal fashion during mass manufacturing.

3.9.1 Advantages

The ease and general acceptability of the stated vacuum deposition process make it a popular choice. The heat evaporation process is effective for producing PSCs at high volumes since it can be easily scaled up. There was no solvent usage in the manufacturing process. Coatings, particularly ultrathin layers, may be deposited uniformly onto surfaces. Careful monitoring of deposition rates associated with certain precursor components may allow for precise film thickness control. Thermal evaporation is a great choice when performing characterization techniques in an ultrahigh vacuum environment. 103 , 104

3.9.2 Disadvantages

Although perovskite solar cells have been studied extensively, their lack of stability continues to be a significant barrier to their widespread adoption and commercialization. Although additives are essential for increasing PSC stability, working them into the vacuum thermal evaporation process may be challenging. Vapor deposition has difficulties, including the possibility of negative interactions between volatile substances and the need to control source evaporation rates and growth processes. PSCs manufactured through the vacuum thermal evaporation technique suffer from a dependability issue because of their notably tiny grain sizes. Perovskites in any dimension, whether two or three, deteriorate when exposed to a vacuum. Solvents that remain after the perovskite layer has been deposited have been demonstrated to reduce the efficiency of solar cells. 103

3.10 Advancements and pathways to commercializing scalable perovskite solar cells

Scaling up the fabrication of perovskite solar cells (PSCs) faces significant challenges related to reproducibility, stability, and long-term performance. Achieving homogeneous, defect-free thin films over large areas is a critical bottleneck. Techniques such as slot-die coating and hybrid meniscus coating have shown promise, with innovations like phenethylammonium iodide passivation improving film uniformity and reducing defects, enabling up to 93 % geometrical fill factors and long-term stability exceeding 3,000 h. 105

PSCs are prone to degradation under moisture, heat, and light exposure. Strategies such as double-sided passivation with phenyltrimethylammonium iodide have effectively removed defects, enhanced crystallinity, and extended stability under thermal and light conditions. 106 Stability enhancements include moisture-resistant encapsulation techniques and the use of 2D/3D hybrid materials. For example, fluorinated phenethylammonium iodide has enabled gradient structures, improving charge transport and reducing recombination, with devices maintaining 88 % of their efficiency over 80 days in ambient conditions. 107 Ion migration contributes to phase segregation and device instability. Incorporating crosslinked polymers into PSC films has been shown to suppress ion migration effectively, enabling devices to retain 90 % of their initial performance after 1,000 h under continuous illumination. 108 Eco-efficient and ambient air-compatible techniques such as spray coating offer scalability with minimal environmental impact. These methods reduce material wastage and energy consumption while ensuring performance and durability. 109 Combining vacuum evaporation with solution processing has improved film quality and reproducibility, achieving certified efficiencies up to 23.7 % for large-area modules while maintaining over 90 % stability after 1,000 h. 110 These advances provide a roadmap to overcoming scaling challenges, emphasizing the need for interdisciplinary approaches to bridge the gap between laboratory-scale efficiencies and commercial viability.

The potential for commercial scalability of perovskite solar cells (PSCs) lies in their cost-effective materials, high efficiency, and compatibility with flexible substrates. Despite challenges, recent advances in scalable fabrication methods, such as slot-die coating, spray coating, and hybrid vacuum-solution processing, have significantly improved the uniformity and reproducibility of large-area modules. Emerging research areas, including tandem architectures (e.g., perovskite-silicon tandems), robust encapsulation techniques, and defect passivation strategies, are pivotal in enhancing long-term operational stability. Additionally, the integration of eco-friendly and energy-efficient manufacturing processes promises to minimize the environmental footprint, driving the technology closer to real-world application. These developments suggest a promising trajectory for PSC commercialization in the renewable energy market.

4 2D materials

The promising applications of 2D materials in domains such as valleytronics, biosensing, electronics, and catalysis have attracted much attention from the scientific community. Layered materials having diverse elemental compositions, such as transition metal MXenes, van der Waals heterostructures, and dichalcogenides, are among the many readily available materials. High carrier mobilities, significant optical and UV adsorption capabilities, mechanical flexibility, favorable thermal conductivity, and superconductivity are just a few of the benefits of 2D materials (Table 1). 111

Fundamental properties of different 2D materials.

| 2D material | ON/OFF ratio | Thermal conductance [Wm−1/K] | Carrier mobility [cm2 V−1 s−1] | Young’s modulus [GPa] | Band gap [ev] | Thermoelectric performance ZT | Fracture strain [%] | Ref. |

|---|---|---|---|---|---|---|---|---|

| Graphene | 5.5–44 | ≈5 × 103 | ≈2 × 105 | 1,000 | 0 | ≈0 | 27–38 | 112 |

| MXene | 103–106 | 10–472 | 0.7 ± 0.2 | 330 ± 30 | 0–3.4 | 0.17–1.1 | – | 113 , 114 |

| MoS2 | 106–108 | 34.5–52 | 10–200 | 270 ± 100 | 1.2–1.8 | 0.4 | 25–33 | 112 |

| WSe2 | 104–106 | 9.7 | 140–500 | 75–195 | 1.2–1.7 | 0.91 | 26–37 | 112 , 115 |

| TiS2 | – | 11.76 | 7.24 | ≈220–270a | 0.02–2.5 | 0.95 | – | 116 , 117 |

| Phosphorene | 103–105 | 10–36 | ≈1,000 | 35–166 | 0.3–2.0 | 1–2.5 | 24–32 | 112 |

| WS2 | 105–108 | 32–53 | 43–234 | 272 ± 18 | 1.3–2.1 | 10−5–10−3 | – | 118 , 119 |

| Antimonene | 104–108 | 15.1 | 0.5–1.2 × 103 | 104 | 0.3–1.5 | 2.15 | 15–32 | 120 , 121 , 122 |

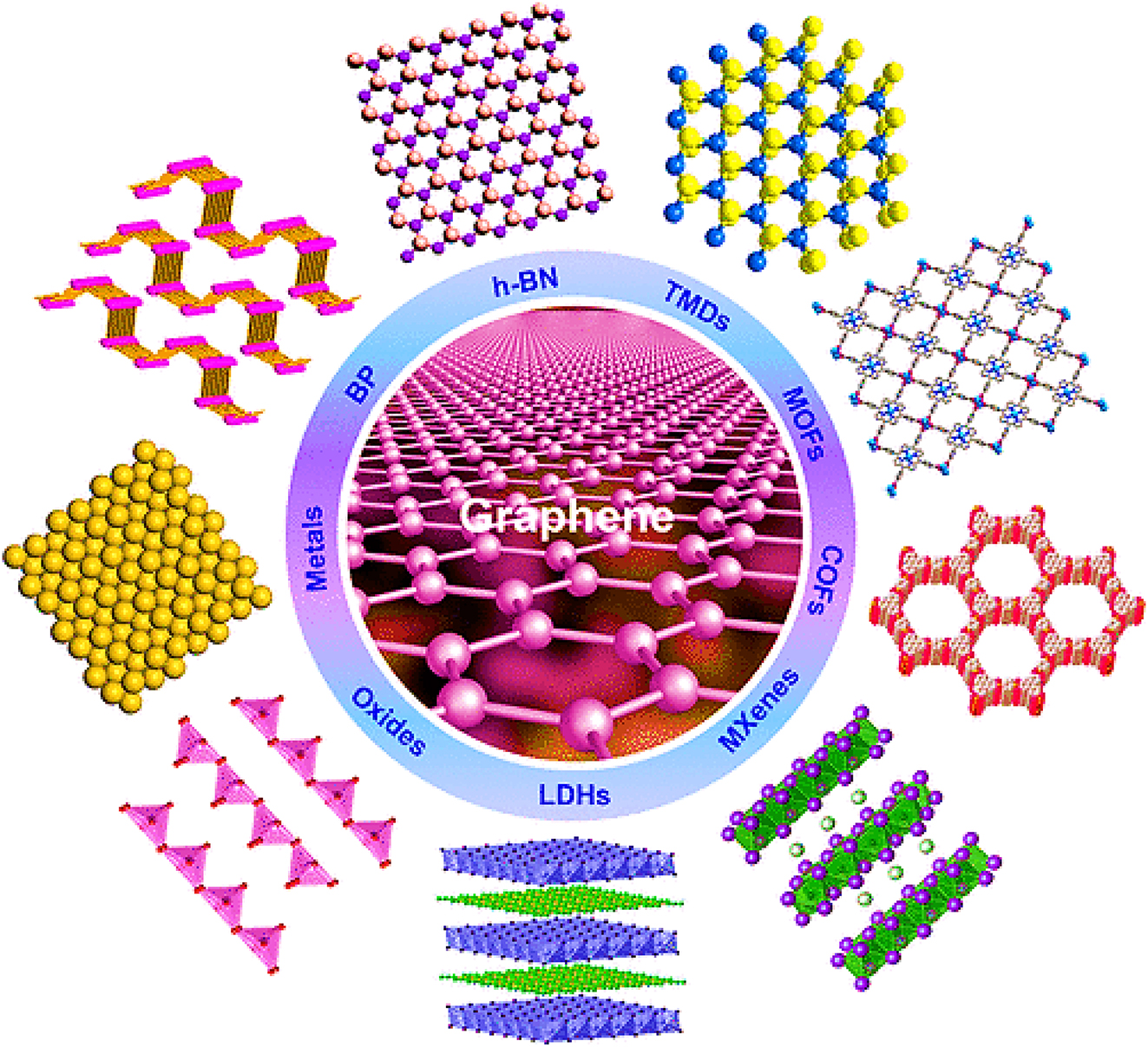

The remarkable physical, optical, and electronic characteristics of graphene have catalyzed our exploration into other 2D nanomaterials that share similar layered structural properties but possess diverse properties. These materials include transition metal dichalcogenides, hexagonal boron nitride such as TiS2, WS2, MoSe2, WSe2, TaS2, MoS2, layered metal oxides, layered double hydroxides, and graphitic carbon nitride. Interestingly, there has been a significant exploration of various novel ultrathin 2D crystals in recent years. These include covalent-organic frameworks, silicene, black phosphorus, MXenes, polymers, metal-organic frameworks, and metals. This exploration has greatly expanded the range of 2D nanomaterials available (Figure 3). In the study of condensed matter, two-dimensional nanoparticles have risen to prominence in physics, chemistry, and materials science due to their distinctive structural characteristics and exceptional capabilities. 123

