Abstract

AA7075 high-strength aluminum alloy, which has many applications in the aircraft, marine and automobile industries, happens to be susceptible to stress corrosion cracking (SCC) when exposed to corrosive environments, resulting in reduced service life of the components. Inappropriate fabrication processes may augment this behavior. The fabrication of AA7075 components using conventional fusion welding processes may produce defects that include hot cracking and porosity. Friction stir welding (FSW) is a solid-state joining process that can avoid these problems and being widely used for components made of aluminum alloys. Because the joining occurs at a temperature that is lower than the melting point of the material, solidification cracking defects can be eliminated. This study investigates the SCC behavior of FSW AA7075-T651 joints. Horizontal-type SCC test was conducted on circumferential-notched tensile (CNT) specimens exposed to 3.5 wt. % NaCl solutions under various axial stress conditions. The different regions of the fractured specimens, such as the machined notch, SCC region and region of ultimate mechanical failure were analyzed by scanning electron microscopy (SEM) to establish the mechanism of SCC. The threshold stress of parent metal (PM) and stir zone (SZ) of the FSW joint were found to be 242 and 175 MPa, respectively.

1 Introduction

High-strength aluminum alloys are generally used in aerospace components, automotive vehicle sprockets, defense and naval applications owing to their high specific strength, easy machinability, and good formability, high strength-to-weight ratio and corrosion resistivity (Rajakumar et al. 2012). AA7075-T651 aluminum alloy (Al–Zn–Cu–Mg), a useful low temperature alloy, has superior corrosion resistance due to the adherent oxide film on its surface (James et al. 2003; Singh et al. 2011). Friction stir welding (FSW) is an ideal process for joining 7075 series aluminum alloys as, unlike conventional fusion welding processes, it is less susceptible to causing porosity, hot cracking and distortion of the weldments. It was developed as a solid-state joining method with significant application in various manufacturing industries and has resulted in welded joints being used in defense and automobiles applications (Çam et al. 2017; Rhodes et al. 1997).

FSW joints normally comprise four different regions: unaffected parent metal (PM), heat-affected zone (HAZ), thermomechanically affected zone (TMAZ) and stir zone (SZ). The features and extent of these regions depend on the flow behavior of the deformed material under the action of nonconsumable tool rotation. The weld nugget microstructure composes of equiaxed grains that are significantly finer than the PM. The frictional heat developed during FSW, softens the material around the tool. In addition, the tool shoulder generates additional heat which plasticizes the material. The rotating tool transfers the softened material around the tool pin. Thus, the SZ experience high plastic deformation and recrystallize. Appreciable changes in the SZ microstructure and softening of HAZ are evident, resulting in the variation of the hardness and corrosion resistance of AA 7075 alloys. The effect of process variables on the corrosion behavior of FSW joints has been studied extensively. It is reported that the physical variables that include degree of agitation, temperature, applied load and the presence of metal ion impurities have an effect on the corrosion resistivity of the aluminum alloys (Fu et al. 2004; Shah et al. 2018; Srinivasa Rao et al. 2015). The aforementioned variables determine the SZ microstructure and control the localized corrosion attack. The different zones that arise from the FSW process are characterized by the differences in their grain orientation, grain size and morphology owing to the transformations in the hardening and precipitation. In general, each zone that comprises the FSW joint is characterized by a distinct corrosion current potential value, which gives rise to microgalvanic coupling phenomena (Lumsden et al. 1999).

AA7075-T651 alloys are susceptible to stress corrosion cracking (SCC) in the aggressive chloride environments as the soluble alloying elements such as zinc, magnesium, copper and their precipitates segregate along the grain boundaries. These fine precipitates at the grain boundaries render the matrix to be anodic. The subsequent anodic dissolution of precipitates may cause SCC, which has led to premature service failures, especially in defense applications, due to the combined effect of corrosive working environments and a net tensile stress state (Chen et al. 2013). Two basic SCC mechanisms have been proposed for Al–Zn–Mg alloys: anodic dissolution and hydrogen embrittlement. Hydrogen-induced cracking is the predominant SCC mechanism on the conditions that the area fraction of the grain boundary precipitates is comparatively low and anodic dissolution dominates the SCC behavior. Moreover, the microstructure as well as electrochemical potential also influences the SCC susceptibility of the FSW joints (Bobby Kannan et al. 2011; Padekar et al. 2013; Song et al. 2004).

