Abstract

Carbon fiber reinforced polymer (CFRP) is widely used in high-tech industries because of its interesting characteristics and properties. This material presents good strength and stiffness, relatively low density, high damping ability, good dimensional stability, and good corrosion resistance. However, the machinability of composite materials is complex because of the matrix/fiber interface, being a challenging machining material. The CFRP milling process is still necessary to meet dimensional tolerances, the manufacture of difficult-to-mold features like pockets or complexes advance surfaces, finish the edges of laminated composites, or drill holes for the assembly of the components. Besides, the demand for low-cost, reconfigurable manufacturing systems of the industry demonstrates that the application of industrial robots (IRs) in the CFRP milling process becomes an alternative for providing automation and flexibility. Therefore, the objective of this work is to evaluate the performance of the low payload IR KUKA KR60 HA in a milling experiment of CFRP, which indicates its potential application as an alternative to milling process. Furthermore, the influence of the cutting tool geometry as well as the cutting parameters in the machining behavior with IRs is evaluated.

1 Introduction

Carbon fiber reinforced polymer (CFRP) is widely used in high-performance applications, where high strength-to-weight ratio (specific strength) and stiffness constitute important requirements. CFRP has two main components: (i) high-strength carbon fibers and (ii) the flexible and tough matrix material [1]. This provides interesting characteristics and properties such as specific strength and stiffness, relatively low density, high damping ability, good dimensional stability, and good corrosion resistance. These qualifications call attention to large industrial areas such as automotive, aerospace, marine industries, and civil engineering, wind-turbines, sport equipment, and robotics [2,3]. Therefore, it possesses a high potential for the substitution of, for example, heavier aluminum and steel [4,5]. However, after the production of CFRP’s shape, the machining of these materials is still necessary to meet dimensional tolerances, the manufacture difficult-to-mold features like pockets or surfaces, finish the edges of laminated composites, or drill holes for reasons of assembly. Further, the cutting mechanism of CFRP greatly varies compared to conventional metallic material cutting mechanism, so that it becomes difficult in analyzing their machining performance [6,7,8]. The main challenges in machining of CFRPs arise from the anisotropy and inhomogeneity of the composite, which generates spalling, delamination, fuzzing, fiber pull-outs, matrix cracking, and thermal degradation [9,10]. The damages caused in the machining process of the CFRP may harm the surface and dimensional quality and can, therefore, cause the rejection of the workpiece [11,12,13]. Despite the research published over the past decades on the process of machining CFRP, this theme is still in the early stages of development.

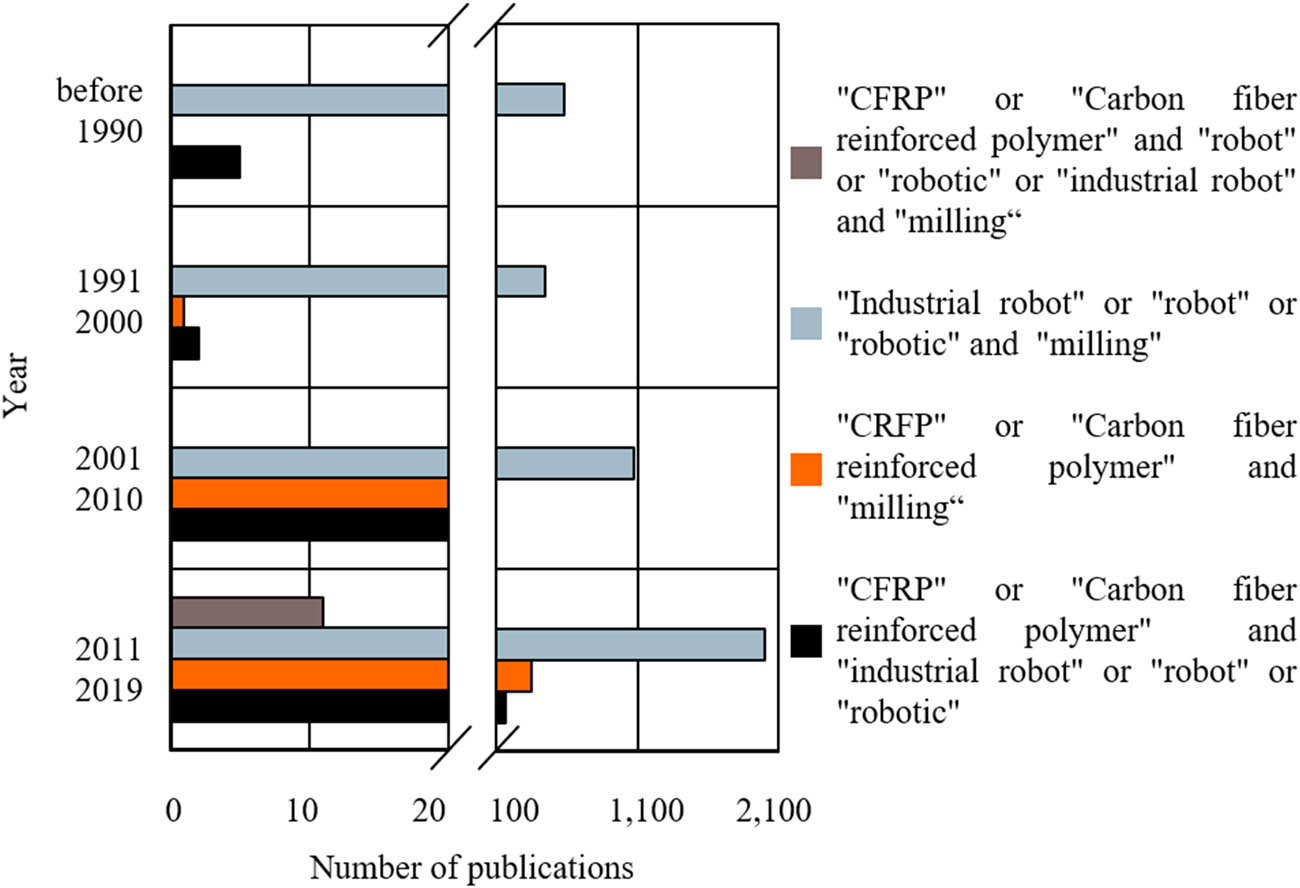

Because it is in early development, there are gaps on the topics of surface finish, reduced form tolerance and increased tool life, as well as increased automation and flexibility of the machining processes. The demand for low-cost, reconfigurable manufacturing systems of the industry demonstrates that the application of industrial robots (IRs) in the CFRP milling process becomes an alternative for providing automation and flexibility [12,14]. In the last 9 years, research focused on CFRP machining applying IRs has become of great academic and industrial interest (see Figure 1). According to Schneider et al., more and more IRs have been unidirectional and wove material, used for a machining operation, because of offering lower costs than conventional machine tools, an exceptional flexibility and a big working area [15]. In addition, the purchase cost of an IR is 30–50% lower when compared to machine tools [16].

Number of researches in machining, robot, and CFRP.

Only 2.0% of IRs is used for processes such as cutting, milling, or grinding [17]. Machining processes that apply IR are currently used for the machining of components characterized by low cutting forces (polishing, deburring, and deflashing) or low accuracy. To ensure the dimensional and surface quality, a combination of factors is required, from the cutting tool to the robotic configuration. It is therefore essential to understand the dynamics of the IR. Krzic et al. [18], Mejri et al. [19], Gonul et al. [14], and Bisu et al. [20] analyzed the dynamic and stability performance of the IR in the machining process. Slamani et al. [21,22] analyzed the application of an IR, with a load capacity of P < 500 kg, for CFRP machining. Zaghbani et al. [23,24] proposed a method based on the variation in spindle speed, which was introduced for machining operation and a new process stability criterion (CS) based on acceleration energy distribution and force signal was proposed for the analysis of an ABB IRB1600 IR.