Schematic illustration showcasing various 2D nanomaterials. Reproduced with permission from 123 . Copyrights (2015), ACS.

4.1 2D materials for PSCs

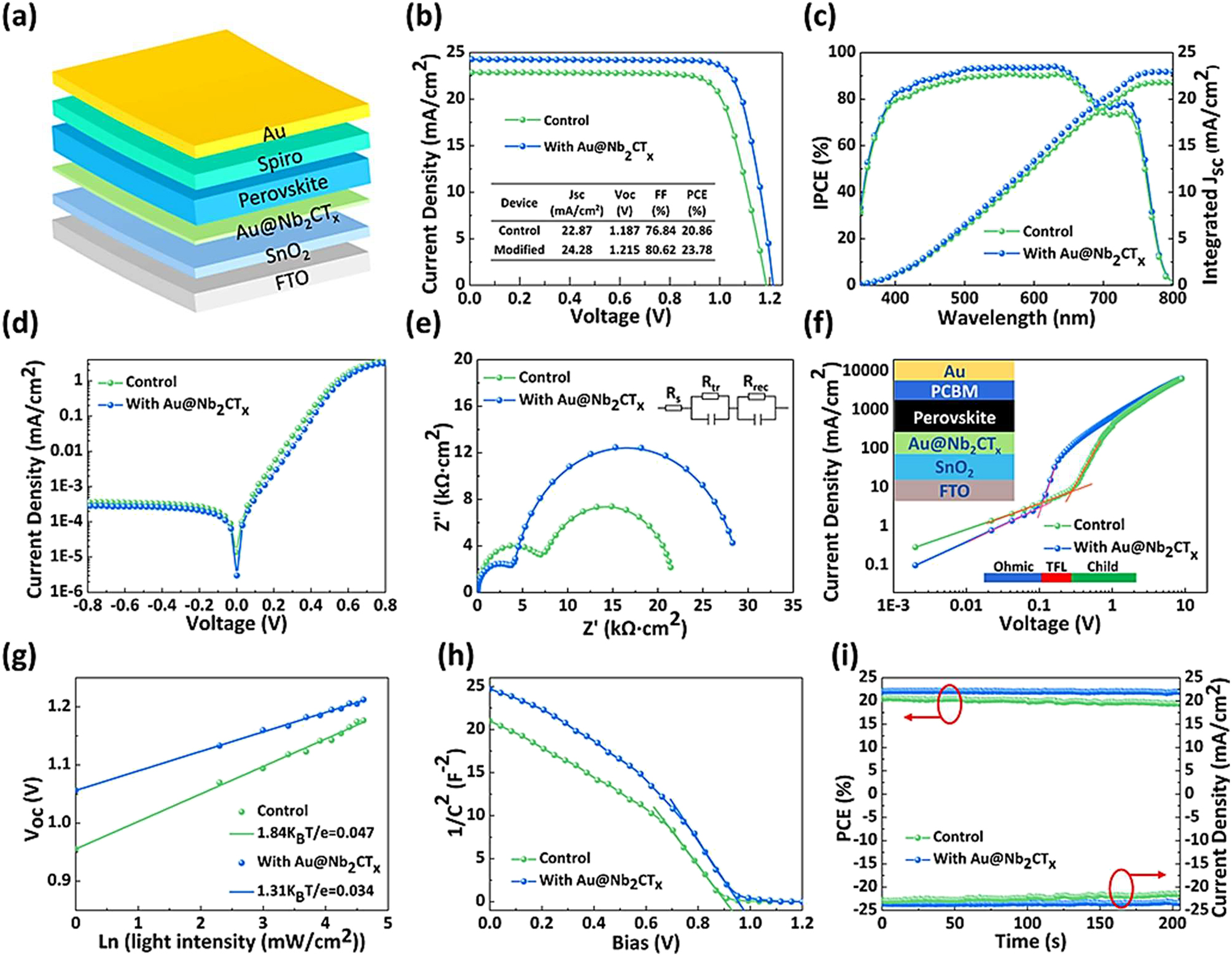

Liu et al. synthesized modified PSC devices using the FTO/SnO2/Au@Nb2CTx-perovskite/MXene/Spiro-OMeTAD/Au architecture (Figure 4a). The SEM picture revealed that the thicknesses of the function layers in PSCs were 550, 45, 550, 150, and 120 nm for FTO, Au@Nb2CTxMXene-modified perovskite, SnO2, Au layers, and Spiro-OMeTAD, respectively. Figure 4b shows the difference between the JV curves of the unmodified and Au@Nb2CTx-MXene devices. The regulating unit has the following specs: Voc = 1.187 V, Jsc = 22.87 mA cm2, FF = 76.84 %, PCE = 20.86 %. The Voc of the Au@Nb2CTx-MXene-modified device was 1.215 V, the Jsc was 24.28 mA cm2, the FF was 80.62 percent, and the PCE was 23.782 percent. Backward and forward scans determine the JV curves of both unmodified and Au@Nb2CTx-MXene-modified devices. Hysteresis is minimized by inserting Au@Nb2CTx-MXene, likely due to improved surface conditions of SnO2 films and improved perovskite film quality. Figure 4c depicts the IPCE spectra of the good PSCs. The computed integrated Jsc values of 21.82 and 22.93 mA cm−2 align with the Jsc values in the J−V measurement. Additionally, the Au@Nb2CTx-MXene-modified device exhibits reduced dark current leakage compared to the control device (Figure 4d), indicating that it slows nonradiative recombination. Au@Nb2CTx-MXene passivates SnO2 substrate surface imperfections, creating a high-quality, high-crystallinity perovskite film that enhances Voc by allowing carrier movement from the layer to the ETL. Figure 3e displays electrode impedance spectroscopy spectra of control and Au@Nb2CTxMXene-modified devices without illumination. The equivalent circuit model is used to fit the EIS spectra of devices. The model includes Rs representing series resistance, Rrec representing carrier recombination, and Rtr representing charge-transfer resistance at the interface. In our scenario, device Rs values are comparable. The upgraded devices may have a lower Rtr value due to increased charge transfer speed at the perovskite/ETL interfaces. Regarding Rrec, the Au@Nb2CTx-MXene-modified device has higher carrier recombination resistance than the control device, indicating increased carrier transportation and reduced nonradiative recombination rate. This finding aligns with PL and TRPL characterizations. In Figure 4f, SCLC was measured using electron-only devices. The connection between Voc and light intensity is shown in Figure 4g. The built-in potential was determined by examining the Mott-Schottky curves (Figure 4h). Next, the control and Au@Nb2CTx-MXene-modified devices were assessed for stable current density and efficiency at maximum output power point circumstances (Figure 4i). Eventually, the device with Au@Nb2CTx-MXene upgrades shows a respectable 23.78 % power conversion efficiency and an unusually high 1.215 V open-circuit voltage (e.g., 1.60 eV). After being stored for 1,000 h in a setting with 40 % air relative humidity, the devices that were not encased showed a power conversion efficiency that was their initial value of 90 %. Furthermore, after 500 h of reaction at full power under 1 sun’s light, the device’s efficiency is still above 80 % of its original value. 124

Series of measurements and analyses of perovskite solar cells (PSCs) modified with Au@Nb2CTx-MXene, including structural, electrical, and performance characteristics. (a) The incorporation of Au@Nb2CTx-MXene has modified the structure of PSCs. (b) J−V curves were measured using the reverse scan mode for both the control and the devices modified with Au@Nb2CTx-MXene. (c) The IPCE spectra of the control and PSCs were modified with Au@Nb2CTx-MXene. (d) The J−V curves of PSCs are shown, comparing those without and with Au@Nb2CTx-MXene. (e) The Nyquist plots of PSCs are displayed here, both without and with Au@Nb2CTx-MXene. (f) J–V curves illustrating the SCLC test using electron-only devices. The picture shows the structure of the devices. (g) Investigating the relationship between light intensity and the Voc of the control and Au@Nb2CTx-MXenemodified PSCs. (h) Plots depicting Mott-Schottky analysis of the control and PSCs modified with Au@Nb2CTx-MXene. (i) The current density and PCE values of the control and Au@Nb2CTx-MXene-modified devices were measured at the MPP for 200 s. 124

