Abstract

Polyurethane (PU) damping materials were prepared by mixed-base PU prepolymers and 4,4′-methylene- bis-(2-chloroaniline) (MOCA) as chain extender. The prepolymer was synthesized from poly(hydroxypivalyl hydroxypivalate succinate) (PHPS) or polypropylene glycol 2000 (PPG-2000) with 2,4-toluene diisocyanate (TDI-100), respectively. The structure, morphology, and dynamic and static mechanical properties were characterized by Fourier transform infrared spectroscopy (FT-IR), scanning tunneling microscopy (STM), dynamic mechanical thermal analysis (DMA), and tensile testing machine, respectively. The results indicated that the mass ratios of polyester prepolymer (PESP) and polyether prepolymer (PETP) (mPESP/mPETP ratio) had significantly affected the dynamic mechanical properties of the PUs. When the mPESP/mPETP ratio was 40/60 and 45/55, and PUs had the temperature range (ΔT) higher than 60°C for efficient loss factor (tanδ>0.4) in the DMA curve with bimodal. The phase diagrams of STM indicated that more complex combination of hard and soft segments existed in the PUs, and the segments of PESP and PETP formed irregular block structures. Furthermore, the mechanical properties of PUs were of higher value. It is believed that PUs may be used as potential damping materials.

1 Introduction

With the advancement of technology and development of society, vibration and noise issues become increasingly severe; thus, much attention is being given to research and applications of polymer damping materials. However, the narrow range of effective temperature for common polymer damping materials limits their applications. To widen the temperature range of polymer damping materials, blending or interpenetrating means has become one of the popular research methods. The polyphenylsiloxane/polymethacrylate (PMAc) damping material, which utilizes simultaneous interpenetrating polymer networks (1) and chlorinated butyl rubber (CIIR)/PMAc blends (2), have achieved better damping properties. The polyurethane (PU) damping material with larger adjustable structures and properties becomes a focus because of its excellent performance. Although the damping properties of polyether PU and polyester PU (3–5) have been studied to a great depth, there were few reports on how to broaden the damping temperature range of PU by utilizing the compatibility difference between polyether and polyester. Tong et al. (6) discussed the effect of preparation methods on dynamic mechanical properties, and the results showed that the post-mixed method (i.e. PU with a different structure was prepared and then mixed with a chain extender) is difficult to operate and industrialize. In addition, this kind of PU is not suitable for damping material due to its narrow damping temperature range.

To improve the operability mentioned above and achieve a damping material with wider temperature range and larger adjustable structures and properties, in this article, PU damping materials with a temperature range (ΔT) higher than 60°C for efficient loss factor (tanδ>0.4) in the DMA curve with bimodal were prepared. According to the group contribution method and the damping properties quantitative theory of polymer (7–9), polyester diol was synthesized by succinate (SA) and hydroxypivalyl hydroxypivalate (HPHP), with pendent bimethyl on the same carbon. The effect of the mass ratios of polyester prepolymer (PESP) and polyether prepolymer (PETP) (defined as the mPESP/mPETP ratio) on the dynamic and static mechanical properties, damping properties, and morphology of PU was investigated, respectively.

2 Experimental

2.1 Materials

HPHP, an industrial product, was obtained from Zibo Chemical of China. Polypropylene oxide glycol (PPG-2000) was supplied by Shandong Dongda Chemical of China. Succinic acid (SA) was analytically pure and supplied by Tianjin Bodi Chemical of China. 2,4-Toluene diisocyanate (TDI-100) was supplied by Bayer. 4,4′-Methylene-bis-(2-chloroaniline) (MOCA) was purchased from Suzhou Xiang Yuan Special Fine Chemical of China. Tetraisopropyl titanate (TPT) was analytically pure and supplied by Alfa Aesar (Tianjin) Chemical of China. A release agent (YB-05H) was obtained from Shanghai Billion State Chemical. Poly(HPHP succinate) (PHPS; average molecular weight of 2300) was prepared in our laboratory.

