Investigating sapwood and heartwood density changes of short rotation teak wood after chemical and thermal modification using X-ray computed tomography

-

Resa Martha

and Philippe Gérardin

Abstract

Differences in characteristics between sapwood and heartwood of short-rotation teak are a significant obstacle to valorize mixed boards containing both types of wood. Chemical and thermal modifications are attractive methods to improve the quality of short rotation teak wood allowing homogenization of both sapwood and heartwood properties like decay resistance, dimensional stability and color. However, no data are available on the difference in density between sapwood and heartwood of short-rotation teak, as well as on the effect of such treatments to achieve homogeneity. Density profiling is important to assess the homogenization of the modification process of chemically and thermally modified wood. The objective of this study was to determine the effect of chemical and thermal modification on the density profile of sapwood and heartwood of short rotation teak from pith to the bark using X-ray computed tomography (XCT). The chemical and thermal modifications applied were furfurylation (FA), thermal modification at 150 and 220 °C, and a combination of glycerol-maleic anhydride (GMA) impregnation and thermal modification at 150 and 220 °C. XCT was used to investigate the density variation of short rotation teak wood before and after chemical and thermal modification. A registration process using Avizo software was applied to overcome the deformation effects due to chemical and thermal modification treatments. The results show that the vessel diameter increased after FA treatment due to polymer-induced swelling, while it decreased after GMA220 treatment due to vessel collapse caused by thermal effects. FA treatment increased the density of short rotation teak wood, and the density profile changes were rather uniform. There was a decrease in density due to thermal and GMA treatments, with a significant difference in density changes between sapwood and heartwood. The density profile allowed to observe the homogeneity of sapwood and heartwood density according to the applied treatment. Chemical and thermal modification showed weak effect on the homogenization of the density profile between sapwood and heartwood.

1 Introduction

Fast-growing plantation wood can be considered as a renewable resource and much needed in a green economy, as its use may lead to the protection of natural forests from over-exploitation and provides an alternative solution to the wood products industry for expanding the global wood supply. However, most fast-growing wood species are characterized by a low density, high dimensional instability, and low durability, therefore with limited end-use applications (Bektaş et al. 2020; Rahayu et al. 2022; Yan et al. 2014). One of the solutions to improve the properties of fast-growing wood is chemical and thermal modification. Improving biological resistance and dimensional stability can be obtained through chemical modification depending on the adequate distribution of reacting chemicals into the wood structure (Hill 2006). Many previous studies have reported that chemical modifications, such as acetylation, furfurylation, and DMDHEU (1,3-dimethylol-4,5-dihydroxyethylenurea) can improve dimensional stability, mechanical properties, and resistance against decay and termite (Dong et al. 2016; Hadi et al. 2020; Lande et al. 2004; Li et al. 2009, 2019). In parallel to chemical modification, thermal modification can reduce hygroscopicity (Belt et al. 2024; Hill et al. 2021), increase decay and weathering resistance (Candelier et al. 2015; Marcon et al. 2023; Pratiwi et al. 2019), and improve dimensional stability (Esteves and Pereira 2009; Martha et al. 2021b). Recently, a combination of chemical and thermal modification has been reported to improve the properties of fast-growing wood particularly dimensional stability and durability (Basri et al. 2022, 2024; Martha et al. 2021a,c; Mubarok et al. 2019). Moreover, it has been shown that several technological properties of short rotation teak sapwood and heartwood like decay resistance, dimensional stability or color can be homogenized after different impregnation treatments (Martha et al. 2024). Due to the chemical modification, the differences in impregnability between sapwood and heartwood allows also to envisage wood density homogenization due to higher uptake of sapwood versus heartwood. The density profile in wood containing sapwood and heartwood is very important to see the homogenization of the modification process performed and consequently its effect on the properties of modified wood.

Wood density is one of the most important physical properties since it is strongly correlated to other wood properties such as shrinkage and strength (Yu et al. 2017; Zhang et al. 2021). There are several methods of measuring wood density yet for a more detailed study comparing the density profile before and after treatment, such as intra-ring density analysis from pith to bark, more sophisticated equipment such as X-ray computed tomography (XCT) scanning is required (De Mil et al. 2016; Gaitán-Alvarez and Roque 2019; Jacquin et al. 2019; Vannoppen et al. 2017). XCT scanning is a good method to obtain wood density profiles non-destructively, with high acquisition speed, and to provide 3-D images of materials giving a large field of view of the internal structure at high resolution (Van den Bulcke et al. 2009). XCT has been used for wood core studies to obtain density profiles (De Ridder et al. 2010; Van den Bulcke et al. 2014). In the case of modified wood, the density profile and the change in density from the pith to the bark direction before and after wood modification can give valuable information on the repartition of the chemicals and consequently on the efficiency of the treatment. It is therefore important to see the effect of the modification on the density of the wood.

Previous studies have reported that X-ray technology enables to determine the changes in wood density after chemical and thermal modification (Biziks et al. 2019; Crisostomo et al. 2023; Hamada et al. 2016; Kurkowiak et al. 2022; Zhou et al. 2011). Thermal modification of wood leads to a decrease in density due to cell wall degradation (Shchupakivskyy et al. 2014). Hamada et al. (2016) investigated the radial density profile and determined the effect on thermal degradation during thermal modification. It was noted in the study that earlywood is more susceptible to thermal degradation than latewood. Density changes in earlywood and latewood after thermal treatment indicate that increasing temperature has a specific effect on the density profile of spruce wood (Biziks et al. 2019). The variation patterns in early and late wood generate a cyclic density profile throughout the growth rings, which can be detected in detailed radial scans of the wood structure. Therefore, the combined influence of radial growth patterns (early and late wood) and functional transitions (sapwood to heartwood) results in a complex but predictable density profile in tree cross sections. X-ray density profiling can be an indicator of the chemical distribution of impregnation in wood modified with sorbitol-citric acid impregnation (Kurkowiak et al. 2022) and citric acid impregnation (Crisostomo et al. 2023).

The main objective of this study was to investigate the effect of chemical and thermal modification on the density profile of sapwood and heartwood of short rotation teak wood using XCT assessment in order to evaluate potential homogenization of the material. Volume registration was also used to overcome the deformation effects due to chemical and thermal modification.