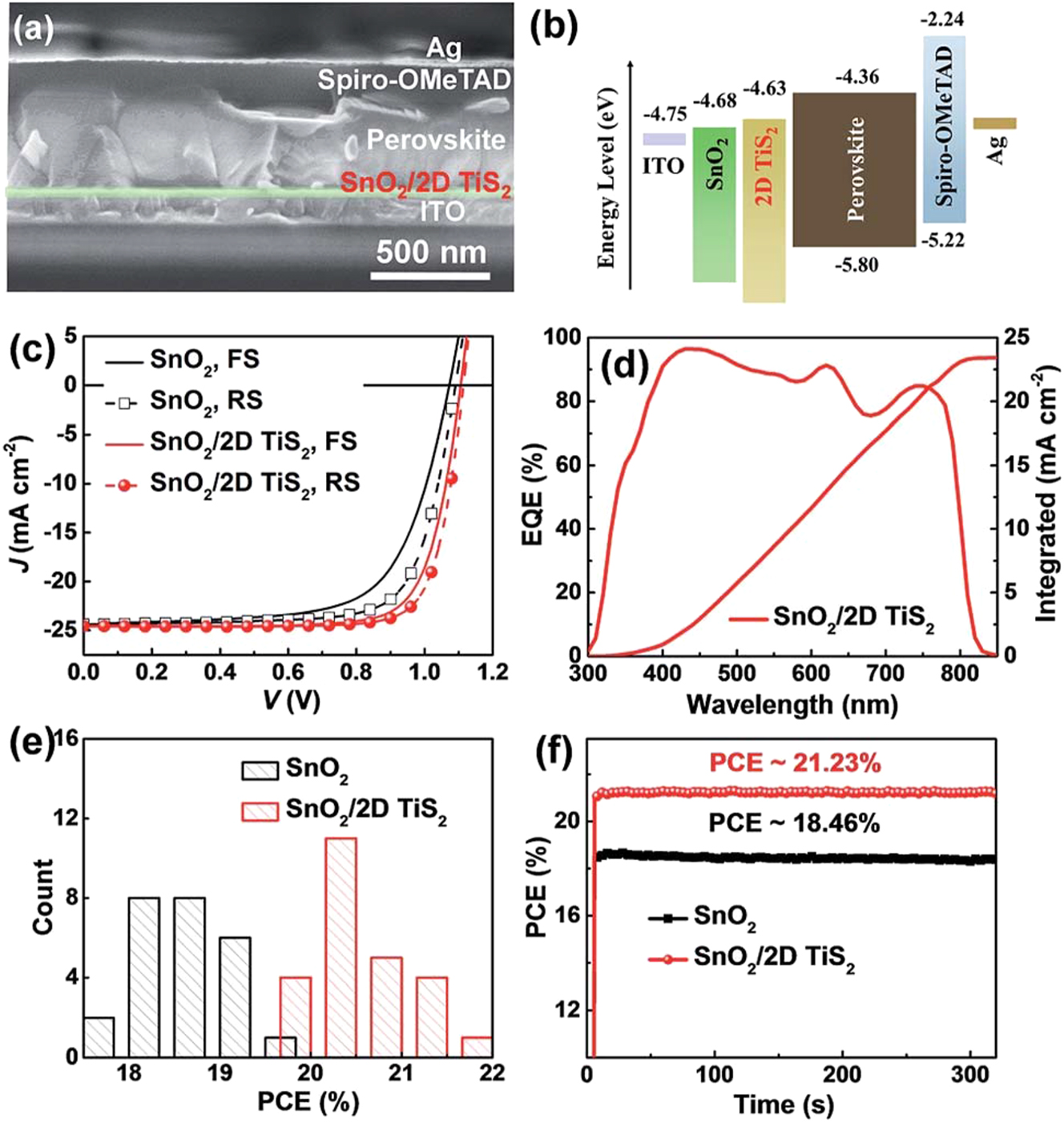

Huang et al. prepared the planar n-i-p perovskite solar cells, which rely heavily on interfacial engineering since it directly impacts charge extraction, transport, and photovoltaic efficiency. This study successfully developed perovskite solar cells with a high-efficiency rate using double structures of SnO2/2D TiS2 as electron transport layers. An example of a scanning electron micrograph picture of a Pero-SC segment is shown in Figure 5a. It was determined that 20 nm was the optimal thickness for the SnO2. Figure 5b depicts a schematic illustration of the energy levels. Figure 5c demonstrates the stark contrast between the forward scan (from 1.2 V to 0 V, FS) and RS curves. Using SnO2/2D TiS2 as the electron transport layer (resulted in the greatest Pero-SC PCE (21.73 %) with a Voc of 1.11 V, Jsc of 24.57 mA cm2, and FF of 79.4 %. Quantum efficiency from the outside, integrated (EQE, Figure 5d) the measured Jsc of 23.42 mA cm2 from the spectrum is quite close to the Jsc calculated from the J–V curves, demonstrating the reliability of these measurements. As shown in Figure 5e, compared to the PCE of Pero-SCs made with just SnO2, the PCE of those made using SnO2/2D TiS2 as the ETL is superior. The average PCE was 20.48 0.50 %. The PCEs of SnO2 and SnO2/2D TiS2-based Pero-SCs were also tested over time at constant voltages of 0.86 V and 0.92 V. As can be seen in Figure 5f, Average PCEs calculated from FS and RS values correlate very well with those obtained by devices using SnO2 and SnO2/two-dimensional/TiS2 as the electron transport layer. The highest power conversion efficiency was 21.73 percent, with an average of 20.48 percent (with a margin of error of 0.5 percent). In addition, the measured hysteresis was minimal. In particular, the lower densities of electron trap states and the alignment of energy levels in the ETL films are likely responsible for the increased performance. This research provided a promising interfacial material and a practical method for reducing the impact of SnO2’s trap states in planar n-i-p Perovskite Solar Cells. 125

Characterization of Pero-SCs with SnO2 and SnO2/2D TiS2 ETLs. (a) Displays a cross-sectional SEM image of the Pero-SC. (b) The diagram illustrates the energy levels. (c) Representative J–V curves of the Pero-SCs with SnO2 or SnO2/2D TiS2 as ETLs are shown. (d) The EQE curve and integrated current density of the Pero-SC with SnO2/2D TiS2 as the ETL are shown. (e) Analyzing the PCE of Pero-SCs with SnO2 and SnO2/2D TiS2 as ETLs, a histogram is generated from 25 cells. (f) The steady-state efficiency of the Pero-SCs using SnO2 and SnO2/2D TiS2 as ETLs was measured under constant voltages of 0.86 V and 0.92 V, respectively. 125

Ji et al. presented the XF2 and XF3 materials, examples of a novel synthesized family of conjugated small molecule hole transport materials with better conjugation in two-dimensional orientations. Researchers used a unique technique by inserting TPA groups into the BDT unit’s side chains to control the molecule’s orientation. According to the results, the – stacking orientation was most common in two-dimensional small molecule HTMs. Through interactions involving Lewis base-acid interactions, the XF3 version, which has functionalized alkoxy groups on the TPA side chains, shows increased hole mobility and enhanced defect passivation on the perovskite surface. Since XF3 is a dopant-free hole transport material, the efficiency of an upgraded photovoltaic solar cell based on this material was 21.44 percent. After being exposed to sunlight for 840 h, the dopant-free XF3 perovskite solar cells maintained 99 % of their initial efficiency. Furthermore, when comparing devices with doped Spiro-OMeTAD to those without, it was shown that both thermal and environmental stability were vastly improved. In general, it can be demonstrated that larger conjugated side chains greatly improve the performance of hole-transporting materials. This result demonstrated the power of the 2D conjugation strategy for creating dopant-free small molecule HTMs. 126

