Abstract

This article investigates piezoelectric materials for harnessing vibrational energy. A nano hollow cylindrical structure based on various piezoelectric materials was designed and utilised to generate the voltage. An accurate and efficient model is developed here, so as to optimized the efficiency of the piezoelectric energy harvester. This work analyses the piezoelectric actuator deflection and involves the Eigen frequency computation. A measurement methodology for investigating the mechanical and electrical behaviour of vibrational harvester's was modelled and analysed by finite element method using COMSOL software. The energy harvesting structure was developed and tested with different piezoelectric materials to attain appreciable voltage through a small deflection. The Simulated results predicts that for the same pressure range, different piezoelectric materials have the different output voltage and Eigen frequencies. The maximum voltage was observed for Barium Titanate (3.0847 V at 250 µm), along with poled Polyvinylidene fluoride. In addition, a comparison was made with different piezoelectric materials ideally suited to intelligent cantilever structure. For optimizing the performance of the piezoelectric energy harvester an accurate and efficient model is required, which was developed in this simulation study. A high voltage value with a small deflection through a cylindrical hollow structure was designed and tested using various piezoelectric materials in this study.

Introduction

The growth of the electronic industry has resulted in a new generation of small electronic devices with a low power consumption. Energy harvesting is the mechanism by which electricity is obtained from the surrounding mechanical vibratory devices. In order to harvest the energy from vibration by means of an energy transfer process, a smart structures made of piezoelectric, electrostatic materials are employed. Microelectromechanical-based wireless sensors have substantially raised the requirement for generation of local electrical energy for low power electronic systems. One of the most recent applications is to power the remotely located weather forecasting station and environment monitoring systems. The vibrational energy harvesting devices could extract mechanical energy from the natural environment and turn it into electricity, and this has received great interest from academia and industry in past few years. The electronic devices are supposed to work with in a continuous and autonomous power source with scalable energy harvester, without any interference from the surrounding. The mechanical vibrations have been found to be the most suitable source of energy for small scale devices with in the vast field of micropower production. Conventionally the batteries are the most common source of electricity, which have not kept pace with those devices which demand for the miniaturization. He et al. (2020) investigated a magnetic excitation cantilever type piezoelectric energy harvester for the rotational motion application, in which rotational angle is varied to modify the output voltage. Tang et al. (2015) reported a vibration energy harvester which generates the electrical power independently for powering of RF devices. Rezaei-Hosseinabadi, Tabesh, and Dehghani (2016) demonstrates the utilisation of multilayer topology that allows a device to have wider band feature while operating with single resonance frequency. Todaro et al. (2018) and Azad and Vaish (2017) reported the piezoelectric energy harvesting (PEH) system used for low power electronics and autonomous wireless sensor and microsystems. Chen et al. (2016) reports the piezoelectric and triboelectric structure that can generate power from periodic vibration of PVDF cantilever caused by vortex shedding. Similarly Chen et al. (2020) proposed a PEH with two anti-symmetrical trapezoidal cantilever plates surrounded by a rigid frame for energy harvesting and able to generate a high voltage in lower frequency range.

Manavizadeh, Nourafkan, and Mohammadi (2019) discussed three different vibration based nano-structures for energy harvesting, utilizing a finite simulation method to analyse the output response. Similarly Damya, Abbaspour Sani, and Rezazadeh (2020) proposed structure which has the ability to produce a higher potential difference and power with smaller dimension even at lower variable natural frequency. For extracting the vibration energy from vacuum pump, a rectangular hole based cantilever energy harvester was designed and was able to extract a maximum output voltage of 1.19 V (Tian et al. 2018). According to Sokolov et al. (2020), electro-mechanical coupling is one of the essential prerequisites of boosting the power output from PEH devices that makes it an effective energy conversion process. The PEH has been reported to be the most common selection among different types of vibration energy harvesters due to its significant advantages in power density, simple structure and ease of application. Due to its large deflection response under the purely bending mode configuration, most piezoelectric energy harvesters are at the early stages of development. Beak et al. (2017) investigated BaTiO3 Nano Wire arrays that were used in PEH for the conversion of vibration energy extracted from mechanical deformation.

Piezoelectric structures have a long history of utilisation in energy harnessing applications. Under mechanical deformation, these materials precisely produce electric charges which can be utilised to charge the batteries. The Piezoelectric Polymer, such as Polyvinylidene fluoride (PVDF), has attracted great attention among different types of piezoelectric materials due to their excellent versality, flexibility and ease of use (Gaur and Rana 2015). Acciari et al. (2017) studied the generation of energy using rain as a source to feed small and low consumption electronic components. Energy harvester have different type of geometry, Alameh, Gratuze, and Nabki (2019) shows variations that can be obtained by changing the design geometry for the same type of structure. Li, Xu, and Tam (2019) studied another type of energy harvesting handrail structure with two working modes. Kordrostami and Roohizadegan (2019) reported different energy harvesting structures, each capable of generating their maximum power from biomorph trenched-C-PEH. Nabavi and Zhang (2019) proposed a structure that has unique geometry comprising of a doubly clamped set of piezoelectric cantilevers with a serpentine shape along with three proof of mass distributors. Wei et al. (2020) investigated the design simulation and performance characterization of the tower shaped piezoelectric energy harvester, which consists of metal mass, acrylic bases and curved beams of PVDF. Compared with traditional cantilever beams, the circular array of curved beams with PVDF scavenge vibrations efficiently from multiple directions. Chen et al. (2018) presents an alternating resistive matching circuit to harvest energy from the micro wind impact type PEH, which aims to optimize the load resistance for both periods, impact and vibrations. Similarly, Balpande, Kalambe, and Pande (2019) reported EHD as an alternative perpetual power source for WBDS with prime focus on bio-compatibility. The magnetic type of energy harvester is another recent development in this field. Ando et al. (2019) demonstrated the operation of non-linear vibration harvester operating in the vertical direction and, the harvester's performances without the repulsive mechanism shows an appreciable energy output that could be used for powering wireless devices. Chamanian et al. (2019) developed an efficient hybrid energy harvesting interface to synergistically scavenge power from electromagnetic sources, which was able to drive single phase load. Costanzo, Schiavo, and Vitelli (2019) reported an structure for extracting energy from non-sinusoidal vibrations and was utilised for supplying power to the small electronic devices. Rui et al. (2020) discussed a piezoelectric energy harvester design specifically targeted to supply power to low-consumptions devices in intelligent vehicles.

