Abstract

As the critical first step in structural health management and fault diagnosis, corrosion monitoring is inherently multidisciplinary in nature. While conventional in situ techniques capture real-time electrical, vibrational, and thermal signatures, their effectiveness is constrained by limited detection precision, inefficient data analysis, and unreliable predictive modeling. The convergence of artificial intelligence (AI) and big data analytics has fundamentally transformed this field, generating considerable academic interest over the past decade. Machine learning (ML) – serving as the cornerstone of this revolution – excels not only in extracting nonlinear features from nonstationary processes but also employs probabilistic inference frameworks to quantify predictive uncertainty, thereby substantially augmenting in situ monitoring capabilities. This review systematically examines advancements in ML-assisted corrosion monitoring throughout the preceding decade, categorizing prevalent algorithms according to domain-specific implementations while evaluating enhanced in situ techniques through empirical case studies demonstrating superior data processing efficacy. Finally, we project future trajectories for intelligent monitoring technology in light of persistent challenges and emergent innovations.

1 Introduction

Material reliability and durability constitute critical determinants of industrial equipment performance, susceptible to degradation from multifaceted factors including thermal, oxidative, mechanical, radiative, and corrosive stresses – whether acting independently or through synergistic coupling effects. Among these degradation mechanisms, corrosion poses particularly severe threats to metallic components, compromising equipment service life and public safety across energy, aerospace, marine, and transportation infrastructure. Contemporary corrosion monitoring technologies address these risks by detecting material physicochemical alterations via sensor networks and analytical systems, enabling quantitative damage prediction. Diverse in situ technologies – ranging from electrochemical impedance spectroscopy and noise analysis to acoustic emission (AE) monitoring and ultrasonic inspection – have consequently been developed for scenario-specific implementation.

Conventional in situ monitoring techniques, while capable of acquiring real-time electrical, vibrational, and thermal signals in controlled environments, remain fundamentally constrained by limited detection precision, analytical inefficiency, and unreliable predictive modeling. These limitations stem from the inherent nonstationarity and nonlinearity of corrosion signals, which arise from dynamic material–environment interactions, fluctuating operational parameters (temperature, humidity, chemical exposure), and evolving damage modalities (pitting, cracking, uniform thinning). The advent of big data analytics, however, has catalyzed a paradigm shift: the exponential accumulation of corrosion datasets now facilitates unprecedented monitoring accuracy through artificial intelligence (AI). AI-driven strategies demonstrate distinct superiority in processing high-dimensional data and deciphering complex corrosion mechanisms that elude traditional analytical approaches – a transformative potential underscored by Li et al. (2015) pioneering proposal for “material corrosion informatics” and cross-industry data sharing platforms. Within this AI landscape, machine learning (ML) has emerged as a particularly potent enabler, constructing multisensor fusion models that significantly enhance corrosion rate prediction accuracy (Wang et al. 2023). Deep learning architectures, for instance, autonomously extract latent relationships from complex in situ datasets to establish intelligent prediction systems. This technological convergence is progressively transforming corrosion management from manual-assisted inspection toward intelligent, full-process monitoring regimes capable of delivering real-time decision support for asset integrity management.

Recently, there has been a significant increasing research interest in the application of ML in field of corrosion monitoring (Bao et al. 2019; Cacciola et al. 2007; Das et al. 2019; Huang et al. 2023; Li et al. 2018; Pregowska et al. 2024; D. Wang et al. 2024a,b,c). In this review, the development of ML-assisted in situ monitoring technologies is systematically overviewed by integrating representative research results in this field over the past 10 years. First part initiates with a systematic categorization of prevalent ML algorithms, accompanied by a concise delineation of their distinctive features and implementation contexts specific to corrosion monitoring applications. Then, several in situ monitoring technologies assisted by machine learning are explored respectively, focusing on how ML enhances traditional monitoring technologies and achieve data processing actively through practical case analysis. Finally, the future development of ML-assisted intelligent corrosion monitoring technology is envisioned with respect to current challenges and cutting-edge trends.

2 Machine learning algorithms for in situ corrosion monitoring

AI, a discipline dedicated to creating systems that emulate human cognitive functions (Hamet and Tremblay 2017), offers a powerful, cognitively inspired framework uniquely suited to the challenges of corrosion monitoring. ML, as a pivotal AI subset, undergoes rapid evolutionary cycles mirroring human learning mechanisms – systems progressively refine their knowledge architecture through continuous data assimilation to enhance operational efficacy. Notably, ML demonstrates particular strengths in addressing temporally dynamic, nonlinear complexities that often constrain conventional methodologies limited by dimensional data restrictions or reliant on hypercubic computational approximations.

The core of machine learning applications is statistical algorithms, which extract corrosive evolution patterns through functional input–output mapping, essentially establishing predictive capabilities via mathematical correlations (Wang et al. 2017). As illustrated in Figure 1, machine learning can be categorized into supervised learning, unsupervised learning, semi-supervised learning, and deep learning based on the type and amount of data available. Supervised frameworks operate on input–output paired datasets, seeking to derive predictive functions that achieve acceptable fidelity in output estimations from given input parameters (Al-Jamimi et al. 2018). Classification-oriented algorithms [support vector machines (SVM), random forests, etc. (Lee et al. 2013; Yan et al. 2020)] find frequent application in corrosion categorization and typology identification while regression techniques (linear and logistic regression, etc.) predominantly serve corrosion rate prognostication and residual lifespan analysis (Feng et al. 2023; Wen et al. 2009). Unsupervised learning emerges as the preferred approach for unlabeled datasets, employing clustering mechanisms (K-means, hierarchical clustering, etc.) and dimensionality reduction techniques [principal component analysis (PCA), independent component analysis, etc.] to unveil latent corrosion patterns and corrosion anomalies. Semi-supervised methodologies synergize limited laboratory-calibrated data with expansive field-collected unannotated information, thereby enhancing model generalization in complex operational environments. Deep learning architectures exhibit marked superiority in temporal sequencing and image processing tasks, particularly in electrochemical signal interpretation and corrosion imagery analysis (Ji et al. 2025; Zhang et al. 2019). Reinforcement learning usually addresses sequential decision-making problems, showing potential in optimizing corrosion control strategies or predictive maintenance actions based on environmental feedback.

Machine learning algorithms common classification.

The selection of appropriate machine learning algorithms for corrosion prediction and analysis requires careful consideration of data characteristics, task objectives, and operational constraints. Given the multifaceted nature of corrosion mechanisms – involving complex interactions between materials, environmental parameters, and electrochemical processes – different algorithms exhibit distinct strengths and limitations. This comparative analysis synthesizes key performance attributes of five widely employed techniques in corrosion research, evaluating their applicability across common scenarios such as corrosion rate forecasting, damage classification, and cross-environmental model generalization. Table 1 provides a structured framework for researchers to align algorithmic capabilities with specific corrosion engineering challenges, accounting for critical factors including data availability, interpretability requirements, and computational efficiency.

Comparison of different machine learning algorithms.

| Algorithm | Core advantages | Applicable scenarios | Limitations |

|---|---|---|---|

| Artificial neural networks | Strong capability for fitting complex data; adaptive feature learning; suitable for multivariate nonlinear modeling | Corrosion rate prediction; localized corrosion classification; environmental factor impact analysis | Requires large datasets; prone to overfitting; poor interpretability |

| Support vector machine | Performs well with small high-dimensional datasets; resists overfitting; kernel functions handle nonlinearity | Corrosion type classification (pitting/stress corrosion); corrosion inhibitor efficacy evaluation | Complex parameter tuning; low computational efficiency for large-scale data |

| Principal component analysis | Eliminates data redundancy; extracts key features; visualizes high-dimensional data | Corrosion data preprocessing, multisensor data fusion; correlation analysis of corrosion factors | Limited to linear dimensionality reduction; interpretability depends on principal components |

| Ensemble learning | High accuracy; strong noise resistance; handles missing data; enables feature importance analysis | Corrosion life prediction; material corrosion resistance rating; multisource data fusion modeling (R. Wang et al. 2024a,b,c) | High model complexity; time-consuming training; multiple hyperparameters |

| Transfer learning | Solves small-sample problems; transfers knowledge from pretrained models; strong cross-scenario adaptability | Lab-to-field application transfer; corrosion model migration across materials/environments | Performance declines with large domain gaps; requires customized transfer strategies |