In the SCC process, axial stress generated along the surface discontinuities initiates a crack. The initiated crack is reliant on the stress intensity and interaction of mechanical stress with corrosive environment propagates the crack tip in three different stages viz. stage I, stage II and stage III. With respect to stress intensity, Stage I propagation is exponential while stage II is influenced by mode of loading, electrochemical potential, composition of corrosive environment etc. In Stage III, the stress intensifies further to mechanically fracture the material (Gruhl 1984; Holroyd and Scamans 2013; Li et al. 2008; Raja and Shoji 2011; Speidel and Hyatt 1972; Yue et al. 2005).

The crack initiation and propagation are time consuming and hence SCC, in general, is referred as a delayed failure process. SCC resistance can be improved by coarsening the grain to inhibit the crack initiation and propagation in intergranular SCC. Furthermore, increasing the copper content in grain boundary precipitates (GBPs) contributes much to the improvement of SCC resistance by decreasing electrochemical activity and increasing the resistance to crack initiation; this effect however, acts in the reverse for zinc (Deng et al. 2015; Meng et al. 2016; Osaki et al. 2003). From the extant literature, it can be concluded that most studies on the corrosion behavior of aluminum alloys have hitherto dealt with corrosion in general with some focus on immersion, and pitting corrosion. Very few investigations have been carried out on the SCC behavior of FSW aluminum alloy joints in marine environments. In this context, the present study aims to determine the threshold stress and corrosion morphology of AA7075-T651 aluminum alloy FSW joints by suitable experiments.

2 Materials and methods

A 10-mm-thick rolled AA7075-T651 alloy plate having a chemical composition of (wt. %), Zn 5.21%, Mg 2.10%, Cu 1.21%, Si 0.58%, Fe 0.35%, Mn 0.12% and balance of aluminum was used in this investigation. The alloy was received in T651 condition (solution heat-treated, stress relieved and artificially aged), and butt-welded plates of dimensions 300 × 100 × 10 mm were fabricated using the FSW machine by joining two plates of size 150 × 50 × 10 mm. The welding was perpendicular to the rolling direction of plate and defect-free welds were produced by using optimal welding parameters. The process parameters used are tabulated in Table 1. The tensile properties of the AA7075-T651 and the newly made FSW joint were evaluated using cross weld samples as per the ASTM E8 standard. The determined tensile properties of the FSW joint and PM are presented in Table 2.

FSW parameters used to fabricate the joints.

| Parameters | Optimized values |

|---|---|

| Tool rotational speed (rpm) | 750 |

| Welding speed (mm/min) | 30 |

| Axial force (kN) | 12 |

| Shoulder diameter (mm) | 30 |

| Pin diameter (mm) | 9–10 |

| Pin length (mm) | 9.5 |

| Pin profile | Taper threaded |

Mechanical properties of parent metal (PM) and stir zone (SZ).

| Material | 0.2% offset yield strength (MPa) | Tensile strength (MPa) | Elongation (%) | Joint efficiency (%) | Notch strength ratio (NSR) |

|---|---|---|---|---|---|

| PM | 485 | 562 | 11 | – | 1.067 |

| FSW joint – SZ | 350 | 389 | 9 | 70 | 1.053 |

-

FSW, friction stir welding.

SCC testing was carried out using a circumferential notch tensile (CNT) specimen, as shown in Figure 1. The CNT specimen was machined with a 60° notch of depth 0.5 mm. A horizontal-type constant load SCC setup, coupled with the calibrated 20 kN load cell, was used for testing CNT specimen (see Figure 2). The specimen was held in Horizontal orientation (L-t). In order to stimulate a typical marine operational environment, the SCC test was conducted in a 3.5 wt. % NaCl solution at various applied stress conditions starting from 100% of the yield strength (YS) of the PM and FSW joint. The stress decrement was as 100, 80, 60, and 50% of YS and was applied axially to the CNT specimen. In this test, three test specimens were used for each loading condition. The tensile load was applied using a compressed helical spring. The load value initially set at the start of the experiment is maintained throughout the experiment by the set-up. The applied load was checked every 12 h with the initial loading condition, and the loading clevis was fabricated with water proof gaskets on each side to avoid the galvanic coupling of the specimen with the clevis material. The PM and the FSW joint CNT specimen were subjected to corrosion environment with the 3.5 wt. % NaCl solution dripping at a rate of 2 ml per minute. The drip solution was replaced every week throughout the test period. SCC test was conducted as per the stipulations of the ASTM G 139 – 05 standards (ASTM 2015). The specimens for the metallographic observation were polished successively using 80, 200, 600, 1000, 1500 and 2500 grit emery sheet, followed by disc polishing in alumina slurry. The final polishing was carried out in a solution of diamond paste after which the specimen was etched using Keller’s reagent to reveal the microstructure. The microstructure was examined using an optical microscope incorporated with an image analyzer. The specimen was exposed in 2 wt. % oxalic acid and examined with the help of a scanning electron microscope (SEM) for the fractographic analysis of the localized corrosion morphology.

