Cogeneration system’s energy performance improvement by using P-graph and advanced process control

-

Fakhrony Sholahudin Rohman

, Hong An Er

Abstract

Cogeneration systems are widely used in industrial settings to meet process steam and power demands efficiently. Optimizing the load allocation among boilers and turbines is critical for improving overall system efficiency and reducing fuel consumption. However, traditional optimization approaches often rely on complex mathematical models, which can be challenging for in-house engineers without advanced optimization expertise. This study addresses this gap by utilizing a graph-theoretic tool, Process Graph (P-Graph), to optimize load allocation while considering the nonlinear part-load efficiency of boilers. Additionally, drum boilers exhibit nonlinear behaviors, such as the shrink-and-swell effect, which require advanced control strategies. To address this, various control strategies, including Proportional-Integral (PI) and Model Predictive Control (MPC), are evaluated under different high-pressure steam (HPS), medium-pressure steam (MPS), and energy demand scenarios. The study comprises two stages: optimization of load allocation among five boilers and three turbines, followed by the application of control strategies to the optimal configuration. Results show that dynamic load distribution involving Boiler 2, Boiler 3, Boiler 5, ST1, and CT achieves the best energy efficiency and cost-effectiveness. The comparison between the base and optimized scenarios underscores the changes in operating strategies achieved through optimization, resulting in a 2.38 % reduction in operating costs, equivalent to RM1727.3 per hour. Moreover, MPC outperforms PI control in closed-loop performance, demonstrating superior energy savings and error minimization.

Award Identifier / Grant number: Q.J130000.21A2.07E17

Funding source: UTM Matching Grant

Award Identifier / Grant number: MG1 - 11.1

Funding source: Facilities Energy Minimisation using P-Graph and RENKEI control strategies

Award Identifier / Grant number: Q.J130000.3046.04M49

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: The authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: Authors declare no conflict of interest.

-

Research funding: The authors greatly acknowledge the financial grants from Universiti Teknologi Malaysia Professional Development Research University Grant (UTM-PDRU) with Vote number Q.J130000.21A2.07E17 and UTM Matching Grant entitled MG1 - 11.1: Facilities Energy Minimisation using P-Graph and RENKEI control strategies with Vote number Q.J130000.3046.04M49.

-

Data availability: Datasets used and/or analysed in this study are available upon reasonable request.

-

Consent for publication: Not applicable.

To optimise different steam loads of MBS, three scenarios are considered. In the first scenario, B1 and B4 are operated in respect of minimum (126 ton/h) and maximum capacity (234 ton/h) while the steam loads of the remaining three boilers are optimised by P-graph. In the second scenario, B1 and B4 are fixed at the optimized loads, 169.21 ton/h and 190.81 ton/h respectively. The optimized loads are obtained by the optimum solution in P-Graph as shown in Figure A1 while the steam loads of the remaining three boilers are optimised by P-graph. The third scenario, where the steam loads of all five boilers are optimized as decision variables in P-graph. To analyse the Cenerg for different scenarios, the optimal solutions for different steam demands and different scenarios are tabulated in Table A1a-A1c. The Cenerg values for different scenarios are summarized in Table A2.