2.1 Artificial neural network

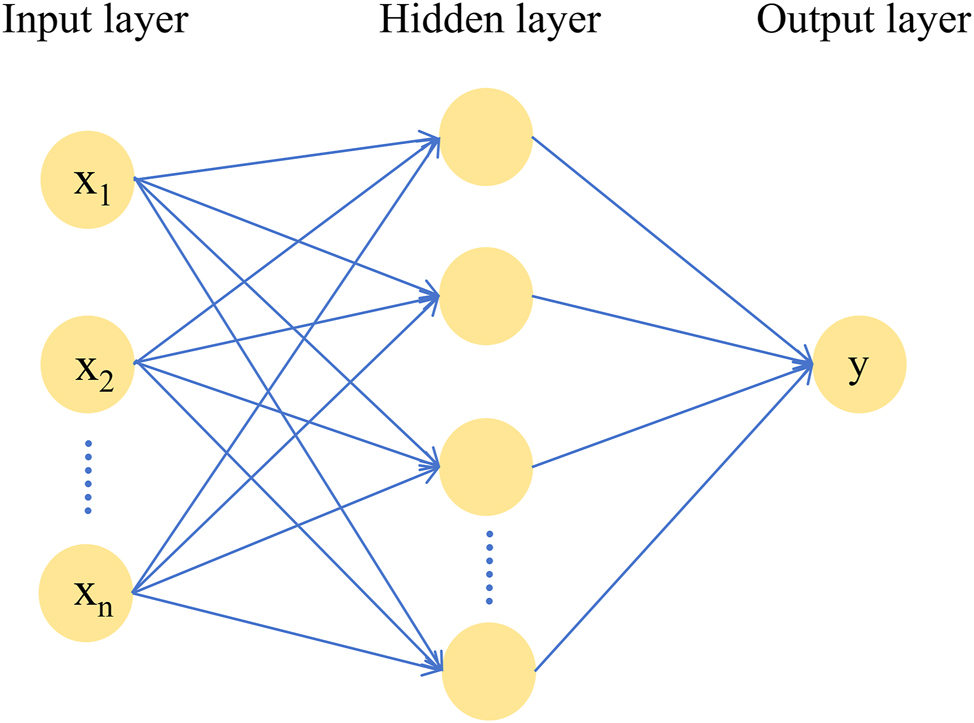

Drawing inspiration from biological neural architectures, artificial neural networks (ANNs) have emerged as powerful computational frameworks where information-processing units mimic cerebral neurons. As shown in Figure 2, these networks operate through interconnected nodes weighted by synaptic parameters, structurally mirroring neuronal configurations with multiple dendritic input channels and singular axonal output pathways. Through this biological analogy, ANNs extract latent patterns from historical datasets, subsequently generalizing these mathematically codified relationships between variables to generate predictions for novel inputs. The essence of neural network training lies in iterative weight optimization – a process where synaptic connection strengths are systematically adjusted to minimize prediction errors, thereby enabling the model’s outputs to converge toward maximal accuracy. This adaptive learning mechanism has universal approximation capabilities: when properly configured, ANNs can model any complex, nonlinear corrosion dynamics (Ma et al. 2023) – capturing interactions among factors like alloy composition, environmental conditions, and corrosion rate (Kamrunnahar and Urquidi-Macdonald 2010) – and deliver high-fidelity predictions through hierarchical architecture.

Typical artificial neural network architecture.

The superiority of ANNs over conventional methods is exemplified by Jiang et al. (2016), who predicted concrete sewer corrosion using corrosion initiation time (ti) and rate (r) as key metrics. To capture realistic corrosion dynamics, critical environmental variables – H2S concentration, temperature, relative humidity (RH), and coupon location – were controlled within 36 laboratory chambers, with validation further established through field data from six sewer sites across Sydney, Melbourne, and Perth. The ANN architecture integrated these inputs via a four-variable input layer, task-specific hidden layers (8 neurons for ti, nine for r), and a predictive output layer, trained with backpropagation using a 70:15:15 training–validation–testing split. The result shows that the ANN significantly outperformed multiple regression (MR): for ti, it achieved training/validation R-values of 0.8291/0.8839 versus MR’s R2 = 0.54; for r, its overall R = 0.9119 exceeded MR’s 0.59. Crucially, the ANN remained reliable under extreme conditions (e.g., 830 ppm H2S, high temperatures) where MR yielded nonphysical results like negative ti. Sensitivity analysis revealed H2S dominance for r and the hierarchy H2S > temperature > RH for ti, with location-specific effects showing partially submerged coupons were more H2S-sensitive while gas-phase coupons responded more to temperature/humidity. Similarly, Rajender and Samanta (2025) demonstrated ANN’s efficacy in predicting reinforcement corrosion in sustainable concrete under chloride-rich environments. Input variables encompassed cement content, microsilica dosage, water-to-cement ratio, admixture type, rebar diameter, exposure conditions, curing duration, and exposure time, with corrosion potential difference serving as the output. An ANN architecture, featuring three distinct layers (input, hidden, output), was employed to capture the intricate nonlinear relationships between the input features and the corrosion potential. This was achieved through weight matrices and bias terms, with parameters subsequently refined via optimization algorithms. Performance evaluation revealed that the ANN models delivered optimal results, exhibiting remarkably high training and testing R2 values ranging from 0.98 to 1.00 and 0.96 to 0.99, respectively, coupled with minimal error rates of merely 1.03 %–1.13 %. Their model achieved near-perfect accuracy, starkly contrasting with traditional threshold chloride models constrained by Fick’s law. These empirical methods, limited by theoretical inadequacies and computational inefficiency, cannot capture the nonlinear chloride-ingress dynamics quantified by the ANN. Parametric analysis identified chloride concentration as the dominant factor, followed by microsilica dosage and water–cement ratio – insights critical for durability design.

In essence, ANNs transcend the limitations of linear or empirical approaches by directly modeling complex, nonlinear interdependencies among corrosion variables. This capacity not only overcomes the physical implausibility and inaccuracy of methods like MR but also provides actionable insights into variable hierarchies, establishing ANNs as indispensable tools for robust corrosion prediction in challenging environments.

2.2 Support vector machine

The SVM emerges as a supervised learning architecture predominantly, as illustrated in Figure 3. Rooted in computational geometry principles, SVM seeks to identify an optimal hyperplane that maximizes interclass margins while segregating distinct data categories. This decision boundary’s determination hinges not merely on linear separability but crucially on strategically positioned support vectors – those critical data points nearest the hyperplane – a characteristic that endows SVM with enhanced generalization capabilities compared to conventional classifiers. Notably, its advantages lie in its strong adaptability to small samples and good anti–noise interference ability, making it particularly suitable for scenarios with complex data and limited samples in corrosion monitoring.

Schematic diagram of a support vector machine. Reproduced with permission from ref. (Ma et al. 2023), De Gruyter.

Lv et al. (2020) exemplify this, developing SVM models to predict steel reinforcement corrosion using a substantial dataset of 1,050 3D-scanned corroded bar cross sections. From these, seven key geometric parameters were extracted as features: the inscribed-to-fitted circle radius ratio (η), circumscribed-to-fitted ratio (δ), inscribed-to-circumscribed ratio (ν), eccentricity (e), ellipse aspect ratio (ε), circularity (χ), and section roughness (γ). Analysis revealed weak individual correlations with corrosion rate (R2 = 0.11–0.29), whereas their combination comprehensively characterized corrosion-induced distortion – evidenced by decreasing η indicating localized pitting and increasing χ reflecting contour irregularity – forming an effective multidimensional input for this nonlinear problem. Crucially, their particle swarm optimized SVM (PSO-SVM: C = 1.998, g = 51.096), trained on this comprehensive dataset, achieved outstanding accuracy (test R2 = 0.98, MAE = 0.007). This vastly outperformed both a standard grid search SVM (GS-SVM: R2 = 0.92, MAE = 0.012) and traditional methods like destructive drainage or costly X-ray CT. This approach overcame a critical limitation of traditional methods by requiring only current 3D scan data, eliminating the impractical need for initial bar dimensions essential for assessing existing structures.

Addressing data scarcity, Wen et al. (2024) tackled chloride-induced corrosion using a meticulously curated, smaller dataset. Starting with 106 samples, rigorous cleaning and validation refined it to 52 high-quality data points. Their Gaussian kernel SVM model used inputs (Cr content, LDH-NO2 dosage [Cl−], pH) to predict polarization resistance. Robustness was ensured through an extensive validation strategy: 100 iterations of rigorous cross-testing. The model demonstrated exceptional precision and stability (R2 > 0.85, low MAE, minimal error variance) in quantifying complex, nonlinear interactions. It autonomously revealed significant synergistic protection (e.g., 3 wt% Cr + 0.4 wt% LDH-NO2 enabling polarization resistance >520 kΩ·cm2 under aggressive conditions: pH 10, 3.5 % Cl−). This capability to extract intricate mechanisms from limited, high-dimensional data starkly contrasts with traditional orthogonal testing, which is fundamentally constrained by dimensionality.

SVM effectively handles complex, nonlinear relationships and diverse dataset sizes (from extensive scans to carefully curated small samples), overcoming traditional method limitations like destructiveness, cost, high-dimensionality constraints, and impractical data requirements. However, SVM’s performance remains inherently dependent on the quality, representativeness, and size of the training data. While offering powerful quantitative insights for tailored protection strategies, it should be viewed as a complementary tool augmenting, not replacing, mechanistic understanding and targeted experimental validation.

2.3 Principal component analysis

In the analysis of complex corrosion phenomena, PCA serves as a powerful unsupervised dimensionality reduction tool. It mathematically transforms high-dimensional datasets – often comprising numerous correlated corrosion variables (e.g., electrochemical parameters, environmental factors, material properties, time-series measurements) – into a lower-dimensional subspace via linear projection. Crucially, PCA achieves this while preserving the primary patterns of variation inherent in the original corrosion data. Its core mathematical objective is to identify mutually orthogonal axes of maximum variance (the principal components, represented by eigenvectors). These components encapsulate the dominant characteristics governing corrosion behavior, effectively distilling the essential information into minimal orthogonal dimensions. This orthogonal decomposition mechanism offers significant computational efficiency for handling large corrosion datasets. More importantly, it enables feature space optimization by reducing noise and redundancy and facilitates the identification of the governing variables and underlying patterns that drive corrosion processes within intricate systems.