2 Materials and methods

2.1 Sample preparation

Wood was collected from trees in a 13-year-short rotation teak from plantation forest – from Bogor, West Java, Indonesia (6° 33′ 15′′ S/106° 40′ 07′′ E). It has a rainy tropical climate with an average rainfall 3,095 mm/year with an average temperature of 30 °C. The trees had an average diameter at breast height (DBH = 1.3 m) of 27 cm. Two trees were harvested and the log section in length of 1 m were taken from the bottom part starting from DBH of each tree stem. According to Figure 1, two disks (T1 and T2) with 10 cm of thickness were cut transversely from the bottom part of each stem, approximately 30 cm from soil. From each disk, a 1 cm wide strip of wood was taken in the middle and was cut from bark to bark through the pith. The increment samples, measuring 1 × 1 cm in cross-section, were prepared from bark to pith. To obtain radial density profiles, this increment sample was analyzed from pith to sapwood using XCT scanning. The same increment sample was scanned before and after treatment. There were 10 increment samples from disk T1 and 8 increment samples from disk T2. The chemical and thermal modifications implemented were 4 increment samples for furfurylation (FA), 3 increment samples for thermal treatment at 150 °C (HT150), 3 increment samples for thermal treatment at 220 °C (HT220), 4 increment samples for glycerol-maleic anhydride treatment at 150 °C (GMA150) and 4 increment samples for glycerol-maleic anhydride treatment at 220 °C (GMA220). The remaining wood from cutting the disks was converted into flat sawn timber with a thickness of 2 cm using a band saw. Meanwhile, anatomical samples were taken from short rotation teak boards taken 1 m from the disk cut. Wood boards were re-sawn into wood block samples for anatomical analysis with the dimensions 200 × 50 × 20 mm3 (L × R × T). The wood blocks were cut into smaller pieces for microscopic observation.

Sampling for XCT scanning. A, furfurylation; B, thermal treatment at 150 °C; C, thermal treatment at 220 °C; D, glycerol-maleic anhydride treatment at 150 °C; and E; glycerol-maleic anhydride treatment at 220 °C.

2.2 Chemical and thermal modification

The chemical modification performed, more specifically furfurylation, was similar as in Martha et al. (2024). A furfuryl alcohol solution was prepared with 45 % of furfuryl alcohol, 5 % of tartaric acid as catalyst, and distilled water. The wood samples were impregnated with this solution using a vacuum-pressure impregnation process in an autoclave. First, a vacuum was applied at 8–10 kPa for 15 min followed by immersion in furfuryl alcohol solution under vacuum conditions 4–5 kPa for 15 min. Then, the pressure process was carried out in a pressure of 1,200 kPa for 30 min. The polymerization process was carried out after release of pressure at 120 °C for 16 h under nitrogen condition.

Thermal modification was performed at 150 and 220 °C in a nitrogen environment as described in Martha et al. (2024). The oven temperature was increased by a heating rate of 20 °C/min from room temperature to the target temperature for 4–6 h. The target temperature was maintained for 20 h.

A combination of chemical treatment using glycerol-maleic anhydride and thermal modification was conducted according to Martha et al. (2024). Glycerol-maleic anhydride adduct (GMA) was synthetized by mixing 1 mol of glycerol (92.09 g/mol) and 2 mol of maleic anhydride (98.06 g/mol) followed by heating at 80 °C for 3 h. GMA was then solubilized in water with the final concentration of 10 % w/w. The impregnation was performed at a vacuum of 8–10 kPa for 30 min followed by a pressure of 1,200 kPa for 60 min. Curing temperatures of 150 and 220 °C were applied for 20 h under nitrogen condition.

2.3 Microscopic characteristics

Light microscopy was used to analyze the microstructural changes of short rotation teak wood after chemical and thermal modification. Three kinds of treatments were investigated: untreated, FA, and GMA220. Five cube samples of 1 × 1 × 1 mm3 (L × R × T) representing sapwood (SW) and heartwood (HW) were used to measure microscopic characteristics. The wood samples were softened using boiling water and then the cross sections were cut in a sliding microtome with a thickness of 20 μm. The sections were rinsed using an ethanol series (50 %, 70 %, 90 %, 95 %, and 99 %). To maintain the chemical integrity of the sample, the section was not stained. Analysis of anatomical characteristics followed the standards as defined by the International Association of Wood Anatomists and was performed by an Olympus SC 100 microscope. Images were taken at 100× magnifications for analysis. The microscopic section of each sample was analyzed to measure vessel diameter in radial and tangential direction (μm). A minimum of 100 vessels were examined for the measurement of each parameter using Fiji Image-J software (Wheeler et al. 1989).

2.4 X-ray CT scanning

2.4.1 Image acquisition and reconstruction

Figure 2 shows the workflow used to assess the density profile before and after treatment using XCT scanning. Increment samples were scanned before and after chemical and thermal modification using a flatbed scanner and the Nanowood X-ray μCT scanner, which was custom-built at the UGent Centre for X-ray Tomography (www.ugct.ugent.be) and recently refurbished in collaboration with TESCAN-XRE (www.XRE.be). This scanning system is equipped with two separate X-ray sources. This scanning system has also two different X-ray detectors with a complementary spectral sensitivity to accommodate the varying X-ray energies emitted by both sources. Increment samples were mounted in a sample holder made from dry floral foam containing 9 increment samples in batch. A reference material with a constant density value of 1.4 kg/m3 was mounted on the edge of the dry floral foam during the scanning process. All samples were scanned at an average tube voltage of 80 kV, a tube power of 8 W, a voxel size of 100

Flowchart of XCT assessment for analyzing the changes in density and density profiles of wood samples before and after chemical and thermal modification.

2.4.2 Volume registration

Chemical and thermal modification can cause sample deformation due to shrinkage from degradation of wood components or swelling from additives penetrating the cell wall. In this study, Avizo software (version 2019.1, Thermo Fisher Scientific) was used to perform volume registration in order to avoid potential shifts in density profile values due to structural deformation of wood after chemical and thermal modification. To provide reliable comparisons and analysis, it entails matching two independent 3D volume datasets of the same sample that differ in time (before and after treatment). 3D volume of PRE and POST samples were imported into Avizo. Then, volume registration was applied to POST sample, using PRE sample as reference. An initial rough alignment was performed as close as possible to reduce computational load during automatic registration. Due to visible anisotropic dimensional changes of wood after treatment, An-iso Scale and Shear options were used in Transform menu during registration. These options correspond to the degrees of freedom of the transformation parameters to be optimized during registration. Selecting An-iso Scale allowed the volume to be transformed using 3 translations, 3 rotations and 3 scales, each in XYZ directions independently. Shear options allowed 3 additional shear angle parameters in each XYZ plane. When selected both, the registration function will optimize the An-iso Scale transformation first, followed by shear transformation. Following the volume registration process, the registered volume of POST then was image-resampled using Resample function in Avizo, using PRE dataset as reference voxel size and dimensions. This step optimizes the accuracy of quantitative measurements and comparative analysis.

2.4.3 Density map, delta density map and density profile before and after treatment

To analyze the changes in density between the PRE and POST samples, a delta density map is necessary. In this study, we focus on the variation of delta density along the radial direction of the sample, comparing the density changes in heartwood versus sapwood after treatment. To achieve this, we averaged the 3D volume dataset along the stem axis using a z-projection function. This process generated a 2D representation of each sample’s cross-sectional view, both before (PRE) and after (POST) treatment. The density maps for PRE and POST were then calibrated by converting the grey values to actual density values using reference materials and air as standards. Each resulting pixel in the density map represents a density value in kg/m3. Next, delta density map was produced through image calculation function by subtracting the density map of POST by density map of PRE. Finally, the density maps were saved in 32 bit TIFF format. Additionally, the density profiles from pith to sapwood of PRE, density map of POST, and its delta, were produced to evaluate the variation of density after treatment. These image analysis steps were done using Fiji/ImageJ image processing software (Schneider et al. 2012) and graph generation (R Core Team 2014).