According to Chen et al. [25], there is still a long way to go before robot machining systems are widely used in practical applications, and the use of existing IRs has hindered the development of robot machining in recent years. The development of new robotic structures will take a few more years and it has also not been confirmed whether the cost of the investment will be economically viable. The development of this technology is a requisite to meet the demands of the current industry [26,27,28]. Therefore, this work contributes to the scientific understanding in evaluating the performance of the low payload IR (KUKA KR60 HA) for a milling of CFRP, which indicates its potential application as an alternative to conventional milling processes performed with machine tools. Furthermore, the influence of the cutting tool geometry as well as the cutting parameters in the machining behavior with IRs is evaluated.

2 Materials and methods

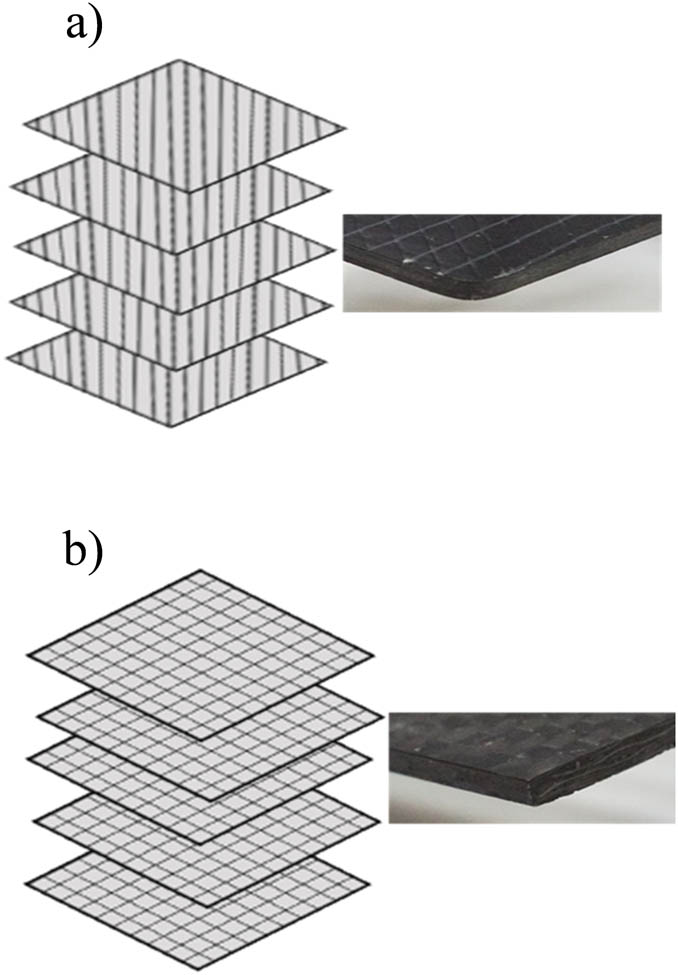

The study explored the functionality of the IR, the geometry of the cutting tools, and the cutting parameters that influence in CFRP machining conditions, in which fiber pull-outs, delamination, surface roughness Ra, and cutting force F were evaluated. Figure 2 shows the details of the unidirectional and woven fibers that were used for the slotting milling tests. The used workpiece material in both plates, unidirectional and wove, is a meshwork of carbon fibers in an epoxy resin. The carbon fibers of unidirectional material have a diameter of 7 μm, an alignment of 0°, and a proportion of ∼65%, with 11 inner layers in 4 mm thick (Figure 2a). The carbon fibers of wove material have a proportion of ∼33%, a diameter of 13 μm, and are woven with an alignment of 0°/90°, an epoxy matrix reinforced with 55% of carbon fiber (Figure 2b). Both materials are in the phase of industrial development.

Illustration of the types of CFRP layups: (a) unidirectional, all fiber area aligned uniformly; (b) woven, fibers within each layer are interlocked.

Some researchers have reported about the consequence of process parameters, such as high spindle speed/cutting speed and feed rate on the quality of the machined surface. Previous research showed that HSC application provides a better surface finish in terms of fiber pull-out. However, it is important to remark that high values of the cutting speed can cause delamination [12,29,30,31,32,33]. This motivated further investigations into the influence of these cutting parameters on the milling of different CFRP materials. Table 1 shows all the factors and levels of the experimental designs used for unidirectional material milling. In the case to milling of the woven composite applied the cutting speed v c = 602 m/min and v c = 904 m/min with feed rate v f = 2 m/min were applied, for all cutting tools. The use of a only one feed rate v f for the two cutting speed v c has been done to understand the influence of the vc on CFRP milling.

Experimental design of experiment

| Factor | Level | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| v c (mmin) | 301 | 602 | 904 |