Several researchers have suggested a variety of multidirectional structure for PEHs to address the various limitations of energy harvesting. When excited by multi-directional vibration sources, traditional vibration energy harvesters (CVEH) might perform poorly in terms of energy harvesting. In this paper, a simple design of the PEH is proposed which is essentially a cylindrical structure designed with piezoelectric material. The study uses the finite element method in COMSOL Multiphysics software and revealed that PEH has a great potential for the vibration energy harvesting (VEH) in multi directionally vibrating applications. The various sections of the paper are organized as follows. The methodology and design consideration of the energy harvester are presented in Section 2. The modelling and simulation of the piezoelectric energy harvesting device was presented in Section 3. The result and discussion were elaborated in Section 4 followed with conclusion.

Methodology and design considerations

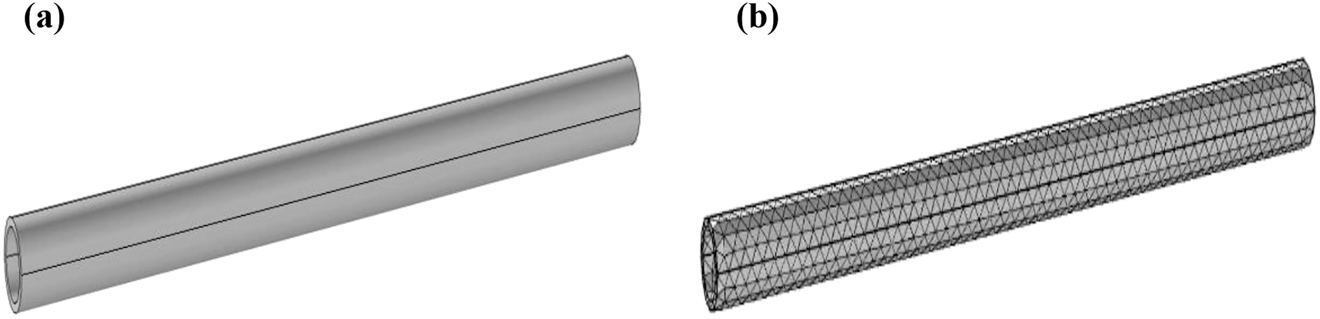

In this research work, the nano cylindrical rod structure is designed which is essentially made up of piezoelectric material. Due to the deformation of cylindrical rod, the curvature appears in piezoelectric cylindrical structure. The electric charges were produced during the bending of the piezoelectric layers. With the electrodes embedded on the top and inside of hollow cylindrical rod, an external electrical circuit is then attached to these electrodes. By connecting a resistive load, the output voltage could be measured for analysis purpose. Figure 1(a) shows the hollow piezoelectric structure and Figure 1(b) shows the meshed structure developed in COMSOL evaluation version.

(a) Design of nano-piezoelectric cylindrical rod. (b) Meshing of piezoelectric cylindrical structure.

In general, the piezoelectric constitutive equations (Özdemir 2019) are given as stress-charge form which is utilised in this study for obtaining the output voltage from the designed structure.

where T, S, D, E denotes the vector of the stress variable, vector of the strain variable, vector of the electric displacement variable, the vector of the electrical field component, the elasticity matrix, piezoelectric coupling matrix, and electrical permittivity coefficient matrix are the cE, e, ɛS the superscripts E, S denotes the parameter at constant electric field and at constant strain, respectively, the superscript t represents the transpose.

The generated charges in the piezoelectric materials are calculated through the electric displacement D by the following relation,

where Ψ, is the area of the effective electrode on the piezoelectric materials. Any metallic contacts can be utilised as electrode, but generally aluminium or copper electrodes are utilised for charge/voltage measurement. The output voltage V is calculated across the resistive load (RL) as Voutput = IRL and