2.5 Data analysis

The average density was calculated based on all test samples of T1 and T2 disks. The statistic tests were divided into two parts, pith-to-bark section and equalized section with balanced sapwood-to-heartwood wood ratio (Figure 2). The pith-to-bark section were calculated using all image slices from pith to sapwood without concerning the proportion of heartwood and sapwood. In this study we wanted to investigate the transition section containing heartwood and sapwood which presents significantly different wood properties. To obtain a better understanding of the homogeneity of the treatment on the heartwood and sapwood in the transition area, calculation was also performed on same proportions of sapwood and heartwood collected directly on each side of transition wood to avoid variability due to the presence of juvenile wood in inner heartwood (equalized section). The transition line, based on the color of the samples was used to determine the equal segment length. The Z-test was selected as the appropriate statistical method for comparing the mean density values of each treatment to the reference value of 0. In addition, a paired T-test was conducted to compare the mean density value between sapwood and heartwood. The Z-test and T-test were performed using R software (R Core Team 2014).

3 Results and discussion

3.1 Microscopic analysis

The mass changes of chemical and thermal modification treatment in increment sample from pith to the bark are presented in Table 1. The mass change increased after furfurylation treatment by 26 %, indicating the presence of additives in the increment sample. The mass loss occurred due to thermal treatment, since high temperatures caused an increase in mass loss. The addition of GMA followed by thermal treatment caused a higher mass change compared to thermal treatment. Even if small differences were observed with previous results reported by Martha et al. (2024) probably due to the size of the samples, results indicated the same trends.

Mass change of different treatment on increment sample from pith to bark and block sample according to previous study (Martha et al. 2024).

| Treatments | Mass change (%) of increment sample from pith to bark | Mass change (%) of block sample according to Martha et al. (2024) |

|---|---|---|

| FA | 26.5 ± 4.4 | 30.9 % (sapwood), 23.4 % (transition) and 23.2 % (heartwood) |

| HT150 | −0.5 ± 0.2 | −7.8 % (sapwood), −8.1 % (transition) and −7.4 % (heartwood) |

| HT220 | −7.6 ± 1.1 | −15.8 % (sapwood), −15.7 % (transition) and −14.8 % (heartwood) |

| GMA150 | 7.5 ± 0.9 | 6.3 % (sapwood), 2.8 % (transition) and 4.6 % (heartwood) |

| GMA220 | −0.5 ± 0.2 | −3.5 % (sapwood), −5.0 % (transition) and −5.4 % (heartwood) |

-

FA, furfurylation; HT150, thermal treatment at 150 °C; HT220, thermal treatment at 220 °C; GMA150, glycerol-maleic anhydride treatment at 150 °C; and GMA220, glycerol-maleic anhydride treatment at 220 °C.

The results of the vessel area and vessel diameter in a radial and tangential direction of untreated and treated short rotation teak wood are presented in Table 2. Heartwood showed a slightly lower vessel diameter compared to sapwood. A similar result was also reported by Ren et al. (2023), measuring a larger vessel diameter in sapwood compared to heartwood of Michelia macclurei. Several studies reported that vessel diameter increases from the pith to the bark to increase hydraulic conductivity in the outer wood (Cardoso et al. 2015; Longui et al. 2014; Rodriguez-Zaccaro et al. 2019; Sperry et al. 2006). In addition, Darmawan et al. (2015) reported that short rotation teak wood has a high proportion of juvenile wood. The presence of juvenile wood in heartwood might have an impact on the size of the vessel diameter. Juvenile wood has a smaller vessel diameter size than mature wood (Bhat et al. 2001). The vessel area and the radial and tangential vessel diameter increased significantly after FA treatment. For sapwood, there was an increase of 13.8 %, and 2.2 % in the tangential and radial vessel diameter, respectively. Meanwhile for heartwood, there was an increase of 10.5 %, and 20.5 % in the tangential and radial vessel diameter, respectively. The increase in vessel diameter might be due to a combination of chemical reaction, physical pressure, and mechanical forces during the FA treatment. During the impregnation process, the introduction of furfuryl alcohol into the wood exerted pressure, therefore the vessel element might swell. The polymerization process of furfuryl alcohol that produced the formation of a polymer network within the wood structure might also cause volume expansion of the entire wood structure, including vessels. As shown in Figure 3, the brownish deposits were observed only in the cross section of both FA treated sapwood and heartwood, while no deposits were observed in the case of untreated control samples. These deposits were most probably furfuryl alcohol polymer deposits resulting from the FA treatment, even if the hypothesis of extractives deposits cannot totally exclude. On the other hand, the vessel area and vessel diameter in a radial and tangential direction decreased significantly after GMA220 treatment. There was a decrease in the tangential vessel diameter of 12.8 % and 12.6 % for sapwood and heartwood, respectively. The decrease in vessel diameter for the GMA220 treatment occurred due to the effect of thermal modification. Thermal treatment could lead to collapse of the vessel, particularly if the internal stress exceeded the mechanical strength of the cell wall. This collapse might lead to a decrease of the vessel diameter. Biziks et al. (2013) also reported that vessel area and vessel diameter of Betula pendula slightly decreased after hydrothermal treatment. Thermo-reticulation reactions resulting from depolymerization of lignin and recondensation reactions reported during wood thermal modification may also explain this decrease of vessel diameter (Gérardin 2016).

Wood anatomical parameters on sapwood (SW) and heartwood (HW) of short rotation teak wood after FA and GMA220 treatment. Standard deviation mentioned between brackets.

| Treatment | Part | Vessel diameter in tangential directions (μm) | Vessel diameter in radial directions (μm) | Lumen area (μm2) |

|---|---|---|---|---|

| Untreated | SW | 158 ± 23 | 216 ± 34 | 26,917 ± 7,409 |

| Untreated | HW | 151 ± 27 | 173 ± 30 | 21,561 ± 7,364 |

| FA | SW | 180 ± 41 | 221 ± 49 | 33,150 ± 13,752 |

| FA | HW | 167 ± 29 | 209 ± 29 | 28,568 ± 9,417 |

| GMA220 | SW | 138 ± 36 | 173 ± 45 | 20,870 ± 11,626 |

| GMA220 | HW | 132 ± 35 | 174 ± 45 | 19,826 ± 9,903 |

-

FA, furfurylation; and GMA220, glycerol-maleic anhydride treatment at 220 °C.

Microscopic cross sections of sapwood (SW) and heartwood (HW) for untreated, furfurylation (FA), and glycerol-maleic anhydride at 220 °C (GMA220) treatment. The red arrow points to a brownish deposit.