Qu et al. (2025) developed a hybrid intelligent model for predicting carbon steel corrosion rates. Utilizing 178 laboratory-generated CO2 corrosion datasets – spanning 14 input parameters (e.g., temperature, CO2 partial pressure, pH, flow rate, ion concentrations) – corrosion rates were precisely measured via weight-loss. The modeling framework first applied PCA to 13 critical factors, extracting the top eight principal components (95.9 % cumulative contribution) as inputs, effectively eliminating multicollinearity and redundancy. Particle swarm optimization then autonomously tuned SVR hyperparameters to enhance prediction accuracy. Analysis revealed complex nonlinear interactions: environmental factors like CO2 partial pressure and temperature interplayed with ionic effects – Cl− promoting localized corrosion, while Ca2+/Mg2+ reduced CO2 solubility. Notably, PCA successfully captured these intricate relationships, overcoming traditional models’ inability to handle multifactorial nonlinearity and providing a high-precision theoretical foundation for corrosion protection.

2.4 Ensemble learning

Ensemble learning (EL) enhances predictive performance by strategically combining multiple models, systematically overcoming individual limitations to achieve superior accuracy, robustness, and generalization. This approach fundamentally reduces error propagation risks inherent in single models through collective decision-making. EL primarily employs two strategies: bagging (bootstrap aggregating) excels in data-rich environments via parallel model training, while boosting proves particularly effective with limited data or complex features through sequential error correction. For corrosion monitoring, ensemble systems offer distinct advantages. Their multi-perspective analysis mitigates underfitting and overfitting risks common in standalone models when deciphering intricate corrosion dynamics – the complex, nonlinear interactions between electrochemical parameters, environmental conditions, and material degradation processes. As a seminal bagging implementation, RF leverages decorrelated decision tree ensembles (Figure 4) to deliver robust performance against complex corrosion data artifacts while combining implementation simplicity with critical corrosion modeling advantages: inherent overfitting resistance when handling sparse field data, parallelizable training workflows enabling rapid iteration, and enhanced immunity to measurement noise characteristic of industrial corrosion environments.

Schematic diagram of random forest modeling.

Elmas et al. (2023) applied RF regression to predict annual external corrosion rates on FPSO oil platforms, utilizing a dataset spanning 7 years from four offshore platforms in Brazil. The dataset integrated climatic variables (hourly wind speed, direction, ambient temperature, relative humidity), design parameters (platform ID, module location, system type like piping or structural supports), and inspection records (annual corrosion percentage by system). Their RF model, structured with 500 decision trees and hyperparameters optimized via grid search, achieved high predictive accuracy (R2 = 0.812, RMSE = 0.0305). Feature importance analysis quantified the dominant drivers of corrosion progression: wind speed (49 % contribution) emerged as the most critical factor due to its role in accelerating electrolyte evaporation and salt deposition, followed by existing corrosion percentage (24.6 %) – reflecting localized damage susceptibility – and platform age (15.1 %), correlating with cumulative exposure time. Compared to XGBoost (R2 = 0.804), RF’s superior robustness stemmed from its inherent resistance to noisy field data and ability to model nonlinear interactions between variables like humidity spikes and structural geometry.

Similarly, Li et al. (2022) leveraged RF to decode dynamic atmospheric corrosion of carbon steel across six diverse Chinese sites, processing over three million data points from Fe/Cu galvanic sensors monitoring minute-scale corrosion currents. The dataset fused electrochemical metrics (instantaneous corrosion rate, cumulative charge), meteorological variables (RH, rainfall rate, wind speed), pollutants (PM2.5, PM10, SO2, NO2), and chloride deposition. Their RF model (100 trees, OOB error for validation) achieved exceptional accuracy (R2 > 0.90) in predicting transient corrosion rates. Feature importance analysis revealed rust layer formation (mass loss, ∼20 % weight) as the paramount factor, as porous corrosion products retained moisture and chlorides, followed by wind speed (∼18 %) – which disrupted protective electrolyte films – and rainfall rate (∼15 %), which replenished corrosive electrolytes. Notably, RF outperformed traditional ISO 9223 classification by quantifying microscopic corrosivity fluctuations (e.g., transient CX-level events undetectable via annual coupons), while its handling of high-dimensional data exposed the negligible impact of low-concentration pollutants.

Notably, the ensemble architecture of RF ameliorates overfitting in noisy and sparse in situ datasets, while its parallelized training paradigm exhibits efficient scalability with high-dimensional data modalities, such as those encompassing 10 or more environmental factors, and its embedded feature importance framework enables the quantification of complex intervariable interactions; this capacity to elucidate dominant corrosion-inducing drivers from multidimensional, nonlinear datasets – where traditional physical models or single-algorithm approaches encounter inherent limitations – renders RF indispensable for predictive maintenance within dynamic industrial ecosystems.

2.5 Deep learning

Deep Learning (DL), one of the broadest techniques used in AI, has demonstrated remarkable capabilities in image recognition, natural language processing, and other pattern recognition applications. Diverging fundamentally from traditional machine learning through its architectural depth and hierarchical feature abstraction capacity, DL employs multi-tiered nonlinear processing via deep neural networks (DNNs) to autonomously extract intricate data representations (LeCun et al. 2015; Sarker 2021). As illustrated in Figure 5, each neuron receives input data, applies weights to the input, and passes it through an activation function to generate an output. The entire process can be described by Formula (1) (Emmert-Streib et al. 2020), where φ is an activation function that performs a nonlinear transformation on the output of the convolutional layer. The weights of the connections between neurons need to be adjusted during training to optimize the performance of the network and achieve more accurate predictions.

A simplified representation of the deep neural network architecture.

DL leverages advanced architectures like convolutional neural networks (CNNs), recurrent neural networks (RNNs), transformers, and generative adversarial networks (GANs) to tackle the intricate challenges of corrosion. Among these, CNNs excel in autonomously extracting nonlinear corrosion–microstructure–stress interactions, overcoming the limitations of manual feature design under variable conditions – as demonstrated by Malashin et al. (2024), whose specialized CNN precisely characterized complex pitting morphology in natural gas pipelines. Research on BG2532 completion string material subjected to aggressive sour environments utilized ultrasonic fatigue testing and precorrosion exposure to generate a critical dataset. This dataset integrates four-dimensional features: corrosion state, stress amplitude, grain density in fatigue origin zones, and the areal fraction of cleavage facets versus step features (Δ) in crack propagation zones. A novel grouped CNN model processes these inputs via grouped convolutions to learn complex fracture relationships, ultimately predicting fatigue life. By explicitly coupling micro-fractographic features (cleavage facet area and grain density), the model confines prediction errors within a factor of two under corrosive/noncorrosive conditions, achieving an RMSE of 2.859 × 106 in corrosive settings – significantly outperforming the traditional Basquin model (errors >3). Quantified H2S corrosion impacts reveal a dual mechanism: corrosion-induced grain boundary damage accelerates dislocation accumulation and localized refinement, reducing fatigue life by 50 % at low stresses while increasing S–N data scatter; simultaneously, corrosion decreases both Δ values and grain density, exacerbating prediction difficulty. Crucially, the CNN’s autonomous extraction of nonlinear corrosion–microstructure–stress interactions surpasses conventional methods like the Basquin model – which suffers from weak predictive regularity and high errors in corrosive environments – enabling unified, high-precision life predictions for tubular string design in high-sulfur fields.

The inherently sequential nature of corrosion progression – where degradation rates depend critically on the cumulative history of material deterioration, not just instantaneous environmental factors like pH, temperature, and chloride concentration – demands robust time-series modeling. RNNs are uniquely suited for this task, capturing complex temporal dynamics essential for long-term integrity prediction (H. Li et al. 2014a, b). Addressing limitations in cumulative damage modeling, Dourado and Viana (2020) developed a physics-informed neural network (PINN) for corrosion fatigue in aircraft aluminum alloys. Traditional models like the Walker equation struggle to capture salt spray-induced accelerated damage (quantified by corrosivity index CIDX based on NaCl concentration), leading to prediction bias in corrosive environments. Their hybrid model, trained on a synthesized fleet dataset simulating 150 aircraft with flight loads, stress ratios, airport corrosivity, and crucially only 10 % actual crack measurements after 5 years, integrates an RNN core. This architecture features a dedicated physics layer implementing fatigue crack growth mechanics and a data-driven multilayer perceptron (MLP) layer acting as a bias estimator that specifically learns the corrosion-induced damage increment (ΔaCORR). The framework achieved significant accuracy: it closely tracked actual crack growth over 5 years, detected all 22 high-risk cases with zero false negatives during a 6-year prognosis, and maintained a remarkably low 12 % MAPE. Crucially, this approach outperforms traditional physics-based or purely data-driven methods by requiring minimal damage-state observations – leveraging extensive input conditions instead of full-cycle output data. This enables the MLP to capture corrosion’s elusive physical processes while inheriting the physics model’s generalizability and interpretability, ultimately providing a more reliable solution for optimizing fleet maintenance strategies like inspection prioritization based on predicted crack lengths.