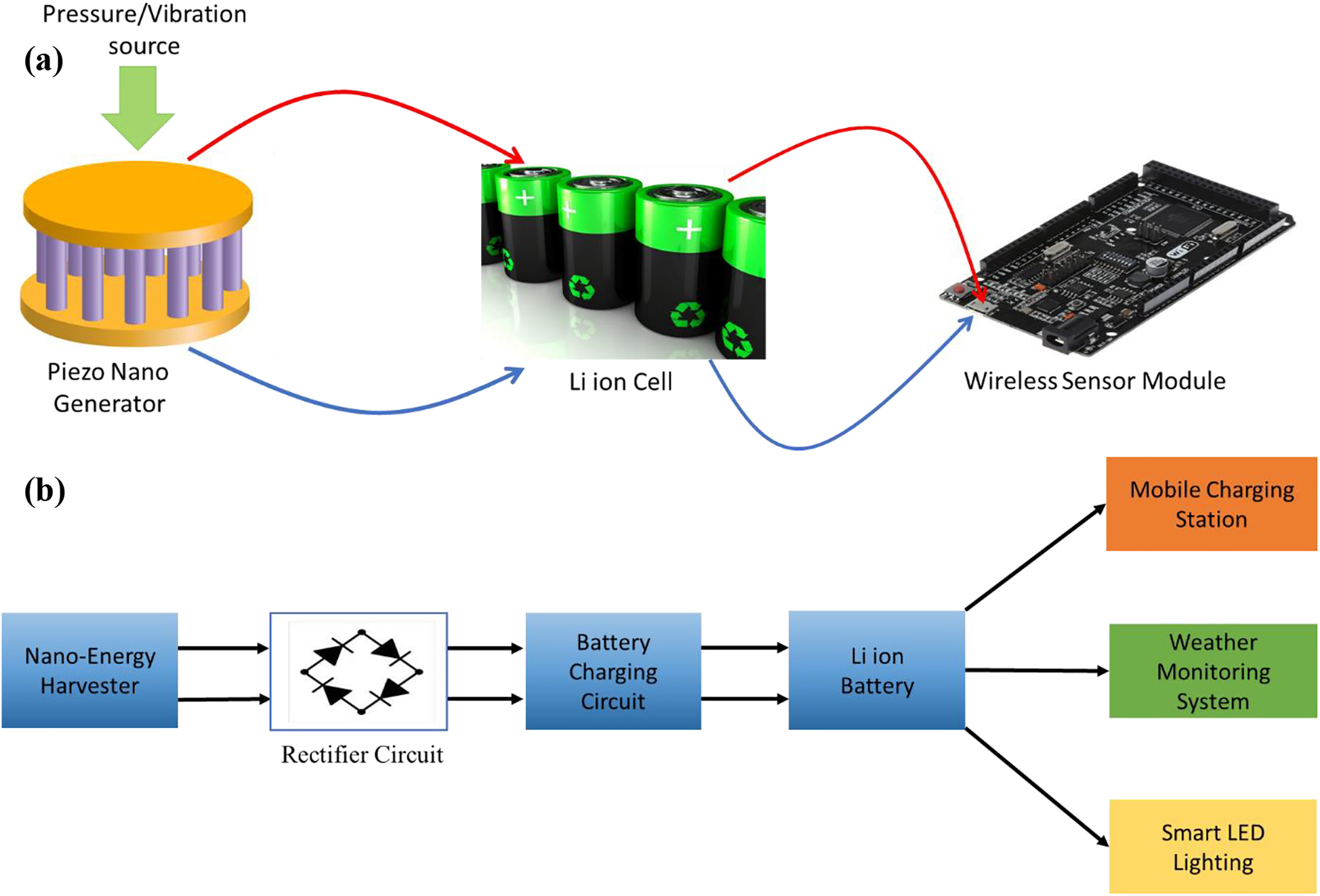

Energy harvester main aim is to utilize the waste energy and converts into electrical energy. In PEH, various vibration sources could be utilised that includes wind, pressure, vibrations etc. The throughput of the energy harvester depends mainly upon the properties of piezoelectric materials that includes density, young's modulus's, charge constant, voltage constant etc. as well as the structure of the harvester. By using the different configuration structure, enhance the energy output from PEH could be enhanced. Figure 2(a) illustrates the arrangement of cylindrical hollow structure used to scavenge the energy from the vibrations. The force/vibration is applied on the top of surface and output voltage can be obtained from the electrodes embedded on top as well as on the bottom layer. Figure 2(b) shows in detail the various components required for piezoelectric energy harvesting system. The energy received from PEH is rectified prior to the battery charging circuit. The battery charging circuit delivers the power to the Li ion battery which provides the electrical energy to various devices such as weather monitoring system, mobile charging system, smart lighting system etc. The added advantage of this proposed system is that it can be embed in the shoes of the individual which can be utilised for powering of smart health monitoring system.

(a) Schematic of piezo nano energy generator, (b) block diagram of piezoelectric energy harvesting.

Modelling of PEH

For modelling of hollow cylindrical rod as energy harvester, a structural mechanics and piezoelectric modules of COMSOL were selected. These modules involve the studies based on Eigen frequency, stationary, time dependent and customized analysis. Each study involves the formation of set of equations by applying appropriate boundary conditions to the developed model. First of all, the nano hollow cylindrical structure was designed and then appropriate materials are selected for the structure. For electrical contacts, aluminium is selected for the inner and outer surface. In between the two electrodes, a nano hollow cylinder is inserted which is consist of piezoelectric materials. For simulation purpose different piezoelectric materials were selected that includes Barium Titanate, PZT 4, PZT5H and PVDF. Table 1 lists the properties of piezoelectric materials used for simulation.

Properties of piezoelectric material used in simulation.