3.2 Effect of chemical and thermal modification treatment on density

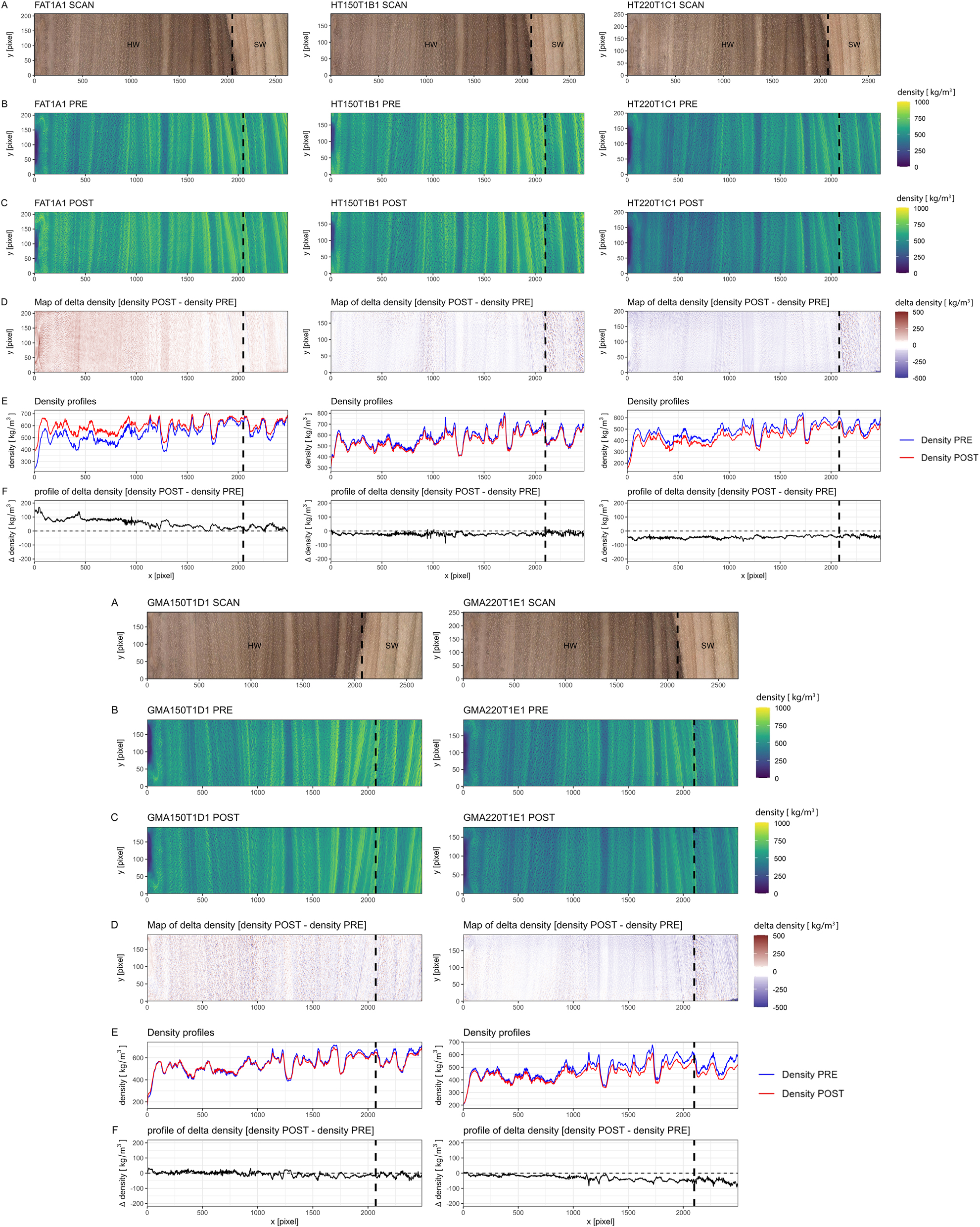

Density is an important characteristic since it determines the wood properties, especially physical and mechanical properties. To visualize the density profile of short rotation teak, the representative samples for each chemical and thermal modification treatment from pith to sapwood are presented in Figure 4. The technique used in this study made it possible to determine heartwood and sapwood. The flatbed scanning image in Figure 4A shows the transition between heartwood (HW) and sapwood (SW). In Figure 4E, the density profiles before and after treatment are plotted according to the different treatments of FA, HT150, HT220, GMA150 and GMA220. Overall, the density profile of short rotation teak wood increased from pith to sapwood, a similar result was also reported by Curvo et al. (2024). These authors noted that X-ray densitometry indicates a higher wood density from pith-to-bark direction with variations in growth rings. Darmawan et al. (2015) also reported that density of long and short rotation teak wood increased proportionally from pith to bark. This is attributed to the presence of juvenile wood near the pith which impacts the density of short rotation teak wood to be lower near the pith.

Visual interpretation of the density profile. (A) Flatbed scanning image from pith to sapwood of short rotation teak before chemical and thermal modification treatments. (B) Density visualization based on an X-ray CT image of short rotation teak before treatment. (C) Density visualization based on an X-ray CT image of short rotation teak after chemical and thermal modification treatments. (D) Map of the density change before and after chemical and thermal modification treatments (E). Density profiles before and after chemical and thermal modification treatments. (F) Density profile changes before and after chemical and thermal modification treatment. FA, furfurylation; HT150, thermal treatment at 150 °C; HT220, thermal treatment at 220 °C; GMA150, glycerol-maleic anhydride treatment at 150 °C; and GMA220, glycerol-maleic anhydride treatment at 220 °C. The black vertical dotted line corresponded to the transition line.

The mean density value of short rotation teak wood before treatment was 560 kg/m3. The increase in density was observed in short rotation teak wood after FA treatment. The mean density value increased by 14.3 % after FA treatment. This result confirmed our previous study indicating that FA treatment increases the density of short rotation teak wood (Martha et al. 2021a). The increase in density is due to polymerization of furfuryl alcohol polymers within the cell wall (Baysal et al. 2004; Dong et al. 2014, 2016). As shown in Table 2, the change of vessel lumen area and vessel diameter after chemical and thermal treatment were correlated with wood density. The results in Figure 3 also confirmed the presence of furfuryl alcohol that led to the increase in density. The increase of density due to FA treatment was higher in the area near the pith (Figure 4F). However, the density profile in Figure 4E was seen to be more homogeneous from pith to the sapwood after FA treatment. This could affect the physical properties of short-rotation teak wood, in particular dimensional stability. Martha et al. (2024) reported that FA treatments can homogenize properties of sapwood and heartwood of short rotation teak wood.

