Abstract

We aim to utilise the tea tree (Melaleuca alternifolia) fibre, a waste from the distillation process, as a reinforcement or filler in tapioca starch (TS) composites. Fabrication of tea tree fibre-reinforced TS composites was successfully developed using a casting method. The physical, thermo-chemical, and mechanical properties were tested in order to get the characterisation of the composites. From the mechanical test, the addition of 5% (v/v) tea tree fibre as a filler improved the tensile strength of the TS composites up to 34.39% in tea tree leaf-reinforced TS composites (TTL/TS), 82.80% in tea tree branch-reinforced TS composites (TTB/TS) and 203.18% in tea tree trunk-reinforced TS composites (TTT/TS). The water absorption and swelling of all tea tree fibre-reinforced composites decreased compared to those of TS composites. Most importantly, all parts of the tea tree waste, namely, the tea tree leaf, tea tree branch and tea tree trunk, have additional potential value as fibres that can act as a reinforcement in developing a green biocomposite.

1 Introduction

There is a huge demand for biofibres for reinforcement purposes. Their high specific stiffness, flexibility during processing and low cost make them attractive for composites (1). The main purpose of developing natural fibre-reinforced materials is to create alternative composites that can replace the available composites derived from glass fibre, metal, plastic and wood (2). Various studies related to the development of biocomposites reinforced by natural fibres have been done before using banana, coconut shell, kenaf, rice husk, coir, sugarcane bagasse, roselle, oil palm, sugar palm tree, carbon and coir-sisal-blended yarn (3–9).

According to Abba et al. (10), various processing methods and conditions are used for composite production such as compression moulding, injection moulding, extrusion method and thermoforming process. A number of thermoplastic polymer starches have been successfully developed using a simple casting method. For examples, Arismendi et al. (11) produced film from tapioca starch (TS) blended with xantham gum, glycerol and potassium sorbate. Wicaksono et al. (12) developed tapioca film using a casting method reinforced by cellulose nanofibres from cassava baggase. Espinel Villacrés et al. (13) produced TS film with hydroxypropyl methylcellulose, glycerol and also potassium sorbate through a casting technique. Versino and García (14) developed cassava-based film reinforced with its own root fibre using a casting method. Gutierrez et al. (15) produced film from cassava starch and native cush-cush yam.

Melaleuca alternifolia, also commonly known as tea tree, is a tall shrub or a small tree from the genus Melaleuca. It is native to Queensland, stretching to northeast of New South Wales, Australia. Famous for its oil, tea tree has been used in a wide range of products, either as formulated or as pure oil, as a preservative, antiseptic, antibacterial, antifungal and even as an anti-pest agent (16, 17). Tea tree oil is produced by steam distillation of the leaves, and the yield of the oil is typically 1–2% of the wet weight of the plant (18). Basically, after distillation, the tea tree leaves are burned or composted (19). Richard (20) reported that, in Australia, there are companies that dry the residue leaves after distillation and then return them to the plantation as mulch. For that reason, these underutilised fibres are undervalued as they are considered as waste (19). To the best of our knowledge, there are no reports on the utilisation of tea tree fibres for reinforcement purposes in biocomposites. This paper aims to show the utility of tea tree fibres as reinforcing fillers by making biocomposites using starch as a matrix material.

2 Materials and methods

2.1 Preparation of materials

Throughout this study, tea tree fibres were taken from Sabah Economic Development & Investment Authority (SEDIA)’s tea tree field at the Demonstration Plot located at Mile 30 Kimanis, Papar, Sabah, Malaysia. A chainsaw was used to cut down the tree for easy ground harvesting of the fibres. Harvesting of the fibres was done manually using a slashing knife. Fibres from different parts of the tree such as tea tree leaf (TTL), tea tree branch (TTB) and tea tree trunk (TTT) were extracted. In order to obtain the fibres, every part of the tea tree was cut separately and dried. The fibres themselves remain relatively unchanged during this process. Tapioca starch and glycerol (Sigma-Aldrich) were supplied by Sri Juta Riang Sdn Bhd (Sabah, Malaysia).

2.2 Determination of the chemical composition of tea tree fibre

In order to obtain the chemical composition of the fibres, every part of the tea tree, TTL, TTB, and TTT, was cut into chips and ground to pass a BS 40-mesh sieve and retained on a BS 60-mesh sieve. The fibre samples used for the chemical composition determination in this study were roughly at equilibrium with the moisture of the air. The cellulose content was determined using TAPPI standard methods (T 203 os; TAPPI: Technical Association of the Pulp and Paper Industry). The fibre samples were extracted consecutively with 17.5% and 8.3% sodium hydroxide solutions at 25°C. The soluble fraction, consisting of β- and γ-cellulose, was determined volumetrically by oxidation with potassium dichromate, and the α-cellulose, as an insoluble fraction, was derived by difference.