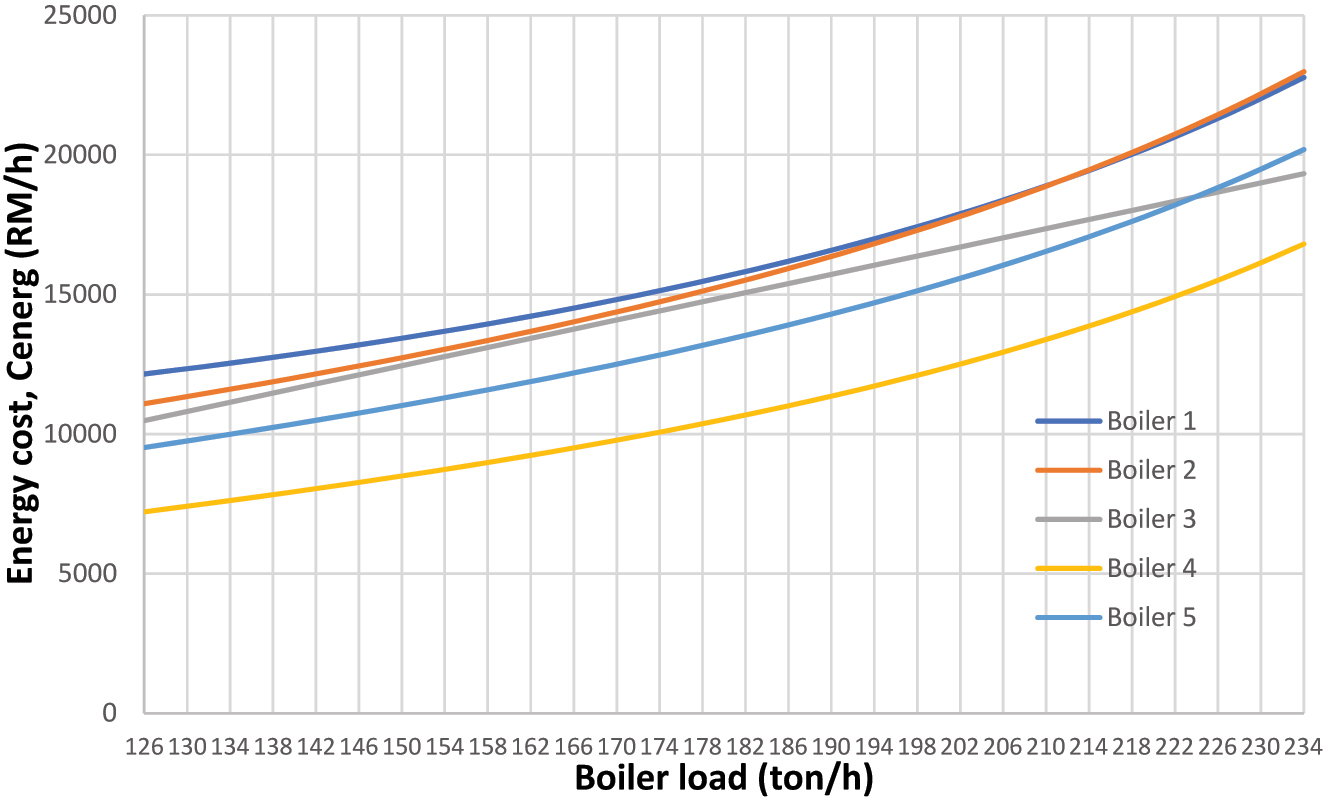

Selection of boilers for fixed operational mode based on cost versus load.

Results P-graph using scenario 1, set to minimum B1 (126 ton/h) and maximum capacity B4 (234 ton/h).

| Load | Sd,total | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 720 (ton/h) | 760 (ton/h) | 800 (ton/h) | 840 (ton/h) | 880 (ton/h) | 920 (ton/h) | 960 (ton/h) | 1,000 (ton/h) | 1,040 (ton/h) | |

| B1 | 126.00 | 126.00 | 126.00 | 126.00 | 126.00 | 126.00 | 126.00 | 126.00 | 126.00 |

| B2 | 126.00 | 126.39 | 147.61 | 169.21 | 169.21 | 169.21 | 175.19 | 193.60 | 212.41 |

| B3 | 126.00 | 126.00 | 126.00 | 141.58 | 181.58 | 221.58 | 234.00 | 234.00 | 234.00 |

| B4 | 234.00 | 234.00 | 234.00 | 234.00 | 234.00 | 234.00 | 234.00 | 234.00 | 234.00 |

| B5 | 126.00 | 147.61 | 166.39 | 169.21 | 169.21 | 169.21 | 190.81 | 212.40 | 233.59 |

| Cenerg (RM/h) | 60,009.3 | 61,389.3 | 64,177.7 | 67,405.6 | 70,692.7 | 73,953.5 | 77,491.9 | 81,869.2 | 87,594.7 |

Results P-graph using scenario 2, boiler 1 and 4 is operated at optimized B1 (169.21 ton/h) and optimized B4 (190.81 ton/h).