On the contrary, a decrease in density was observed for thermal treatment. The increase of thermal treatment temperature led to a larger decrease in density. The mean density of short rotation teak decreased by 3.6 % and 9.1 % for HT150 and HT220, respectively. Furthermore, the trend of density change after thermal modification was uniform from pith to sapwood. The degradation of the vascular tracheal wall and the degradation of chemical compounds, especially hemicellulose, into volatile products and evaporation or degradation of extractives are the main reasons for the decrease in density (Esteves and Pereira 2009; Pfriem et al. 2012). This study showed that increasing the heating temperature led to a greater decrease in density. Shchupakivskyy et al. (2014) reported that oak wood heat treated at three different temperatures (180, 200 and 220 °C) with a duration of 2 h resulted in stronger reductions in density according to the treatment temperature.

Previous studies reported that density decreased after GMA treatment (Martha et al. 2021c; Mubarok et al. 2019). In this study, the mean density of short rotation teak increased by 1.7 % for GMA150 and decreased by 7.4 % for GMA220. The increase in the mean density of GMA150 might be due to GMA impregnation and its polymerization with wood components. The density change of GMA220 was lower than HT220 indicating GMA treatment could reduce wood degradation during the curing process. The density change tended to decrease slightly from pith to sapwood. Sapwood exhibited a higher decrease in density change compared to heartwood. This indicated that sapwood was more sensitive to thermal degradation and therefore more easily degraded.

Figure 5 shows the density changes of short rotation teak wood after chemical and thermal modification. According to the Z-test (95 % confidence level), there was a significant difference in density change after chemical and thermal treatment (Figure 5A). To evaluate how the treatment homogenized the density in the transition area, the analysis was performed with the same proportion of heartwood and sapwood (Figure 5B). The result shows that the trend of density change was similar for each treatment, indicating that there is insufficient proof that the proportion of heartwood has an impact on the magnitude of the density change.

Density changes of short rotation teak wood after chemical and thermal modification for average images of pith-to-bark section (A) and average images of equalized section with balanced sapwood-to-heartwood wood ratio (B). FA, furfurylation; HT150, thermal treatment at 150 °C; HT220, thermal treatment at 220 °C; GMA150, glycerol-maleic anhydride treatment at 150 °C; and GMA220, glycerol-maleic anhydride treatment at 220 °C.

The density changes for the different treatments on sapwood and heartwood are shown in Figure 6. A T-test was applied (95 % confidence level) shows that the density change between sapwood and heartwood is statistically different (Figure 6A). A similar phenomenon also was observed with the same data number by drawing the same proportion of heartwood and sapwood (Figure 6B). The mean density values and density changes are shown in Table 3 in relation to their initial mean density values to illustrate the extent of density changes for the different treatments on sapwood and heartwood. Overall, heartwood presented a lower initial density compared to sapwood. The heartwood in short rotation teak contains juvenile wood that has thin-walled fibers with lower density and lower strength properties (Clark et al. 2006; Darmawan et al. 2015; Gryc et al. 2011). The presence of juvenile wood might have a significant contribution to the increase in density due to FA treatment. As shown in Table 3, the density change in heartwood was higher than that in sapwood. Conversely to the GMA treatment, heartwood was more resistant to thermal degradation than sapwood. The higher resistance of heartwood to thermal stress explained the lower decrease in density of heartwood compared to sapwood.

Density changes of short rotation teak wood for the different treatments on sapwood (SW) and heartwood (HW): (A) Calculating based on average images from of pith-to-bark section, (B) calculating based on average images of equalized section with balanced sapwood-to-heartwood wood ratio. FA, furfurylation; HT150, thermal treatment at 150 °C; HT220, thermal treatment at 220 °C; GMA150, glycerol-maleic anhydride treatment at 150 °C; and GMA220, glycerol-maleic anhydride treatment at 220 °C.

Mean density and density change of sapwood (SW) and heartwood (HW) of short rotation teak wood before (PRE) and after (POST) chemical and thermal modification treatments.

| Samples | Part | Mean density PRE (kg/m3) | Mean density POST (kg/m3) | Mean density DELTA (kg/m3) |

|---|---|---|---|---|

| FA | HW | 520 ± 70 | 600 ± 50 | 90 ± 40 |

| FA | SW | 710 ± 110 | 740 ± 100 | 20 ± 20 |

| HT150 | HW | 540 ± 80 | 520 ± 70 | −20 ± 10 |

| HT150 | SW | 670 ± 100 | 660 ± 100 | −10 ± 10 |

| HT220 | HW | 510 ± 80 | 460 ± 70 | −50 ± 20 |

| HT220 | SW | 670 ± 130 | 620 ± 100 | −50 ± 20 |

| GMA150 | HW | 530 ± 70 | 540 ± 60 | 10 ± 20 |

| GMA150 | SW | 720 ± 100 | 700 ± 100 | −20 ± 20 |

| GMA220 | HW | 490 ± 70 | 460 ± 60 | −30 ± 20 |

| GMA220 | SW | 680 ± 140 | 610 ± 130 | −70 ± 20 |

-

FA, furfurylation; HT150, thermal treatment at 150 °C; HT220, thermal treatment at 220 °C; GMA150, glycerol-maleic anhydride treatment at 150 °C; and GMA220, glycerol-maleic anhydride treatment at 220 °C.

Contrary to what could be expected at the beginning of this study, results were not in line with results generally reported in the literature on density evolution between heartwood and sapwood, especially on conventional long rotation teak wood. Heartwood generally presents a higher density compared to sapwood. However, in our study, the initial density of short rotation teak wood increased slightly from pith to sapwood. The presence of juvenile wood in the area near the pith was responsible of lower density value of heartwood. Consequently, the hypothesis suggesting that a difference in density between heartwood and sapwood could be reduced after chemical modification due to higher impregnability of sapwood was not confirmed, given the measured initial densities. The variation in density profiles of the chemical and thermal modifications appeared similar to those observed for the original wood. The results indicate that the chemical and thermal modification did not have a significant effect on the density profile, especially in the homogenization of the density profile between sapwood and heartwood after chemical modification. However, short rotation teak wood containing sapwood and heartwood does become more homogeneous, especially in leachability, color and durability, after FA and GMA220 treatment (Martha et al. 2024).

4 Conclusions

The vessel diameter increases after FA treatment due to swelling and polymerization effects and decrease after GMA220 treatment likely due to thermal-induced vessel collapse and cell wall polymers degradations. This study shows that the registration method is a reliable method that can measure density changes before and after treatment by minimizing deformation due to chemical and thermal modification. The 3D volume analysis method can be applied to measure the density profile. XCT scanning shows that there is a trend of increasing density from pith to the sapwood of short rotation teak wood. The density value of heartwood, especially in the area near the pith, is lower than that of sapwood. Chemical and thermal modifications have an effect on the density profile. FA treatment leads to an increase in density due to polymerization of FA polymers into the cell wall. In contrast, thermal and combinations of thermal and GMA treatments lead to a decrease in density, and a higher temperature is leading to a stronger density reduction. Density profiling by XCT scanning after chemical and thermal modification showed no wood density homogenization after treatments. However, this study did highlight the lower density of the heartwood of short rotation teak wood compared to sapwood.