(a) SCC specimen dimension, (b) photograph of SCC specimen.

Horizontal-type SCC testing machine.

3 Results and discussion

3.1 Microstructure analysis

Optical micrographs shown in Figure 3a,b reveal the cross sectional features of both the PM and the SZ. The microstructure of the PM, shown in Figure 3a, is characterized by elongated grains as well as a large number of subgrains, extending along the rolling direction. During the FSW process, the stir zone undergoes significant stirring action as well as frictional heating, causing temperatures as high as 530 °C (Lumsden et al. 2003; Sivaraj et al. 2014). Therefore, the coarse grains in this zone undergo significant breakage and partial recrystallization occurs, leading to the formation of finer, equiaxed grains (see Figure 3b), which are usually characterized by high-angle grain boundaries.

Optical micrographs

(a) PM, (b) SZ.

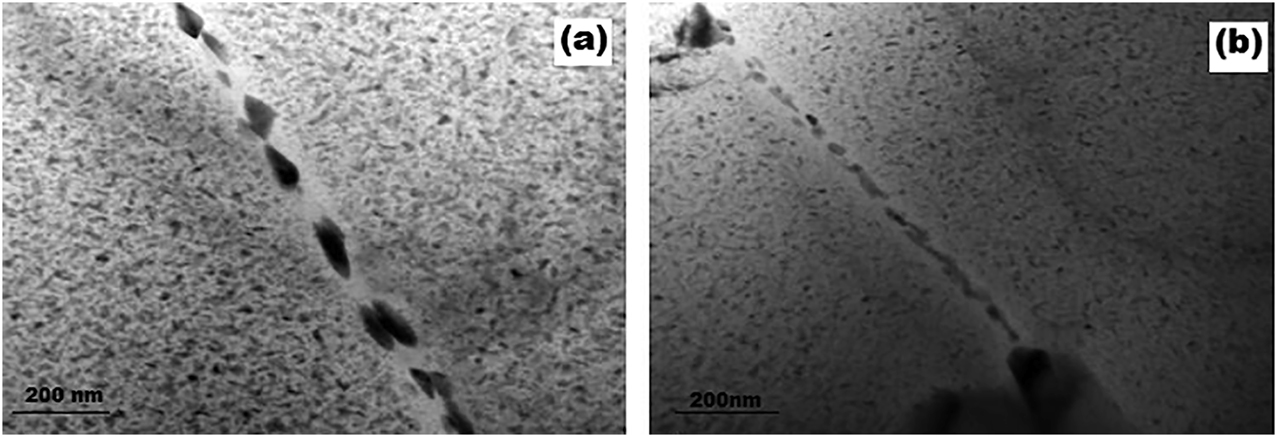

Figure 4 shows the transmission electron microscopy (TEM) images of the PM and SZ, elucidating their microstructural characteristics. The grain boundary precipitates in the PM (see Figure 4a) are discontinuous and relatively coarse in structure while in the SZ, the boundaries become a largely continuous network of finer grain boundary precipitates (Figure 4b). The X-ray diffraction (XRD) pattern of the as-received PM is shown in Figure 5a. The XRD pattern was analyzed based on the JCPDS database and six diffraction peaks were identified at different 2θ angles. Based on δ-spacing, in the PM, the highest intensity peak was associated with aluminum, while there were three peaks of lower intensity associated with the presence of MgZn2GB, Al7Cu2Fe and Mg3Cr2Al18 constituent phases. The XRD pattern of the SZ contain four peaks with the highest intensity being associated with aluminum, and two low-intensity peaks consistent with the presence of MgZn2GB and Al7Cu2Fe phases, formed at 32°, 38°, 43°, 45°, 65° and 75°, respectively. The XRD pattern for the SZ of the FSW joint is shown in Figure 5b.

TEM micrographs

(a) PM, (b) SZ.

XRD pattern

(a) PM, (b) SZ.

3.2 Mechanical behavior

The notch tensile properties of the PM and FSW joint are summarized in Table 2. From the obtained notch strength ratio (NSR), it can be confirmed that the PM as well as FSW joint underwent ductile failure (NSR > 1.0). The joint efficiency, based on ultimate notch tensile strength was 70% and 45° shear mode failure occurs at the TMAZ of the advancing side (AS). This may be attributed to the lack of fine grains and the presence of wide precipitate-free zones in the TMAZ region, which could be responsible for the failure of the material. This kind of failure was observed to be a common feature in FSW joints of aluminum alloys (Colligan et al. 2008; Rajakumar et al. 2011).