| Load | Sd,total | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 720 (ton/h) | 760 (ton/h) | 800 (ton/h) | 840 (ton/h) | 880 (ton/h) | 920 (ton/h) | 960 (ton/h) | 1,000 (ton/h) | 1,040 (ton/h) | |

| B1 | 169.20 | 169.20 | 169.20 | 169.20 | 169.20 | 169.20 | 169.20 | 169.20 | 169.20 |

| B2 | 126.00 | 126.39 | 147.61 | 169.21 | 169.21 | 169.21 | 175.19 | 193.60 | 212.41 |

| B3 | 126.00 | 126.00 | 126.00 | 141.58 | 181.58 | 221.58 | 234.00 | 234.00 | 234.00 |

| B4 | 190.80 | 190.80 | 190.80 | 190.80 | 190.80 | 190.80 | 190.80 | 190.80 | 190.80 |

| B5 | 126.00 | 147.61 | 166.39 | 169.21 | 169.21 | 169.21 | 190.81 | 212.40 | 233.59 |

| Cenerg (RM/h) | 57,226.8 | 58,594.6 | 61,395.2 | 64,638.6 | 67,910.2 | 71,186.1 | 74,691.2 | 79,093.9 | 84,812.8 |

Results P-graph using scenario 3, all five boilers are optimized.

| Load | Sd,total | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 720 (ton/h) | 760 (ton/h) | 800 (ton/h) | 840 (ton/h) | 880 (ton/h) | 920 (ton/h) | 960 (ton/h) | 1,000 (ton/h) | 1,040 (ton/h) | |

| B1 | 151.18 | 169.21 | 169.21 | 169.21 | 169.21 | 169.21 | 190.81 | 190.80 | 190.80 |

| B2 | 126.00 | 147.60 | 147.61 | 169.21 | 169.21 | 169.21 | 169.20 | 190.81 | 190.80 |

| B3 | 126.00 | 126.00 | 126.00 | 141.56 | 181.57 | 221.57 | 234.00 | 234.00 | 234.00 |

| B4 | 169.21 | 169.21 | 187.97 | 190.81 | 190.80 | 190.81 | 190.81 | 193.59 | 212.41 |

| B5 | 147.61 | 147.98 | 169.21 | 169.21 | 169.21 | 169.20 | 175.18 | 190.80 | 211.99 |

| Cenerg (RM/h) | 55,618.5 | 58,359.5 | 61,370.4 | 64,638.6 | 67,910.2 | 71,186.1 | 74,605.5 | 78,455.8 | 82,871.9 |

Results of Cenerg of P-graph using different scenarios.

| Scenario | Sd,total | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 720 (ton/h) | 760 (ton/h) | 800 (ton/h) | 840 (ton/h) | 880 (ton/h) | 920 (ton/h) | 960 (ton/h) | 1,000 (ton/h) | 1,040 (ton/h) | |

| Cenerg 1 (Rm/h) | 60,009 | 61,389 | 64,178 | 67,406 | 70,693 | 73,954 | 77,492 | 81,869 | 87,595 |

| Cenerg 2 (Rm/h) | 57,227 | 58,595 | 61,395 | 64,639 | 67,910 | 71,186 | 74,691 | 79,094 | 84,813 |

| Cenerg 3 (Rm/h) | 55,618 | 58,360 | 61,370 | 64,639 | 67,910 | 71,186 | 74,605 | 78,456 | 82,872 |

| Diff 1–3 (%) | 7.89 | 5.19 | 4.57 | 4.28 | 4.10 | 3.89 | 3.87 | 4.35 | 5.70 |

| Diff 2–3 (%) | 2.89 | 0.40 | 0.04 | 0.00 | 0.00 | 0.00 | 0.11 | 0.81 | 2.34 |

Tables A1 and A2 show that scenario 3, which optimizes all boilers, results in the lowest energy cost, while scenario 1 yields the highest energy cost. However, constantly adjusting all boilers according to varying steam demands is not conducive to control applications. It is preferable to simplify the MIMO controller configuration by fixing the load of some boilers while allowing the remaining boilers to adapt to changing steam demands. Therefore, scenario 2, which optimizes the load of the most effective boilers at a reasonable energy cost, will be integrated with the controller for the next step. Table A2 also indicates that the difference between scenarios 2 and 3 is relatively small.