These implementations underscore DL’s dual strength in spatial pattern recognition and temporal sequence modeling, positioning it as a versatile toolkit for addressing corrosion’s multifaceted challenges through data-driven computational intelligence.

2.6 Transfer learning

Transfer learning (TL) fundamentally revolves around the strategic transfer of knowledge – gained from models trained on a source domain – to a distinct target domain for final application. This paradigm is particularly crucial in corrosion science and engineering, where obtaining sufficient, high-quality target data is notoriously challenging. TL directly addresses the pervasive issues of data scarcity and prohibitively high labeling costs within the target domain. Its core value shines in bridging the significant gap between accelerated laboratory testing data and real-world, long-term outdoor exposure data. By leveraging knowledge from data-rich source domains (e.g., extensive laboratory corrosion datasets under controlled conditions or historical field data from similar environments), TL enables the development of robust predictive models for target scenarios even when direct, comprehensive target data are scarce or expensive to acquire, thus offering a powerful solution to the fundamental data limitations hindering accurate corrosion prediction and lifetime assessment.

A pioneering application demonstrating this unique advantage is the work by Vangrunderbeek et al. (2023). They employed an MLP neural network to predict the galvanic current output of an Fe/Cu corrosion sensor, a proxy for corrosion activity, based on environmental inputs (temperature and relative humidity). Crucially, their source domain consisted of abundant data generated under the controlled, cyclic conditions of the SAE J2334 accelerated salt spray test (simulating wet, spray, and dry phases). The target domain was the unpredictable, real-world outdoor atmospheric environment in Nanjing, China, where only limited data were available. Their optimized TL approach – freezing the initial MLP layer to preserve fundamental corrosion relationships learned from accelerated testing while fine-tuning subsequent layers at a low learning rate (1 × 10−5) on sparse outdoor data – achieved a mean accuracy of 69 % when forecasting summer corrosion using only 8 weeks of winter training data. This significantly outperformed traditional models (RF, SVM, CNN, LSTM, MLP) trained solely on the same limited outdoor dataset, whose accuracy plateaued around 43–62 %. Critically, the TL model excelled where others failed: it successfully identified 48 % of high-corrosion activity peaks (IACM>500nAIACM>500 nA) caused by rainfall events, while baseline models completely missed these critical events (0 % accuracy). This superior peak detection capability, essential for predicting severe corrosion damage, persisted even with minimal target data (as little as 1 week), showcasing TL’s exceptional data efficiency in overcoming the seasonal extrapolation challenge inherent to atmospheric corrosion modeling.

3 Machine learning–assisted in situ corrosion monitoring technologies

With the deepening of digital transformation, sensor networks deployed across infrastructure now continuously collect numerous parameters, building extensive corrosion databases (Alamdari et al. 2017). These databases typically combine quantitative measurements with visual documentation. Historically, numerical data relied on classical statistics and signal processing [e.g., Fourier transforms, wavelet decomposition, Kalman filtering (Klyuev et al. 2021; Wharton et al. 2003)] for noise reduction and feature extraction. While effective for steady-state, low-dimensional signals, these methods struggle with modern corrosion datasets characterized by nonstationary dynamics, multivariate dependencies, and environmental noise. Similarly, conventional image processing techniques (edge detection, adaptive thresholding (Ali et al. 2023; Yan et al. 2025; Zhou et al. 2022)) enable morphological assessment but face challenges with material heterogeneity and stochastic damage. Corrosion data itself is often incomplete, noisy, heterogeneous, and voluminous with low value density (Carden and Fanning 2004). The interplay of complex factors like instrumentation, harsh environments, and temporal variations further reduces measurement accuracy and analysis reliability. Traditional methods also risk missing key features in nonstationary processes due to resolution limitations (Xia et al. 2016).

This is where ML offers transformative potential. AI-driven approaches excel at handling noisy inputs and performing adaptive pattern recognition. Crucially, ML enables nonlinear feature extraction from nonstationary data and provides probabilistic frameworks to quantify prediction uncertainty. These capabilities make ML-enhanced in situ monitoring systems essential for overcoming historical limitations in corrosion prognostics. Such systems progressively transform raw sensor data – including physical, electrochemical, and chemical measurements – into physics-informed corrosion models, providing deeper mechanistic insights and predictive power under varying conditions.

3.1 Physical inspection technology

3.1.1 Ultrasonic inspection

Ultrasonic inspection leverages high-frequency acoustic pulses (>20 kHz) transmitted into materials, where discontinuities (e.g., corrosion defects, structural interfaces) generate characteristic wave reflections and scattering patterns (Honarvar et al. 2013). These interactions enable the nondestructive detection of subsurface anomalies – including cracks, pitting, and thickness variations – by analyzing the amplitude and arrival time of reflected waves (D. Li et al. 2014a,b). The technique’s material characterization capability further stems from the intrinsic relationship between ultrasonic wave velocity and a material’s elastic properties, making it valuable for monitoring surface corrosion, cracking, and internal degradation (Jhang 2009; Li et al. 2021; Marcantonio et al. 2019).

However, despite its widespread use in plant equipment monitoring (Honarvar and Varvani-Farahani 2020), practical application faces significant challenges. The complexity of component internal structures and the inherent multimodal, dispersive nature of guided waves complicate signal processing (Han et al. 2024). Consequently, conventional data-driven algorithms struggle to accurately map the complex relationships between raw ultrasonic signals and critical defect features, often necessitating manual feature extraction heavily reliant on specialized expertise.

To overcome these limitations, researchers are increasingly turning to DL. Zhang et al. (2023) proposed a hybrid VAE-GRU architecture for corrosion defect localization. This model denoises and compresses raw 1024-sample ultrasonic signals into compact 64-dimensional representations using a convolutional VAE, while a GRU network deciphers temporal dependencies. Demonstrating exceptional performance, it achieved a median localization error of 0.0021 m, significantly outperforming benchmarks like VAE-LSTM in speed (4.85s vs. 7.48s per training cycle) and accuracy, while autonomously capturing scattering patterns, overcoming manual extraction limitations under noise, and showing superior generalization (46 % over SAE/CAE). Mukhti et al. (2023) employed RNNs (specifically BiLSTM) to assess early-stage concrete deterioration from chloride-induced rebar corrosion using ultrasonic pulse data. Trained on data from 108 concrete specimens varying in key parameters, the BiLSTM model, fed with instantaneous frequency and spectral entropy features, achieved 74 % accuracy in classifying damage (using a 3 % corrosion threshold), outperforming the insensitive traditional ultrasonic pulse velocity (UPV) method (53 % accuracy). This highlights DL’s ability to detect subtle nonlinear signature changes linked to corrosion factors. Addressing the specific challenge of underwater inspection, where fluid interaction hinders traditional methods and empirical formulas fail (Xu et al. 2018), W. Wang et al. (2024a,b,c) utilized a conditional generative adversarial network (CGAN). Using corrosion rate as a conditional label, the CGAN generates simulated ultrasound data. By employing the Bray–Curtis distance to measure distribution similarity and rejection sampling to filter anomalies, the method ensures generated data fidelity, effectively solving the underwater data acquisition problem and opening new avenues for data expansion.

These DL approaches represent significant advancements, automating feature extraction, enhancing accuracy and robustness under challenging conditions (noise, complex morphologies), and tackling specific environmental limitations like underwater inspection. However, a critical consideration remains: their performance and generalization heavily depend on the quality, quantity, and representativeness of the training data. While demonstrating strong results on their respective datasets, broader applicability across vastly different materials, defect types, and operational environments requires further validation. The computational demands of complex models like hybrid VAE-GRU or CGAN for real-time, online monitoring also warrant attention.

3.1.2 Acoustic emission

Acoustic emission technology monitors transient stress waves generated by rapid energy release during material deformation, damage, microcracking, or corrosion (Bi et al. 2013). This enables the detection and localization of defects such as stress corrosion cracking, corrosion fatigue cracking, corrosion film rupture, and microcracks by analyzing signal characteristics like amplitude, duration, energy, and rise time (Manthei et al. 2012; May et al. 2020; Zhao et al. 2020). Modern systems typically employ resonant piezoelectric transducers to convert mechanical waves into electrical signals, which are then amplified, filtered, and processed for analysis (Figure 6). However, acoustic wave dispersion due to material elasticity and interference from nonstructural noise sources complicate signal interpretation and defect identification (Ding et al. 2004). These limitations have spurred the adoption of ML frameworks capable of extracting meaningful patterns from complex AE signatures.

Acoustic emission detection scheme. AE sensor captures the signal and passes it to a preamp, which then sends it to a band-pass filter. Subsequently, the selected spectrum is amplified and passed to the signal processor.