2.3 Fabrication of the composites

Tea tree fibre-reinforced TS composites were prepared in accordance with Chillo et al. (21) with slight modification. Tapioca starch and glycerol were mixed and dispersed in distilled water. The mixture contained 80% (v/v) water, 15% (v/v) glycerol and 5% (v/v) TS. The mixture was heated on a hot plate at 130°C for 30 min under continuous stirring until the mixture gelatinised. Subsequently, the mixture was cast in a mould sized 17×17×1 cm. The mixture was then dried at room temperature. The method was repeated for the fabrication of tapioca composites reinforced with tea tree fibres, by adding another 5% (v/v) tea tree fibres. The tea tree fibres were added when the mixture gelatinised. The composites were labelled as TS, TTL/TS, TTB/TS and TTT/TS, respectively.

2.4 Mechanical properties

Tensile tests were carried out in accordance with ASTM D5083 (1996) (22) using a universal testing machine (AI-7000M, Gotech, Taiwan). The rate of testing used was 5 mm/min. Five samples of size 10 cm (L)×1 cm (W)×thickness (T) in centimetres were tested for different composite groups.

2.5 Thermogravimetric analysis

Thermogravimetric analysis was carried out using a PerkinElmer analyser. Analyses were performed in a temperature range between a room temperature of 30°C and 700°C at a heating rate of 20°C/min in an atmosphere of nitrogen and a flow rate of 20 ml/min. A sample of the materials weighing 10–20 mg of each sample was heated in a sample pan.

2.6 Thickness of the composites

The thickness of the composites was determined by using a Mitutoyo micrometer clip. Readings from 10 random positions of the composites were evaluated.

2.7 Measurement of the density of the tea tree fibre and its composite

Density was determined by using the following formula: ρ (g/cm3)=m/V, where m and V are the mass and volume of the composite, respectively

The density (ρ) of the tea tree fibres was determined using a specific gravity bottle and water as the liquid. Initially, the fibres were weighed (m) before being immersed in water. The amount of water changes before and after immersion was recorded.

For the density (ρ) of the composites, it was measured directly from the composite itself. The average of 10 samples was calculated.

2.8 Water absorption testing

Prior to the water absorption measurements, the samples were dried at 80°C until they reached a constant weight. Ten samples of each type of composites were soaked in water for 24 h. The average value of the final weight was taken. Weight gain (WG) was calculated using the following equations:

where W1 is the initial weight (g) before soaking in water and W2 is the final weight (g) after soaking to water.

2.9 Fourier transform infrared spectroscopy

Fourier transform infrared (FTIR) spectroscopy was used in order to detect the presence of the functional groups in the composites. The spectra of the composites were obtained using an IR spectrometer (Perkin-Elmer Spectrum 100). About 2 mg of the sample was pressed into a disc of about 1 mm thick. The FTIR spectra of the sample were collected in the range of 4000–600 cm-1.

2.10 Scanning electron microscopy

A scanning electron microscope (Zeiss EVO-MA) with an operating voltage of 0.3–30 kV was used to obtain scanning electron micrographs from the fractured tensile test samples of the composites to evaluate the homogeneous distribution of the fibres and the matrix and the adhesion between them.

3 Results and discussion

3.1 Chemical composition of the tea tree fibre

From Table 1, it can be seen that TTT has the highest cellulose content compared to the other fib res, followed by TTB and TTL, respectively. Plant fibres are composite materials designed by nature. Cellulose is the main structural component that gives strength and stability to plant cell walls and fibres (23, 24). Most plant fibres consist of cellulose, hemicellulose, lignin, extractives and ash (25). The results of this chemical composition will determine the mechanical properties of the composites.

Chemical composition and density of the tea tree fibres

| Part | Cellulose (%) | Density (g/cm3) |

|---|---|---|

| Tea tree leaf (TTL) | 13.5 (±0.01) | 0.42 (±0.06) |

| Tea tree branch (TTB) | 27.2 (±1.10) | 0.24 (±0.04) |

| Tea tree trunk (TTT) | 33.9 (±0.30) | 0.18 (±0.02) |

Values in parentheses are standard deviations.

3.2 Fourier transform infrared spectroscopy

FTIR spectroscopy is one of the most powerful tools used for evaluating the specificity of the functional groups that exist in each morphological region. Figure 1 shows the FTIR spectra for all composites. As can be seen in the figure, the spectra were almost the same for all composites. The peak at 3200–3500 cm-1 indicates the presence of the OH groups. This is due to the hydroxyl groups of cellulose, hemicellulose and lignin (26). The peak at 2850–3000 cm-1 shows the C-H stretching. The peak at 1600–1800 cm-1 shows the existence of the carbonyl group C=O in the hemicellulose and lignin. The peak at 1475–1600 cm-1 corresponds to the stretching of the aromatic groups present in lignin (27). The peak at 1000–1300 cm-1 shows the presence of the C-O groups (28).