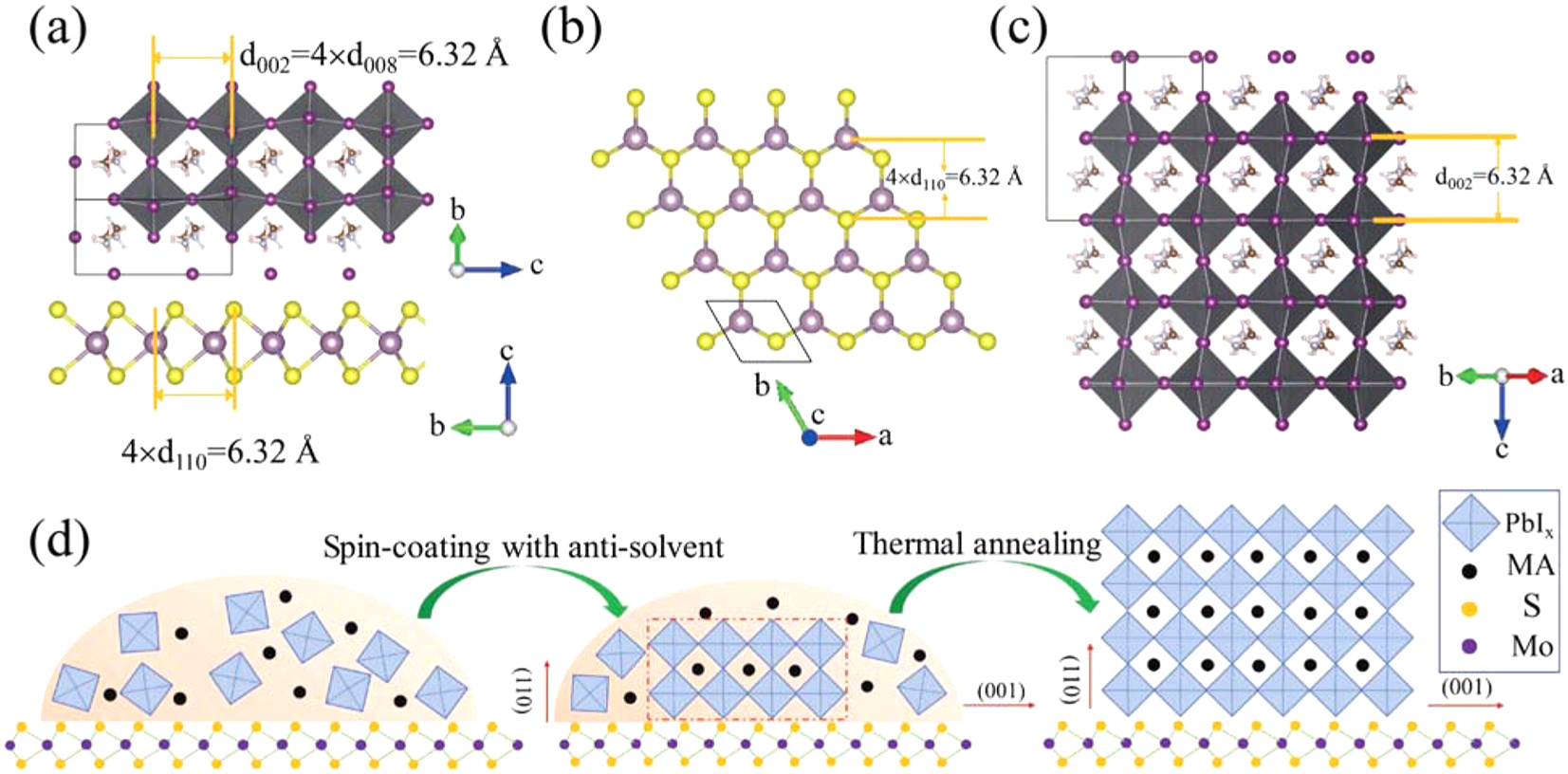

Tang et al. reported that the perovskite layer plays a pivotal role in determining how well perovskite solar cells work. It is difficult to maintain the desired crystallinity and orientation in solution-treated perovskite films. Here, they discussed the solution-phase van der Waals epitaxy development of MAPbI3 perovskite films on MoS2 flakes. Figure 6a–d shows the position and orientation of perovskite and MoS2 atoms in their crystal structures, as determined using electron diffraction analysis. The perovskite films that develop as a consequence of this interaction have larger grains, development is favored in a direction, and rap densities are reduced perpendicular to the surface of MoS2. When the active layers are developed on top of MoS2 flakes coated on hole-transport layers, the power conversion efficiency of perovskite solar cells increases by about 15 %. Two key variables, enhanced hole extraction and transmission at the interface and improved perovskite layer crystallinity, are responsible for this improvement. Using two-dimensional materials as interfacial layers, this research introduces a revolutionary strategy for manufacturing efficient perovskite solar cells and other optoelectronic devices. 127

Atomic crystal structure and epitaxial growth of MAPbI3 on MoS2. (a) Shows a side view of the atomic crystal heterojunction between MAPbI3 and MoS2. (b and c) The atomic crystal structure of the (001) plane of MoS2 (b) and the (110) plane of perovskite is shown. (d) Schematic diagram illustrating the vdW epitaxial growth process of a MAPbI3 grain on a MoS2 surface.

A balanced efficiency in extracting electron transport layer interfaces, as well as PSCs-hole transport layer interactions, can be attributed to the connection between lead sulfide and the microcosmic mosaic structure present at the interface of perovskite crystals and SnS2. Suppressing charge recombination at interfaces is another benefit of this interaction. As a result, 20.12 % PCE was attained by the 2D ETL-based perovskite solar cell. Both the open- and short-circuit current densities were very high, at an astounding 1.161 V and 23.55 mA/cm2, respectively. For the advancement of high-efficiency solution-processed planar perovskite solar cells, which use two-dimensional materials, this study offers crucial background. 128 Table 2 provides a summary of various 2D materials as efficient PSC devices in recent times.

Efficient PSCs use cutting-edge 2D materials.

| Structure of device | Function | Jsc (mA cm−2) | FF (%) | Voc (V) | PCE (%) | Ref. |

|---|---|---|---|---|---|---|

| CsBr–PbI2 | PSCs | 23.394 | 71.80 | 1.030 V | 17.31 | 129 |

| ITO/SnS2/Perovskite/Spiro-OMeTAD/Au | SnS2 – ETM | 23.55 | 0.73 | 1.161 | 20.12 | 128 |

| ITO/SnO2/TiS2/Perovskite/Spiro-OMeTAD/Ag | TiS2 – ETM | 24.57 | 0.79 | 1.110 | 21.73 | 125 |

| ITO/Perovskite/PTAA/PCBM/BCP/Ag/BPQDs/ | BPQDs – active material | 21.90 | 0.83 | 1.100 | 20.00 | 130 |

| PSS/Perovskite/BPQDs/PCBM/Ag: PEDOT/ITO | BPQDs – HTM | 20.56 | 0.80 | 1.014 | 16.69 | 131 |

| Antimonene/PTAA/ITO/PCBM/Bphen/Al/PSCs | Antimonene – HTM | 23.52 | 0.77 | 1.114 | 20.11 | 132 |

| Ti3C2T x | – | 20.87 | 67.84 | 1.11 | 15.71 | 133 |

| ITO/Perovskite-MXene/SnO2/Spiro-OMeTAD/Au | MXene – active material | 22.26 | 0.76 | 1.030 | 17.41 | 134 |

| CT x -MXene-Au@Nb2 | Charge transport layer | 23.58 | 78.75 | 1.220 | 23.78 | 124 |

| ITO/MoS2/Perovskite/PTAA/PCBM/BCP/Ag | MoS2 – HTM | 22.66 | 0.80 | 1.130 | 20.55 | 127 |

| ITO/GO/Perovskite/PEDOT:PSS/PCBM/MoS2/Ag | Graphene oxide – HTM; MoS2 – ETM | 22.83 | 0.74 | 1.135 | 19.14 | 135 |

| Spiro-OMeTAD | HTMs | 24.24 | 78.65 | 1.08 | 21.44 % | 126 |

| SnO2–Ti3C2/ITO MXene/Spiro-OMeTAD/Ag/PSCs |

MXene – ETM | 23.14 | 0.75 | 1.060 | 18.34 | 136 |

| FTO/TiO2–phosphorene/Perovskite/Spiro-OMeTAD/Au | Phosphorene – ETM | 23.32 | 0.71 | 1.080 | 17.85 | 137 |

5 3D materials

The architectures of 3D nanomaterials are characterized by the presence of linked macro/mesopores, which effectively hinder the processes of aggregation and restacking. This nanomaterial has the most accessible surface area compared to other nanomaterials. Several scholarly sources have shown further benefits of 3D nanomaterials. 138

Macro and mesoporous channels facilitate the exposure of internal surfaces and enable the entry of molecules and ions into the empty spaces. This facilitates the use of applications such as catalysis, medication delivery, sensing, and other related fields.

The presence of a porous structure facilitates a significant increase in the loading capacity of functional components, such as catalyst particles or medicines.

The presence of pores gives rise to confinement effects, which can influence chemical and physical characteristics.

An inner empty space facilitates the transportation of mass inside the three-dimensional structure.

The three-dimensional morphology of nanoparticles enhances their mechanical stability compared to nanomaterials with one-dimensional or two-dimensional structures.