| v f (mmin) | 1 | 2 | 4 |

| Tool | F0 | F1 | F2 |

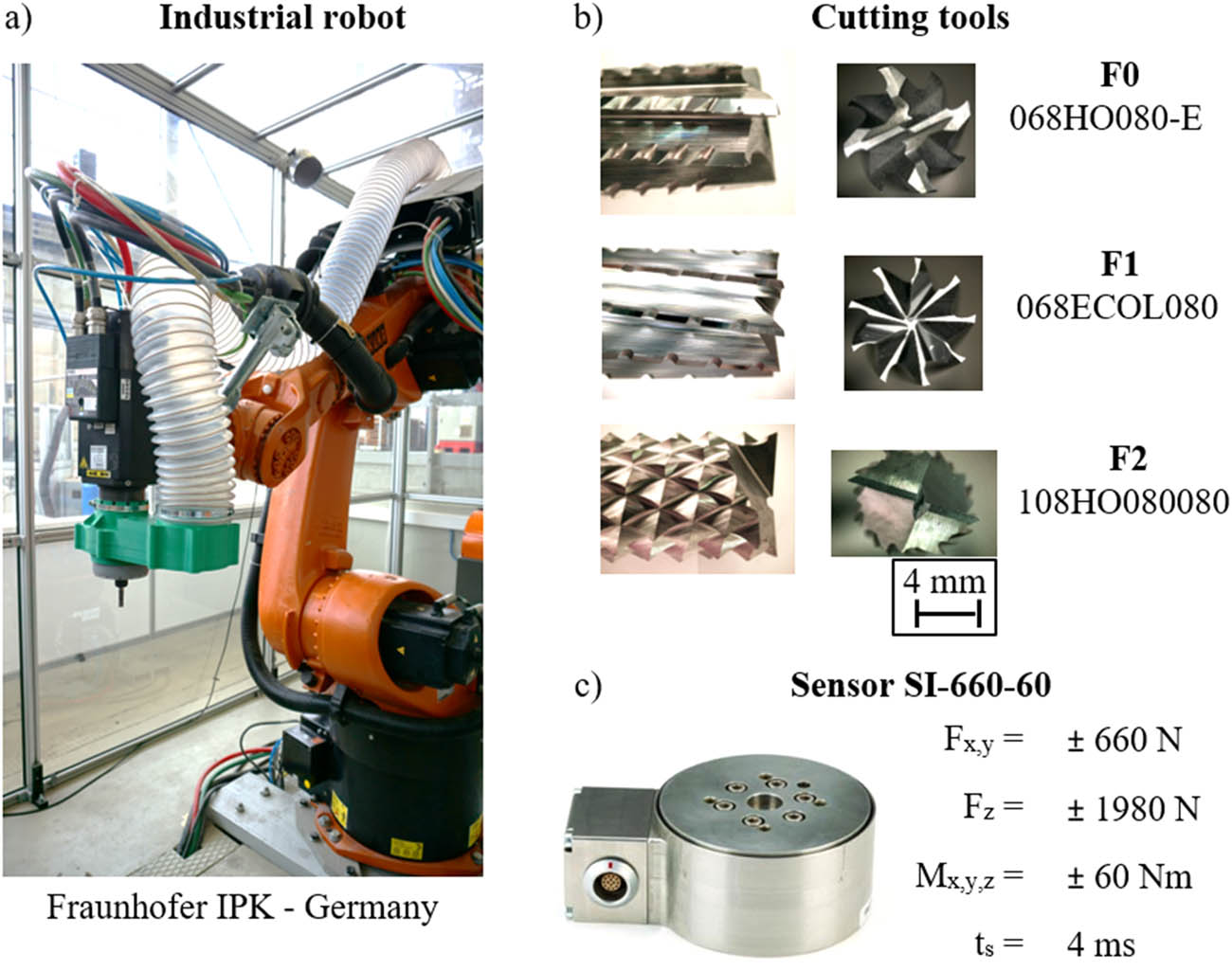

The slotting milling tests were carried out on a 6-axis IR, from the company KUKA AG, Augsburg, Germany, KR60 HA that manipulated a spindle ES350L 4P of 8 kW nominal power – HSD SPA delivering spindle speeds of n = 36,000 rpm, from the company HSD SPA, Gradara, Italy. A suction system was used to remove dust with an extraction nozzle placed locally in the spindle (Figure 3a). Three sets of tests were produced. The cutting tool F0 has a geometry with four cutting teeth and four secondary teeth, and 6° right flute. The cutting tool F1 has the geometry with nine teeth in right helix, with right cutting and optimized chip breaker division, and the cutting tool F2 has a geometry with two teeth end mill style, narrow-toothed with pyramidal edge, with grinding functionality to the matrix of the composite (Figure 3b). All tested cutting tools are from the company Hufschmied Zerspannungssysteme GmbH, Germany. The company generally suggests the use of diamond coated tools for CFRP machining. However, in this work it was chosen to use tools without coating to verify more quickly the influence of the geometry on the work result. All used tools are made of uncoated carbide with a cobalt content w Co = 6 M%, a hardness 1,620 HV 30, and an average grain size d WC = 1.3 μm. Cutting force F signals during the milling process were monitored by an SI-660-60 sensor from the company ATI Industrial Automation, Apex, USA (see Figure 3c). This sensor is installed between the IR flange (6 – axis) and the spindle.

Experimental setup: (a) IR setup; (b) cutting tools, and (c) cutting force sensor.

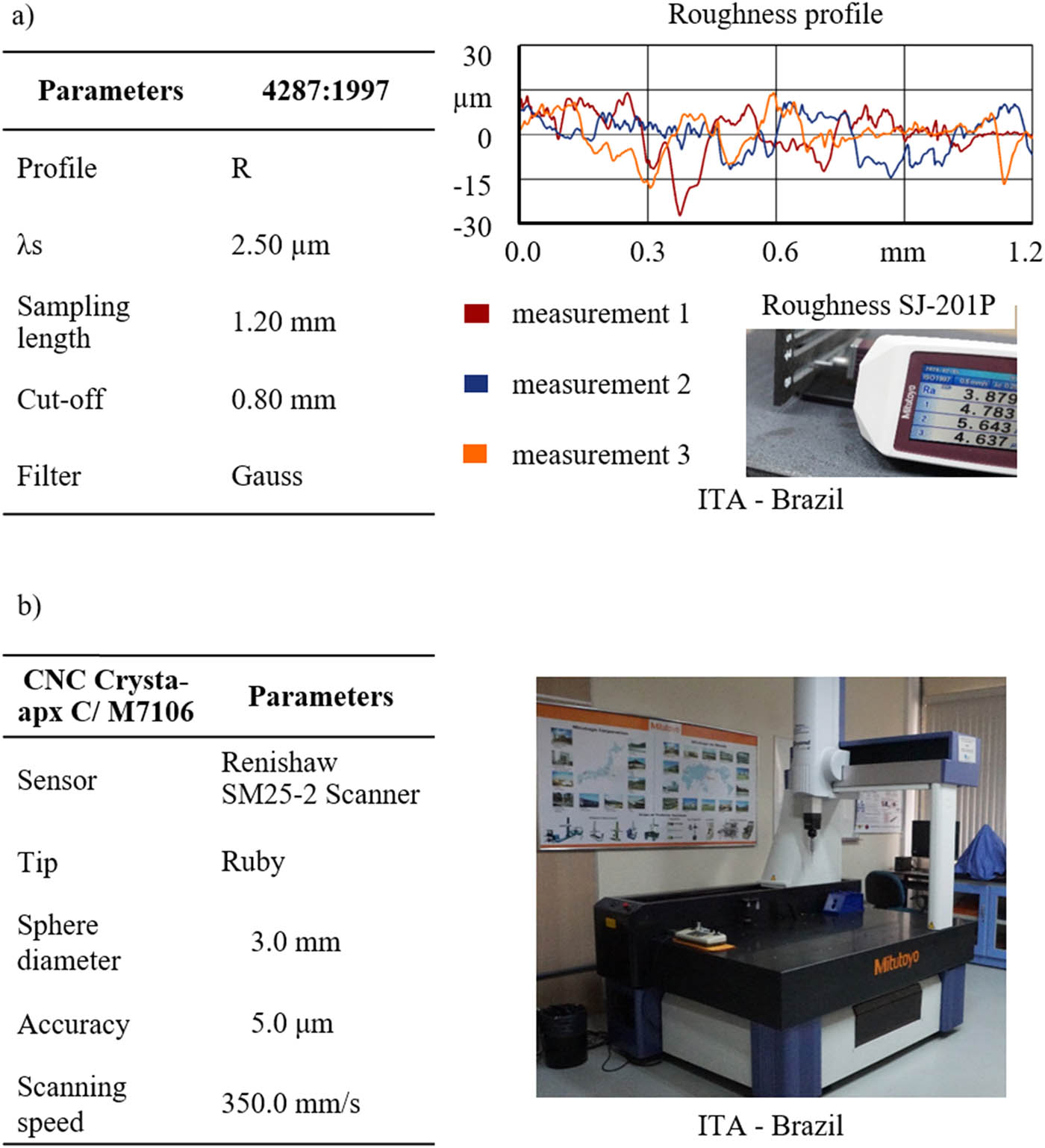

According to Gao et al. [34], the surface roughness Ra has a predominant role in determining the machining accuracy. The surface roughness Ra of CFRP machined depends on many factors, such as fiber orientation, cutting speed, feed rate, and depth of cut, for a given machine tool and workpiece setup. Thus, it is necessary to measure the roughness of the machined surface to evaluate both the machining process and the type of fiber orientation. The machined surface roughness Ra parameter used throughout this work is defined by ISO 4287:1997 [35]. The SJ-201P Portable Surface Roughness Tester, from the company MITUTOYO, Tokyo, Japan, was used for roughness measurements according to ISO 4287:1997 recommendation (see Figure 4a). The roughness was measured at three different positions on each sample. The average values were taken, evaluating the surface roughness Ra of the down milling and up milling, individually. The arithmetic average surface roughness Ra used in this work can be described in mathematical function as equation (1):

where H i is the height of roughness irregularities from profile and N is the number of measured points in sample length. Ra value can be calculated from the mean height [35].