FTIR spectra of the composites.

3.3 Mechanical properties

Figure 2 shows the tensile stress-strain behaviour of the tea tree fibre-reinforced TS composites (TS, TTL/TS, TTB/TS and TTT/TS). The deformation behaviour of the composites can be understood through the tensile stress-strain curve. It was found that all types of composites have a brittle nature owing to the linear increase in tensile stress at low strain rates followed by the drastic decrease shown in the tensile stress-strain curve. Figure 2 also shows that TTB/TS exhibited a higher stiffness compared to the other composites as determined from the slope of the stress-strain curve.

Tensile strength vs. tensile strain of the tea tree fibre-reinforced tapioca starch (TS) composites.

Table 2 shows the starch-based film composites collected from the literature. The tensile strength, elongation at break and Young’s modulus of the TS composites used in the present work are comparable to those of many other starch-based composites. In this study, the tensile strength of the TS composites is not far from that of the composite film of Parra et al. (29) (cassava starch: 1 g of starch/100 ml of water+1 g of glycerol/100 ml of water), Arismendi et al. (11) (TS: 4.5 g/100 g+2.5 g/100 g) and Espinel Villacrés et al. (13) (TS: 3 g/100 g+2 g/100 g of glycerol). Dieulot and Skurtys (30) reported the starch-based film composites from 322 observations collected from the literature and found that the tensile strength of tapioca-based film is within the average of 0.3–85 MPa. The elongation at break of the TS composites in this study is close to that of Arismendi et al. (11) and Versino and García (14) (3% w/w starch+25% w/w glycerol). Dieulot and Skurtys (30) reported from their literature review that the strain at break is in the range of 1–150%. In terms of Young’s modulus, the TS composites in this study are stiffer than the composites in Espinel Villacrés et al. (13).

Mechanical properties of the other starch films.

| Composite type | Tensile strength (Mpa) | Elongation at break (%) | Young’s modulus (Mpa) | References |

|---|---|---|---|---|

| TS+glycerol | 0.16 (±0.01) | 131 (±5.01) | 1.25 (±0.037) | Current study |

| TS+glycerol+KS | 0.38 | 280.6 | – | (14) |

| TS+sorbitol | 1.45(±0.5) | 33.89 (±4) | – | (15) |

| TS+glycerol+KS | 0.2 (±0.1) | 2.2 (±0.3) | 0.13 (±0.02) | (16) |

| CS+glycerol | 2.03 (±0.85) | 284.4 (±18.8) | – | (17) |

| CS+glycerol | 1.16 (±0.05) | 38 | 6.2 (±0.4) | (18) |

| TS+glycerol | 0.36(±0.018) | 11 (±0.47) | – | (31) |

| Starch-based film | 0.3–85 | 1–150 | – | (32) |

| TS+glycerol | 0.69 (±0.15) | – | – | (33) |

| TS+glycerol | 2.5 | 43 | – | (34) |

| PS+glycerol | 3.89 | 42 | – | (35) |

| CS+sorbitol+glycerol | 3.5 | – | 50 | (36) |

Values in parentheses are standard deviations. TS, tapioca starch; CS, cassava starch; PS, potato starch; KS, potassium sorbate.

For a better understanding of the effects of tea tree fibre reinforcement in TS composites, we compared the TS composites with other tea tree fibre-reinforced TS composites. Figure 3 shows the tensile strength of tea tree fibre-reinforced TS composites. The figure shows that TTT/TS had the highest tensile strength, followed by TTB/TS, TTL/TS and TS. The addition of 5% (v/v) tea tree fibre as a filler improved the tensile strength, with 34.39% for TTL/TS, 82.80% for TTB/TS and 203.18% for TTT/TS. The trend can be correlated to the amount of cellulose, where it was highest in TTT, followed by TTB and TTL (Table 1). The work of Habibi et al. (34) supports the trend in that the mechanical properties are strongly influenced by the cellulose content of the fibres. Strengthening mechanisms were associated with the ability of the fibres to form a network structure with the matrix and were attributed to the high contact surface area of the smaller fibres (35). Tea tree fibres are believed to work as a carrier of load in the starch matrix. The stronger bonding between matrix and fibres leads to enhanced interfacial adhesion between them, thus resulting in a great transfer of stress from the matrix to the tea tree fibres during the tensile test (6). The mechanical properties of the composites also depend on the dispersion of the fibres in the starch matrix, whereby if the fibres are equally dispersed in the matrix, the stress can be transferred equally to the whole composites and vice versa. This fact also explains why different composite materials demonstrate different mechanical properties. This is evident in the scanning electron micrographs of the composites in Figure 4.