Funding source: FWO

Award Identifier / Grant number: G019521N

Award Identifier / Grant number: G00972ON

Funding source: French Embassy in Jakarta

Funding source: BOF Special Research Fund

Award Identifier / Grant number: BOF.COR.2022.008

Award Identifier / Grant number: BOFSTG2018000701

Funding source: Ministry of RISTEK DIKTI

Award Identifier / Grant number: 027/E5/PG.02.00.PL/2024

Funding source: Ministère de l’Europe et des Affaires Etrangères

Funding source: Lorraine Université d’Excellence (LUE)

Funding source: ANR Lab of Excellence ARBRE

Award Identifier / Grant number: ANR-11-LABX-0002-01.

Funding source: National Research and Innovation Agency, Indonesia

Award Identifier / Grant number: 61/II.7/HK/2024

Funding source: Faculty of Bioscience Engineering

Acknowledgments

The authors would like to thank Toon Gheyle for the technical support in scanning the samples.

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: The authors state no conflict of interest.

-

Research funding: The authors acknowledge the financial support by the BOF Special Research Fund for the UGCT Core Facility (BOF.COR.2022.008) and for the Nanowood CT system (BOF Starting Grant JVdB, BOFSTG2018000701) as well as the FWO (project ACTREAL with grant number G00972ON, project XyloDynaCT with grant number G019521N) and the Faculty of Bioscience Engineering (FBW-CWO-UGent grant JVdB) for the support of the Nanowood CT system. The authors wish also to thank MEAE (Ministère de l’Europe et des Affaires Etrangères) for the France Excellence Eiffel and French Embassy in Jakarta for the France Excellence allowing the doctorate funding of the first author at Université de Lorraine and Lorraine Université d’Excellence (LUE) for the DREAM mobility accorded to the first author allowing the scientific mission at Ghent University. This work was also supported by Directorate for Research and Community Service of the Ministry of RISTEK DIKTI, Indonesia [grant number 027/E5/PG.02.00.PL/2024], and by National Research and Innovation Agency, Indonesia [grant number 61/II.7/HK/2024]. LERMAB is supported by a grant overseen by the French National Research Agency (ANR) as part of the “Investissements d’Avenir” program (ANR-11-LABX-0002-01. Lab of Excellence ARBRE).

-

Data availability: Not applicable.

References

Basri, E., Hanifah, N., Martha, R., Rahayu, I.S., Darmawan, W., Gérardin, P., and Gérardin, P. (2022). Effect of citric acid and benzophenone tetracarboxyclic acid treatments on stability, durability, and surface characteristic of short rotation teak wood. Forests 13: 1938, https://doi.org/10.3390/f13111938.Search in Google Scholar

Basri, E., Rahayu, I.S., Saefudin, S., Santoso, A., Sulastiningsih, I.M., Damayanti, R., Martha, R., and Darmawan, W. (2024). Enhancement on physicomechanical properties of short-rotation teak woods by non-biocide chemical and thermal treatments. BioResources 19: 3290–3305, https://doi.org/10.15376/biores.19.2.3290-3305.Search in Google Scholar

Baysal, E., Ozaki, S.K., and Yalinkilic, M.K. (2004). Dimensional stabilization of wood treated with furfuryl alcohol catalysed by borates. Wood Sci. Technol. 38: 405–415, https://doi.org/10.1007/s00226-004-0248-2.Search in Google Scholar

Bektaş, İ., Tutuş, A., and Gültekin, G. (2020). The Effect of sapwood and heartwood differences on mechanical properties of fast-growing tree species. Drvna Ind. 71: 261–269, https://doi.org/10.5552/drvind.2020.1940.Search in Google Scholar

Belt, T., Altgen, M., Awais, M., Nopens, M., and Rautkari, L. (2024). Degradation by brown rot fungi increases the hygroscopicity of heat-treated wood. Int. Biodeterior. Biodegrad. Art. no. 105690, https://doi.org/10.1016/j.ibiod.2023.105690.Search in Google Scholar

Bhat, K.M., Priya, P.B., and Rugmini, P. (2001). Characterisation of juvenile wood in teak. Wood Sci. Technol. 34: 517–532, https://doi.org/10.1007/s002260000067.Search in Google Scholar

Biziks, V., Andersons, B., Belkova, L., Kapaca, E., and Militz, H. (2013). Changes in the microstructure of birch wood after hydrothermal treatment. Wood Sci. Technol. 47: 717–735, https://doi.org/10.1007/s00226-013-0531-1.Search in Google Scholar

Biziks, V., van Acker, J., Militz, H., Grinins, J., and van den Bulcke, J. (2019). Density and density profile changes in birch and spruce caused by thermo-hydro treatment measured by X-ray computed tomography. Wood Sci. Technol. 53: 491–504, https://doi.org/10.1007/s00226-018-1070-6.Search in Google Scholar

Candelier, K., Hannouz, S., Elaieb, M., Collet, R., Dumarçay, S., Pétrissans, A., Pétrissans, M., and Pétrissans, M. (2015). Utilization of temperature kinetics as a method to predict treatment intensity and corresponding treated wood quality: durability and mechanical properties of thermally modified wood. Maderas 17: 253–262, https://doi.org/10.4067/s0718-221x2015005000024.Search in Google Scholar

Cardoso, S., Sousa, V.B., Quilhó, T., and Pereira, H. (2015). Anatomical variation of teakwood from unmanaged mature plantations in East Timor. J. Wood Sci. 61: 326–333, https://doi.org/10.1007/s10086-015-1474-y.Search in Google Scholar

Clark, A., Daniels, R.F., and Jordan, L. (2006). Juvenile mature wood transition in loblolly pine as defined by annual radial increment specific gravity, proportion of latewood, and microfibril angle. Wood Fiber Sci. 38: 292–299.Search in Google Scholar

Crisostomo, M., del Menezzi, C., Militz, H., Kurkowiak, K., Mayer, A., Carvalho, L., and Martins, J. (2023). Effect of citric acid on the properties of sapwood of Pinus sylvestris submitted to thermomechanical treatment. Forests 14: 1839, https://doi.org/10.3390/f14091839.Search in Google Scholar

Curvo, K.R., Silva, G.A.O., Castro, V.R., Gava, F.H., Pereira, B.L.C., and Oliveira, A.C. (2024). Heartwood proportion and density of Tectona grandis L.f. wood from Brazilian fast-growing plantations at different ages. Eur. J. Wood Prod. 82: 357–369, https://doi.org/10.1007/s00107-023-02031-5.Search in Google Scholar