Setup for evaluation of surface roughness Ra and dimensional quality: (a) Mitutoyo SJ-201P portable surface roughness tester and (b) Crysta-Apex C 7000 MPEE.

The changing industrial scenario related to Industry 4.0 is motivating researchers to develop more flexible, efficient, and smart processes. Machining CFRP by applying IRs is an alternative to what is currently used in the industry. However, on account of the need for increasingly high feed rates and low rigidity of IRs, it is fundamental to ensure the dimensional quality of the machined workpiece. Therefore, to measure the dimensional quality of machining tests by applying an IR, a coordinate measuring machine Crysta-Apex C 7000 MPEE, from the company MITUTOYO, Tokyo, Japan, was used (see Figure 4b). The evaluation of the pull-outs and delamination was measured from the photos taken by Dino-Lite digital microscope, from the company DINO-LITE, New Taipei City, Taiwan. All the combinations of cutting parameters in milling experiments were evaluated.

3 Results and discussion

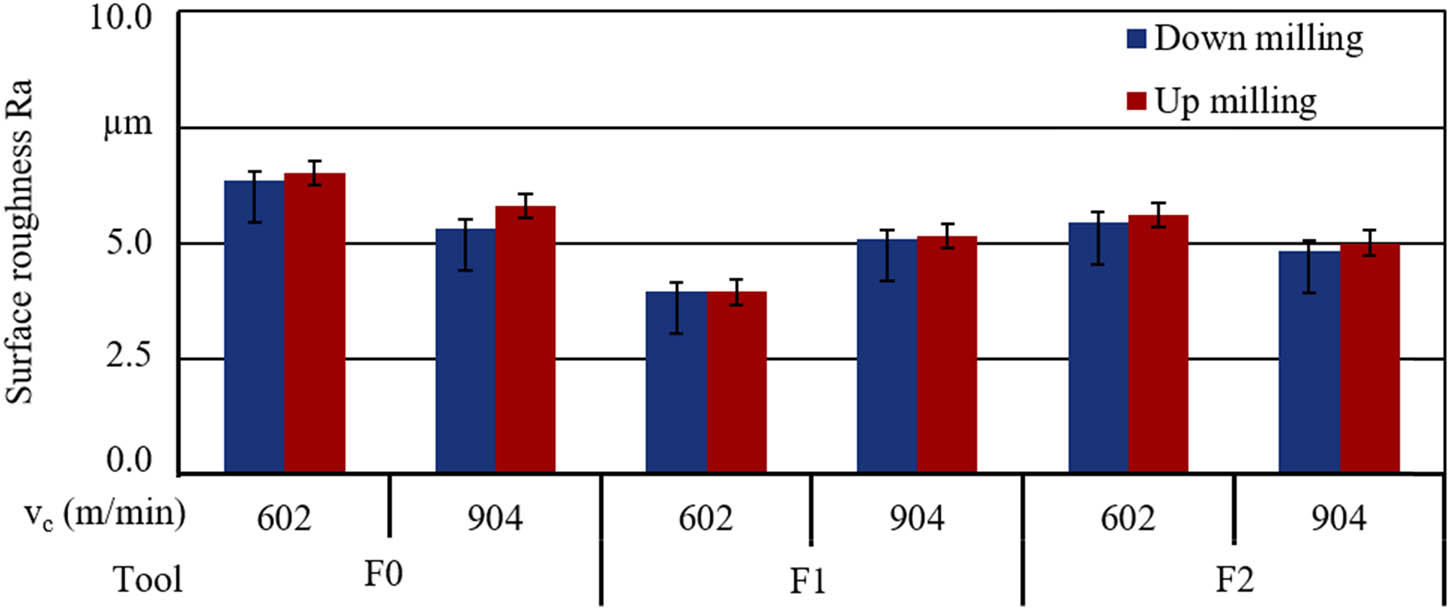

According to Kalla et al. [36], the machining quality of CFRP is described by the surface finish and surface integrity. The measurement results of average surface roughness Ra are shown in Figures 5 and 6. According to Choudhury and Hashmi [37], the surface roughness Ra on the workpiece tends to decrease as the cutting speed increases. Considering the evaluated cutting tools in the wove material milling process, the cutting tool F1 showed an increase in surface roughness Ra as the cutting speed increases in wove material (Figure 5). The geometry profile of the cutting tool F1 shows chip breakage divisions, and because the size of the chip breakage slots and the positioning of these slots are aligned, this generates nonuniform cutting regions. Even so, the geometry of the cutting tool F1 obtained the lower surface roughness results for the wove material. The cutting tool F0 has of geometry with four cutting teeth and four secondary teeth, both of serrated teeth. The cutting tool F0 obtained the highest surface roughness Ra values, between Ra = 6.52 µm and Ra = 5.32 µm. The serrated teeth profile provided the highest surface roughness Ra values. However, the increased cutting speed v c resulted in a decrease in surface roughness Ra. This was because of a lower feed per tooth f z, causing less roughness spacing on the surface of the material. The same roughness profile characteristic is found for cutting tool F2. The narrow-toothed with pyramidal edge provides cuts in the material plane by intercalated teeth (see Figure 5).

Roughness surface (Ra) results of wove material.