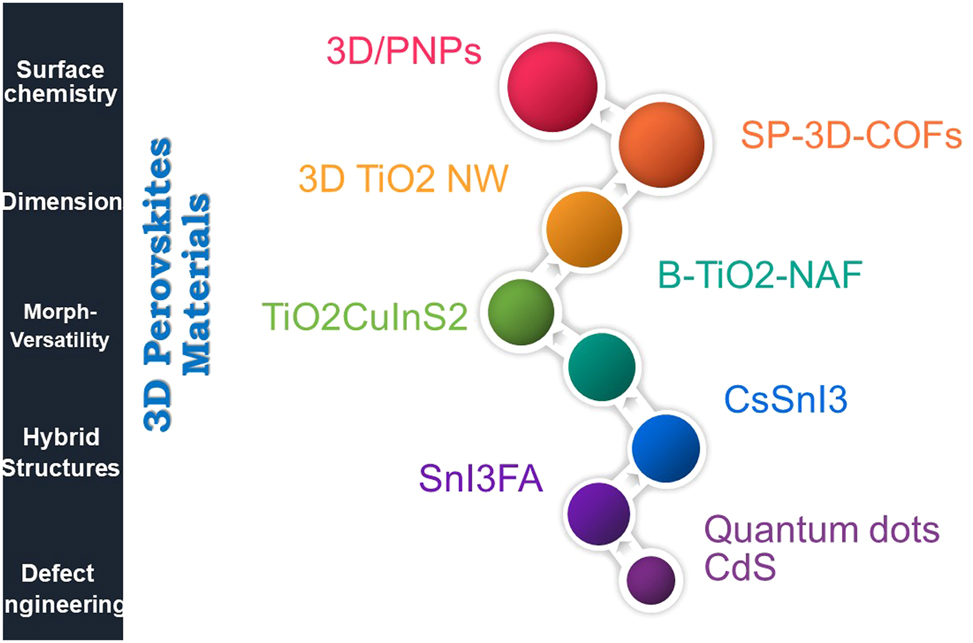

Further points of comparison regarding the structural merits of 3D nanomaterials with alternative dimensionalities include the following (Figure 7). 139 , 140 , 141

Structural properties modification of 3D materials.

Surface chemistry: The expansive surface area shown by 3D nanomaterials affords enhanced prospects for customizing surface chemistry through functionalization. There is an increased availability of binding sites that can be modified with target molecules.

Dimensions: The dimensionality of nanomaterials may be effectively controlled, allowing for the intentional construction of three-dimensional structures with precise macro/mesoporosity and interconnected pores. This enables the adjustment of the three-dimensional configuration to achieve certain characteristics.

Morphological versatility: The morphological plasticity of 3D nanomaterials allows for their synthesis in a diverse range of forms, including spheres, tubes, and gyroids, among others. This enables the process of optimizing forms to suit various purposes.

Hybrid structures: Hybrid structures are characterized by their three-dimensional porosity network, which facilitates the integration of various components to generate hybrid nanomaterials. An instance of this would be the integration of 3D graphene with metal nanoparticles.

Defect engineering: Defect engineering refers to deliberately manipulating flaws in 3D nanomaterials to control and modify their reactivity. The increased surface area in these nanomaterials offers a greater scope for implementing defect engineering strategies.

In brief, these nanoparticles’ distinctive three-dimensional porous structure confers significant benefits, including a substantial accessible surface area, adjustable void spaces, improved mass transmission, high loading capacity, and exceptional mechanical stability. These advantages provide a wide range of applications across several disciplines. Moreover, the distinctive architectural benefits of 3D nanoparticles provide enhanced structural manipulation, multifunctionality, synergistic effects, processability, and optimization of performance in comparison to nanomaterials of various dimensionalities.

5.1 3D materials for PSCs

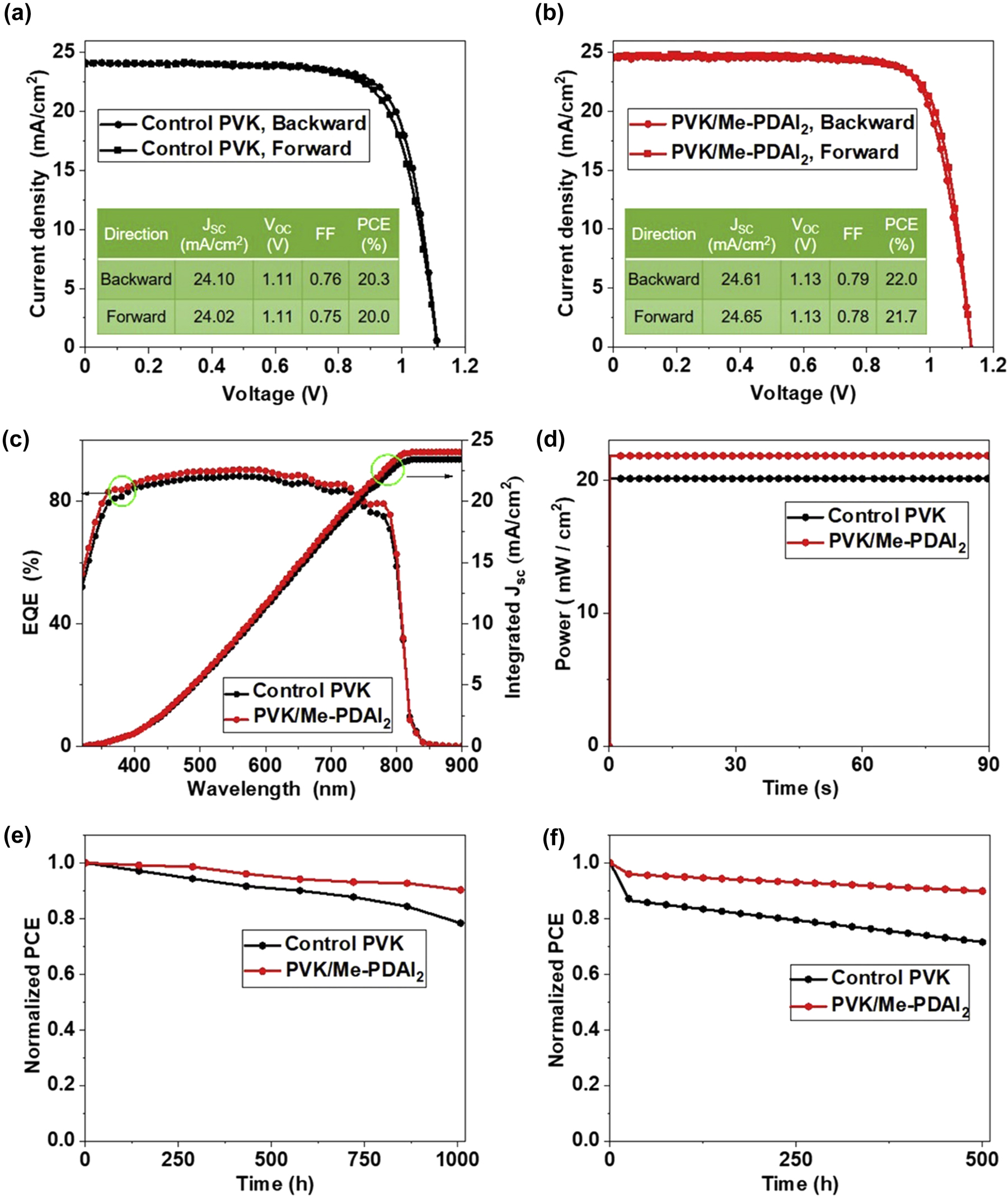

Zhang et al. demonstrated that a 3D structured perovskite, namely (MePDA)Pb2I6, may be used as a surface-modification layer on top of a more typical 3D perovskite material. In Figure 8a and b, under simulated one-sun (AM 1.5 G) illumination, both the unmodified and Me-PDAI2-enhanced PSCs’ photocurrent density-voltage curves are shown, with the relevant PV parameters listed in the insets. Figure 8c shows that the Jsc values from the J–V observations are in excellent agreement with the external quantum efficiency spectra that correspond to the integrated current densities. Figure 8d shows the stabilized power outputs, which are in good agreement with the J–V measurements, at 20.1 % and 21.8 % for the unmodified and Me-PDAI2-modified PSCs. Un-encapsulated PSCs have a shelf life of two to four years in room temperature air with a relative humidity of 20%–40 %, as shown in Figure 8e. Me-PDAI2-modified PSCs had a 90 % reduction in PCE after 1,008 h, whereas control PSCs had a 22 % decrease. Maximum power point tracking in N2 is displayed in Figure 8f, in addition to the results of ISOS/L stability testing on devices without enclosures in normal use conditions. Perovskite thin films had improved features after having their top layer, generated as the initial three-dimensional perovskite, transformed into a perovskite. The enhanced carrier lifetimes, enhanced carrier motilities, and decreased surface defect densities demonstrate this enhancement. They increased the device’s effectiveness from around 20 %–22 % using the aforementioned way while also maintaining its steadiness. After 500 h of maximum power point monitoring under constant one-sun illumination, 90 % of the device’s initial value remained intact. Several other types of perovskite compositions, i.e., FAMA-, Perovskites of lead halides based on MA, and CsFAMA– have been shown to benefit from the surface engineering method we have described. 142

J–V curves of PSCs using the (a) control and (b) Me-PDAI2-modified perovskite films. (c) (d) EQE spectra and integrated current curves of the corresponding devices and SPO. (e) (f) Comparing the stability of shelf ISOS-D−1 at room temperature with 20%–40 % relative humidity and the stability of operation ISOS-L−1. 142