References

1. Liu, X, Cui, J. Economic model predictive control of boiler-turbine system. J Process Control 2018;66:59–67. https://doi.org/10.1016/j.jprocont.2018.02.010.Search in Google Scholar

2. Sun, L, Li, D, Lee, KY, Xue, Y. Control-oriented modelling and analysis of direct energy balance in coal-fired boiler-turbine unit. Control Eng Pract 2016;55:38–55. https://doi.org/10.1016/j.conengprac.2016.06.013.Search in Google Scholar

3. Bindlish, R. Power scheduling and real-time optimization of industrial cogeneration plants. Comput Chem Eng 2016;87:257–66. https://doi.org/10.1016/j.compchemeng.2015.12.023.Search in Google Scholar

4. Borzellieri, RA. Performance evaluation of control methods on the water side of drum boilers [Thesis]. Philadelphia, Pennsylvania, USA: Temple University; 2019.Search in Google Scholar

5. Adasho, AA. Optimal controller for steam boiler drum water level control using neural network estimator and LQR [Thesis]. Addis Ababa, Ethiopia: Addis Ababa University; 2018.Search in Google Scholar

6. Chen, C, Bollas, GM. Dynamic optimization of a subcritical steam power plant under time-varying power load. Processes 2018;6:114–33. https://doi.org/10.3390/pr6080114.Search in Google Scholar

7. Cáceres, IE, Montañés, RM, Nord, LO. Flexible operation of combined cycle gas turbine power plants with supplementary firing. J Power Technol 2018;98:188–97.Search in Google Scholar

8. Sun, L, Gai, L, Smith, R. Site utility system optimization with operation adjustment under uncertainty. Appl Energy 2017;186:450–6. https://doi.org/10.1016/j.apenergy.2016.05.036.Search in Google Scholar

9. Wan, A, Chang, Q, Zhang, Y, Wei, C, Agbozo, RSK, Zhao, X. Optimal load distribution of CHP based on combined deep learning and genetic algorithm. Energies 2022;15. https://doi.org/10.3390/en15207736.Search in Google Scholar

10. Jiménez-Romero, J, Azapagic, A, Smith, R. Style: a new optimization model for Synthesis of uTility sYstems with steam LEvel placement. Comput Chem Eng 2023;170. https://doi.org/10.1016/j.compchemeng.2022.108060.Search in Google Scholar

11. Cheayb, M, Chalmers, D, De Paepe, W, Hajjar, A, Poncet, S. A new approach based on off-design R-curve and thermal load duration curve for the design and optimization of bioresources driven cogeneration Rankine cycle: application on industrial site in Nova Scotia, Canada. Energy Convers Manag 2023:287.10.1016/j.enconman.2023.117108Search in Google Scholar

12. Aspen Technology, I. BPCL Mumbai refinery enhances energy management using AspenTech solutions. Mumbai, India: Aspen Technology; 2018:16 p.Search in Google Scholar

13. Er, HA, Wan Alwi, SR, Manan, ZA. Load optimisation of multiple boiler system (MBS) via P-graph. Chem Eng Trans 2023;103:1–6.Search in Google Scholar

14. Friedler, F, Tarjan, K, Huang, YW, Fan, LT. Graph-theoretic approach to process synthesis: axioms and theorems. Chem Eng Sci 1992;47:1973–88. https://doi.org/10.1016/0009-2509(92)80315-4.Search in Google Scholar

15. Frielder, F, Tarjan, K, Huang, YW, Fan, LT. Graph-theoretic approach to process synthesis - polynomial algorithm for maximal structure generation. Comput Chem Eng 1993;17:929–42. https://doi.org/10.1016/0098-1354(93)80074-w.Search in Google Scholar

16. Sørensen, K. Dynamic boiler performance modelling, simulating and optimizing boilers for dynamic operation. Aalborg, Denmark: Aalborg Universitet; 2004.Search in Google Scholar

17. Huan, L, Weide, H. A water level dynamics simulation model of AP1000’s steam generator based on Åström-Bell model. IOP Conf Ser Earth Environ Sci 2019;310:032036. https://doi.org/10.1088/1755-1315/310/3/032036.Search in Google Scholar

18. Klaučo, M, Kvasnica, M. Control of a boiler-turbine unit using MPC-based reference governors. Appl Therm Eng 2017;110:1437–47. https://doi.org/10.1016/j.applthermaleng.2016.09.041.Search in Google Scholar

19. Astrom, KJ, Bell, RD. Drum-boiler dynamics. Automatica 2000;36:363–78. https://doi.org/10.1016/s0005-1098(99)00171-5.Search in Google Scholar

20. Andreescu, GD, Iacob, M. Drum-boiler control system employing shrink and swell effect remission in thermal power plants. In: 3rd international congress on ultra modern telecommunications and control systems and workshops (ICUMT). Budapest, Hungary: IEEE; 2011.Search in Google Scholar