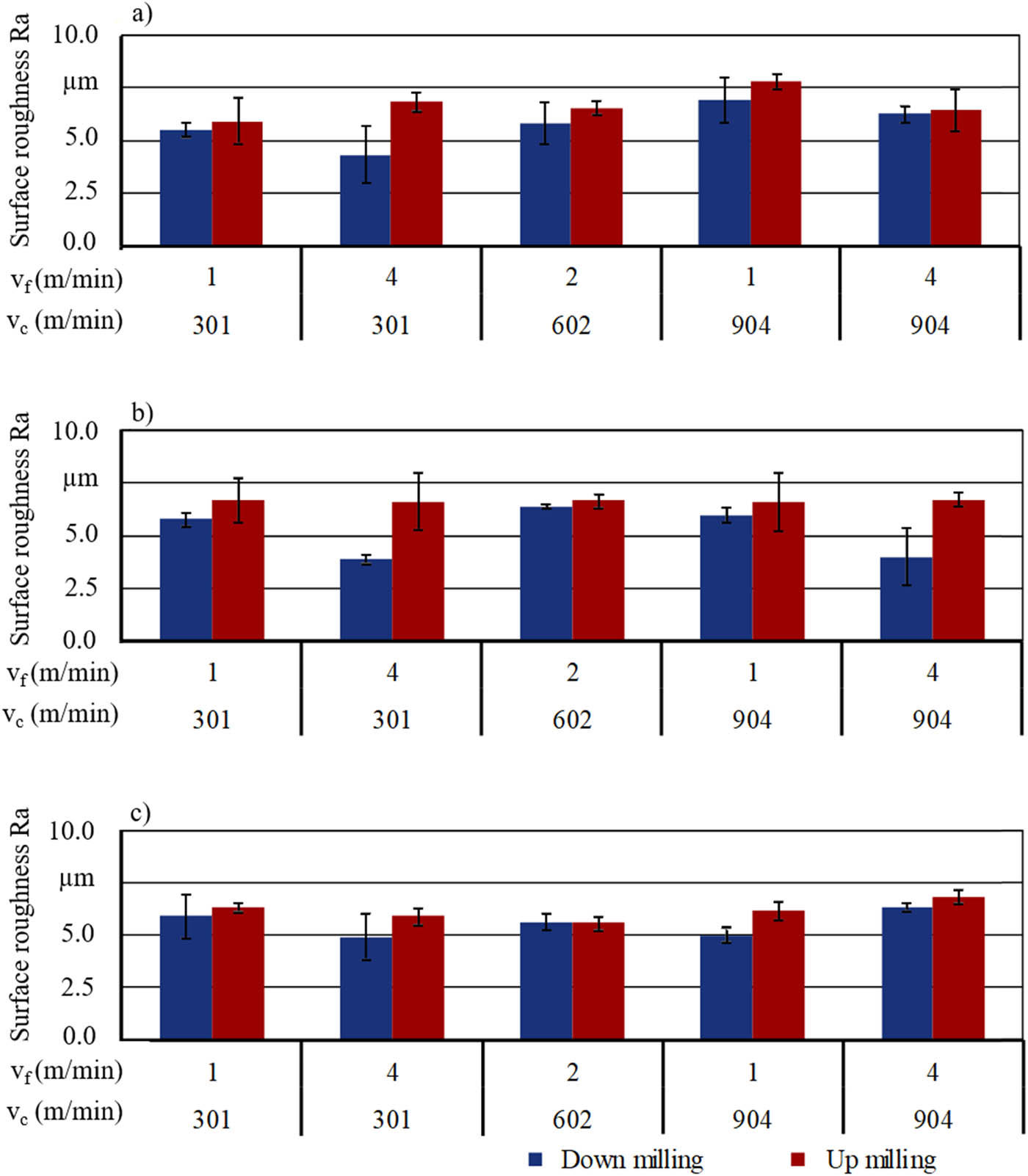

Roughness surface results of unidirectional material: (a) cutting tool F0, (b) cutting tool F1, and (c) cutting tool F2.

Regarding the surface roughness Ra of the unidirectional material, the cutting tools F0 and F1 also showed different behavior suggested by Choudhury and Hashmi [37]. In Figure 6, the cutting tools F0 and F1 in the down milling process showed a decrease in the surface roughness Ra when the feed rate v f is increased, at the same cutting speed v c. Besides, the cutting tool F0 when analyzing the increased cutting speed v c and constant feed rate v f provides an increase in surface roughness. The cutting tool F1 maintained the surface roughness Ra constant for increased cutting speed v c (Figure 6). The cutting tool F2 showed a uniform surface roughness Ra profile in all experiments, unidirectional, and wove material. This can be explained by its narrow-toothed cutting geometry with pyramidal edge (see Figures 5 and 6). Another factor to note is the down milling results in lower surface roughness Ra than up milling, regardless of the cutting tool used. Diverging what was proposed by Sheikh-Ahmad et al. [38] and Gara and Tsoumarev [39], that damage occurred always on the down-milling process. The cutting tool F0 had the poorer performance of surface roughness Ra = 7.83 µm to speed cutting v c = 904 m/min and feed rate v f = 1 m/min (Figure 6). This states that the machinability of composite materials, for example, CFRP, should be analyzed on a case-by-case basis. According to Azmi and Lin [40], the higher feed rate v f leads to an increase in strain rate on the composite, which generates fracture of the fiber resulting in poor surface roughness. The factors tested (cutting tool geometries, cutting parameters and up and down milling) showed no significant influence on the milled surface roughness. This is because of anisotropy and the inhomogeneity of the composite, and occasionally the surface roughness Ra results are non-standard.