Recent studies highlight ML-driven advances. For corrosion monitoring in bolted connections, Di et al. (2024) developed a wireless AE sensor network (WASN) system. Using feature selection (ReliefF algorithm) and optimized extreme learning machines (GOOSE-ELM) on data from progressively corroded bolts, their model achieved exceptional accuracy (98.04 %), precision (98.02 %), recall (98.06 %), and F1-score (0.9804). This approach significantly outperformed traditional ELM, offering improved sensitivity to minor corrosion while eliminating the need for periodic calibration and extensive cabling. Addressing marine titanium alloy corrosion, Zhang et al. (2024) correlated AE signals with residual yield life in seawater-corroded TC4 specimens. By applying PCA for dimensionality reduction and developing an enhanced LSTM model (optimized with interpolation and batch input techniques), they achieved 95.8 % accuracy in predicting tensile yield life. This data-driven method surpassed traditional SVM and physical models by autonomously capturing the temporal dynamics of corrosion-related AE signals and quantifying environmental factor impacts. Further advancing sensor technology for tank floors, Feng et al. (2024) replaced error-prone piezoelectric sensors with optical fiber AE sensors (OFAES). Capturing seven distinct signal types in simulated corrosive environments, they created an image dataset (2,694 samples) and trained an optimized ResNet50 model incorporating transfer learning, PReLU, and CBAM mechanisms. The model achieved 95.1 % mean accuracy, with corrosion-specific signals (metal dissolution, hydrogen evolution) identified at >98 % accuracy. Key innovations reduced training time by 38 s while boosting accuracy by 32.1 %, overcoming the inefficiency and high false-negative rates of manual analysis. In structural steel assessment, Barile et al. (2022) employed AE combined with CNNs to evaluate corroded CORTEN steel. By converting raw waveforms into Mel-spectrograms and decoupling geometric from corrosion effects, their three-layer CNN achieved >99 % classification accuracy. The model quantified corrosion’s pronounced fivefold reduction in power spectral density (PSD), contrasting with geometric-induced frequency shifts. This ML approach demonstrated superior sensitivity to subtle time-frequency alterations and enabled objective tracking of corrosion progression compared to conventional methods.

While these ML approaches demonstrate remarkable accuracy (> 95 % across studies) and address key limitations of conventional AE analysis, such as noise sensitivity, feature extraction subjectivity, and sensor constraints, significant challenges persist. Their performance remains heavily dependent on the quality and representativeness of training data, often derived from laboratory simulations. Real-world applicability requires validation in uncontrolled environments with unpredictable noise sources and variable corrosion morphologies. Furthermore, the computational complexity of advanced architectures (e.g., enhanced LSTMs, ResNet50 with attention modules) may hinder real-time field deployment. Standardization across studies is also lacking, making comparative evaluation difficult and raising questions about generalizability beyond specific experimental setups. Future work should prioritize robust validation frameworks, model lightweighting, and establishing protocols for cross-study benchmarking to translate these promising laboratory results into reliable industrial practice.

3.1.3 Eddy current testing

Eddy current testing (ECT) is based on the principle of electromagnetic induction. When a coil of alternating current is placed near an electrically conductive material, an alternating magnetic field causes eddy currents to be induced in the metal object located in the magnetic field. These eddy currents generate a secondary magnetic field that reverses the impedance (both resistance and inductance) of the primary coil. Defects at or near the surface of the material affect the distribution and strength of the eddy currents, so by analyzing the change in coil impedance, it is possible to infer the surface defects and corrosion condition. However, traditional ECT faces significant limitations: heavy reliance on operator expertise leading to subjectivity and inconsistency, and sensitivity to confounding factors like lift-off (caused by coating thickness variations) and excitation frequency, which induce signal phase shifts and compromise defect localization and sizing (Tang et al. 2024).

The integration of ML into ECT methodologies traces its conceptual origins to the 1990s (Benoist et al. 1995), when expert systems were developed for ECT data. However, it was difficult to explore the full potential of the region due to the low computing power available at the time to handle multidimensional data. Modern ML leverages algorithms like SVM, ANN, and RF for smaller datasets, while CNNs and ResNet excel with image/big data for comprehensive defect analysis. Recent advancements demonstrate ML’s effectiveness in overcoming core ECT limitations. Le et al. (2024) addressed PECT’s transient signals, lift-off interference, and low small-corrosion sensitivity using an unsupervised LSTM-Conv1D autoencoder. Trained on 11,160 normal signals, it identified corrosion via reconstruction error on 25,760 test signals, achieving a 100–200 % SNR improvement over traditional methods and excelling at minor defect detection; this data-driven approach bypasses subjective expert interpretation and complex signal compensation algorithms, significantly enhancing robustness and automation. Zuo et al. (2025) overcame the limitations of single-parameter assessment and manual subjectivity by fusing multiparameter PEC features (DTCSV, TTS) with a PSO-optimized SVM. Their model classified steel corrosion severity (2.5–10 mm loss) into four levels with 95 % accuracy and proved robust against burial depth variations (<30 mm). Thuong Pham et al. (2025) tackled PECT’s broad bandwidth, lift-off sensitivity, and environmental noise by integrating Gaussian-PECT with a spiking CNN. Achieving 96.2 % accuracy on aluminum corrosion while consuming only 10 % of a standard CNN’s energy, their model provided superior SNR, overcame background interference, and enabled clear imaging of small corrosion regions. Ogata et al. (2025) circumvented issues like prior rebar localization needs and limited depth resolution (typically ∼10 mm) common in traditional eddy current by using a triaxial magnetic sensor array and CNN. Their system achieved 92.22 % mean accuracy, generalized to unseen depths (22–47 mm), and attained a high 3 mm depth resolution, markedly improving efficiency and applicability without requiring prior knowledge of rebar position.

Collectively, these ML-enhanced ECT approaches demonstrate transformative potential by automating interpretation, suppressing noise/interference like lift-off, enabling high-resolution detection of small defects, quantifying multiparameter corrosion states objectively, and improving robustness in complex environments – effectively addressing the core limitations that have historically constrained traditional ECT methodologies.

3.1.4 Infrared thermography method

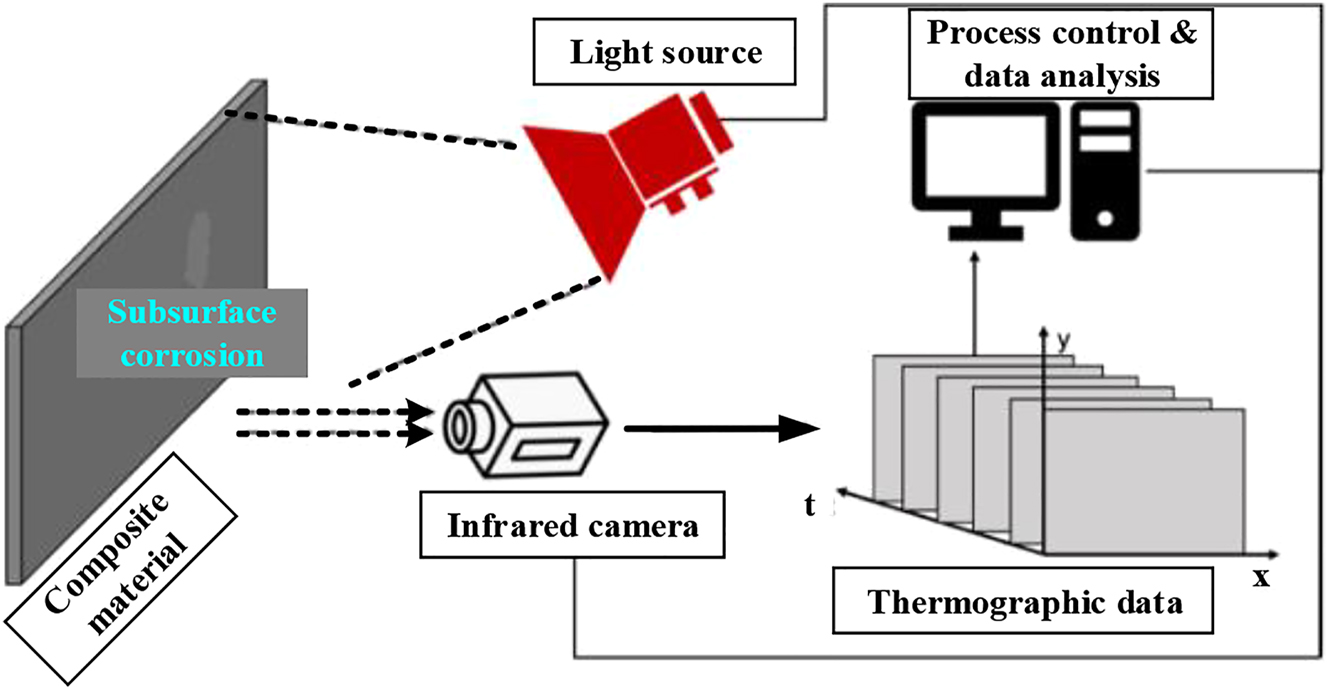

Infrared imaging technology identifies material corrosion by analyzing variations in thermal conductivity through temperature distribution patterns. This detection principle leverages inherent differences in thermophysical properties between corroded and intact regions – including disparities in thermal conductivity and heat capacity – which manifest as measurable temperature gradients during thermal transients (heating/cooling cycles). Thermal imaging visualization generates component isothermal maps through two primary methodologies: active and passive approaches (Titman 2001). The active technique introduces controlled external heat stimuli to observe differentiated thermal responses in corrosion-affected zones, whereas passive implementation capitalizes on naturally occurring temperature differentials arising from environmental heat exchange processes.