Darmawan, W., Nandika, D., Sari, R.K., Sitompul, A., Rahayu, I., and Gardner, D. (2015). Juvenile and mature wood characteristics of short and long rotation teak in Java. IAWA J. 36: 429–443, https://doi.org/10.1163/22941932-20150112.Search in Google Scholar

de Mil, T., Vannoppen, A., Beeckman, H., van Acker, J., and van den Bulcke, J. (2016). A field-to-desktop toolchain for X-ray CT densitometry enables tree ring analysis. Ann. Bot. 117: 1187–1196, https://doi.org/10.1093/aob/mcw063.Search in Google Scholar PubMed PubMed Central

de Ridder, M., van den Bulcke, J., Vansteenkiste, D., Van Loo, D., Dierick, M., Masschaele, B., De Witte, Y., Mannes, D., Lehmann, E., Beeckman, H., et al.. (2010). High-resolution proxies for wood density variations in Terminalia superba. Ann. Bot. 107: 293–302, https://doi.org/10.1093/aob/mcq224.Search in Google Scholar PubMed PubMed Central

Dong, Y., Yan, Y., Zhang, S., and Li, J. (2014). Wood/polymer nanocomposites prepared by impregnation with furfuryl alcohol and nano-SiO2. BioResources 9: 6028–6040, https://doi.org/10.15376/biores.9.4.6028-6040.Search in Google Scholar

Dong, Y., Qin, Y., Wang, K., Yan, Y., Zhang, S., Li, J., and Zhang, S. (2016). Assessment of the performance of furfurylated wood and acetylated wood: comparison among four fast-growing wood species. BioResources 11: 3679–3690, https://doi.org/10.15376/biores.11.2.3679-3690.Search in Google Scholar

Esteves, B.M. and Pereira, H.M. (2009). Wood modification by heat treatment: a review. BioResources 4: 370–404, https://doi.org/10.15376/biores.4.1.esteves.Search in Google Scholar

Gaitán-Alvarez, J. and Roque, R.M. (2019). The use of X-ray densitometry to evaluate the wood density profile of Tectona grandis trees growing in fast-growth plantations. Dendrochronologia 55: 71–79, https://doi.org/10.1016/j.dendro.2019.04.Search in Google Scholar

Gérardin, P. (2016). New alternatives for wood preservation based on thermal and chemical modification of wood: a review. Ann. For. Sci. 73: 559–570, https://doi.org/10.1007/s13595-015-0531-4.Search in Google Scholar

Gryc, V., Vavrcik, H., and Horn, K. (2011). Density of juvenile and mature wood of selected coniferous species. J. For. Sci. 57: 123–130, https://doi.org/10.17221/18/2010-jfs.Search in Google Scholar

Hadi, Y.S., Herliyana, E.N., Mulyosari, D., Abdillah, I.B., Pari, S., and Hiziroglu, S. (2020). Termite resistance of furfuryl alcohol and imidacloprid treated short rotation tropical wood species as function of field test. Appl. Sci. 10: 6101, https://doi.org/10.3390/app10176101.Search in Google Scholar

Hamada, J., Pétrissans, A., Mothe, F., Ruelle, J., Pétrissans, M., and Gerardin, P. (2016). Variations in the natural density of European oak wood affect thermal degradation during thermal modification. Ann. For. Sci. 73: 277–286.10.1007/s13595-015-0499-0Search in Google Scholar

Hill, C.A.S. (2006). Wood modification: chemical, thermal and other processes. Wiley, England.10.1002/0470021748Search in Google Scholar

Hill, C., Altgen, M., and Rautkari, L. (2021). Thermal modification of wood – a review: chemical changes and hygroscopicity. J. Mater. Sci. 56: 6581–6614, https://doi.org/10.1007/s10853-020-05722-z.Search in Google Scholar

Jacquin, P., Mothe, F., Longuetaud, F., Billard, A., Kerfriden, B., and Leban, J.M. (2019). A software for fast measurement of wood density on increment cores by CT scanning. Comput. Electron. Agric. 156: 606–617, https://doi.org/10.1016/j.compag.2018.12.008.Search in Google Scholar

Kurkowiak, K., Mayer, A.K., Emmerich, L., and Militz, H. (2022). Investigations of the chemical distribution in sorbitol and sitric acid (SorCA) treated wood: development of a quality control method on the basis of electromagnetic radiation. Forests 13: 151, https://doi.org/10.3390/f13020151.Search in Google Scholar

Lande, S., Westin, M., and Schneider, M. (2004). Properties of furfurylated wood. Scand. J. Res. Suppl. 19: 22–30, https://doi.org/10.1080/0282758041001915.Search in Google Scholar

Li, J.Z., Furuno, T., Zhou, W.R., Ren, Q., Han, X.Z., and Zhao, J.P. (2009). Properties of acetylated wood prepared at low temperature in the presence of catalysts. J. Wood Chem. Technol. 29: 241–250, https://doi.org/10.1080/02773810903009499.Search in Google Scholar

Li, W., Chen, L., and Li, X. (2019). Comparison of physical-mechanical and mould-proof properties of furfurylated and DMDHEU-modified wood. BioResources 14: 9628–9644, https://doi.org/10.15376/biores.14.4.9628-9644.Search in Google Scholar

Longui, E.L., Romeiro, D., Pfleger, P., Lima, I.L., Silva, F.G., Garcia, J.N., Bortoletto, G., Freire Neto, A.O.L., and Florsheim, S.M.B. (2014). Radial variation of anatomical features, physicomechanical properties and chemical constituents and their potential influence on the wood quality of 45-year-old Eucalyptus propinqua. Aust. For. 77: 78–85, https://doi.org/10.1080/00049158.2014.905739.Search in Google Scholar

Marcon, B., Viguier, J., Candelier, K., Thevenon, M.-F., Butaud, J.-C., Pignolet, L., Gartili, A., Denaud, L., and Collet, R. (2023). Heat treatment of poplar plywood: modifications in physical, mechanical and durability properties. iForest 16: 1–9, https://doi.org/10.3832/ifor4159-015.Search in Google Scholar

Martha, R., Mubarok, M., Batubara, I., Rahayu, I.S., Setiono, L., Darmawan, W., Akong, F.O., George, B., Gerardin, C., and Gerardin, P. (2021a). Effect of furfurylation treatment on technological properties of short rotation teak wood. J. Mater. Sci. Technol. 12: 1689–1699, https://doi.org/10.1016/j.jmrt.2021.03.092.Search in Google Scholar

Martha, R., Basri, E., Setiono, L., Batubara, I., Rahayu, I.S., Gerardin, P., and Darmawan, W. (2021b). The effect of heat treatment on the characteristics of the short rotation teak. Int. Wood Prod. J. 12: 218–227, https://doi.org/10.1080/20426445.2021.1953723.Search in Google Scholar

Martha, R., Mubarok, M., Batubara, I., Rahayu, I.S., Setiono, L., Darmawan, W., Akong, F.O., George, B., Gerardin, C., and Gerardin, P. (2021c). Effect of glycerol-maleic anhydride treatment on technological properties of short rotation teak wood. Wood Sci. Technol. 55: 1795–1819, https://doi.org/10.1007/s00226-021-01340-3.Search in Google Scholar

Martha, R., George, B., Rahayu, I.S., Gerardin, P., and Darmawan, W. (2024). Technological properties homogenization on sapwood and heartwood of short rotation teak wood by non-biocide method based on chemical and thermal treatments. Eur. J. Wood Wood Prod. 82: 371–386, https://doi.org/10.1007/s00107-023-01997-6.Search in Google Scholar