3.3 SCC behavior

Figure 6 shows the relationship between the applied stress and time to failure of the PM and SZ of the FSW joint. It was observed that the survival of specimen is directly proportional to the applied stress. PM specimen was initially loaded with an axial stress of 242 MPa and the specimen sustained for 900 h of loading without failure. Hence, the test was terminated at 1000 h, and the load measured at this point is considered to be the threshold stress of PM. Similarly, the FSW test specimen continued for 900 h at an axial stress level of 175 MPa.

Applied axial stress versus time to failure.

The corrosion elongation graphs provide insights into the SCC mechanisms prevalent in the PM and FSW joint. The “corrosion elongation curves” obtained at 291 MPa (0.6 × YS PM) and 210 MPa (0.6 × YS FSW joint) tensile stress in a 3.5 wt. % NaCl solution at 29° temperature are shown in Figure 7. Corrosion elongation parameters such as iss (steady state), tss (time to transition) and tf (time to final failure) were derived from these curves. The slope of the curve in the secondary region, before the tss to tertiary region, represents the rate of iss. During the iss, the material undergoes a corrosion reaction, for a relatively prolonged period, which is followed by the crack initiation at the tss state. In this stage, the material is severely affected by the applied stress which will eventually lead to the fracture. The corrosion elongation curves provide details regarding the SCC mechanisms involved in the PM and weld joint.

Elongation curve and its parameters.