| Material | Density (kg/m3) | Poisson's ratio | Young's modulus (GPa) |

|---|---|---|---|

| Barium titanate | 5700 | 0.28 | 79 |

| PZT 4 | 7500 | 0.30 | 63 |

| PZT 5H | 7500 | 0.33 | 64 |

| PVDF | 1780 | 0.34 | 3 |

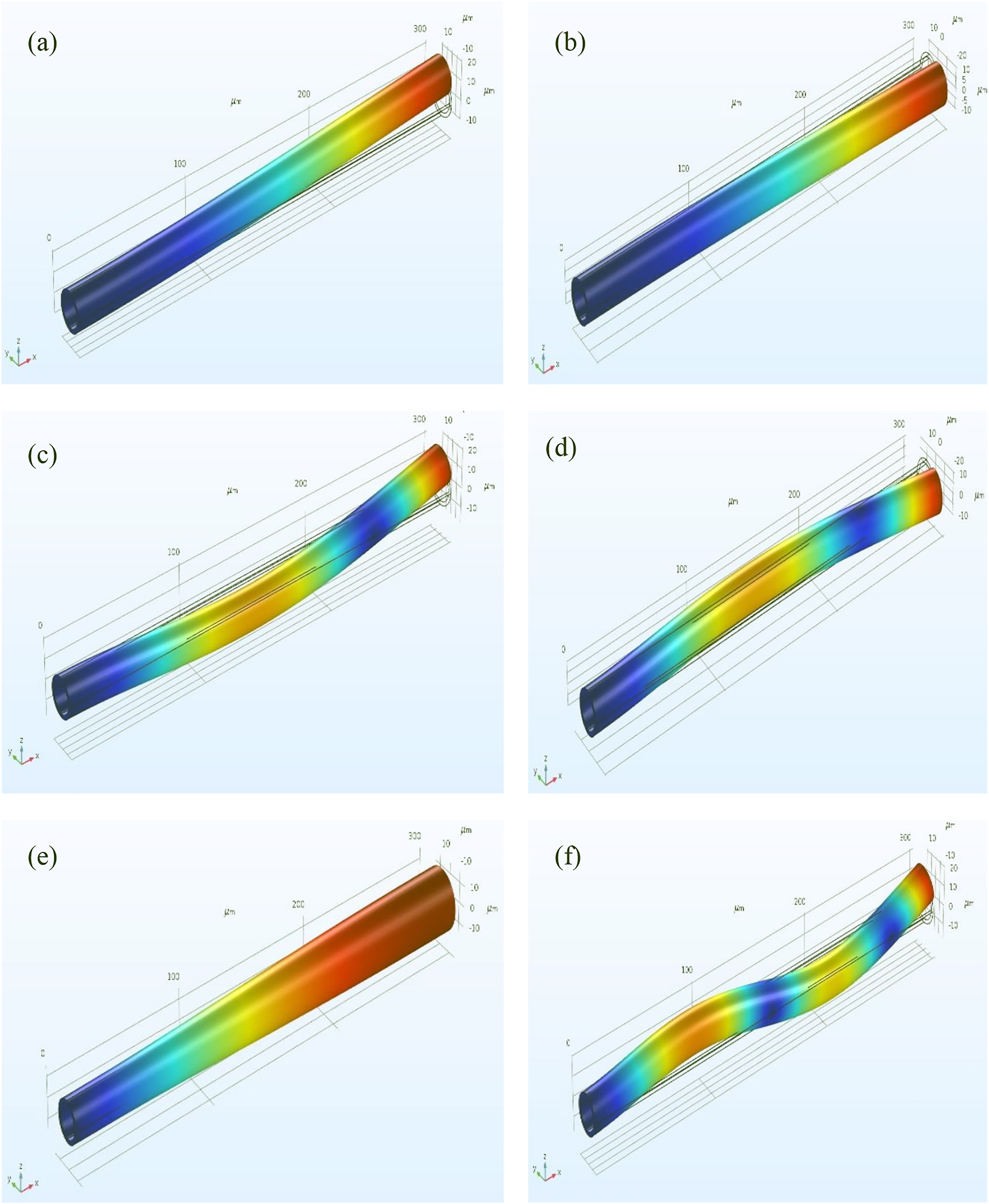

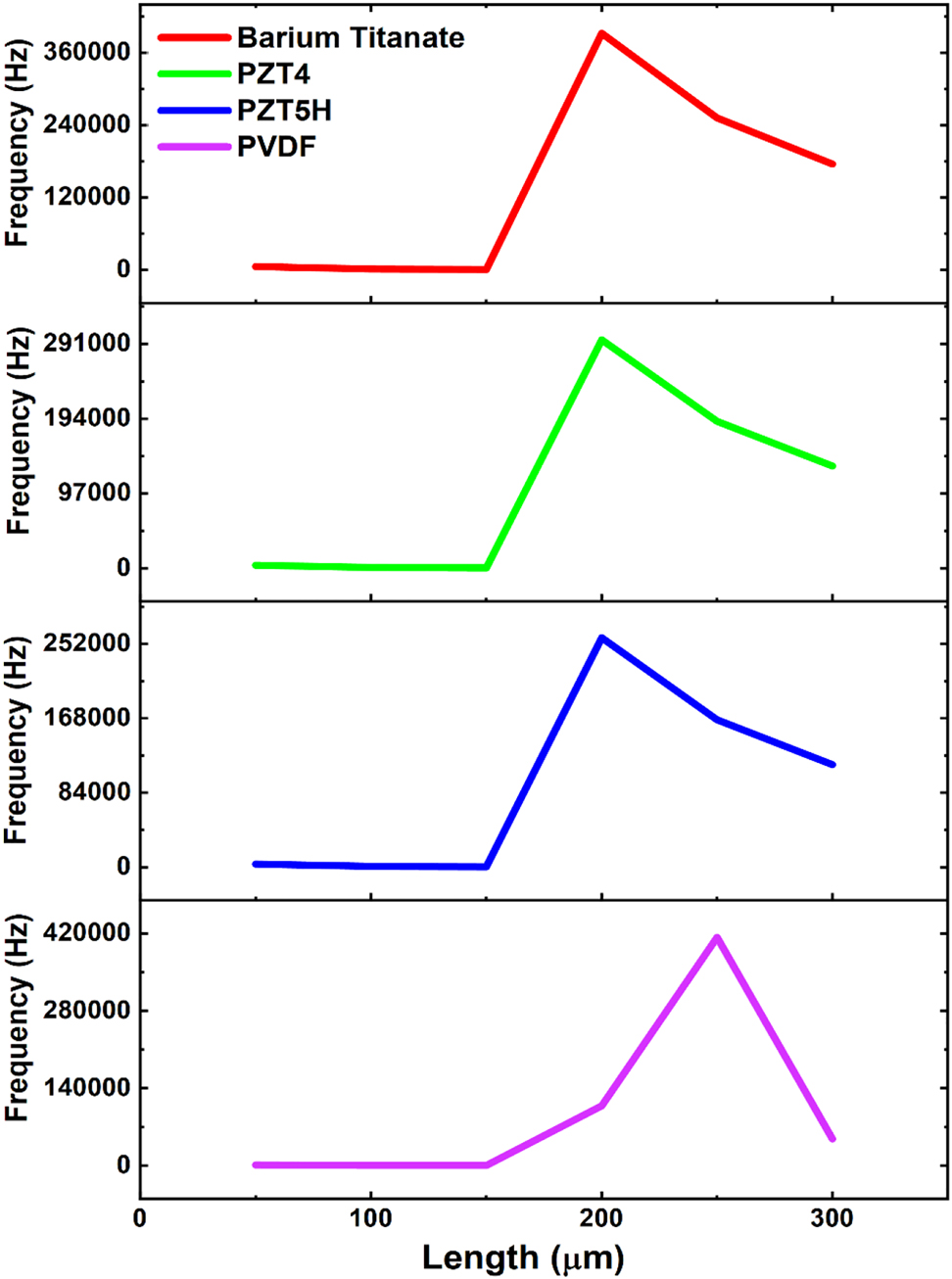

The structural mechanics module was selected to perform the Eigen frequency analysis. The developed model calculates the 36 Eigen frequencies for different length of beam for different materials. The mode shapes are shown in Figure 3 for first six Eigen frequencies. Table 2 lists the length versus frequency comparison for the nano cylindrical structure. The developed model comprises of 13,886 elements which takes almost 24 s to solve with 62,847 degrees of freedoms.

Modes shapes of piezoelectric hollow cylindrical rod of PVDF for 300 μm length at different frequencies (a) 48.345 kHz (b) 48.412 kHz (c) 291.79 kHz (d) 291.98 kHz (e) 592.66 kHz (f) 774.63 kHz.

Comparison of Eigen frequencies of nano hollow energy harvester.

| Length (µm) | Eigen frequencies of different materials (in Hz) | |||