Mubarok, M., Dumarcay, S., Militz, H., Candelier, K., Thevenon, M.F., and Gerardin, P. (2019). Comparison of different treatments based on glycerol or polyglycerol additives to improve properties of thermally modified wood. Eur. J. Wood Wood Prod. 77: 799–810, https://doi.org/10.1007/s00107-019-01429-4.Search in Google Scholar

Pfriem, A., Dietrich, T., and Buchelt, B. (2012). Furfuryl alcohol impregnation for improved plasticization and fixation during the densification of wood. Holzforschung 66: 215–218, https://doi.org/10.1515/hf.2011.134.Search in Google Scholar

Pratiwi, L.A., Darmawan, W., Priadi, T., George, B., Merlin, A., Gerardin, C., Dumarcay, S., and Gerardin, P. (2019). Characterization of thermally modified short and long rotation teaks and the effects on coatings performance. Maderas 21: 209–222, https://doi.org/10.4067/s0718-221x2019005000208.Search in Google Scholar

Rahayu, I., Prihatini, E., Maddu, A., Kurniati, M., and Darmawan, W. (2022). Density and dimensional stability of a wood-polymer nano-composite from fast-growing wood. BioResources 17: 750–762, https://doi.org/10.15376/biores.17.1.750-762.Search in Google Scholar

Ren, S., Wang, Z., Yan, L., Feng, Q., Chen, Z., and Zhao, R. (2023). Comparison of anatomical characteristics and chemical compositions between sapwood and heartwood of Michelia macclurei. Ind. Crops Prod. 193: 116190, https://doi.org/10.1016/j.indcrop.2022.116190.Search in Google Scholar

Rodriguez-Zaccaro, F.D., Valdovinos-Ayala, J., Percolla, M.I., Venturas, M.D., Pratt, R.B., and Jacobsen, A.L. (2019). Wood structure and function change with maturity: age of the vascular cambium is associated with xylem changes in current year growth. Plant Cell Environ. 42: 1816–1831, https://doi.org/10.1111/pce.13528.Search in Google Scholar PubMed

Schneider, C., Rasband, W., and Eliceiri, K. (2012). NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 9: 671–675, https://doi.org/10.1038/nmeth.2089.Search in Google Scholar PubMed PubMed Central

Shchupakivskyy, R., Clauder, L., Linke, N., and Pfriem, A. (2014). Application of high-frequency densitometry to detect changes in early- and latewood density of oak (Quercus robur L.) due to thermal modification. Eur. J. Wood Wood Prod. 72: 5–10, https://doi.org/10.1007/s00107-013-0744-x.Search in Google Scholar

Sperry, J.S., Hacke, U.G., and Pittermann, J. (2006). Size and function in conifer tracheids and angiosperm vessels. Am. J. Bot. 93: 1490–1500, https://doi.org/10.3732/ajb.93.10.1490.Search in Google Scholar PubMed

van den Bulcke, J., Boone, M., van Acker, J., and van Hoorebeke, L. (2009). Three-dimensional X-ray imaging and analysis of fungi on and in wood. Microsc. Microanal. 15: 395–402, https://doi.org/10.1017/s1431927609990419.Search in Google Scholar PubMed

van den Bulcke, J., Wernersson, E.L.G., Dierick, M., van Loo, D., Masschaele, B., Brabant, L., Boone, M.N., Hoorebeke, L.V., Hance, K., Brun, A., et al.. (2014). 3D tree-ring analysis using helical X-ray tomography. Dendrochronologia 32: 39–46, https://doi.org/10.1016/j.dendro.2013.07.001.Search in Google Scholar

Vannoppen, A., Maes, S., Kint, V., de Mil, T., Ponette, Q., van Acker, J., van den Bulcks, J., Verheyen, K., and Muys, B. (2017). Using X-ray CT based tree-ring width data for tree growth trend analysis. Dendrochronologia 44: 66–75, https://doi.org/10.1016/j.dendro.2017.03.003.Search in Google Scholar

Wheeler, E., Baas, P., and Gasson, P. (1989). IAWA list of microscopic features for hardwood identification. IAWA Bull. 10: 219–332.10.1163/22941932-90000496Search in Google Scholar

Yan, Y., Dong, Y., Li, C., Chen, H., Zhang, S., and Li, J. (2014). Optimization of reaction parameters and characterization of glyoxal-treated poplar sapwood. Wood Sci. Technol. 49: 241–256, https://doi.org/10.1007/s00226-014-0674-8.Search in Google Scholar

Yu, Y., Zhang, F., Zhu, S., and Li, H. (2017). Effects of high-pressure treatment on poplar wood: density profile, mechanical properties, strength potential index, and microstructure. BioResources 12: 6283–6297, https://doi.org/10.15376/biores.12.3.6283-6297.Search in Google Scholar

Zhang, S.Y., Ren, H., and Jiang, Z. (2021). Wood density and wood shrinkage in relation to initial spacing and tree growth in black spruce (Picea mariana). J. Wood Sci. 67: Art. no. 30, https://doi.org/10.1186/s10086-021-01965-9.Search in Google Scholar

Zhou, C., Dai, C., and Smith, G.D. (2011). Modeling vertical density profile formation for strand-based wood composites during hot pressing: part 2. Experimental investigations and dodel validation. Compos. Part B Eng. 42: 1357–1365, https://doi.org/10.1016/j.compositesb.2011.05.037.Search in Google Scholar

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Wood Chemistry

- Variability in the chemical composition and antioxidant properties of sapwood and heartwood extracts of some tropical woods from Côte d’Ivoire

- Valorisation the bark of forest species as a source of natural products within the framework of a sustainable bioeconomy in the Amazon

- Wood Physics/Mechanical Properties

- Mechanism of changes in the mechanical properties of wood due to water adsorption and desorption described by rheological considerations

- Investigating sapwood and heartwood density changes of short rotation teak wood after chemical and thermal modification using X-ray computed tomography

- Wood Technology/Products

- Fire behavior of thermally modified pine (Pinus sylvestris) treated with DMDHEU and flame retardants: from small scale to SBI tests

Articles in the same Issue

- Frontmatter

- Wood Chemistry

- Variability in the chemical composition and antioxidant properties of sapwood and heartwood extracts of some tropical woods from Côte d’Ivoire

- Valorisation the bark of forest species as a source of natural products within the framework of a sustainable bioeconomy in the Amazon

- Wood Physics/Mechanical Properties

- Mechanism of changes in the mechanical properties of wood due to water adsorption and desorption described by rheological considerations

- Investigating sapwood and heartwood density changes of short rotation teak wood after chemical and thermal modification using X-ray computed tomography

- Wood Technology/Products

- Fire behavior of thermally modified pine (Pinus sylvestris) treated with DMDHEU and flame retardants: from small scale to SBI tests