2.2 Preparation of PU damping materials

2.2.1 Preparation of PHPS

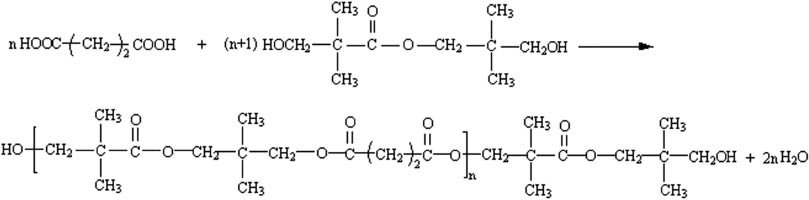

SA (823 g) was placed into a four-necked round-bottomed flask equipped with a stirrer, a thermometer, and a fractionating column, and then HPHP (1661 g) and TPT (0.285 g) as a catalyst were added. The reaction mixture was heated to 210°C–220°C and maintained at this temperature. Acid number and hydroxyl number were measured every 2 h, and then the reaction mixture was vacuumed until the acid number dropped to 0.7 mg KOH/g. Finally, PHPS with an average molecular weight of 2300 the molecular weight is achieved by calculate was obtained. The PHPS preparation is schematically presented in Figure 1.

Preparation of PHPS.

2.2.2 Preparation of PETP and PESP

PPG (550 g) was added to a three-neck flask equipped with a stirrer and a thermometer, then it heated to 110°C–130°C and dehydrated for 2 h in a vacuum(-0.095 to 0.098 MPa). PPG-2000 was cooled to 60°C and thoroughly mixed with TDI-100 (98 g) and then heated slowly to 75°C±5°C and maintained for 2 h. Finally, PETP was degassed under 80°C–85°C and sealed.

The synthesis route of PESP based on PHPS and TDI-100 was as the same as that of PETP.

2.2.3 Preparation of PU damping materials

PESP and/or PETP were preheated to 85°C–90°C, mixed with MOCA, then poured into a hot glass mold coated with the release agent, and finally, vulcanized for 7 days at room temperature or for 4 h at 100°C to obtain the PU damping materials. Several different mPESP/mPETP ratios were used for preparing PU samples (Table 1).

PU samples with different mPESP/mPET ratios.

| Sample name | mPESP/mPETP | Chain extension coefficient |

|---|---|---|

| PU-1 | 0/100 | 0.98 |

| PU-2 | 40/60 | 0.98 |

| PU-3 | 45/55 | 0.98 |

| PU-4 | 60/40 | 0.98 |

| PU-5 | 100/0 | 0.98 |

2.3 Measurement and characterization

Dynamic mechanical thermal analysis (DMTA) was carried out on a DMA Q800 analyzer with film tensile mode in a temperature range from -50°C to 60°C at a frequency of 1 Hz and a heating rate of 1°C/min. The tensile strength was measured on a CMT7104 universal testing machine (Shenzhen SANS Test Machine, Shenzhen, P. R. China) with a crosshead rate of 200 mm/min according to ISO 37:2005. The tear strength was tested on the same machine as tensile test according to ISO 34-1:2004. Five replicates of each sample were taken. The hardness of the samples was measured using a hardness tester. The hydroxyl value was determined by acetic anhydride and p-toluene sulfonic acid acylation method. The acid value was measured through toluene and ethanol solution. The Fourier transform infrared (FT-IR) spectra were recorded by a 5DX-B IR spectrometer with the attenuated total reflection accessory. Scanning tunneling microscopy (STM) imaging was performed on a Nanoscope IV with tapping mode, sweep range of 10×10 μm, height of 60 nm, and frequency of 1 Hz.

3 Results and discussion

3.1 FT-IR analysis

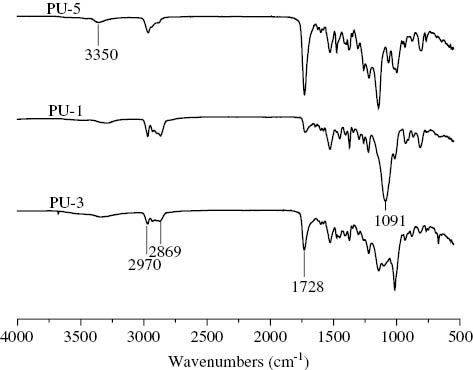

Figure 2 shows the FT-IR spectra of PU-1, PU-3, and PU-5. The peaks among 2970 and 2869 cm-1 were assigned to CH symmetric and asymmetric stretching of -CH3 and -CH2 (Figure 2). The peak at 1091 cm-1 belonged to the stretching peak of the C-O-C ether linkage in PU-1 and PU-3. The peak at 2270 cm-1 corresponding to the NCO group disappeared, indicating that the NCO had completely reacted. The characteristic peak at 3350 and 1728 cm-1 was assigned to the stretching of the secondary amino -NH- group and the C=O group, respectively, and this indicates that there were a large number of the -NHCO- group in the polymer molecule chains. The results showed that PUs were successfully synthesized.