|---|---|---|---|---|

| PVDF | PZT 5H | PZT 4 | Barium titanate | |

| 50 | 1450.6 | 3419.00 | 3951.8 | 5344.2 |

| 100 | 415.81 | 977.02 | 1137.8 | 1513.6 |

| 150 | 190.3 | 446.69 | 521.35 | 690.89 |

| 200 | 108,140 | 259,010.00 | 296,390 | 392,270 |

| 250 | 412,940 | 166,440.00 | 190,610 | 252,130 |

| 300 | 48,412 | 115,840.00 | 132,720 | 175,510 |

Modelling of piezoelectric hollow cylindrical rod

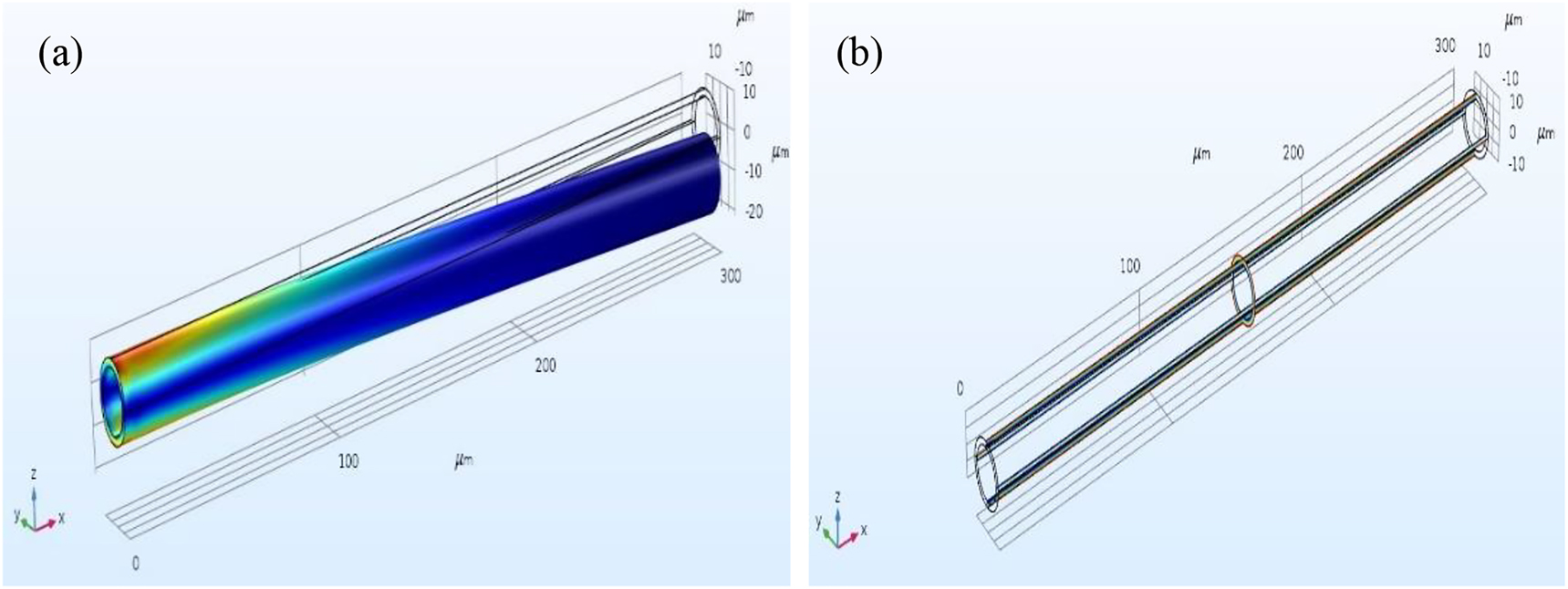

The complete piezoelectric structural module was developed with piezoelectric materials. The deflection pattern of developed model is shown in Figure 4(a). The simulation involves the finite element model where the whole structure of piezoelectric hollow cylindrical rod made up of different piezoelectric materials. The whole structure was formed with one of the boundaries fixed and other boundaries were free to deflect. For deflection analysis pressure was applied on the top of the body of the hollow cylindrical rod which act as reference electrode and bottom inside layer act as ground. Figure 4(b) shows the potential distribution along the length of nano energy harvester.