An infrared imaging system operates by capturing electromagnetic radiation emitted from objects through specialized detectors, subsequently translating these signals into visible pseudocolor thermograms. Advanced processing stages involve digitizing the thermal data, extracting discriminative thermal features, and implementing pattern recognition algorithms (Figure 7). This systematic workflow ultimately establishes correlations between thermal patterns and subsurface corrosion defects (Cadelano et al. 2016), enabling nondestructive evaluation of material integrity through temperature-anomaly interpretation. However, traditional thermographic techniques face fundamental limitations: accurate defect sizing and localization are hindered by blurred thermal conduction and low edge contrast (Jönsson et al. 2010), and performance degrades under environmental interference (e.g., airflow, particulates).

Thermal imaging devices for corrosion detection and monitoring. Reproduced with permission from ref. (Liu et al. 2021), Springer.

Emerging machine learning paradigms directly address these core challenges in corrosion monitoring. For instance, De Bortoli et al. (2025) designed a hybrid architecture where a five-layer CNN extracted spatial features from thermal sequences, while an LSTM network decoded temporal evolution patterns. This framework overcame quantification and low-contrast limitations in steel plate analysis, achieving direct defect sizing with a low average error (16.1 %) without simulation data and significantly boosting recall for critical low-contrast edge delamination defects to 76 %. Further tackling the bottleneck of limited real-world data, Rezayiye et al. (2024) innovated in data synthesis by integrating COMSOL-simulated defect profiles with real thermograms. They benchmarked advanced architectures including UNet++, DeepLabV3+, and feature pyramid network (FPN) with ResNet152 encoders, demonstrating that FPN trained on hybrid data achieved a 0.94 mean IoU – far surpassing traditional threshold-based segmentation in capturing complex corrosion morphology. Similarly, addressing environmental noise susceptibility, Kulkarni et al. (2023) combined PCA for spatio-temporal feature enhancement with a Bidirectional Feature Pyramid Network (BiFPN) architecture. Trained on Gaussian noise-augmented images, this system achieved 85 % road cavity detection accuracy – a 24 % improvement over YOLOv5 – proving robust against environmental noise where conventional methods falter.

These ML-based approaches mark a paradigm shift in infrared corrosion monitoring. They overcome traditional sizing ambiguity through direct, accurate defect quantification – a critical advancement previously unattainable with conventional thermography. Simultaneously, they achieve early intervention capability by excelling at low-contrast defect detection, while thriving on limited real-world data via physics-informed simulation. Crucially, their robustness persists in environmentally noisy conditions. By systematically resolving these persistent limitations, the approaches pioneer autonomous, reliable, and widely applicable corrosion assessment systems.

3.2 Electrochemical detection technology

3.2.1 Electrochemical impedance spectroscopy

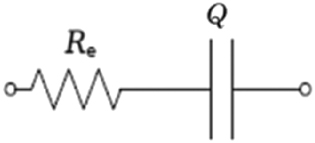

Electrochemical impedance spectroscopy (EIS) utilizes frequency-domain analysis to probe electrochemical interfaces via controlled AC excitation, typically applying low-amplitude sinusoidal perturbations (10–20 mV) at metal–electrolyte interfaces (EL Euch et al. 2019; Lei et al. 2018). This nondestructive technique captures critical insights into corrosion mechanisms by correlating frequency-dependent charge transfer dynamics with degradation processes. However, interpreting multidimensional EIS data remains challenging, as conventional methods rely on equivalent circuit modeling (ECM) to deconvolute interfacial phenomena into physical parameters, such as solution resistance (R s ), double-layer capacitance (Cdl), polarization resistance (R p ), Warburg impedance, and charge transfer resistance (Rct). The criticality of model selection stems from its direct impact on analytical validity – improper equivalent electrical circuit (EEC) configurations risk fundamental misinterpretation of interfacial corrosion mechanisms. A common chemical equivalent circuit diagram and the corresponding complex impedance expression equations are shown in Table 2 (Xia et al. 2022). Critically, ECM is inherently subjective in that researchers must manually iterate through candidate circuit configurations while balancing mathematical fitting against electrochemical principles, a process prone to bias and analytical error.

Some common electrochemical and corrosion systems and their EECs.

| No. | Corrosion system | Electrochemical equivalent circuit | Impedance |

|---|---|---|---|

| EEC1 | Blocking electrode |

|

|

| EEC2 | Blocking electrode (CPE) |

|

|

| EEC3 | Corroding electrode |

|

|

| EEC4 | Corroding electrode (CPE) |

|

|

| EEC5 | Metal covered by organic coating |

|

|

| EEC6 | Metal covered by organic coating (CPE) |

|

|

-

Reproduced with permission from ref. (Xia et al. 2022), Elsevier.

To address these limitations, initiatives like Macdonald’s Electrochemical Genome Project aim to develop comprehensive EIS spectral databases coupled with artificial intelligence systems capable of proposing optimized circuit models, thereby enhancing objectivity and reproducibility in data interpretation (Macdonald 2006). ML analysis methods can improve the accuracy and efficiency of the analysis, reduce subjective effects, and accommodate different features and fluctuations of the data (Jordan and Mitchell 2015). Zhu et al. (2019) pioneered ML application by employing an SVM classifier. They trained the model on over 250 literature-derived EIS datasets, processed via discretization and normalization, to categorize spectra into five fundamental equivalent circuit models. Crucially, through systematic optimization of SVM kernel functions and hyperparameters, they achieved classification accuracies of 84 % for training and 78 % for test, demonstrating ML’s potential to surpass human efficiency despite challenges like dataset size limitations and model overfitting. Bongiorno et al. (2022) systematically quantified the impact of training dataset size on an ANN architecture – comprising four dense layers with three dropout layers (rate: 0.1) to mitigate overfitting. Their work demonstrated that just 100–200 simulated EIS spectra sufficed to train models for both regression (parameter fitting) and classification (circuit identification), achieving mean MSE below 0.05 for resistances and ∼15 % average error for capacitances in EEC fitting. Critically, this approach eliminated the need for manual circuit selection, which relies on expert intuition and iterative optimization, often requiring hours per spectrum. Addressing feature relevance and model robustness, Chen et al. (2025) implemented a sophisticated RF approach. Their methodology integrated Recursive Feature Elimination with RF (RFE-RF) for automated identification of critical EIS features, followed by comprehensive hyperparameter tuning via grid search. This rigorous technical pipeline resulted in exceptional predictive performance: model-predicted equivalent circuits exhibited a remarkably low fitting error of only 4.4 % against experimental corrosion data, decisively outperforming conventional fitting techniques in precision and objectivity. Transitioning from simulated to real-world data challenges, Sáez-Pardo et al. (2025) addressed inherent discrepancies in experimental EIS datasets by painstakingly curating a balanced database of 502 spectra. They resolved critical issues – noise via redigitization, label inconsistencies through literature validation, and class imbalance (originally 195:46 samples for common:rare EECs) by expanding underrepresented classes – resulting in a refined corpus spanning five EEC types. Their rigorous benchmarking of five ML algorithms (SVM, NN, naïve Bayes, KNN, decision tree) revealed that KNN optimized with city block distance and one neighbor delivered superior test accuracy (median: 47.22 %; 95 % CI: 38.89–56.48 %), outperforming traditional heuristic EEC matching (typically <30 % accuracy for complex circuits) and other ML models (e.g., SVM: 38.9 %, NN: 39.8 %).

These advances underscore ML’s transformative role in corrosion monitoring, overcoming traditional EIS bottlenecks through computational efficiency and reproducibility. Nevertheless, challenges persist – including data scarcity, model overfitting, and the need for standardized databases, as highlighted by Macdonald’s Electrochemical Genome Project. Ultimately, ML elevates EIS from subjective interpretation toward a high-throughput diagnostic tool, though algorithmic transparency remains vital for industrial adoption.

3.2.2 Electrochemical noise

Electrochemical noise (EN) analysis captures the stochastic current and potential fluctuations arising from transient imbalances between localized anodic and cathodic reactions during metallic corrosion processes (Cottis 2021). These spontaneously generated signals inherently encode critical information about corrosion mechanisms, evidenced by distinct noise signatures correlating with specific degradation phenomena, such as the characteristic electrical perturbations observed during organic coating failure preceding pitting initiation (Mills et al. 2014). Traditional approaches to interpreting this rich data stream primarily utilize time-domain and frequency-domain analyses (Xia et al. 2016). Time-domain methods directly examine current/potential-time curves, employing mathematical models to fit transient waveforms and extract kinetic parameters like standard deviation, root-mean-square value, skewness, and local exponents (Eckermann et al. 2008), with derived resistance noise offering quantitative estimates of uniform corrosion rates akin to polarization resistance. Conversely, frequency-domain techniques, employing transforms like FFT or MEM, reveal mechanistic insights through statistical or wavelet analyses, where high-frequency dominance often indicates uniform corrosion, while low-frequency peaks may signal localized attack (Ma et al. 2017). However, extracting deeper mechanistic insights from EN data remains challenging due to inherent multisource noise interference and the limitations of conventional methods, particularly under low-corrosion conditions where poor signal-to-noise ratios amplify uncertainty. While strategies like optimized detrending and cross-correlation have improved signal reliability by excluding noise-contaminated segments (Smulko et al. 2007), their effectiveness diminishes precisely in these critical low-corrosion scenarios.