3.4 SCC fracture surface

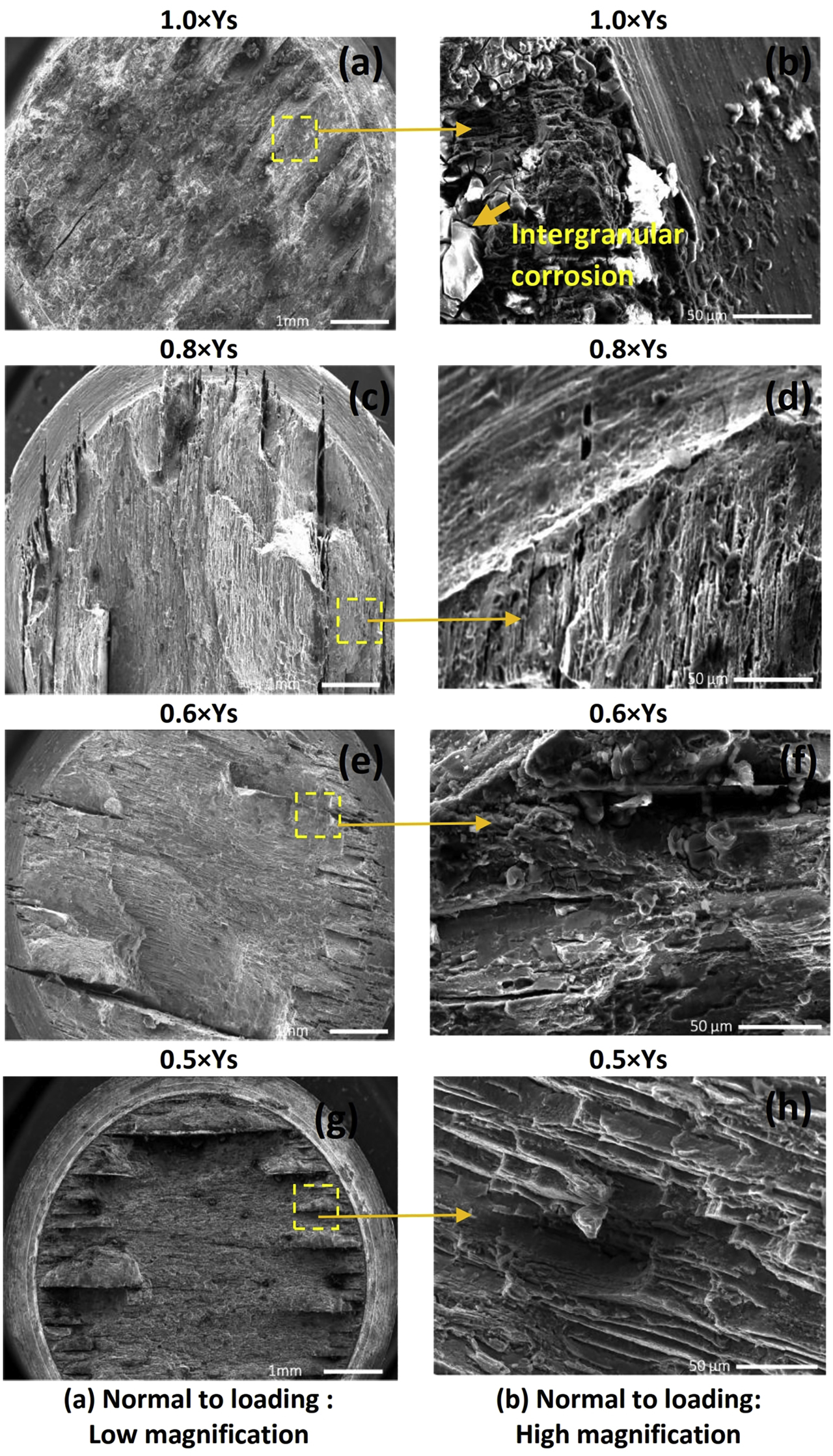

Figure 8a–h shows the fracture surface morphology of the PM and SZ of the FSW joint exposed to 3.5 wt. % NaCl solution. The fractured specimens were cleaned using a mixture of chromium trioxide and ortho-phosphoric acid, and subjected to SEM analysis. It is evident from the SEM fractographs that, SCC initiated from the pit surface and the crack propagates along the grain boundaries (GBs) of the MgZn2 precipitates of the PM and SZ. The overall fracture surface of the PM, shown in Figure 8a, reveals that the crack initiates from the notch surface due to the anodic dissolution of the aluminum matrix and second-phase particles. The observed morphologies of the SCC fracture specimen are highlighted in Figure 8a. Figure 8b shows the overall fracture surface of the SZ. The surface morphology indicates that the SZ is more susceptible to SCC than the PM. The interface regions of SCC are shown in Figure 8c,d. In both the cases, crack initiation occurs from the pits, and further pits form in the localized anodic dissolution mode under the action of the constant stress. Moreover, aluminum matrix is susceptible to the rich chloride ions in the marine environments. These chloride ions initiate the electrochemical pitting of the aluminum matrix and these pits, in their turn, initiate anodic dissolutions on the surface. Thus, the SCC of high strength aluminum alloys generally occur in the dissolved anodic mode owing to the effect of the second-phase grain boundary precipitates (Davis 1999; Navaser et al. 2017; Prabhuraj et al. 2017).

SEM fractographs of PM and SZ.

Figure 8e–f shows the SCC region of the PM and SZ. Examination of the fracture surface revealed an intergranular morphology of SCC. The FSW process produced finer grains at the SZ, which are very active in the simulated corrosive environment, causing severe SCC in the SZ than the PM. This phenomenon is confirmed by Figure 8f. Figure 8e–f shows the intergranular SCC morphology of the PM and SZ. The presence of Zn in the stir zone causes crack initiation. Rambabu et al. (2017) reported that decrease in overall corrosion resistance of 7xxx series aluminum alloys is evident with the addition of zinc and magnesium. Further, the cracks interconnect and join the main crack, propagated in the SCC specimen. The combined action of electrochemical reaction and applied tensile load accelerates the anodic dissolution and the crack size as well as crack growth rates are accelerated by MgZn2 precipitates at the grain boundary. Zhao et al. (2018) highlighted that intergranular corrosion is attributed by the formation of coarse, compositionally variant precipitates and precipitate free zone (PFZ) in and around the GB. Figure 8g–h shows the final failure region of the PM and SZ. The final fracture surface reveals dimpled characteristic morphology.

3.5 Effect of applied stress on SCC behavior

The fracture surface morphologies of SCC specimens tested at different stress levels, for PM as well as SZ are shown in Figures 9 and 10, respectively. The orientation of the crack surfaces is observed to be normal to the loading direction. Reduction in crack count is evident as the applied stress levels decrease, both for the PM (see Figure 9b) and SZ (see Figure 10b). The fracture surface of the PM and SZ at low magnification (see Figures 9a and 10a) indicates brittle failure. The morphologies demonstrate that the SZ is more susceptible to SCC than the PM, due to the abundant crack initiation sites in the SZ. The FSW process generates fine grain microstructure with continuous and discontinuous grain boundary precipitates (see Figure 4b), whose enhanced activity in the 3.5 wt. % NaCl solution causes severe SCC in the SZ. It is concluded that pits are usually initiated between the precipitates and the aluminum matrix, and thus, the number of pits is proportionate to the number of available precipitates in the matrix.

Fracture surface morphology of PM.

Fracture surface morphology of SZ.