(a) Deflection pattern of micro sensor, (b) potential distribution in micro sensor.

Results and discussion

Figure 5 shows the variation of Eigen frequency with the length of beam. The different Eigen frequencies at different length were computed through simulation and plotted for different piezoelectric materials i.e. Barium Titanate, PZT-4, PZT-5H, PVDF. The length of beam was varied from 50 to 300 µm. The length cannot be varied further due to limited memory capacity from computing facility available for the simulation. It is observed from the curves that Barium Titanate and PVDF has highest Eigen frequencies in comparison to other two materials i.e. PZT-4 and PZT-5H.

Frequency versus voltage of modelled piezoelectric energy harvester.

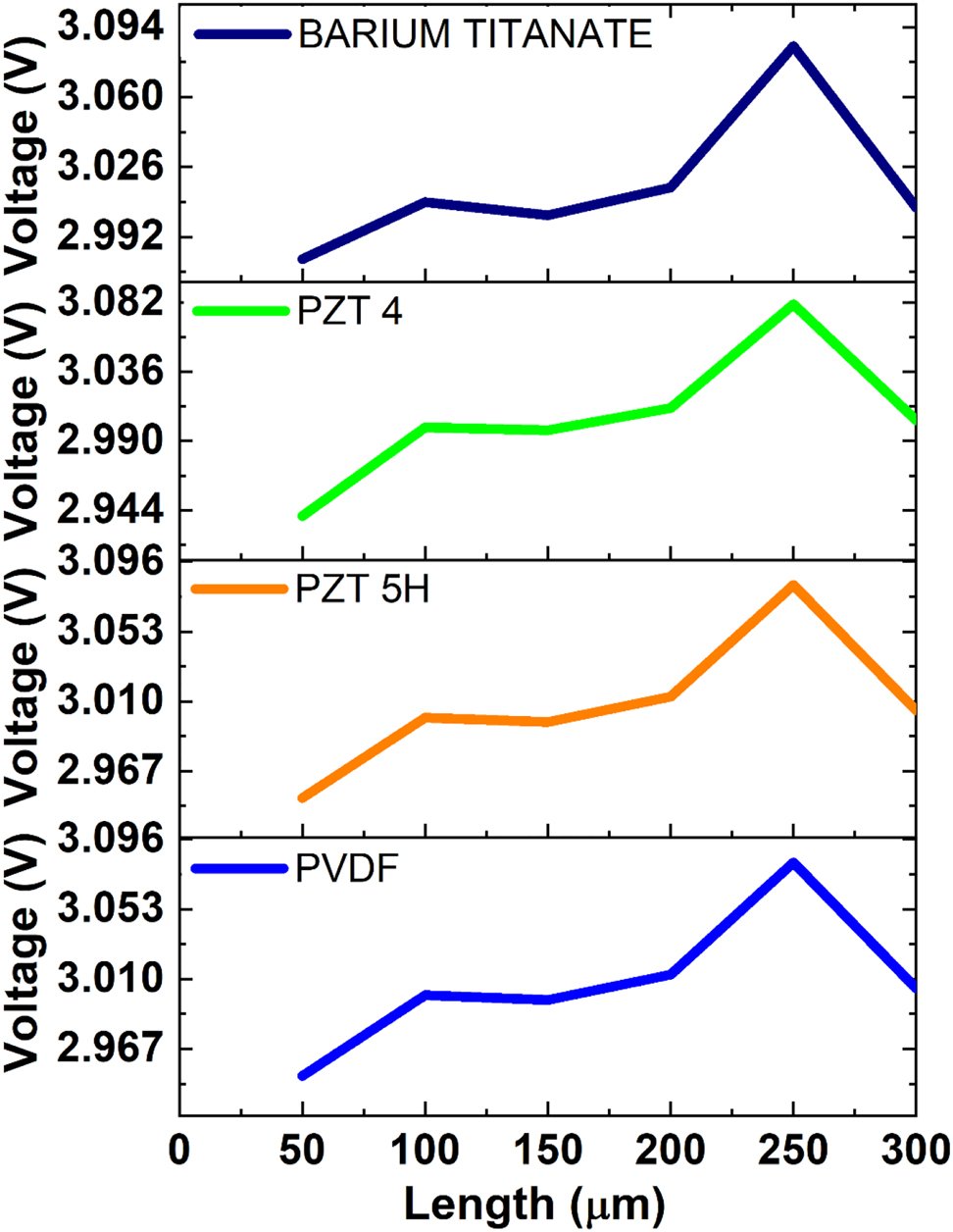

The simulated deflection of piezoelectric actuator at different length in range of 50–300 µm is shown in Figure 6. The simulation results show the deflection for different piezoelectric materials for Barium Titanate, PZT-4, PZT-5H, PVDF. It can be observed from the curve that maximum voltage was obtained for Barium Titanate which was approximately 3.0847 V at 250 µm. This confirms the Barium Titanate as a potential piezoelectric material for development of micro actuator as compare to other piezoelectric materials, but it suffers a limitation that it is not elastic. So other material that suits energy harvester structure is PVDF owing to its good elasticity and is also resistant to harsh environment (Gaur and Rana 2014). Figure 6 shows the curve between voltage versus length of micro actuator. It is observed from curve, as the length increases so the deflection of micro actuator also increases. At one particular point known as saturation point, further increase in length there is no appreciable increase in deflection. Thus, optimal dimension must be computed in order to achieve high energy output from nano cylindrical energy harvester.