Tensile strength of the tea tree fibre-reinforced TS composites.

Scanning electron micrographs of (A) TS, (B) TTL/TS, (C) TTB/TS and (D) TTT/TS.

Figure 5 shows the elongation at break of the composites. High values of elongation at break indicate high ductility of the materials. It was observed that TS gave the highest value of elongation at break, followed by TTT/TS, TTB/TS and TTL/TS. By the addition of 5% (v/v) tea tree fibre, the ductility of the TS plastic decreased by 18.23% in TTT/TS, 58.35% in TTB/TS and 59.27% in TTL/TS, respectively. This might be due to the cellulose content in the composites, which reduced the elasticity and ductility of the materials by giving them mechanical strengths. Wicaksono et al. (12) reported that the reduction in elongation at break is caused by the restriction of the molecular mobility of the polymer chains due to the addition of the fibres. The interaction between starch chains and cellulose fibres can interfere with the interactions between starch chains and water, thus making the film more rigid, which reduces its flexibility (12).

Elongation at break of the composites.

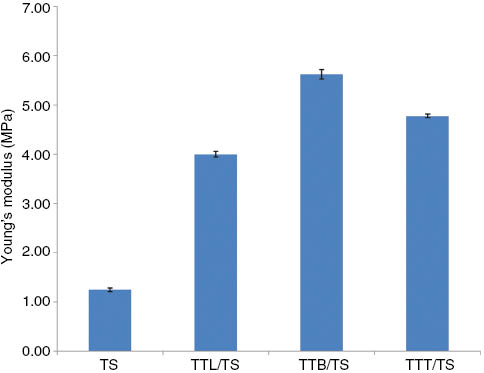

Figure 6 shows the tensile modulus or Young’s modulus of the composites. The slope of the graph of the tensile strength vs. elongation at break gives the tensile modulus. The tensile modulus indicates the relative stiffness property of a material (4, 36), i.e. the ability of a material to resist deformation in tension. The tensile modulus is higher for stiffer materials (4, 37). TTB/TS had the highest stiffness followed by TTT/TS, TTL/TS and TS, respectively (Figure 6). With the addition of 5% (v/v) tea tree fibre as a filler, the Young’s modulus of TS improved by 350% for TTB/TS, 282% for TTT/TS and 220% for TTL/TS.

Young’s modulus of the composites.

With the addition of tea tree fibres, the mechanical properties were improved compared to TS even though the quantity was only 5% (v/v). Figure 4A is the TS plastic surface of the fractured part after the tensile test was done. Figure 4B is the TTL/TS composite. It can be clearly seen in the figure that the TTL fibre is embedded in the TS matrix, although voids still exist. The voids in the matrix will loosen the fibre-starch bond, and thus the stress cannot be transferred effectively to the whole composite. This explains why TTL/TS exhibited a lower tensile strength compared to TTB/TS and TTT/TS, yet was still higher than that of TS. Figure 4C is the TTB/TS composite, where the TTB fibre adheres to the matrix very well. Figure 4D is the TTT/TS composite, where the TTT fibre is tightly bound to the matrix. This explains why TTT/TS exhibited the highest tensile strength as the bond between the fibres and the starch was strong. The mechanical properties can be improved further by changing the composite preparation procedure, such as using the vacuum process to avoid air bubbles, as the casting method could provide inhomogeneity in fibre distribution (12). As suggested by Oksman et al. (38), the poor dispersion of fibres in the matrix prevents them from performing their mechanical behaviour effectively. Humidity is one of the most important factors affecting the mechanical properties of thermoplastic starch. For example, the mechanical strength of starch composites can reach 20 MPa in 0% relative humidity (RH); however, at high moisture conditions, the tensile strength may be below 1 MPa due to water plasticisation (39, 40).

3.4 Thermogravimetric analysis

Thermogravimetric analysis is one of the thermal analysis techniques used for measuring the mass change, thermal decomposition and thermal stability of materials. Figure 7 shows the thermogravimetric curve of the composites. The mass loss behaviour was similar for all composites. The molecular structure of the composites was degraded when heated. The first mass loss in the range of 31–100°C may be due to water loss (41). According to Mohanty et al. (42), the mass loss between 150°C and 380°C in tea tree fibre-reinforced TS composites is due to the decomposition of the three major constituents of natural fibres: hemicellulose, cellulose and lignin. Generally, the thermal decomposition of these fibres consists of four phases: decomposition of hemicellulose, cellulose, lignin and ash (43, 44). The mass loss below 290°C indicates the vaporisation of glycerol, as the boiling point of pure glycerol is 290°C (45). The large degradation at 310°C shows the further elimination of the polyhydroxyl groups, accompanied by depolymerisation and decomposition in starch (46). A carbonaceous (substance rich in carbon) residue remains after all the volatile products have been driven out (47). Sahari et al. (6) reported that the component left after lignin has been completely decomposed is inorganic materials in the fibre, which can be assumed as ash content, and it can be completely decomposed at very high temperature of up to 1723°C. As seen in Figure 7, at almost 690°C, the lignin and ash content of TS, TTL/TS, TTB/TS and TTT/TS were 6.1%, 9.4%, 6.9% and 7.3%, respectively. These results prove that tea tree fibres increase the thermal stability of composites.