Figures 9b and 10b confirm the intergranular mode of crack propagation for both PM and SZ of FSW joint at all stress levels, with decohesion of grains occurring at the GB. Recent studies report two predominant SCC mechanisms, anodic dissolution and hydrogen embrittlement, govern cracking under load in the interface and grain boundaries (Najjar D et al. 1997; Sun et al. 2013). Anodic dissolution leads to the formation of a slip step that may influence the continuous crack growth in matrix as the contact surfaces are highly active in corrosive NaCl environment. Hydrogen diffuses and segregates the grain boundaries to induce cracks. The key factor for SCC susceptibility is the continuous dispersal of grain boundary precipitates, which leads to corrosion crack initiation as it supplies potential difference between GBPs and the matrix element (Dugdale et al. 2013; Guohong et al. 2010).

4 Conclusion

The following conclusions are derived from this investigation:

The threshold stress of the PM and SZ of FSW joint are found to be 242 and 175 MPa, respectively.

The SCC is intergranular in nature under all applied tensile stress conditions, and the cracking mechanism is found to be localized anodic dissolution mode. The orientation of the crack surfaces is normal to the loading direction and, the number of cracks decreases with the decrease in applied stress.

FSW process resulted in finer grains at SZ, which acts as crack initiation sites in the corrosive environment. Hence, SZs are vulnerable to SCC than PM.

Funding source: Department of Science and Technology (DST), SERB Division, Government of India

Award Identifier / Grant number: SB/FTP/ETA-281/2012 (SR)

-

Author contributions: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: The authors are grateful to the Department of Science and Technology (DST), SERB Division, Government of India, New Delhi, for the financial support provided under the Fast Track Young Scientist Scheme through a R&D Project No. SB/FTP/ETA-281/2012 (SR).

-

Conflicts of interest: The authors declare no conflicts of interest regarding this article.

References

ASTM. (2015). Standard test method for determining stress-corrosion cracking resistance of heat-treatable aluminum alloy products using breaking load method. ASTM International, West Conshohocken, PA.Search in Google Scholar

Bobby Kannan, M., Bala Srinivasan, P., and Raja, V.S. (2011). Stress corrosion cracking (SCC) of aluminium alloys. In: Stress corrosion cracking: theory and practice. Woodhead Publishing Series in Metals and Surface Engineering, pp. 307–340. https://doi.org/10.1533/9780857093769.3.307.Search in Google Scholar

Çam, G. and İpekoğlu, G. (2017). Recent developments in joining of aluminum alloys. Int. J. Adv. Manuf. Technol. 91: 1851–1866. https://doi.org/10.1007/s00170-016-9861-0.Search in Google Scholar

Chen, S., Chen, K., Dong, P., Ye, S., and Huang, L. (2013). Effect of recrystallization and heat treatment on strength and SCC of an Al–Zn–Mg–Cu alloy. J. Alloys Compd. 581: 705–709. https://doi.org/10.1016/j.jallcom.2013.07.177.Search in Google Scholar

Colligan, K.J. and Mishra, R.S. (2008). A conceptual model for the process variables related to heat generation in friction stir welding of aluminum. Scripta Mater. 58: 327–331. https://doi.org/10.1016/j.scriptamat.2007.10.015.Search in Google Scholar

Davis, J.R. (Ed.) (1999). Corrosion of aluminum and aluminum alloys. ASM International, Materials Park, OH.10.31399/asm.tb.caaa.9781627082990Search in Google Scholar

Deng, Y., Peng, B., Xu, G., Pan, Q., Ye, R., Wang, Y., Lu, L., and Yin, Z. (2015). Stress corrosion cracking of a high-strength friction-stir-welded joint of an Al–Zn–Mg–Zr alloy containing 0.25 wt. % Sc. Corrosion Sci. 100: 57–72. https://doi.org/10.1016/j.corsci.2015.06.031.Search in Google Scholar

Dugdale, H., Armstrong, D.E.J., Tarleton, E., Roberts, S.G., and Lozano-Perez, S. (2013). How oxidized grain boundaries fail. Acta Mater. 61: 4707–4713. https://doi.org/10.1016/j.actamat.2013.05.012.Search in Google Scholar

Fu, Z.-H., He, D.-Q., and Wang, H. (2004). Friction stir welding of aluminum alloys. J. Wuhan Univ. Technol. 19: 61–64. https://doi.org/10.1007/BF02838366.Search in Google Scholar

Gruhl, W. (1984). Stress corrosion cracking of high strength aluminum alloys. Z. Metallkd. 75: 819–826.10.1515/ijmr-1984-751101Search in Google Scholar

Guohong, L., Ruidong, F.U., Chunlin, D., Miao, K., and Ju, H. (2010). Corrosion behaviors of friction stir welded joint of 7075 aluminum alloys under natural salt spray. J. Chin. Soc. Corrosion Protect 30: 236–240.Search in Google Scholar