FT-IR spectra of PUs.

3.2 Dynamic mechanical thermal analysis

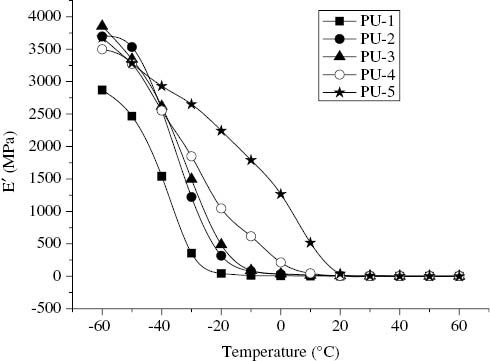

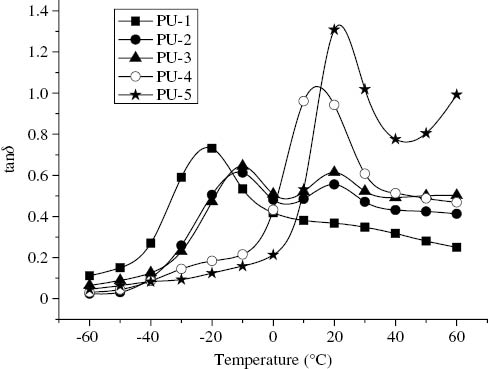

In this study, the temperature range (ΔT) for effective loss factor (tanδ>0.4) was taken to quantitatively evaluate the damping properties of the PU materials. The temperature dependence of the storage modulus (E′) and tanδ for PUs are shown in Figures 3 and 4, respectively. The effects of the mPESP/mPETP ratio on the dynamic mechanical properties of PUs were investigated.

DMTA curves of the storage modulus E′ vs. temperature for PUs.

DMTA curves of tanδ vs. temperature for PUs.

Figure 3 shows that E′ decreased as temperature increased. In the -40°C to 20°C temperature range, the E′ of PU-5 was the maximum. This is because the structure of the PESP was more rigid than that of the PETP. The E′ of PU-1 was minimum, and those of other PUs were between PU-1 and PU-5. As the temperature has reached beyond 20°C, the E′ values of PUs tended to the same value.

As shown in Figure 4, the damping performances of PUs from five mPESP/mPETP ratios were significantly different. Among the five curves, PU-1 and PU-5 indicated single glass transition temperatures (Tg) of -20°C and 22°C, respectively. Each of the other samples displayed two kinds of relaxations, and the low temperature peaks are related to the Tg of the PETP segment phase CIIR; high temperature peaks correspond to the Tg of the PESP segment phase. This is because the micro-phase separation for PUs varied with the mPESP/mPETP ratio. When the mPESP/mPETP ratio has reached an appropriate ratio range, the PETP and PESP segments would exhibit a certain degree of micro-phase separation in PUs. As seen in Figure 4, bimodal appeared in PU-2 and PU-3, tanδ was up to 0.65, and the ΔT of tanδ>0.4 was beyond 60°C. The improvement of the ΔT was attributed to a strong interaction between a flexible ether bond in the propoxylated group and rigid neopentyl groups and ester groups of PUs. Meanwhile, the mechanical vibration energy that converted into thermal energy was higher due to the friction within the PU matrix with the side methyl group. As the content of the PESP exceeded 60%, PU-4 exhibits efficient damping property in a narrow temperature range and could only be used at the temperature >0°C. Those results indicated that the combination of PESP and PETP with the side methyl group was effective for increasing ΔT to improve operating temperature and damping capacity.

3.3 Mechanical property analysis

The tensile and tear strength of PUs from different mPESP/mPETP ratios were shown in Table 2. The tensile strength and tear strength of the PUs increased slightly as the PESP content increased (Table 2). However, the elongation at break was in contrast. As the content of PESP increased, the relatively rigid segments gradually increased. Therefore, the tensile strength further increased. At the same time, the flexibility of the polymer chain deteriorated, and the tensile deformation was essentially a process of “consume” flexibility of polymer chain. Thus, increasing PESP content led to a decline in the elongation at break compared to net PESP.