Thermogravimetric analysis curve of the composites.

3.5 Physical properties

3.5.1 Density and thickness of composite

Table 2 shows the density of the tea tree fibres. According to the method, the volume of water dispersed after the fibres have been immersed in water is equivalent to the volume of the fibres, which we put in the formula to get the density of the fibres. It was observed that TTL had the highest density, followed by TTB and TTT. Meanwhile, Table 3 shows the density of the composites. This matches with the density of the corresponding fibres. The density of composites depends on the dispersion of fibres in the matrix. If the dispersion of fibres is good and they are properly embedded in the matrix with no voids and tight packing, then the composites will show higher density owing to the decreased volume. As such, this packed matrix also gives higher mechanical strengths to the composites.

Some of the physical properties of the composites.

| Composite | Thickness (mm) | Density (g/cm3) | Water absorption (%) | Thickness swelling (%) |

|---|---|---|---|---|

| TS | 1.47 (±0.05) | 1.1 (±0.04) | 37.64 (±0.66) | 16.96 (±0.74) |

| TTL/TS | 1.70 (±0.02) | 1.13 (±0.04) | 35.28 (±0.77) | 14.96 (±0.73) |

| TTB/TS | 1.25 (±0.03) | 0.93 (±0.03) | 33.16 (±0.62) | 13.24 (±0.6) |

| TTT/TS | 1.37 (±0.03) | 0.83 (±0.04) | 27.06 (±0.62) | 8.9 (±0.6) |

Values in parentheses are standard deviations.

Table 3 shows the thickness of the composites. It can be seen in the table that all composites are thicker than TS, which has a thickness of 1.47 mm (±0.06). TTL/TS is the thickest, followed by TTT/TS and TTB/TS. In this study, we prepared the composites by using volume over volume (v/v) ratio, so we expected to get the same desired final volume for all composites. We also expected to obtain the same final volume for the mould. However, since we used a casting method and drying under room temperature, it was hard to control the desired volume as evaporation of water from the composites occurred.

3.5.2 Water absorption and thickness swelling of the composites

Table 3 shows the water absorption of all composites. TS absorbed water the most, followed by TTL/TS, TTB/TS and TTT/TS, respectively. The results of the water absorption were closely related to the thickness swelling of the composites. As shown in the table, the pattern of the thickness swelling of the composite graph is similar to water absorption, where TS swelled most, followed by TTL/TS, TTB/TS and TTT/TS, respectively. From these results, it can be seen that, with the addition of fibres, even at just 5% (v/v), the water absorption and swelling of composites decreased. This is due to the hydrophobic nature of tea tree fibres compared to starch matrix (7). Ma et al. (48) claimed that starch is a multi-hydroxyl polymer with three hydroxyl groups per monomer. The decrease in water absorption after tea tree fibres were introduced indicates that these fibres are a better water-resistant material than starch matrix TS. This may also be due to the interfacial bonding between the matrix and the fibres as well as to the hindrance in absorption caused by the fibres (7). These criteria demonstrate the high potential of these tea tree fibre-reinforced composites as a packaging material in the industry. In addition, the characteristics of the product to be packaged and the packaging requirements should also be taken into consideration (15).

4 Conclusion

The fabrication and characterisation of tea tree fibre-reinforced TS composites were successfully done. All composites showed superior mechanical properties in comparison to TS. The addition of 5% (v/v) tea tree fibres as a filler to TS led to the improvement in Young’s modulus by 350% for TTB/TS, 282% for TTT/TS and 220% for TTL/TS. The mechanical properties are related to the cellulose content. Scanning electron microscopy showed a good dispersion of the tea tree fibre in the matrix. Also, the addition of the fibres decreased the water absorption and thickness swelling compared to TS composites. Fourier transform infrared spectroscopy, as well as thermogravimetric analysis, showed a similar pattern for all composites. Most importantly, the tea tree fibre-reinforced TS composites are better than the TS composites in all aspects. Hence, all parts of the tea tree waste, namely, the tea tree leaf, tea tree branch and tea tree trunk, can act as a reinforcement or a filler in the development of green biocomposites. This provides a better option to the industry in making green and renewable biocomposites.

Acknowledgments

The authors would like to thank Sabah Economic Development & Investment Authority (SEDIA), University Malaysia Sabah (UMS), University Putra Malaysia (UPM) and the Ministry of Higher Education Malaysia through RACE grant for their support in this research.