Voltage versus length of modelled piezoelectric energy harvester.

Conclusion

The piezoelectric cylindrical-based energy harvester was proposed in this study. The modelling and simulation study was carried out using finite method (FEM) in COMSOL Multiphysics. The simulated results reveals that the harvester can be used to collect the energy generated by cylindrical rod in different motion states. The developed model can be used to predict the output voltage from the energy harvester. Also, the Eigen frequency analysis was performed and electric potential generation were studied for different length of nano cylindrical rod. Simulated results indicated that different piezoelectric material have different output voltage and different Eigen frequency. By changing the material, the output voltage and Eigen frequency can be tuned, so as to optimize the performance of energy harvester. Also, a comparison of the Eigen frequencies of different materials with the identical length was carried out and calculates the Eigen frequency where maximum output voltage could be obtained. It was observed that maximum the deflection, more energy conversion can take place from vibrational energy to electrical energy or vice versa. Future work includes design and structure improvement of the PEH harvester mechanism to enhance the output voltage that can be utilised for powering of medium power wireless electronic devices.

-

Author contributions: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: The authors received no financial support for this research.

-

Conflict of interest statement: There is no conflict of interest in this work.

References

Acciari, G., M. Caruso, R. Miceli, L. Riggi, P. Romano, G. Schettino, and F. Viola. 2017. “Piezoelectric Rainfall Energy Harvester Performance by Advanced Arduino Based Measuring System.” IEEE Transactions on Industry Applications 54: 458–68.10.1109/TIA.2017.2752132Search in Google Scholar

Alameh, A. H., M. Gratuze, and F. Nabki. 2019. “Impact of Geometry on the Performance of Cantilever-Based Piezoelectric Vibration Energy Harvesters.” IEEE Sensors Journal 19 (22): 10316–26, https://doi.org/10.1109/jsen.2019.2932341.Search in Google Scholar

Andò, B., S. Baglio, V. Marletta, A. Pistorio, and A. R. Bulsara. 2019. “A Measurement Methodology for the Characterization of a Compensated Nonlinear Energy Harvester for Vertical Operation.” IEEE Transactions on Instrumentation and Measurement 68 (8): 3032–41, https://doi.org/10.1109/tim.2018.2869182.Search in Google Scholar

Azad, P., and R. Vaish. 2017. “Portable Triboelectric Based Wind Energy Harvester for Low Power Applications.” The European Physical Journal Plus 132 (6): 253, https://doi.org/10.1140/epjp/i2017-11520-y.Search in Google Scholar

Baek, C., H. Park, J. H. Yun, D. K. Kim, and K. I. Park. 2017. “Lead-Free BaTiO3 Nanowire Arrays-Based Piezoelectric Energy Harvester.” MRS Advances 2: 3415–20, https://doi.org/10.1557/adv.2017.305.Search in Google Scholar

Balpande, S., J. Kalambe, and R. Pande. 2019. “Development of Strain Energy Harvester as an Alternative Power Source for the Wearable Biomedical Diagnostic System.” Micro & Nano Letters 14: 777–81, https://doi.org/10.1049/mnl.2018.5250.Search in Google Scholar

Chamanian, S., B. Çiftci, H. Uluşan, A. Muhtaroğlu, and H. Külah. 2019. “Power-Efficient Hybrid Energy Harvesting System for Harnessing Ambient Vibrations.” IEEE Transactions on Circuits and Systems I: Regular Papers 66 (7): 2784–93, https://doi.org/10.1109/tcsi.2019.2900574.Search in Google Scholar

Chen, L., L. Chang, H. Jing, and H. Li. 2020. “Design and Study of Rigid-Flexible Coupled Piezoelectric Energy Harvester.” Smart Materials and Structures 29 (5): 055012, https://doi.org/10.1088/1361-665x/ab78b9.Search in Google Scholar

Chen, N., T. Wei, D. S. Ha, H. J. Jung, and S. Lee. 2018. “Alternating Resistive Impedance Matching for an Impact-Type Microwind Piezoelectric Energy Harvester.” IEEE Transactions on Industrial Electronics 65 (9): 7374–82, https://doi.org/10.1109/tie.2018.2793269.Search in Google Scholar

Chen, T., Y. Xia, W. Liu, H. Liu, L. Sun, and C. Lee. 2016. “A Hybrid Flapping-Blade Wind Energy Harvester Based on Vortex Shedding Effect.” Journal of Microelectromechanical Systems 25: 845–7, https://doi.org/10.1109/jmems.2016.2588529.Search in Google Scholar

Costanzo, L., A. L. Schiavo, and M. Vitelli. 2019. “Power Extracted from Piezoelectric Harvesters Driven by Non-Sinusoidal Vibrations.” IEEE Transactions on Circuits and Systems I: Regular Papers 66 (3): 1291–303, https://doi.org/10.1109/tcsi.2018.2879751.Search in Google Scholar

Damya, A., E. Abbaspour Sani, and G. Rezazadeh. 2020. “An Innovative Piezoelectric Energy Harvester Using Clamped–Clamped Beam with Proof Mass for WSN Applications.” Microsystem Technologies 26 (10): 3203–11, https://doi.org/10.1007/s00542-018-3890-6.Search in Google Scholar