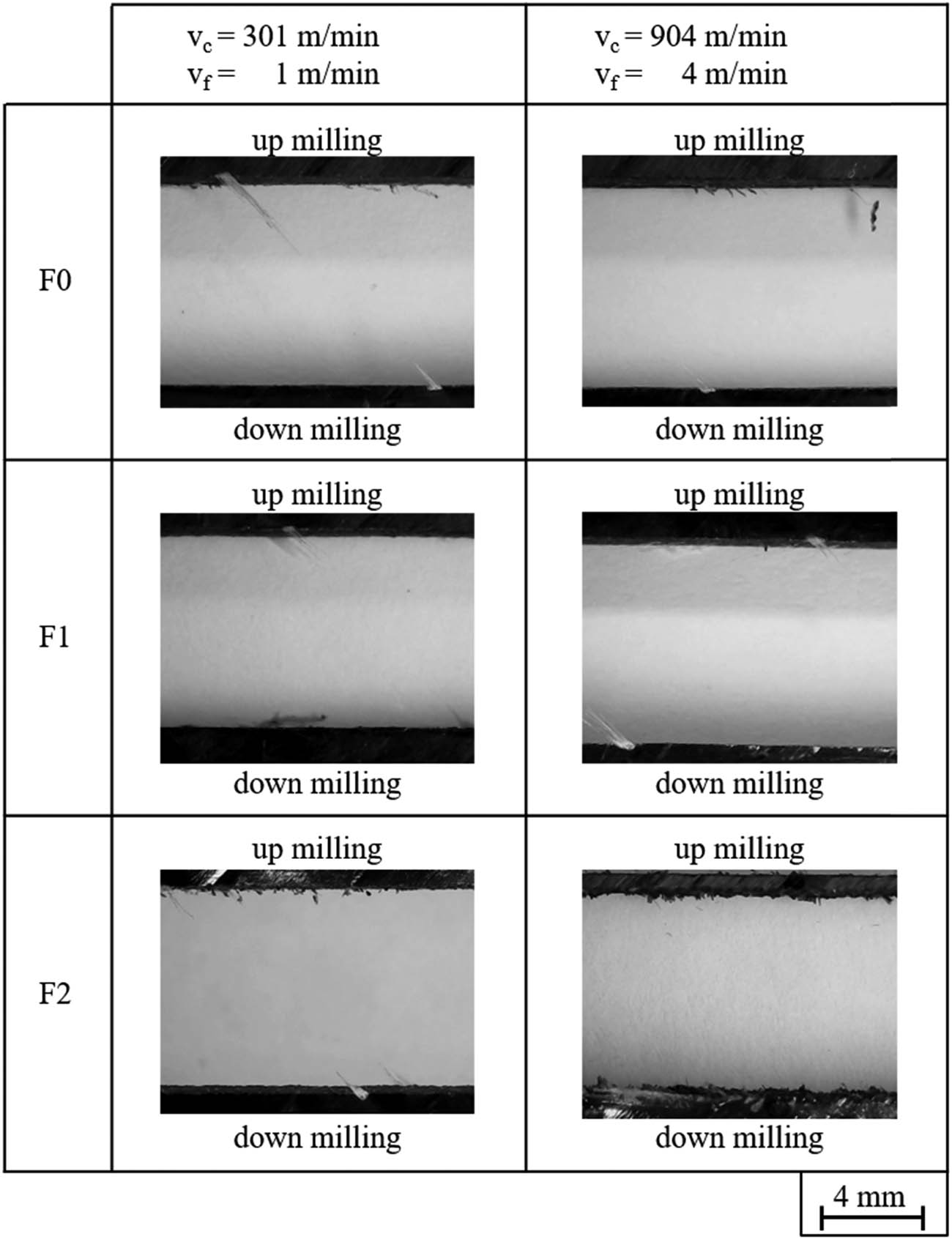

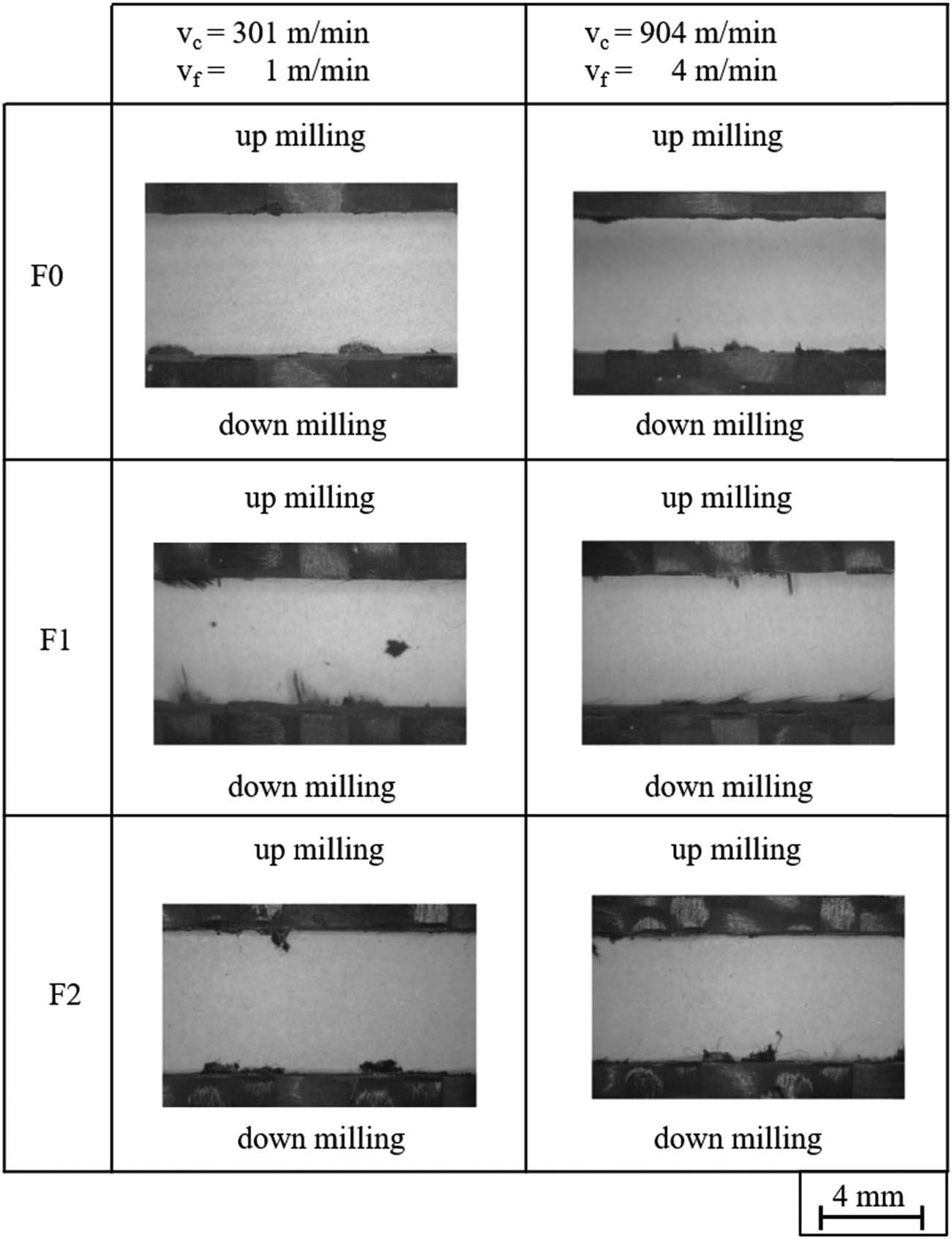

Milling quality analysis includes dimensional, surface, pull-outs, and delamination deviation. According to Jayaweera and Webb [41], the aero-structure components could be assembled within tol = 0.6 mm tolerance. To achieve the desired quality of the machined surface, it is necessary to understand the cutting mechanisms of material removal and the kinetics of machining processes influencing the performance of the cutting tools [42]. According to Bolar et al. [43], the surface quality is an important requirement for components used in the aerospace and automobile industries. The quality of the CFRP part machined is assessed according to the delamination and fiber protrusion, and this is particularly crucial to avoid rejection of parts. Currently, there is no standardized method for the CFRP quality control, which makes the analyses strongly conditioned to each end-user [12]. Figures 7 and 8 show qualitative results of the machined surface of unidirectional material and wove material, respectively. The cutting tool F0 in down milling operation showed less damage to the surface when compared to up milling operation (Figure 7). Nevertheless, in the experiment with wove material the cutting tool F0 presented better finishing surface for up milling operation (Figure 8). In general, the geometry of the cutting tool F1 showed the best qualitative results, cutting condition v c = 904 m/min and v f = 4 m/min, for both materials (Figures 7 and 8). The cutting tool F2 showed higher surface damage, crack, to the cutting condition of the high feed rate, v f = 4 m/min. However, in the wove material experiment the up milling operation presented better conditions of the machined surface and showed no surface damage to any of the cutting tool geometries (Figure 8). This demonstrates the importance of an excellent correlation between material, cutting parameters, and cutting tool geometry to achieve satisfactory surface qualities. The wove material presents higher surface damage, crack of the laminates. This demonstrated the influence of cutting parameters in quality of the material machining. Further research is required to make this type of correlation possible. Delamination occurred only for F2 with extreme cutting condition.

Comparison of surface quality criteria of unidirectional material – cutting parameters and cutting tool geometries.

Comparison of surface quality criteria of wove material – cutting parameters and cutting tool geometries.