This fundamental constraint underscores the transformative potential of ML for advancing corrosion monitoring, enabling direct interpretation of complex, noisy signals. Early efforts by Hu et al. (2022) demonstrated enhanced field applicability by integrating an improved EN setup – utilizing a single working electrode with a platinum wire counter electrode instead of traditional symmetrical pairs – with an ANN. Their model, using relative energy values from wavelet decomposition as input, successfully synchronized real-time monitoring of both corrosion rate and type (passivation, pitting, inhibition), providing a practical solution for in situ deployment. Building on this progress toward real-time analysis, Homborg et al. (2024) innovatively treated EN time-frequency spectra as image classification problems. By applying continuous wavelet transform (CWT) and extracting mode-maximum (MM) features to generate grayscale images, their CNN model achieved robust performance with remarkably limited raw data – transforming just 11 EN signals into 480 training images. This approach not only overcomes traditional deep learning’s heavy reliance on vast datasets but also enables the automatic extraction of key transient patterns previously obscured by noise, representing a significant methodological leap. More recently, Bongiorno et al. (2025) further demonstrated ML’s classification power using feature-engineered EN parameters with Random Forests, achieving 89 % accuracy in distinguishing uniform corrosion, pitting, and passivation states – a level of precision surpassing conventional pattern recognition capabilities.

Collectively, these ML advancements, evolving from simplified hardware integration to innovative algorithmic interpretation and optimized classification accuracy, represent a paradigm shift. They overcome the interpretative limitations of traditional EN analysis by directly deciphering complex signal patterns to provide deeper, more reliable, and actionable insights into corrosion mechanisms, even in challenging low-signal environments.

4 Technical challenges and perspective

Machine intelligence–assisted corrosion monitoring has emerged as a transformative paradigm for intelligent structural health management. Significant advancements have been achieved through the synergistic integration of signal processing, advanced sensor technology, and big data analytics, substantially enhancing the efficiency and accuracy of conventional methods. As artificial intelligence expands ambitiously beyond information processing domains, deeper mechanistic insights into corrosion phenomena are anticipated.

Machine learning offers a powerful framework for quantitative assessment and corrosion mechanism inference in complex equipment operating under extreme conditions. Nevertheless, formidable challenges persist: the inherent complexity and imperceptibility of corrosion processes, coupled with multisource data heterogeneity and inconsistency, render single-model approaches inadequate for reliable prediction. Data quality remains the primary impediment to fusion algorithms, as corrosion datasets – often compromised by environmental interference, sensor noise, and experimental constraints – exhibit missing values, anomalous fluctuations, and feature heterogeneity that critically undermine model training. Furthermore, sparse historical data and divergent data formats across sources compromise model robustness and transferability. The insufficiency of model generalization presents another critical limitation. Algorithms developed in idealized laboratory environments frequently fail to adapt to real-world industrial scenarios characterized by material diversity, dynamic environmental parameters, and multiphysical field coupling effects. Most consequentially, while contemporary “black box” models adeptly capture nonlinear relationships, their inability to elucidate physical correlations with electrochemical corrosion mechanisms erodes confidence in engineering decision-making.

To address these constraints, four research priorities emerge:

Data enhancement techniques: generative adversarial networks integrated with physical simulations should be leveraged to synthesize high-fidelity datasets for extreme or data-scarce environments, thereby mitigating distributional bias.

Multimodal data fusion: heterogeneous data integration (e.g., acoustic emission, infrared thermography, electrochemical noise) is essential for monitoring multifactor corrosion where single sensing modalities prove insufficient. Advanced fusion methodologies must extract coherent features from these disparate inputs.

Interpretable AI-mechanistic hybridization: embedding electrochemical kinetics and material degradation models within ML architectures can develop “gray box” systems that enhance predictive interpretability.

Unified corrosion databases: establishing standardized repositories with consistent data formats, collection protocols, and sharing mechanisms is fundamental for model iteration and cross-domain validation.

Converging advances in materials science, electrochemistry, signal processing, and machine learning will ultimately bridge microscale mechanisms to macroscale monitoring systems, enabling a paradigm shift from reactive corrosion diagnosis to proactive life prediction and prevention. Emerging technologies such as quantum computing and digital twins promise to further advance autonomous, adaptive monitoring frameworks, thereby providing a robust foundation for lifecycle integrity management of industrial assets.

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission. Ruiyi Li: writing – original draft, writing – review & editing, investigation, resources; Huanchun Wang: supervision, conceptualization, writing – review & editing, formal analysis; Yuhao Zhu and Xiaogang Mu: review and editing; Xuanjun Wang: project administration, funding acquisition.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

-

Research funding: This work supported by Postdoctoral Fellowship Program of CPSF (no. GZC20233564) and Shaanxi Provincial Natural Science Foundation funds research projects in basic scientific areas (2024JC-YBQN-0149).

-

Data availability: Not applicable.

References

Al-Jamimi, H.A., Al-Azani, S., and Saleh, T.A. (2018). Supervised machine learning techniques in the desulfurization of oil products for environmental protection: a review. Process Saf. Environ. Prot. 120: 57–71, https://doi.org/10.1016/j.psep.2018.08.021.Search in Google Scholar

Alamdari, M.M., Rakotoarivelo, T., and Khoa, N.L.D. (2017). A spectral-based clustering for structural health monitoring of the sydney harbour bridge. Mech. Syst. Signal Process. 87: 384–400, https://doi.org/10.1016/j.ymssp.2016.10.033.Search in Google Scholar

Ali, A.A.I.M., Jamaludin, S., Imran, M.M.H., Ayob, A.F.M., Ahmad, S.Z.A.S., Akhbar, M.F.A., Suhrab, M.I.R., and Ramli, M.R. (2023). Computer vision and image processing approaches for corrosion detection. J. Mar. Sci. Eng. 11: 1954, https://doi.org/10.3390/jmse11101954.Search in Google Scholar

Bao, Q., Yuan, S., Guo, F., and Qiu, L. (2019). Transmitter beamforming and weighted image fusion-based multiple signal classification algorithm for corrosion monitoring. Struct. Health Monit.- Int. J. 18: 621–634, https://doi.org/10.1177/1475921718764848.Search in Google Scholar

Barile, C., Casavola, C., Pappalettera, G., and Kannan, V.P. (2022). Designing a deep neural network for an acousto-ultrasonic investigation on the corrosion behaviour of CORTEN steel, Procedia struct. integr., ICSI 2021 the 4th international conference on structural integrity 37, pp. 307–313, https://doi.org/10.1016/j.prostr.2022.01.089.Search in Google Scholar

Benoist, B., Gaillard, P., Pigeon, M., and Morizet-Mahoudeaux, P. (1995). Expert system for the characterization of defect signals in steam generator tubes. Eng. Appl. Artif. Intell. 8: 309–318, https://doi.org/10.1016/0952-1976(95)00011-O.Search in Google Scholar

Bi, H., Li, Z., Cheng, Y., Isaac, and Wang, J. (2013). The corrosion acoustic emission source location technique and its new trend, Manufacturing process and equipment. In: Liu, X.H., Zhang, K.F., and Li, M.Z. (Eds.). Presented at the 4th International Conference on Manufacturing Science and Engineering (ICMSE 2013). Bach, Trans Tech Publications Ltd, pp. 1167–1172.10.4028/www.scientific.net/AMR.694-697.1167Search in Google Scholar

Bongiorno, V., Curioni, M., and Zhou, X. (2025). An automated electrochemical noise analysis for corrosion type identification using random forest: features selection and cross-material performance. J. Electrochem. Soc. 172: 21503, https://doi.org/10.1149/1945-7111/adb215.Search in Google Scholar

Bongiorno, V., Gibbon, S., Michailidou, E., and Curioni, M. (2022). Exploring the use of machine learning for interpreting electrochemical impedance spectroscopy data: evaluation of the training dataset size. Corros. Sci. 198: 110119, https://doi.org/10.1016/j.corsci.2022.110119.Search in Google Scholar

Cacciola, M., Calcagno, S., Morabito, F.C., and Versaci, M. (2007). Swarm optimization for imaging of corrosion by impedance measurements in eddy current test. IEEE Trans. Magn. 43: 1853–1856, https://doi.org/10.1109/TMAG.2007.892513.Search in Google Scholar

Cadelano, G., Bortolin, A., Ferrarini, G., Molinas, B., Giantin, D., Zonta, P., and Bison, P. (2016). Corrosion detection in pipelines using infrared thermography: experiments and data processing methods. J. Nondestruct. Eval 35: 49, https://doi.org/10.1007/s10921-016-0365-5.Search in Google Scholar