Holroyd, N.H. and Scamans, G.M. (2013). Stress corrosion cracking in Al–Zn–Mg–Cu aluminium alloys in saline environments. Metall. Mater. Trans. 44: 1230–1253. https://doi.org/10.1007/s11661-012-1528-3.Search in Google Scholar

James, C., Williams, E., and Starke, A.Jr. (2003). Progress in structural materials for aerospace systems. Acta Mater. 51: 5775–5779. https://doi.org/10.1016/j.actamat.2003.08.023.Search in Google Scholar

Li, J.F., Peng, Z.W., Li, C.X., Jia, Z.Q., Chen, W.J., and Zheng, Z.Q. (2008). Mechanical properties, corrosion behaviors and microstructures of 7075 aluminium alloy with various aging treatments. Trans. Nonferrous Metals Soc. China 18: 755–762. https://doi.org/10.1016/s1003-6326(08)60130-2.Search in Google Scholar

Lumsden, J.B., Mahoney, M.W., Pollock, G., and Rhodes, C.G. (1999). Intergranular corrosion following friction stir welding of aluminum alloy 7075-T651. Corrosion 55: 1127–1135. https://doi.org/10.5006/1.3283950.Search in Google Scholar

Lumsden, J.B., Mahoney, M.W., Rhodes, C.G., and Pollock, G.A. (2003). Corrosion behavior of friction-stir-welded AA7050-T7651. Corrosion 59: 212–219. https://doi.org/10.5006/1.3277553.Search in Google Scholar

Meng, C., Zhang, D., Zhuang, L., and Zhang, J. (2016). Correlations between stress corrosion cracking, grain boundary precipitates and Zn content of Al–Mg–Zn alloys. J. Alloys Compd. 655: 178–187. https://doi.org/10.1016/j.jallcom.2015.09.159.Search in Google Scholar

Najjar, D., Magnin, T., and Warner, T.J. (1997). Influence of critical surface defects and localized competition between anodic dissolution and hydrogen effects during stress corrosion cracking of 7050 AA. Mater. Sci. Eng. A 238: 293–302. https://doi.org/10.1016/s0921-5093(97)00369-9.Search in Google Scholar

Navaser, M. and Atapour, M. (2017). Effect of friction stir processing on pitting corrosion and intergranular attack of 7075 aluminum alloy. J. Mater. Sci. Technol. 33: 155–165. https://doi.org/10.1016/j.jmst.2016.07.008.Search in Google Scholar

Osaki, S., Kinoshita, K., and Naganuma, D. (2003). Intergranular corrosion and SCC properties of Al–Mg–Si alloy sheets. J. Jpn. Inst. Light Metals 53: 157–162. https://doi.org/10.2464/jilm.53.157.Search in Google Scholar

Padekar, B.S., Raja, V.S., Raman, R.K.S., and Lyon, P. (2013). Stress corrosion cracking behavior of magnesium alloys EV31A and AZ91E. Mater. Sci. Eng. A 583: 169–176. https://doi.org/10.1016/j.msea.2013.06.085.Search in Google Scholar

Prabhuraj, P., Rajakumar, S., Lakshminarayanan, A.K., and Balasubramanian, V. (2017). Evaluating stress corrosion cracking behaviour of high strength AA7075-T651 aluminium alloy. J. Mech. Behav. Mater. 26: 105–112. https://doi.org/10.1515/jmbm-2017-0019.Search in Google Scholar

Raja, V.S. and Shoji, T. (2011). Stress corrosion cracking: theory and practice. Woodhead Publishing, pp. 307–334.10.1533/9780857093769Search in Google Scholar

Rajakumar, S. and Balasubramanian, V. (2012). Establishing relationships between mechanical properties of aluminium alloys and optimised friction stir welding process parameters. Mater. Des. 3: 2878–2890.10.1016/j.matdes.2012.02.054Search in Google Scholar

Rajakumar, S., Muralidharan, C., and Balasubramanian, V. (2011). Predicting tensile strength, hardness and corrosion rate of friction stir welded AA6061-T6 aluminium alloy joints. Mater. Des. 32: 2878–2890. https://doi.org/10.1016/j.matdes.2010.12.025.Search in Google Scholar

Rambabu, P., Eswara Prasad, N., Kutumbarao, V.V., and Wanhill, R.J.H. (2017). Aluminium Alloys for aerospace applications, aerospace materials and material technologies. In: Prasad, N. and Wanhill, R. (Eds.), Aerospace materials and material technologies. Indian Institute of Metals Series, pp. 29–52. https://doi.org/10.1007/978-981-10-2134-3_2.Search in Google Scholar

Rhodes, C.G., Mahoney, M.W., Bingel, W.H., Spurling, R.A., and Bampton, C.C. (1997). Effects of friction stir welding on microstructure of 7075 aluminum. Scripta Mater. 36: 69–75. https://doi.org/10.1016/s1359-6462(96)00344-2.Search in Google Scholar