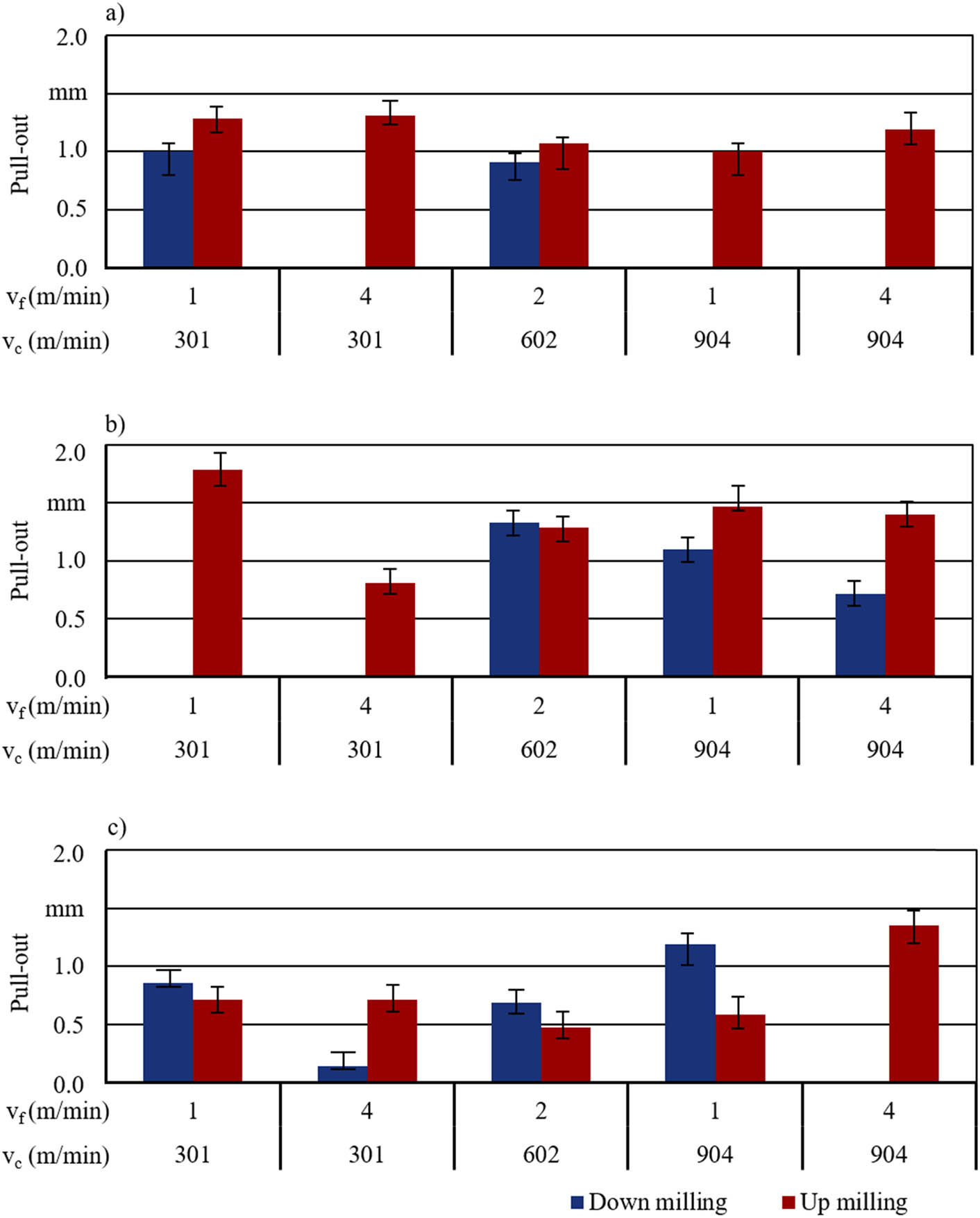

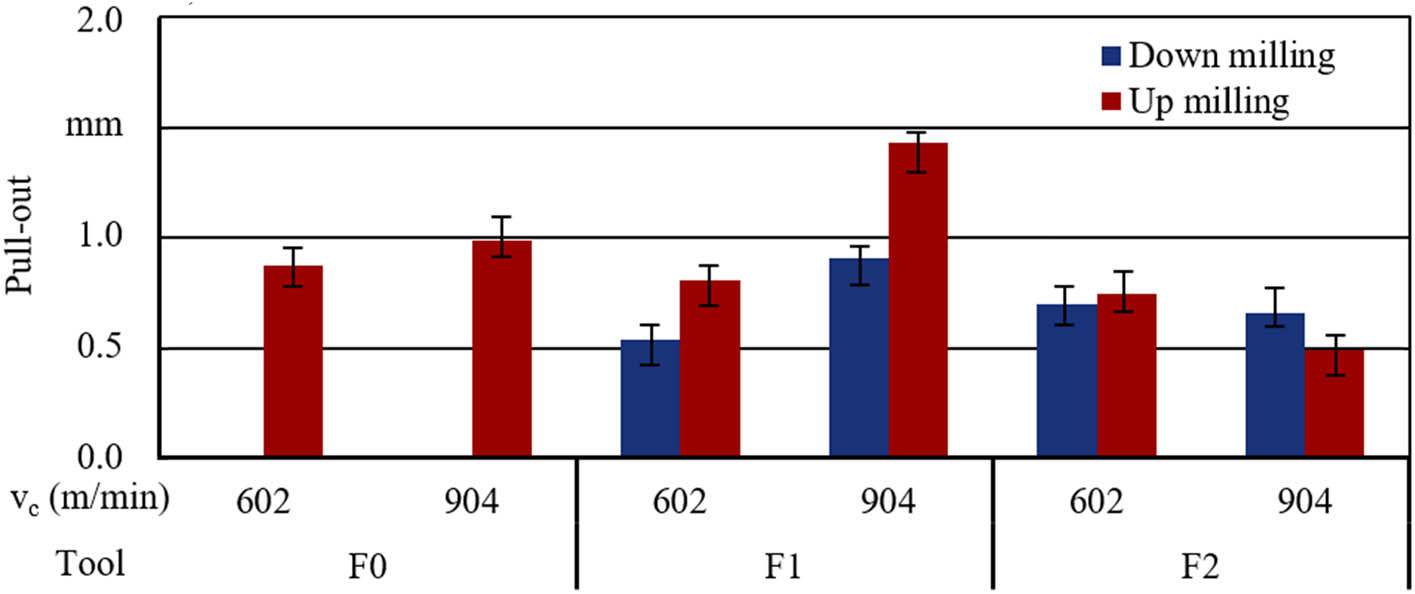

Another way to evaluate the pull-out compliance was considered quantitative measure. Figure 9 shows the pull-out values in down and up milling for unidirectional material. The cutting tool F0 did not have a pull-out in down milling for high feed rate v f = 4 m/min and cutting speeds of v c = 301 m/min and v c = 904 m/min (Figure 9a). The cutting tool F1 did not have a pull-out in down milling for low cutting speeds (Figure 9b). The cutting tool F2 did not have a pull-out in down milling only at v c = 904 m/min and v f = 4 m/min (Figure 9c). Pull-out occurred for all combinations of up milling cutting parameters. In wove material experiments, only the cutting tool F0 did not have a pull-out in the down milling (Figure 10). The cutting tool F1 had the highest pull-out values for both materials. These qualitative results corroborate that the current state of the literature cannot yet directly correlate the pull-out with cutting parameter or cutting tool geometry.

Pull-out results of unidirectional material (a) F0, (b) F1, (c) F2.

Pull-out results of wove material.