References

1. Sahari J, Sapuan SM. Natural fibre reinforced biodegradable polymer composites. Rev Adv Mater Sci. 2011;30:166–74.Search in Google Scholar

2. Sain M, Suhara P, Law S, Bouilloux A. Interface modification and mechanical properties of natural fiber-polyolefin composite products. J Reinf Plast Compos. 2005;24(2):121–30.10.1177/0731684405041717Search in Google Scholar

3. Sahari J, Sapuan SM, Ismarrubie ZN, Rahman MZ. Comparative study on physical properties of different part of sugar palm fibre reinforced unsaturated polyester composites. Key Eng Mater. 2011;471–2:455–60.10.4028/www.scientific.net/KEM.471-472.455Search in Google Scholar

4. Sahari J, Sapuan SM, Ismarrubie ZN, Rahman MZ. Investigation on bending strength and stiffness of sugar palm fibre from different parts reinforced unsaturated polyester composites. Key Eng Mater. 2011;471–2:502–6.10.4028/www.scientific.net/KEM.471-472.502Search in Google Scholar

5. Sahari J, Sapuan SM., Ismarrubie ZN, Rahman MZ. Physical and chemical properties of different morphological parts of sugar palm fibres. Fibres Text East Eur. 2012;20,2(91):23–6.10.1177/096739111202000913Search in Google Scholar

6. Sahari J, Sapuan SM, Zainudin ES, Maleque MA. Mechanical and thermal properties of environmentally friendly composites derived from sugar palm tree. Mater Des. 2013;49:285–9.10.1016/j.matdes.2013.01.048Search in Google Scholar

7. Sahari J, Sapuan SM, Zainudin ES, Maleque MA. Thermo-mechanical behaviors of thermoplastic starch derived from sugar palm tree Arenga pinnata. Carbohydr Polym. 2013;92(2):1711–6.10.1016/j.carbpol.2012.11.031Search in Google Scholar PubMed

8. Jun HS. Manufacturing method of carbon and glass fabric composites with dispersed nanofibers using vacuum-assisted resin transfer molding. e-Polymers 2014;14(5):345–52.10.1515/epoly-2014-0091Search in Google Scholar

9. Anil A, Jose ET, George G, Joseph K. Commingled composites of polypropylene/coir-sisal yarn: effect of chemical treatments on thermal and tensile properties. e-Polymers 2015; 15(3):169–77.10.1515/epoly-2014-0186Search in Google Scholar

10. Abba HA, Ismarrubie ZN, Sapuan MS. Review of agro waste plastic composites production. J Miner Mater Charact Eng. 2013;1:271–9.10.4236/jmmce.2013.15041Search in Google Scholar

11. Arismendi C, Chillo S, Conte A, Del Nobile MA, Flores S, Gerschenson LN. Optimization of physical properties of xanthan gum/tapioca starch edible matrices containing potassium sorbate and evaluation of its antimicrobial effectiveness. LWT Food Sci Technol. 2013;53:290–6.10.1016/j.lwt.2013.01.022Search in Google Scholar

12. Wicaksono R, Syamsu K, Yuliasih I, Nasir M. Cellulose nanofibers from cassava bagasse: characterization and application on tapioca-film. Chem Mater Res. 2013;3(13):79–87.Search in Google Scholar

13. Espinel Villacrés RA, Flores SK, Gerschenson LN. Biopolymeric antimicrobial films: study of the influence of hydroxypropyl methylcellulose, tapioca starch and glycerol contents on physical properties. Mater Sci Eng C 2014;36:108–17.10.1016/j.msec.2013.11.043Search in Google Scholar PubMed

14. Versino F, García MA. Cassava (Manihot esculenta) starch films reinforced with natural fibrous filler. Ind Crops Prod. 2014;58:305–14.10.1016/j.indcrop.2014.04.040Search in Google Scholar

15. Gutierrez TJ, Tapia MS, Perez E, Fama L. Structural and mechanical properties of edible films made from native and modified cush-cush yam and cassava starch. Food Hydrocolloids 2015;45:211–7.10.1016/j.foodhyd.2014.11.017Search in Google Scholar

16. Southwell I, Lowe R. The tea tree genus Melaleuca. Netherlands: Harwood Academic Publishers; 1999. pp. 63–76, 81–9.10.1201/9780203303603Search in Google Scholar

17. Colton RT, Murtagh GJ, Drinnan J, Clarke B. Tea tree oil. Agfact P6.4.6. 2nd ed. Orange: NSW Agriculture; 2000.Search in Google Scholar

18. Wrigley JW, Fagg M. Bottlebrushes, paperbarks and tea trees and all other plants in the Leptospermum Alliance. Pymble, Australia: Angus & Robertson; 1993.Search in Google Scholar