Mechanical properties of PUs from different mPESP/mPETP ratios.

| Sample name | Tensile strength (MPa) | Tear strength (kN/m) | Elongation at break (%) |

|---|---|---|---|

| PU-1 | 3.63 | 7.98 | 1472 |

| PU-2 | 3.76 | 8.87 | 1236 |

| PU-3 | 3.94 | 9.97 | 1150 |

| PU-4 | 4.24 | 10.84 | 1088 |

| PU-5 | 5.97 | 22.97 | 779 |

3.4 STM analysis

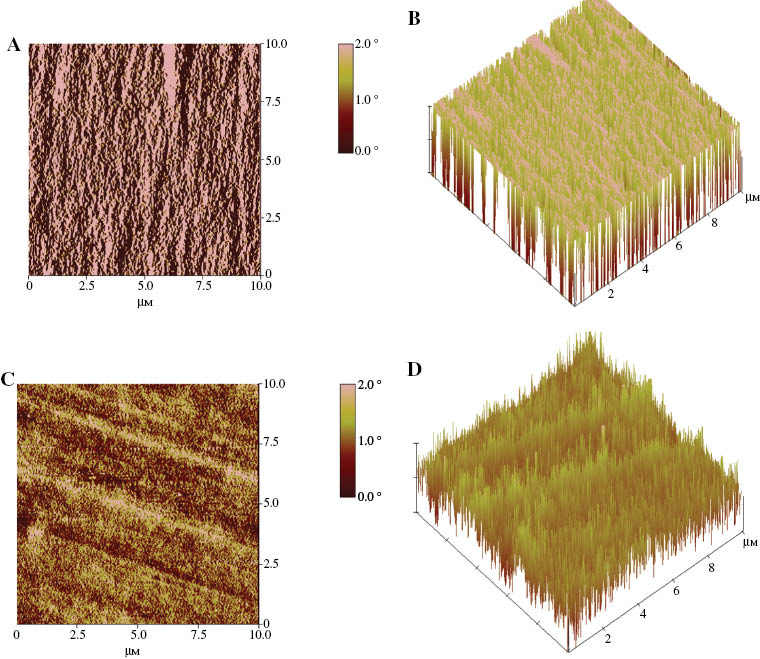

In recent years, STM have been successfully used in microscopic surface morphology and performance analysis, inspection measurement, etc. (10). To understand the morphology of PUs, STM measurements were conducted to investigate the surface morphology of PU-2 and PU-5 films. Two-phase structures were observed in PU-2 and PU-5 from Figure 5. The darker part corresponding to the hard segment in diagram was the low-lying portion of the surface, and the lighter part corresponding to the soft segments in diagram was the convex portion of the surface. In PU-2, polyester segments may be considered as harder segments relative to polyether segments, indicating that PU-2 had more efficient phase separation and more complicated combination of hard and soft segments compared to PU-5. It can be concluded from Figure 5D that the bump height was not consistent but scattered high and low, which was due to the irregular “block” of PESP and PETP.

STM images of PU-5 and PU-2: (A, C) height and (B, D) three dimensions.

4 Conclusions

PUs with a wide damping temperature range were prepared from mixed-base PESP and PETP, and the structures and properties of PUs were investigated. As the mPESP/mPETP ratio was 40/60 and 45/55, PU-2 and PU-3 presented a wide temperature range of ΔT beyond 60°C, with tanδ of more than 0.4 and the tanδ maximum reached up to 0.65. The tensile strength and tear strength could reach 3.76 and 3.94 MPa and 8.87 and 9.97 kN/m, respectively. Those results indicated that the combination of PESP and PETP with side methyl group were effective for increasing ΔT to greatly improve operating temperature and damping capacity. This method was a good way to obtain high-damping-performance PU materials. It can be concluded from the phase diagram of STM that the structures of PUs from mixed-base PETP and PESP were more complex and with irregular “block” structures. Thus, PUs may find use in high-performance damping materials.