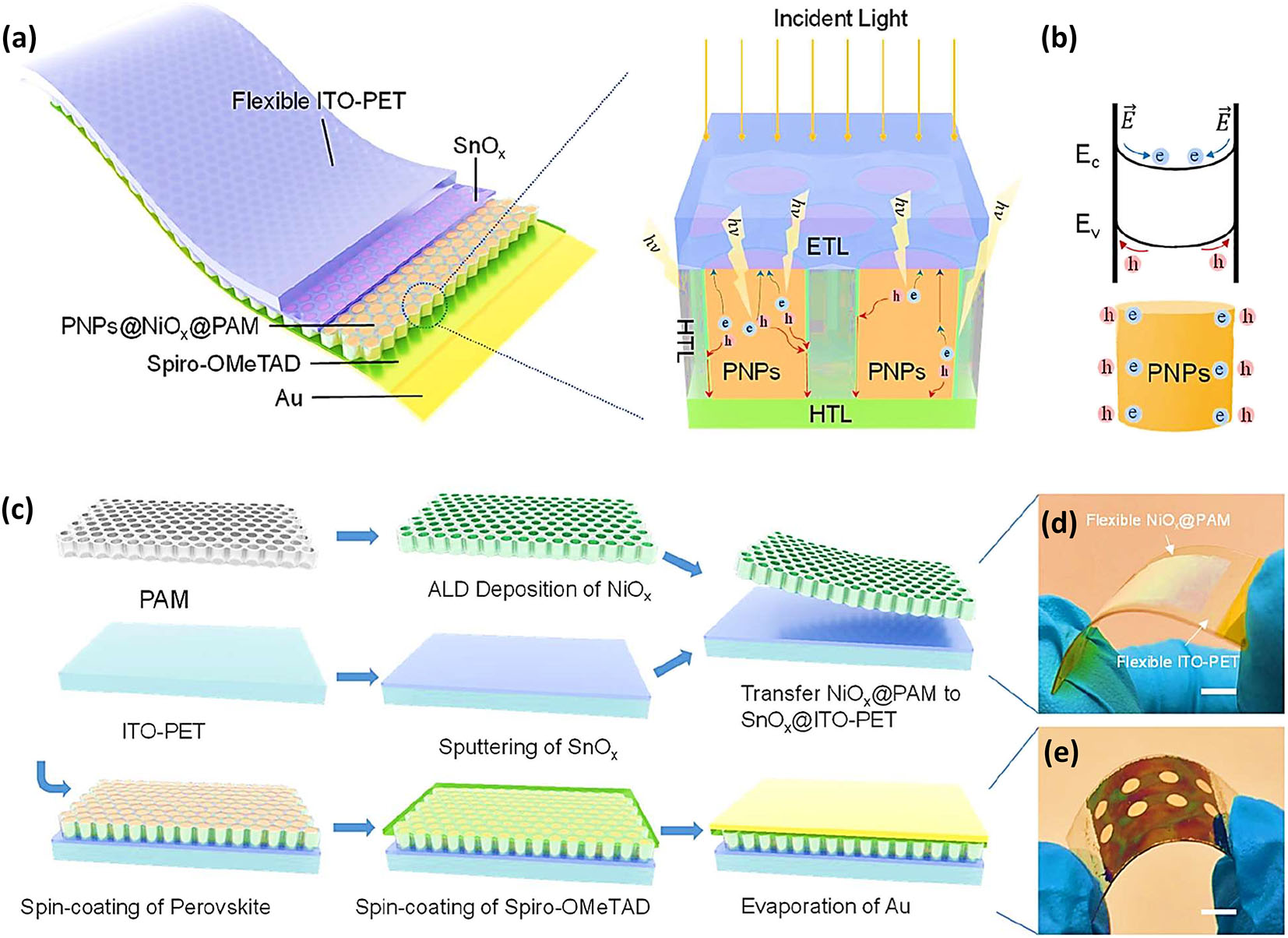

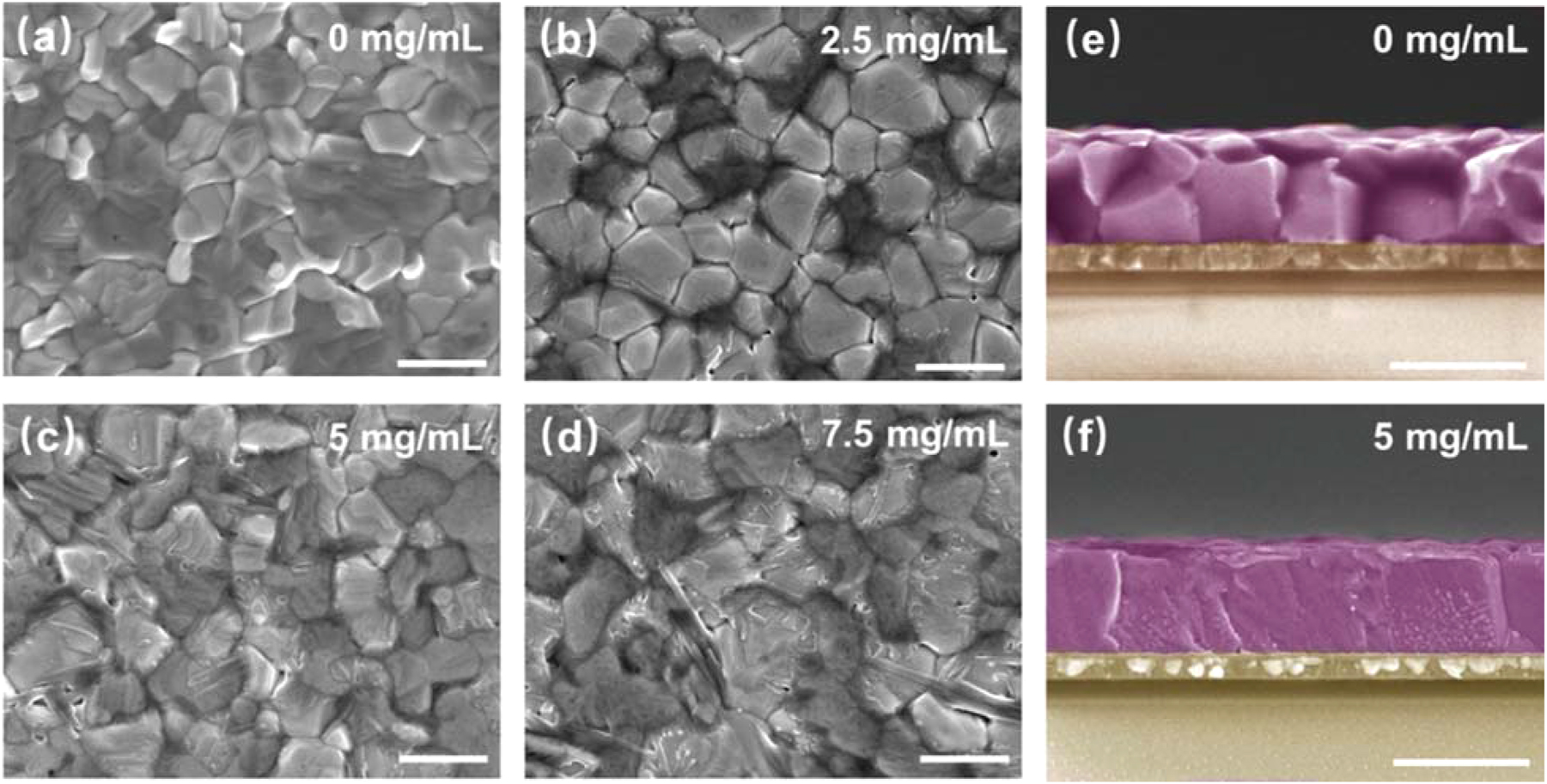

Zhu et al. presented that perovskite nanopillars can replace thin films in flexible photovoltaic applications because of their advantageous properties for solar energy absorption, as shown in Figure 9a–e. To maximize daily energy output, photovoltaic systems must absorb light from the sun at a broad range of incidence angles and in the whole spectrum of usable wavelengths. A comprehensive evaluation of core-shell-based 3D PNP-based flexible photovoltaics was performed. At their peak performance, the vertically oriented PNP arrays absorb at a rate of 95.70 and 75.10 percent, respectively, when the incidence angle is set to 60°. Broadband wavelength external quantum efficiency is improved by efficient absorption and orthogonal carrier collecting techniques to a range of 84.0%–89.18 %. PNPs have been successfully used in flexible solar cells. With a porous alumina barrier protecting PNPs from oxygen and water, photovoltaic systems may last longer and be less likely to break down. Novel PNP-based technology has extraordinary mechanical stress and strain resistance enabling efficient solar-to-electricity conversion even when bent. 143

Structure, fabrication, and implementation of PNP-based solar cells. (a) Complete structure diagram and cross-sectional schematic diagram of PNP-based solar cells. (b) The schematic band structure of the PNP crystal surface showcases the formation of a built-in electric field. (c) A schematic illustration depicting the fabrication procedure for PNP-based devices. (d) Photographs showing the implementation of NiOx-coated PAM (NiOx@PAM) on the SnO2-coated ITO-PET (SnO2@ITO-PET) and (e) the complete device. 143