19. Rodney J, Sahari J, Mohd Kamal Mohd Shah. Review: tea tree (Melaleuca Alternifolia) as a new material for biocomposites. J Appl Sci Agric. 2015;10(3):21–39.Search in Google Scholar

20. Richard LD. The Australian tea tree oil industry. In: IFEAT International Conference “Australia and New Zealand: Essential Oils and Aroma Chemicals – Production and Markets”, 2–6 November 2003, Sydney, Australia; 2003.Search in Google Scholar

21. Chillo S, Flores S, Mastromatteo M, Conte A, Lia Gerschenson, Del Nobile MA. Influence of glycerol and chitosan on tapioca starch-based edible film properties. J Food Eng. 2008;88:159–68.10.1016/j.jfoodeng.2008.02.002Search in Google Scholar

22. ASTM D 5083. American Society for Testing Materials; 1996.Search in Google Scholar

23. Reddy N, Yang Y. Biofibers from agricultural byproducts for industrial applications. Trends Biotechnol. 2005;23(11):22–7.10.1016/j.tibtech.2004.11.002Search in Google Scholar

24. Ray D, Rout J. Natural fibers, biopolymers, and biocomposites. Boca Raton: CRC Press; 2005. pp. 291–345.10.1201/9780203508206.ch9Search in Google Scholar

25. Rowell RM. In: Prasad PN, Mark JE, Kandil SH, Kafafi ZH, editors. Science and technology of polymers and advanced materials. New York: Plenum Press; 1998. pp. 717–32.Search in Google Scholar

26. Kazayawoko M, Balatinecz JJ, Woodhans RT. Diffuse reflectance Fourier transform infrared spectra of wood fibres treated with maleated PP. J Appl Polym Sci. 1997;66:1163–73.10.1002/(SICI)1097-4628(19971107)66:6<1163::AID-APP16>3.0.CO;2-2Search in Google Scholar

27. Glasser WG, Kelley SS, Lignin. In: Mark HF, Kroschwits JI, editors. Encyclopedia of polymer science and engineering, 2nd ed. New York: Wiley; 1987. pp. 795–852.Search in Google Scholar

28. Himmelsbach DS, Khalili S, Akin DE. The use of FT-IR micro-spectroscopic mapping to study the effects of enzymatic retting of flax (Linum usitatissium L.) stem. J Sci Food Agric. 2002;82:685–96.10.1002/jsfa.1090Search in Google Scholar

29. Parra DF, Tadini CC, Ponce P, Lugao AB. Mechanical properties and water vapor transmission in some blends of cassava starch edible films. Carbohydr Polym. 2004;58(4):475–81.10.1016/j.carbpol.2004.08.021Search in Google Scholar

30. Dieulot JY, Skurtys O. Classification, modeling and prediction of the mechanical behavior of starch-based films. J Food Eng. 2013; 119:188–95.10.1016/j.jfoodeng.2013.05.028Search in Google Scholar

31. Mali S, Sakanaka LS, Yamashita F, Grossmann MV. Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect. Carbohydr Polym. 2005;60:283–9.10.1016/j.carbpol.2005.01.003Search in Google Scholar

32. Cheng J, Zheng P, Zhao F, Ma X. The composites based on plasticized starch and carbon nanotubes. Int J Biol Macromol. 2013;59:13– 9.10.1016/j.ijbiomac.2013.04.010Search in Google Scholar

33. Zainuddin SY, Ahmad I, Kargarzadeh H, Abdullah I, Dufresne A. Potential of using multiscale kenaf fibers as reinforcing filler in cassava starch-kenaf biocomposites. Carbohydr Polym. 2013;92:2299–305.10.1016/j.carbpol.2012.11.106Search in Google Scholar

34. Habibi Y, El-Zawawy W, Ibrahim MM, Dufresne A. Processing and characterization of reinforced polyethylene composites made with lignocellulosic fibres from Egyptian agro-industrial residues. Compos Sci Technnol. 2008;68:1877–85.10.1016/j.compscitech.2008.01.008Search in Google Scholar

35. Bilbao-Sainz C, Bras J, Williams T, Sénechal T, Orts W. HPMC reinforced with different cellulose nano-particles. Carbohydr Polym. 2011;86:1549–57.10.1016/j.carbpol.2011.06.060Search in Google Scholar

36. Shash V. Handbook of polymer testing. New York: Wiley Interscience; 1983.Search in Google Scholar

37. Ke J, Yu K. Fibre-reinforced cellulose acetate composites. (http://www.odec.ca/projects/2007/yuka7k2/tensile.html) (accessed on 23 April 2014) (2007).Search in Google Scholar