References

1. Li Q, Huang GS, Jiang LX. Compatibility and damping properties of PMPS/PMAc simultaneous interpenetrating polymer networks. Acta Polym Sin. 2003;2003:409–13.Search in Google Scholar

2. He XR, Huang GS, Zhou H, Jiang LX, Zhao XD, Zhang J, Wang JH. Investigation of the damping behaviour of CIIR/PMAc blends. Acta Polym Sin. 2005;2005:108–12.Search in Google Scholar

3. Wang BZ, Huang WB, Huang BC, Yao W. Damping properties of polyether-based polyurethanes. China Synth Rubber Ind. 2004;27:309–13.Search in Google Scholar

4. Xu LS, Zhou HJ, Zhang XL, Liu DJ, Li YT, Qu XW. Preparation, characterization and properties of polyurethane damping materials with different polyester diol structures in the main chains. Polym Mater Sci Eng. 2012;28:125–8.Search in Google Scholar

5. Zhang XL, Zhou HJ, Li YT, Liu DJ, Qu X W. Characterization and properties of polyester type polyurethane damping materials. Polym Mater Sci Eng. 2013;29:62–5.Search in Google Scholar

6. Tong YC, Lv ZP, Guo XP, Yu X, Zhang X and Wu R. Preparation and characterization of polyurethane by different preparation method. Polym Mater Sci Eng. 2013;29:58–61.Search in Google Scholar

7. Chang MCO, Thomas DA, Sperling LH. Group contribution analysis of the damping behavior of homopolymers, statistical copolymers, and interpenetrating polymer networks based on acrylic, vinyl, and styrenic mers. l. Polym Sci B Polym Phys. 1988;26:1627–40.10.1002/polb.1988.090260806Search in Google Scholar

8. Chang MCO, Thomas DA, Sperling LH. Characterization of the area under loss modulus and tanδ-temperature curves: acrylic polymers and their sequential interpenetrating polymer networks. J Appl Polym Sci. 1987;34:409–22.10.1002/app.1987.070340132Search in Google Scholar

9. Fay JJ, Thomas DA, Sperling LH. Evaluation of the area under linear loss modulus-temperature curves. J Appl Polym Sci. 1991;34:1617–23.10.1002/app.1991.070430905Search in Google Scholar

10. Bao JJ, Gao MZ, Zhou HF, Rao XM, Qu QY, Xu GW. Advance on the application of atomic force microscope to polyurethane material analysis. China Elastomerics. 2006;16:53–7.Search in Google Scholar

©2015 by De Gruyter

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- In this Issue

- Guest Editorial

- Novel insights in polymer and composite materials

- Full length articles

- Ultraviolet high-transmitting cross-linked polymer materials derived from mercaptopropyl polyhedral oligomeric silsesquioxane

- Research on mechanical properties of a polymer membrane with a void based on the finite deformation theory

- Study of the effects of water content and temperature on polyacrylamide/polyvinyl alcohol interpenetrating network hydrogel performance by a molecular dynamics method

- Electrospun acetaminophen-loaded cellulose acetate nanofibers fabricated using an epoxy-coated spinneret

- Structure performance of UVA and UVB light irradiated poly-p-phenylene benzobisoxazole fiber (PBO)

- Preparation and characterization of polyurethane damping materials derived from mixed-base prepolymers containing numerous side methyls

- Energy dissipation of a two-relaxation-time material

- Investigation into the toughening mechanism of epoxy reinforced with multi-wall carbon nanotubes

- Surface characterization of trimethoxysilane-containing high-solid hydroxyl acrylic resin films

- Synthesis and characterization of temperature-sensitive hydrogels

- Novel authigenic gas foaming hydrogels for preventing coal spontaneous combustion

Articles in the same Issue

- Frontmatter

- In this Issue

- Guest Editorial

- Novel insights in polymer and composite materials

- Full length articles

- Ultraviolet high-transmitting cross-linked polymer materials derived from mercaptopropyl polyhedral oligomeric silsesquioxane

- Research on mechanical properties of a polymer membrane with a void based on the finite deformation theory

- Study of the effects of water content and temperature on polyacrylamide/polyvinyl alcohol interpenetrating network hydrogel performance by a molecular dynamics method

- Electrospun acetaminophen-loaded cellulose acetate nanofibers fabricated using an epoxy-coated spinneret

- Structure performance of UVA and UVB light irradiated poly-p-phenylene benzobisoxazole fiber (PBO)

- Preparation and characterization of polyurethane damping materials derived from mixed-base prepolymers containing numerous side methyls

- Energy dissipation of a two-relaxation-time material

- Investigation into the toughening mechanism of epoxy reinforced with multi-wall carbon nanotubes

- Surface characterization of trimethoxysilane-containing high-solid hydroxyl acrylic resin films

- Synthesis and characterization of temperature-sensitive hydrogels

- Novel authigenic gas foaming hydrogels for preventing coal spontaneous combustion