Chen et al., 2022 synthesized by using a post-treatment, a one-dimensional PbI2(Phen) adduct phase was successfully incorporated into a three-dimensional perovskite. The structural and optoelectronic features of the underlying three-dimensional film were not noticeably altered by the presence of a one-dimensional structure on surface. The passivation of the surface of the 1D-3D perovskite film led to a reduction in trap density compared to the 3D perovskite film. In a three- and one-dimensional perovskite solar cell, the greatest power conversion efficiency ever reported was 23.3 %. The perovskite film showed improved endurance in a range of environmental conditions when made of several components. For 1D structures, the protective covering performed a dual purpose as a capping against ion movement. The one-dimensional/three-dimensional structural photovoltaic device was more stable than its three-dimensional counterpart because of its simpler design. This research shows that mixed-dimensional engineering may be used to make superior perovskite films, which might hasten the development of perovskite solar cells for a wide range of uses. 144

Gao et al., 2023 stated that due to its excellent performance features, a lot of people are interested in the organic-inorganic hybrid perovskite solar cells that have been developed lately as a potential new direction for next-generation photovoltaic systems. However, the interfacial stability of these materials is poor, which limits their marketability. Improving stability is a major area of focus in the sciences today. The purpose of this research was to find a solution to this problem by synthesizing a bilayered titanium dioxide nanorod array-flower for use in hybrid perovskite solar cells as an electron transport medium. The lowered electron trap density, reduced carrier recombination resistance, improved electron injection, and reduced nonradiative recombination rate all contribute to the B–TiO2-NAF device’s impressive 21.8 % power conversion efficiency. The internal photoexciton diffusion distance is decreased when B–TiO2-NAF is used because it provides a uniform D/A interface in all three dimensions. With an efficiency that remains at over 83 % after 30 days, the gadget clearly exhibits outstanding long-term stability. Our study’s findings might aid in the development of 3-D semiconductor materials and provide new light on how to improve the durability of perovskite solar panels. 145

Jing et al., 2022 presented the growing single crystal anatase three-dimensional-TiO2 electron layer transport on FTO substrates hydrothermally using a TiF4 solution, which has shown to be an efficient method. When compared to devices using carbon-TiO2 electron transport layers produced with TiCl4 solution, the photovoltaic performance of CsPbIBr2 perovskite solar cells employing 3D-titania electron transport layers is dramatically improved. When a three-dimensional titanium dioxide electron transport layer is added to a CsPbIBr2 perovskite solar cell, the power conversion efficiency may reach 10.65 percent. The device employing the widely used Spiro hole transporter and gold electrode produces a PCE of 10.79 %, making this PCE similar. Furthermore, the power conversion efficiency of the CsPbIBr2 PSC with 3D-TiO2 ETL is much greater than that of the device, including a titanium dioxide ETL made using a titanium tetrachloride solution, which reaches 8.38 %. In particular, the three-dimensional titania electron transport layer is effective in blocking harmful ultraviolet light. This quality effectively counteracts the main shortcoming of conventional TiO2 ETLs, which is their sensitivity to ultraviolet light. This makes it easier to create cesium lead iodide bromide perovskite solar cells, which are very resistant to the effects of sunlight. Not only are devices with 3D-TiO2 electron transport layers resistant to dampness and heat, but they also perform well in these environments. Therefore, the use of 3D-TiO2 ETLs might be a promising strategy for the development of high-performance and long-lasting all-inorganic perovskite solar cells. 146 Table 3 provides a summary of various three-dimensional materials as efficient PSC devices in recent times.

3D material-based for perovskite solar cell.

| 3D material | Band gap | PCE (%) | Voc (V) | FF (%) | Jsc (mA cm−2) | Main approach | Ref. |

|---|---|---|---|---|---|---|---|

| ITO/SnO2/perovskite/Spiro-OMeTAD/Ag | 2.51 | 23.3 | 1.08 | 80.7 | 24.9 | Two-step deposition method | 144 |

| SnI3/FA | – | 10.81 | 0.69 | 75.00 | 21.59 | Iodine-pentafluorobenzene-oxyethyl ester | 147 |

| SP-3D-COFs | 16.70 | 1.028 | 72.1 | 22.50 | Annealing | 148 | |

| Me-PDAI2 | 22.0 | 1.00 | 90.3 % | 52.8 | Vapor deposition | 142 | |

| 3D/PNPs | – | 89.18 | 0.97 | 79.01 | 21.19 | Two-step anodic anodization method | 143 |

| 3D-TiO2NW | – | 4.0 | 0.71 | 0.63 | 12.2 | PCVD with a restricted surface reaction rate | 149 |

| B–TiO2-NAF | – | 21.8 | 1.11 | 82 | 23.1 | Electrochemical deposition | 145 |

| FA/SnI3 + Br/PEA | – | 14.63 | 0.91 | 77.10 | 20.60 | Single-step SnI2.DMSO synthesis | 150 |

| CsPbBr2/TiO2/PSCs | 2.3 | 25.5 | 2.01 | – | – | Hydrothermal | 146 |

| SnI3FA0.75 MA0.25 | 1.37 | 10.30 | 0.63 | 75.50 | 21.62 | Vacuum treatment | 151 |

| Quantum dots CdS | 2.25 | 8.50 | – | – | – | Grafting route | 152 |

| FA0.75SnI3 MA0.25 | 1.31 | 9.26 | 0.58 | 72.81 | 21.93 | Hydrazine dihydrochloride additive | 153 |

| CsSnI3 | 1.31 | 10.10 | 0.64 | 72.10 | 21.81 | Band alignment by localized electron engineering using a phthalimide additive and an indene-C60 disadduct | 154 |

| FAI3Sn | 1.40 | 7.53 | 0.53 | 65.80 | 21.80 | Polyethylene glycol scaffold | 155 |

| SnI3FA | 1.35 | 7.40 | 0.60 | 65.00 | 16.45 | Iodine-pentafluorobenzene-oxyethyl ester | 156 |

| FA0.75SnI2MA0.25Br | – | 6.02 | 0.56 | 65.00 | 16.66 | Catechin dopant/antioxidant | 157 |

| GeI2doped (EA0.1FA0.90)SnI3 EDA0.01 | 1.42 | 13.24 | 0.84 | 78.00 | 20.32 | GeO4 surface passivation, bandgap alignment by EA doping, and protection | 158 |

| TiO2CuInS2 | 1.55 | 5.0 | 0.53 | 0.55 | 17 | Chemical spray deposition | 159 |

| FA0.75SnI3 MA0.23 |

1.36 | 11.50 | 0.76 | 69.00 | 22.00 | Sn nanoparticles in a precursor solution, and then EDA and PC61BM were applied to their surfaces. | 160 |

6 2D/3D heterojunctions

The formula for 2D-3D multi-dimensional mixed-halide perovskites is M2An 1BnX3n + 1, where M is an inorganic cation such as methylammonium/formamidinium/Cesium; A is an organic cation such as methylammonium/formamidinium/Cesium; B refers to tin or lead; halide anion represents by X (Cl, Br, or I); and n = number of metal halide sheets, whereby the solution’s precursor composition is used to roughly predict n values. 161 For 3D perovskites, n = ∞ is the limit, but for 2D halide perovskites, n = 1 is the case. In phase-pure crystals containing n-member perovskite, the decrease in thermodynamic stability of larger n-members as n increases has a profound effect on the development of specific n-layer isolation in the pure form and can even lead to the mixture of products. 162 It is worth noting that for large n values, such as n = 30, 40, 50, or 60, a mixture of low n-member phases (n 3) and 3D perovskites may form owing to the presence of organic/inorganic molecules as a spacer. It is difficult to get exceptionally pure samples by devising in situ processes due to the kinetically rapid, self-assembled, and controlled nature of n-membered perovskites during the thin-film production from the solution process. Therefore, such 2D-3D perovskites are often described by their M-molar percentages, as in M/(A+ M), rather than by n numbers. 163