Shah, P.H. and Badheka, V. (2018). Effect of various welding parameters on corrosion behavior of friction-stir-welded AA 7075-T651 alloys. Metallogr. Microstruct. Anal. 7: 308–320. https://doi.org/10.1007/s13632-018-0440-7.Search in Google Scholar

Singh, R.K.R., Sharma, C., Dwivedi, D.K., Mehta, N.K., and Kumar, P. (2011). The microstructure and mechanical properties of friction stir welded Al–Zn–Mg alloy in as welded and heat treated conditions. Mater. Des. 32: 682–687. https://doi.org/10.1016/j.matdes.2010.08.001.Search in Google Scholar

Sivaraj, P., Kanagarajan, D., and Balasubramanian, V. (2014). Effect of post weld heat treatment on tensile properties and microstructure characteristics of friction stir welded armour grade AA7075-T651 aluminium alloy. Defence Technol. 10: 1–8. https://doi.org/10.1016/j.dt.2014.01.004.Search in Google Scholar

Song, R.G., Dietzel, W., Zhang, B.J., Liu, W.J., Tseng, M.K., and Atrens, A. (2004). Stress corrosion cracking and hydrogen embrittlement of an Al–Zn–Mg–Cu alloy. Acta Mater. 52: 4727–4743. https://doi.org/10.1016/j.actamat.2004.06.023.Search in Google Scholar

Speidel, M.O. and Hyatt, M.V. (1972). Stress-corrosion cracking of high-strength aluminum alloys [C]//advances in corrosion science and technology. Springer, New York and London, pp. 115–335.10.1007/978-1-4615-8255-7_3Search in Google Scholar

Srinivasa Rao, T., Madhusudhan Reddy, G., and Koteswara Rao, S.R. (2015). Microstructure and mechanical properties of friction stir welded AA7075–T651 aluminum alloy thick plates. Trans. Nonferrous Metals Soc. China 25: 1770–1778. https://doi.org/10.1016/s1003-6326(15)63782-7.Search in Google Scholar

Sun, X.Y., Zhang, B., Lin, H.Q., Zhou, Y., Sun, L., Wang, J.Q., Han, E.-H., and Ke, W. (2013). Correlations between stress corrosion cracking susceptibility and grain boundary microstructures for an Al–Zn–Mg alloy. Corrosion Sci. 77: 103–112. https://doi.org/10.1016/j.corsci.2013.07.032.Search in Google Scholar

Yue, T., Yan, L., Dong, C., and Chan, C. (2005). Stress corrosion cracking behaviour of laser treated aluminium alloy 7075 using a slow strain rate test. Mater. Sci. Technol. 21: 961–966. https://doi.org/10.1179/174328405x47573.Search in Google Scholar

Zhao, H., De Geuser, F., Kwiatkowski da Silva, A., Szczepaniak, A., Gault, B., Ponge, D., and Raabe, D. (2018). Segregation assisted grain boundary precipitation in a model Al–Zn–Mg–Cu alloy. Acta Mater. 156: 318–329. https://doi.org/10.1016/j.actamat.2018.07.003.Search in Google Scholar

© 2020 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Reviews

- Corrosion of rail tracks and their protection

- Electrogalvanization using new generation coatings with carbonaceous additives: progress and challenges

- Phytochemicals as steel corrosion inhibitor: an insight into mechanism

- Original articles

- Corrosion behavior of 15CrMo steel for water-wall tubes in thermal power plants in the presence of urea and its byproducts

- Stir zone stress corrosion cracking behavior of friction stir welded AA7075-T651 aluminum alloy joints

- Optimization of erosion wears of Al–Mg–Si–Cu–SiC composite produced by the PM method

- Annual reviewer acknowledgement

- Reviewer acknowledgement Corrosion Reviews volume 38 (2020)

Articles in the same Issue

- Frontmatter

- Reviews

- Corrosion of rail tracks and their protection

- Electrogalvanization using new generation coatings with carbonaceous additives: progress and challenges

- Phytochemicals as steel corrosion inhibitor: an insight into mechanism

- Original articles

- Corrosion behavior of 15CrMo steel for water-wall tubes in thermal power plants in the presence of urea and its byproducts

- Stir zone stress corrosion cracking behavior of friction stir welded AA7075-T651 aluminum alloy joints

- Optimization of erosion wears of Al–Mg–Si–Cu–SiC composite produced by the PM method

- Annual reviewer acknowledgement

- Reviewer acknowledgement Corrosion Reviews volume 38 (2020)