Gaur, A. M., and D. S. Rana. 2014. “Modelling and Eigen Frequency Analysis of Piezoelectric Cantilever Beam.” International Journal of Engineering Sciences 3 (7): 52–9.Search in Google Scholar

Gaur, A. M., and D. S. Rana. 2015. “Dispersion Relations for SH Waves Propagation in a Porous Piezoelectric (PZT–PVDF) Composite Structure.” Acta Mechanica 226 (12): 4017–29, https://doi.org/10.1007/s00707-015-1443-y.Search in Google Scholar

He, L., Z. Wang, X. Wu, Z. Zhang, D. Zhao, and X. Tian. 2020. “Analysis and Experiment of Magnetic Excitation Cantilever-Type Piezoelectric Energy Harvesters for Rotational Motion.” Smart Materials and Structures 29 (5): 055043, https://doi.org/10.1088/1361-665x/ab7f45.Search in Google Scholar

Kordrostami, Z., and S. Roohizadegan. 2019. “A Particle Swarm Approach to the Optimization of Trenched Cantilever Based MEMS Piezoelectric Energy Harvesters.” IET Science, Measurement & Technology 13, https://doi.org/10.1049/iet-smt.2018.5371.Search in Google Scholar

Li, Z., Q. Xu, and L. M. Tam. 2019. “Design of a New Piezoelectric Energy Harvesting Handrail with Vibration and Force Excitations.” IEEE Access 7: 151449–58, https://doi.org/10.1109/access.2019.2948085.Search in Google Scholar

Manavizadeh, N., M. Nourafkan, and E. Mohammadi. 2019. “Influence of the ZnO Nanostructures Shape on Piezoelectric Energy Harvesters Performance.” IEEE Transactions on Electron Devices 66 (11): 4989–96, https://doi.org/10.1109/TED.2019.2942777.Search in Google Scholar

Nabavi, S., and L. Zhang. 2019. “Nonlinear Multi-Mode Wideband Piezoelectric MEMS Vibration Energy Harvester.” IEEE Sensors Journal 19 (13): 4837–48, https://doi.org/10.1109/jsen.2019.2904025.Search in Google Scholar

Özdemir, A. E. 2019. “Circuit Topology for Piezoelectric Transducers in a Piezoelectric Energy Harvester.” IET Renewable Power Generation 13 (12): 2105–10, https://doi.org/10.1049/iet-rpg.2018.6106.Search in Google Scholar

Rezaei-Hosseinabadi, N., A. Tabesh, and R. Dehghani. 2016. “A Topology and Design Optimization Method for Wideband Piezoelectric Wind Energy Harvesters.” IEEE Transactions on Industrial Electronics 63 (4): 2165–73.Search in Google Scholar

Rui, X., Z. Zeng, Y. Zhang, Y. Li, H. Feng, X. Huang, and Z. Sha. 2020. “Design and Experimental Investigation of a Self-Tuning Piezoelectric Energy Harvesting System for Intelligent Vehicle Wheels.” IEEE Transactions on Vehicular Technology 69 (2): 1440–51, https://doi.org/10.1109/tvt.2019.2959616.Search in Google Scholar

Sokolov, A., D. Mallick, S. Roy, M. P. Kennedy, and E. Blokhina. 2020. “Modelling and Verification of Nonlinear Electromechanical Coupling in Micro-Scale Kinetic Electromagnetic Energy Harvesters.” IEEE Transactions on Circuits and Systems I: Regular Papers 67 (2): 565–77, https://doi.org/10.1109/tcsi.2019.2938421.Search in Google Scholar

Tang, Q., Q. He, M. Li, C. Dong, D. Xu, and X. Li. 2015. “Wireless Alarm Microsystem Self-Powered by Vibration-Threshold-Triggered Energy Harvester.” IEEE Transactions on Industrial Electronics 63: 2447–56, https://doi.org/10.1109/tie.2015.2510503.Search in Google Scholar

Tian, Y., G. Li, Z. Yi, J. Liu, and B. Yang. 2018. “A Low-Frequency MEMS Piezoelectric Energy Harvester with a Rectangular Hole Based on Bulk PZT Film.” Journal of Physics and Chemistry of Solids 117: 21–7, https://doi.org/10.1016/j.jpcs.2018.02.024.Search in Google Scholar

Todaro, M. T., F. Guido, L. Algieri, V. M. Mastronardi, D. Desmaële, G. Epifani, and M. De Vittorio. 2018. “Biocompatible, Flexible, and Compliant Energy Harvesters Based on Piezoelectric Thin Films.” IEEE Transactions on Nanotechnology 17 (2): 220–30, https://doi.org/10.1109/tnano.2017.2789300.Search in Google Scholar

Wei, X., H. Zhao, J. Yu, Y. Zhong, Y. Liao, S. Shi, and P. Wang. 2020. “A Tower-Shaped Three-Dimensional Piezoelectric Energy Harvester for Low-Level and Low-Frequency Vibration.” International Journal of Precision Engineering and Manufacturing-Green Technology 1–14, https://doi.org/10.1007/s40684-020-00281-9.Search in Google Scholar

© 2021 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- 10.1515/ehs-2021-frontmatter2

- Research articles

- Topology optimized thermoelectric generator: a parametric study

- Design and simulation of piezoelectric nano cylindrical hollow structure for energy harnessing applications

- Improved performance of partially shaded photovoltaic array with reformed-total cross tied configuration

Articles in the same Issue

- 10.1515/ehs-2021-frontmatter2

- Research articles

- Topology optimized thermoelectric generator: a parametric study

- Design and simulation of piezoelectric nano cylindrical hollow structure for energy harnessing applications

- Improved performance of partially shaded photovoltaic array with reformed-total cross tied configuration