38. Oksman K, Skrifvars M, Selin JF. Natural fibers as reinforcement in poly (lactic acid) composites. Compos Sci Technol. 2003;63:1317–24.10.1016/S0266-3538(03)00103-9Search in Google Scholar

39. Liu D, Zhong T, Chang PR, Li K, Wu Q. Starch composites reinforced by bamboo cellulosic crystals. Bioresour Technol. 2010;101:2529–36.10.1016/j.biortech.2009.11.058Search in Google Scholar PubMed

40. Lu Y, Weng L, Cao X. Morphological, thermal and mechanical properties of ramie crystallites – reinforced plasticized starch biocomposites. Carbohydr. Polym. 2006;63(2):198–204.10.1016/j.carbpol.2005.08.027Search in Google Scholar

41. Ma X, Yu J, Jin F. Urea and formamide as a mixed plasticizer for thermoplastic starch. Polym Int. 2004;53:1769–73.10.1002/app.20628Search in Google Scholar

42. Mohanty S Verma SK, Nayak SK. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos Sci Technol. 2006;66:538–47.10.1016/j.compscitech.2005.06.014Search in Google Scholar

43. Ishak MR, Sapuan SM, Leman Z, Rahman MZ, Anwar UM. Characterization of sugar palm (Arenga pinnata) fibres: tensile and thermal properties. J Therm Anal Calorim. 2012;109:981–9.10.1007/s10973-011-1785-1Search in Google Scholar

44. El-Shekeil YA, Sapuan SM, Abdan K, Zainudin ES. Influence of fiber content on the mechanical and thermal properties of kenaf fibre reinforced thermoplastic polyurethane composites. Mater Des. 2012;40:299–303.10.1016/j.matdes.2012.04.003Search in Google Scholar

45. Acros Organics. Reference handbook of fine chemicals. Geel: Acros Organics; 2006.Search in Google Scholar

46. Aggarwal P, Dollimore D. A thermal analysis investigation of partially hydrolyzed starch. Thermochim Acta 1998;319:17–25.10.1016/S0040-6031(98)00355-4Search in Google Scholar

47. Marchessault RH, Taylor MG, Fyfe CA, Veregin RP. Solid-state 13C-c.p. m.a.s. n.m.r. of starches. Carbohydr Res. 1985;144:C1–5.10.1016/0008-6215(85)85019-9Search in Google Scholar

48. Ma X, Yu J, John FK. Studies on the properties of natural fibres-reinforced thermoplastic starch composites. Carbohydr Polym. 2005;62:19–24.10.1016/j.carbpol.2005.07.015Search in Google Scholar

©2015 by De Gruyter

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- In this Issue

- Full length articles

- Carbon fiber-reinforced plastics based on epoxy resin toughened with core shell rubber impact modifiers

- Microencapsulation of diglycidyl 1,2-cyclohexanedicarboxylate by in situ polymerization: preparation and characterization

- Reactions taking place during molecular chlorine impact on monomers in a wide range of temperatures

- Composition-dependent depression of the glass transition temperature of the rubber phase in a PE-SBR blend

- Thermochemical and mechanical properties of tea tree (Melaleuca alternifolia) fibre reinforced tapioca starch composites

- Hydrogel beads from sugar cane bagasse and palm kernel cake, and the viability of encapsulated Lactobacillus acidophilus

- Composite materials derived from biodegradable starch polymer and Atriplex halimus fibers

- Simultaneous utilization of soju industrial waste for silica production and its residue ash as effective cationic dye adsorbent

- Enhancement of the dielectric performance of PA11/PVDF blends by a solution method with dimethyl sulfoxide

- Communication

- Temperature dependence of the viscosity of epoxy acrylate-tripropylene glycol diacrylate binary mixtures

Articles in the same Issue

- Frontmatter

- In this Issue

- Full length articles

- Carbon fiber-reinforced plastics based on epoxy resin toughened with core shell rubber impact modifiers

- Microencapsulation of diglycidyl 1,2-cyclohexanedicarboxylate by in situ polymerization: preparation and characterization

- Reactions taking place during molecular chlorine impact on monomers in a wide range of temperatures

- Composition-dependent depression of the glass transition temperature of the rubber phase in a PE-SBR blend

- Thermochemical and mechanical properties of tea tree (Melaleuca alternifolia) fibre reinforced tapioca starch composites

- Hydrogel beads from sugar cane bagasse and palm kernel cake, and the viability of encapsulated Lactobacillus acidophilus

- Composite materials derived from biodegradable starch polymer and Atriplex halimus fibers

- Simultaneous utilization of soju industrial waste for silica production and its residue ash as effective cationic dye adsorbent

- Enhancement of the dielectric performance of PA11/PVDF blends by a solution method with dimethyl sulfoxide

- Communication

- Temperature dependence of the viscosity of epoxy acrylate-tripropylene glycol diacrylate binary mixtures