Carden, E.P. and Fanning, P. (2004). Vibration based condition monitoring: a review. Struct. Health Monit. 3: 355–377, https://doi.org/10.1177/1475921704047500.Search in Google Scholar

Chen, W., Yan, B., Xu, A., Mu, X., Zhou, X., Jiang, M., Wang, C., Li, R., Huang, J., and Dong, J. (2025). An intelligent matching method for the equivalent circuit of electrochemical impedance spectroscopy based on random forest. J. Mater. Sci. Technol. 209: 300–310, https://doi.org/10.1016/j.jmst.2024.05.024.Search in Google Scholar

Cottis, R.A. (2021). 5 – Electrochemical noise for corrosion monitoring. In: Yang, L. (Ed.). Techniques for corrosion monitoring. Woodhead publishing series in metals and surface engineering, 2nd ed. Woodhead Publishing, Oxford, pp. 99–122.10.1016/B978-0-08-103003-5.00005-9Search in Google Scholar

Das, A.K., Suthar, D., and Leung, C.K.Y. (2019). Machine learning based crack mode classification from unlabeled acoustic emission waveform features. Cem. Concr. Res. 121: 42–57, https://doi.org/10.1016/j.cemconres.2019.03.001.Search in Google Scholar

de Bortoli, T.J., Barros, V.T., and Albertazzi, A. (2025). Classification and sizing of circular defects in composite coated metal plates using thermography and neural networks. Measurement 249: 116815, https://doi.org/10.1016/j.measurement.2025.116815.Search in Google Scholar

Di, S., Wu, Y., and Liu, Y. (2024). Research on a method for classifying bolt corrosion based on an acoustic emission sensor system. Sensors 24: 5047, https://doi.org/10.3390/s24155047.Search in Google Scholar PubMed PubMed Central

Ding, Y., Reuben, R.L., and Steel, J.A. (2004). A new method for waveform analysis for estimating AE wave arrival times using wavelet decomposition. NDT E Int. 37: 279–290, https://doi.org/10.1016/j.ndteint.2003.10.006.Search in Google Scholar

Dourado, A. and Viana, F.A.C. (2020). Physics-informed neural networks for missing physics estimation in cumulative damage models: a case study in corrosion fatigue. J. Comput. Inf. Sci. Eng. 20: 61007, https://doi.org/10.1115/1.4047173.Search in Google Scholar

Eckermann, F., Suter, T., Uggowitzer, P.J., Afseth, A., Davenport, A.J., Connolly, B.J., Larsen, M.H., Carlo, F.D., and Schmutz, P. (2008). In situ monitoring of corrosion processes within the bulk of AlMgSi alloys using X-ray microtomography. Corros. Sci. 50: 3455–3466, https://doi.org/10.1016/j.corsci.2008.09.015.Search in Google Scholar

El Euch, S., Bricault, D., Cachet, H., Sutter, E.M.M., Tran, M.T.T., Vivier, V., Engler, N., Marion, A., Skocic, M., and Huerta-Ortega, B. (2019). Temperature dependence of the electrochemical behavior of the 690 Ni-base alloy between 25 and 325 °C. Electrochim. Acta 317: 509–520, https://doi.org/10.1016/j.electacta.2019.05.131.Search in Google Scholar

Elmas, F.R., Rios, M.P., Lima, E.R.D.A., Caiado, R.G.G., and Santos, R.S. (2023). Prediction of external corrosion rate in oil and gas platforms using ensemble learning: a maintenance 4.0 approach. Braz. J. Oper. Prod. Manag. 20: 1952, https://doi.org/10.14488/BJOPM.1952.2023.Search in Google Scholar

Emmert-Streib, F., Yang, Z., Feng, H., Tripathi, S., and Dehmer, M. (2020). An introductory review of deep learning for prediction models with big data. Front. Artif. Intell. 3, https://doi.org/10.3389/frai.2020.00004.Search in Google Scholar PubMed PubMed Central

Feng, Y., Jianwei, L., Wei, L., Peng, J., and Yuhan, D. (2024). Identification of corrosion-induced optical fiber acoustic emission sensor signals on the bottom plate of oil storage tank based on multichannel attention mechanism (CBAM). IEEE Sens. J. 24: 22790–22800, https://doi.org/10.1109/JSEN.2024.3406685.Search in Google Scholar

Feng, S., Sun, X., Chen, G., Wu, H., and Chen, X. (2023). LBE corrosion fatigue life prediction of T91 steel and 316 SS using machine learning method assisted by symbol regression. Int. J. Fatigue 177: 107962, https://doi.org/10.1016/j.ijfatigue.2023.107962.Search in Google Scholar

Hamet, P. and Tremblay, J. (2017). Artificial intelligence in medicine. Metabolism 69S: S36–S40, https://doi.org/10.1016/j.metabol.2017.01.011.Search in Google Scholar PubMed

Han, G., Lv, S., Tao, Z., Sun, X., and Du, B. (2024). Evaluation of bolt corrosion degree based on non-destructive testing and neural network. Appl. Sci.-Basel 14: 5069, https://doi.org/10.3390/app14125069.Search in Google Scholar

Homborg, A., Mol, A., and Tinga, T. (2024). Corrosion classification through deep learning of electrochemical noise time-frequency transient information. Eng. Appl. Artif. Intell. 133: 108044, https://doi.org/10.1016/j.engappai.2024.108044.Search in Google Scholar

Honarvar, F., Salehi, F., Safavi, V., Mokhtari, A., and Sinclair, A.N. (2013). Ultrasonic monitoring of erosion/corrosion thinning rates in industrial piping systems. Ultrasonics 53: 1251–1258, https://doi.org/10.1016/j.ultras.2013.03.007.Search in Google Scholar PubMed

Honarvar, F. and Varvani-Farahani, A. (2020). A review of ultrasonic testing applications in additive manufacturing: defect evaluation, material characterization, and process control. Ultrasonics 108: 106227, https://doi.org/10.1016/j.ultras.2020.106227.Search in Google Scholar PubMed

Hu, Q., Zhang, T., Chen, S., Hu, K., Yin, Q., and Wang, F. (2022). An instantaneous corrosion monitoring technique based on combining modified electrochemical noise and artificial neural network for determination of corrosion type and 2014 aluminium alloy corrosion rate in NaCl and Ce(NO3)3 solutions. Int. J. Electrochem. Sci. 17: 220213, https://doi.org/10.20964/2022.02.30.Search in Google Scholar

Huang, T., Liu, T., Ai, Y., Ren, Z., Ou, J., Li, Y., and Xu, N. (2023). Modelling the interface bond strength of corroded reinforced concrete using hybrid machine learning algorithms. J. Build. Eng. 74: 106862, https://doi.org/10.1016/j.jobe.2023.106862.Search in Google Scholar

Jhang, K.-Y. (2009). Nonlinear ultrasonic techniques for non-destructive assessment of micro damage in material: a review. Int. J. Precis. Eng. Manuf. 10: 123–135, https://doi.org/10.1007/s12541-009-0019-y.Search in Google Scholar

Ji, H., Liu, J.-C., and Ye, H. (2025). Time-series prediction of steel corrosion in concrete using recurrent neural networks. Nondestruct. Test. Eval: 1–20, https://doi.org/10.1080/10589759.2025.2456668.Search in Google Scholar

Jiang, G., Keller, J., Bond, P.L., and Yuan, Z. (2016). Predicting concrete corrosion of sewers using artificial neural network. Water Res. 92: 52–60, https://doi.org/10.1016/j.watres.2016.01.029.Search in Google Scholar PubMed

Jönsson, M., Rendahl, B., and Annergren, I. (2010). The use of infrared thermography in the corrosion science area. Mater. Corros. 61: 961–965, https://doi.org/10.1002/maco.200905525.Search in Google Scholar

Jordan, M.I. and Mitchell, T.M. (2015). Machine learning: trends, perspectives, and prospects. Science 349: 255–260, https://doi.org/10.1126/science.aaa8415.Search in Google Scholar PubMed

Kamrunnahar, M. and Urquidi-Macdonald, M. (2010). Prediction of corrosion behavior using neural network as a data mining tool. Corros. Sci. 52: 669–677, https://doi.org/10.1016/j.corsci.2009.10.024.Search in Google Scholar

Klyuev, A.L., Davydov, A.D., and Grafov, B.M. (2021). Relationship between the structure function of random time series and the discrete chebyshev spectrum. Fluct. Noise Lett. 20: 2150029, https://doi.org/10.1142/S0219477521500292.Search in Google Scholar

Kulkarni, N.N., Raisi, K., Valente, N.A., Benoit, J., Yu, T., and Sabato, A. (2023). Deep learning augmented infrared thermography for unmanned aerial vehicles structural health monitoring of roadways. Autom. Constr. 148: 104784, https://doi.org/10.1016/j.autcon.2023.104784.Search in Google Scholar

Le, M., Pham, P.H., Trung, L.Q., Hoang, S.P., Le, D.M., Pham, Q.V., and Luong, V.S. (2024). Enhancing corrosion detection in pulsed eddy current testing systems through autoencoder-based unsupervised learning. NDT E Int. 146: 103175, https://doi.org/10.1016/j.ndteint.2024.103175.Search in Google Scholar