21. Kalita, D. Modeling, simulation and control of A drum boiler, Thesis. India: BITS Pilani; 2016.Search in Google Scholar

22. How, BS, Teng, SY, Leong, WD, Ng, WPQ, Lim, CH, Ngan, SL, et al.. Nonlinear programming via P-graph framework. Chem Eng Trans 2019;76:499–504.Search in Google Scholar

23. P-Graph; 2017. https://p-graph.org/ [Accessed 17 Jan 2024].Search in Google Scholar

24. Ong, BHY, Walmsley, TG, Atkins, MJ, Walmsley, MRW, Neale, JR. Approximation of nonlinear cost functions in P-graph structures. Chem Eng Trans 2016;52:1093–8.Search in Google Scholar

25. Molloy, B. Modelling and predictive control of a drum-type boiler [Ph.D. thesis]. Northside of Dublin, Ireland: Dublin City University; 1997.Search in Google Scholar

26. Minhajullah, S. Multivariable control of a drum type boiler [Thesis]. Dhahran, Eastern Province, Saudi Arabia: King Fahd University of Petroleum & Minerals; 2011.Search in Google Scholar

27. Rohman, FS, Muhammad, D, Aziz, N. Implementation of model predictive control in tracking dynamic optimal profiles of semi batch autocatalytic esterification reactor. Asia Pac J Chem Eng 2020;15:e2418. https://doi.org/10.1002/apj.2418.Search in Google Scholar

28. Rohman, FS, Othman, MR, Muhammad, D, Azmi, A, Idris, I, Ilyas, RA, et al.. Nonlinear control of fouling in polyethylene reactors. ACS Omega 2022;7:39648–61. https://doi.org/10.1021/acsomega.2c03078.Search in Google Scholar PubMed PubMed Central

29. Dunn, AC, Du, YY. Optimal load allocation of multiple fuel boilers. ISA Trans 2009;48:190–5. https://doi.org/10.1016/j.isatra.2008.10.009.Search in Google Scholar PubMed

30. Rohman, FS, Wan Alwi, SR, Azmi, A, Er, HA, Termizi, SNNA. Dynamic optimization of boiler for minimizing energy consumption in the intentionally transient process operation: effect of different interval number. Chem Prod Process Model 2024;19:775–93. https://doi.org/10.1515/cppm-2024-0018.Search in Google Scholar

31. El-Guindy, A, Runzi, S, Michels, K. Optimizing drum-boiler water level control performance: a practical approach. In: 2014 IEEE international conference on control applications (CCA) part of 2014 IEEE multi-conference on systems and control. Juan Les Antibes, France: IEEE; 2014:1–6 pp.10.1109/CCA.2014.6981553Search in Google Scholar

© 2024 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Research Articles

- Cogeneration system’s energy performance improvement by using P-graph and advanced process control

- Numerical simulation of R134a evaporation in a cold water production system

- Implementing a radial basis function model to anticipate the outcomes of the gasification

- Sensitivity analysis and optimization of the whole process of continuous catalytic reforming for Persian gulf star oil company using an optimized data-driven model with tuned parameters

- Evaluating the therapeutic potential of 4-hydroxyflavanes diastereomers derivatives against (MetAP2) for anti-cancer therapy: a molecular docking study

- Enhanced cryogenic distillation column identification for methane separation: a hybrid artificial neural network approach

- Natural Gas and hydrogen blending: a perspective on numerical modeling and CFD analysis for transient and steady-state scenarios

- Simulation and optimization of Venturi type bubble generator to improve cavitation

Articles in the same Issue

- Frontmatter

- Research Articles

- Cogeneration system’s energy performance improvement by using P-graph and advanced process control

- Numerical simulation of R134a evaporation in a cold water production system

- Implementing a radial basis function model to anticipate the outcomes of the gasification

- Sensitivity analysis and optimization of the whole process of continuous catalytic reforming for Persian gulf star oil company using an optimized data-driven model with tuned parameters

- Evaluating the therapeutic potential of 4-hydroxyflavanes diastereomers derivatives against (MetAP2) for anti-cancer therapy: a molecular docking study

- Enhanced cryogenic distillation column identification for methane separation: a hybrid artificial neural network approach

- Natural Gas and hydrogen blending: a perspective on numerical modeling and CFD analysis for transient and steady-state scenarios

- Simulation and optimization of Venturi type bubble generator to improve cavitation