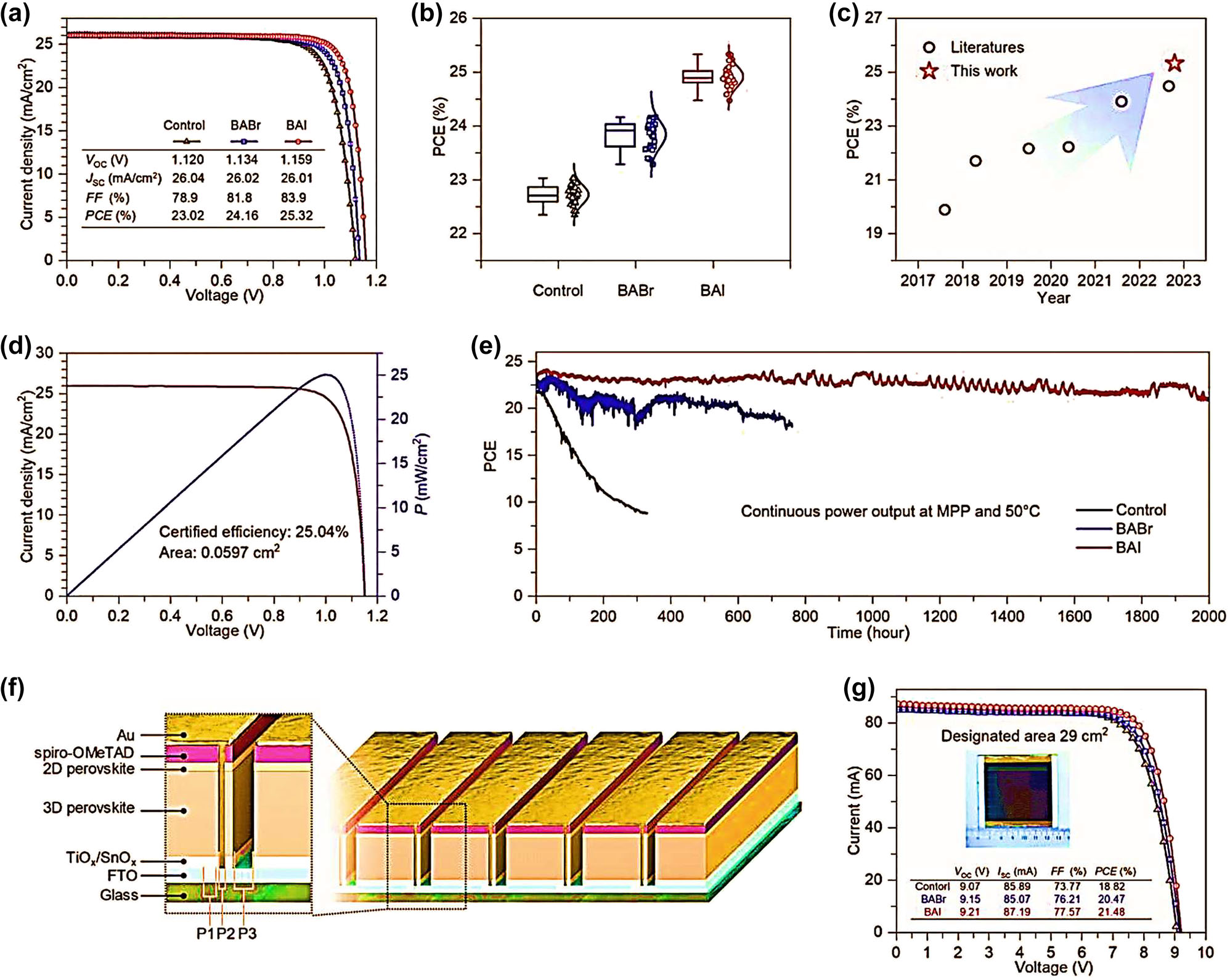

Conventional PSCs, such as a perovskite-perovskite heterojunction, were modeled using device physics to examine chemical- and field-effect passivation processes. They found that a 0.2 eV energy offset (bi) for the perovskite junctions significantly improves the interface’s defect tolerance, requiring less preparation time and effort. Figure 10a displays photovoltaic characteristics and J–V curves for the best devices in each category of PSCs. The control PSC’s PCE, Jsc, Voc, and FF are all below 80 %. The control PSC’s Voc is just 1.120 V. The BABr and BAI PSCs have a high PCE (24.16 % and 25.32 %), a low V OC (1.134 and 1.159 V), and a remarkable FF (81.8 % and 83.2 %). At a constant rate of change, the PCE for these three was 22.57 %, 23.84 %, and 25.04 %. Success in achieving a PCE of 25.32 (Figure 10b and c) is an all-time high for 2D/3D perovskite-based PSCs. An authorized lab confirmed it by testing a BAI-based 2D/3D PSC. Figure 10d displays the results of the tests, which revealed a PCE of 25.04 %, a high Voc of 1.152 V, a wonderful Jsc of 25.986 mA cm2, and a fantastic FF of 83.68 %. By monitoring the devices’ output power under constant illumination (100 mW cm2) and at MPP circumstances, we could gauge the reliability of their long-term functioning. In under 100 h (T80), the PSC in the control group had degraded to 80 % of its original PCE. The T80 stability of a PSC based on BABr with 2D/3D heterojunctions was increased to 500 h. Notably, after 2000 h of operation (T90 = 2000 h), 90 % of the original values of BAI-based PSCs with 2D/3D heterojunctions remained unchanged. They were also employed to build PSC modules to investigate the perovskites’ performance in large-area devices (Figure 10f). Figure 10g shows that the best BAI-based PSC module achieved a Jsc of 2.83 mA cm2, an FF of 80.3 %, a Voc of 9.416 V, and a PCE of 21.39 %, while the average PCE of 16 PSC modules exhibited comparable improvements in PCE (Table 4).

Performance and characterization of 2D/3D PSC devices and modules. (a) Highlighting the impressive performance of the 2D/3D PSC devices and modules. Graph showing the J–V curves of the champion cells. (b) PCE statistics of 34 cells for each type. (c) Displays the power conversion efficiencies of 2D/3D perovskite-based photovoltaic solar cells (d) J–V and P–V curves certified by the Photovoltaic and Wind Power Systems Quality Test Centre, IEE, Chinese Academy of Sciences for the BAI-based 2D/3D heterojunction PSCs. (e) Photovoltaic cell efficiency of the photovoltaic solar cells under continuous illumination at maximum power point operating conditions. (f) A schematic of the PSC modules with nine sub-cells connected in series. (g) Graph showing the J–V curve of the champion PSC modules tested with an aperture mask of 29 cm2. 164

PSCs based on 2D-3D mixed-perovskite absorbers and their efficiency and stability.

| Perovskite | Voc/V | FF | PCE% | Jsc/mA cm−2 | Stability | Device structure | Ref. |

|---|---|---|---|---|---|---|---|

| PSCS-MEMI | 1.106 | 0.802 | 22.41 | 25.27 | 7.5 % after aging in the dark air condition for 300 h | FTO/TiO2/Rb0.02(FA0.95Cs0.05)0.98PbI2.91Br0.03Cl0.06(3D)/2D-PVK/Spiro-OMeTAD/Ag | 165 |

| PbI2:MAI:AnI (1:0;8:0.2) | 1.04 | 0.60 | 15.96 | 25.55 | NA | ITO/PEDOT:PSS/perovskite/PCBM-61/BCP/Ag | 166 |

| (BzDA)(Cs0.05MA0.15FA0.8)9– Pb10(I0.93Br0.07)31 (n = 10) | 1.02 | 0.71 | 15.6 | 21.5 | 80 percent PCE in 84 h of darkness and 20–50 percent RhB | TiO2/m-TiO2/PVK/FTO/c/spiro-OMeTAD/Au | 167 |

| MA39CA2Pb40I121 (n = 40) | – | – | 6.6 | – | After 264 h in the dark at 77 % RH, PCE is 59 %. | PVK/SnO2/spiro-OMeTAD/ITO/Au | 168 |

| Gua0.1/Pb(I0.83Br0.17)3/[Cs0.1(FA0.83MA0.17)0.9]0.9/ | 1.19 | 0.75 | 21.21 | 23.66 | 100 % OF PCE after 500s | ITO/SnO2/PVK/spiro-OMeTAD/MoO3/Ag | 169 |

| (DA2PbI4)0.05MAPbI3 | 1.05 | 0.79 | 19.09 | 22.95 | After 60 days, 80 % of PCE is in the dark. | spiro-OMeTAD/TiO2/PVK/ITO/MoO3/Ag | 170 |

| [Pb(I0.83Br0.17)3) (FA0.83MA0.17)Cs0.05] | 1.1 | 79.68 | 20.23 | 23.08 | A PCE of 21.4 % and excellent background air condition consistency over 1,000 h | – | 171 |

| 0.91Pb(I0.6Br0.4)3 BA0.09(FA0.83Cs0.17) | 1.18 | 0.73 | 17.2 | 19.8 | After 1,000 h in the dark and air, 80 % PCE | SnO2/FTO/PC61BM/spiro-OMeTAD/PVK/Au | 172 |

| FA/MA/Cs | 1.085 | 79.2 | 19.8 | 23.3 | 25 % of PCE after 5,000 h under illumination and in dark | – | 173 |

| (AVA2PbI4)0.03(MAPbI3)0.97 (Cell) | 0.857 | 0.59 | 23.60 | 10.10 | PCE reached 100 % after 10,000 h at 55 °C with continuous light exposure | FTO/TiO2/ZrO2/PVK/C | 163 |

| PEI2PbI4)x(MAPbI3)1 − x | 1.11 | 0.67 | 11.01 | 15.01 | 78.5 % after 160 h in RH 55 % | PEDOT/ITO/Ag:PSS/PVK/BCP/PCBM | 174 |

| PSCs-PTAA | 1.125 | 25.96 | 24P.6 % | 84.32 | Initial PCE of under LED light and N2 environment | – | 29 |

| ACI | – | – | 22.26 | – | 93.81 percent PCE over 1,200 h at 25 degrees C and 25 % relative humidity. | TiO2/PVK/spiro-MeOTAD/Au-FTO/c | 175 |

| PbnI3n + 1 (BA)2(MA)n − 1 | 1.11 | 0.78 | 19.56 | 22.49 | 96.5 % at 95 °C in the absence of light after 100 h | PTAA/Cu/PVK/ITO/PCBM/C60/BCP | 176 |