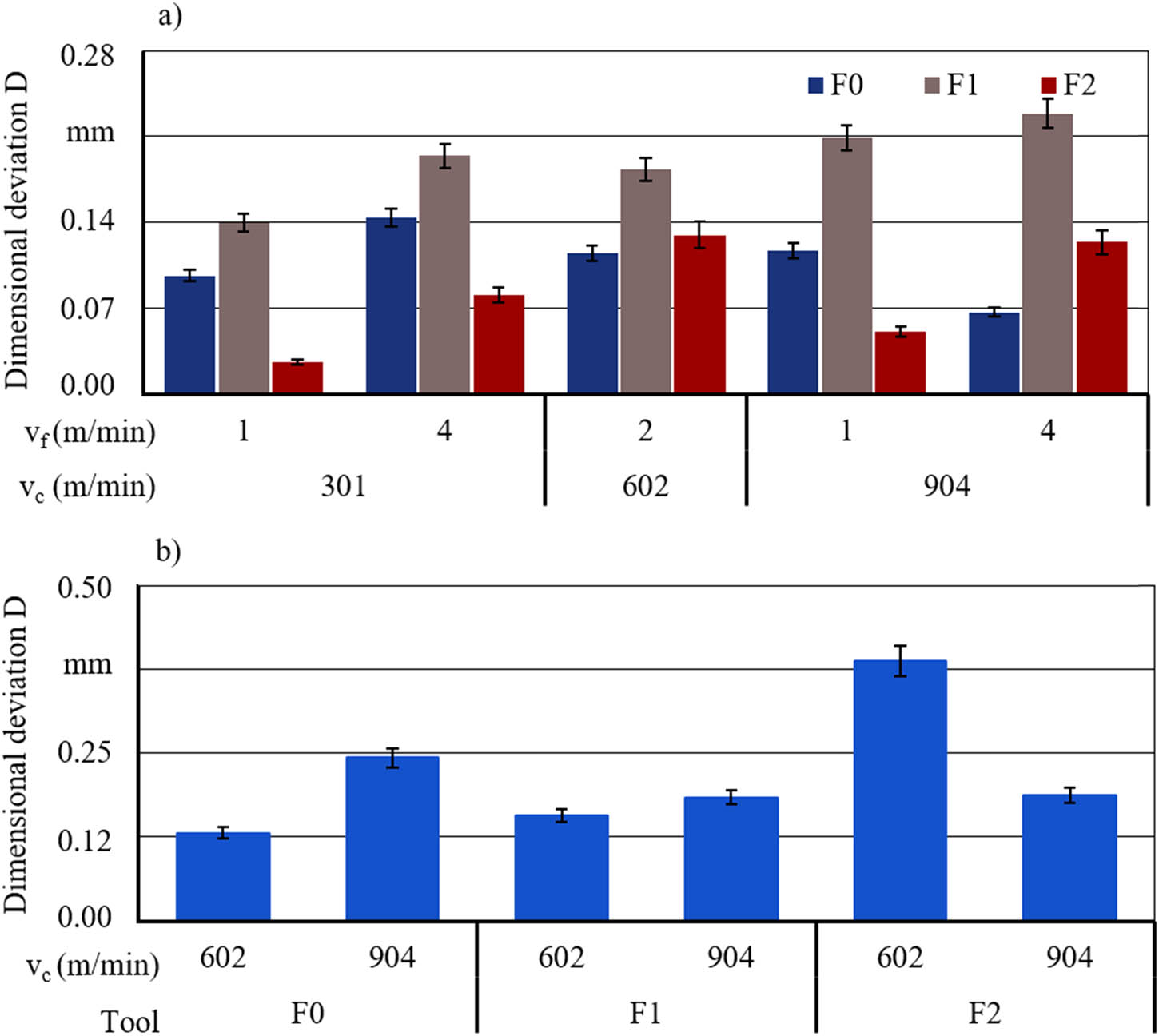

Roesch [44] has machining experiments with a robot of type KR 240 R2500. In Roesch’s experiments, an achievable absolute positional error of E = 0.14 mm was evidenced and showed a reduction in process-related tool path deviations. To validate the performance of the low payload IR KR 60 HA in CFRP milling, the dimensional deviation was measured. The dimensional deviation was calculated by the difference between the standard geometry and the final geometry after robotic machining. The dimensional quality for CFRP machining by the application of low load IR was influenced by all study factors: cutting tool geometry, composite material type, and cutting parameters. The cutting tools F0 and F2 showed dimensional errors below D = 0.14 mm in the experiments for the unidirectional material, and the cutting tool F1 has the largest dimensional deviations (see Figure 11a). These results are directly the oscillation of the cutting force, as shown in Figure 12. It is important to note that the increased cutting speed for all experiments has negatively influenced the tool path. Moreover, only the combination of cutting tool F0 and v c = 602 m/min obtained a dimensional deviation of less than D = 0.14 mm for wove material milling. The woven composite presented higher values for dimensional deviation (see Figure 11b), which can be explained by the fact that it contains in its reinforced epoxy matrix a proportion of 55% of carbon fiber with a fiber orientation of 0/90°. The cutting process for this type of material generated greater instabilities, which influenced the tool path.

Dimensional deviation results: (a) unidirectional material and (b) wove material.

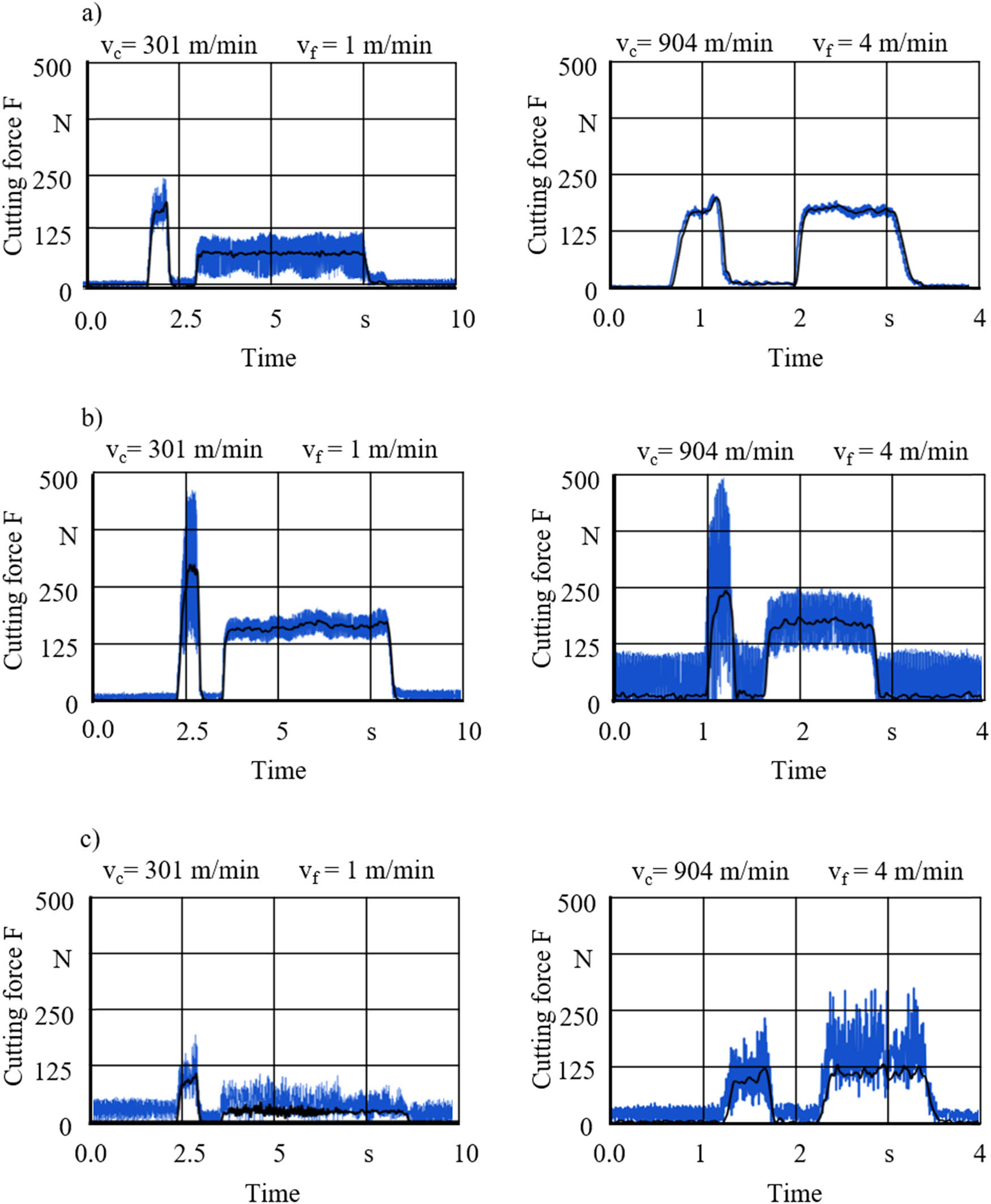

Cutting force profile for material unidirectional material: (a) cutting force F0, (b) cutting force F1, and (c) cutting force F2.

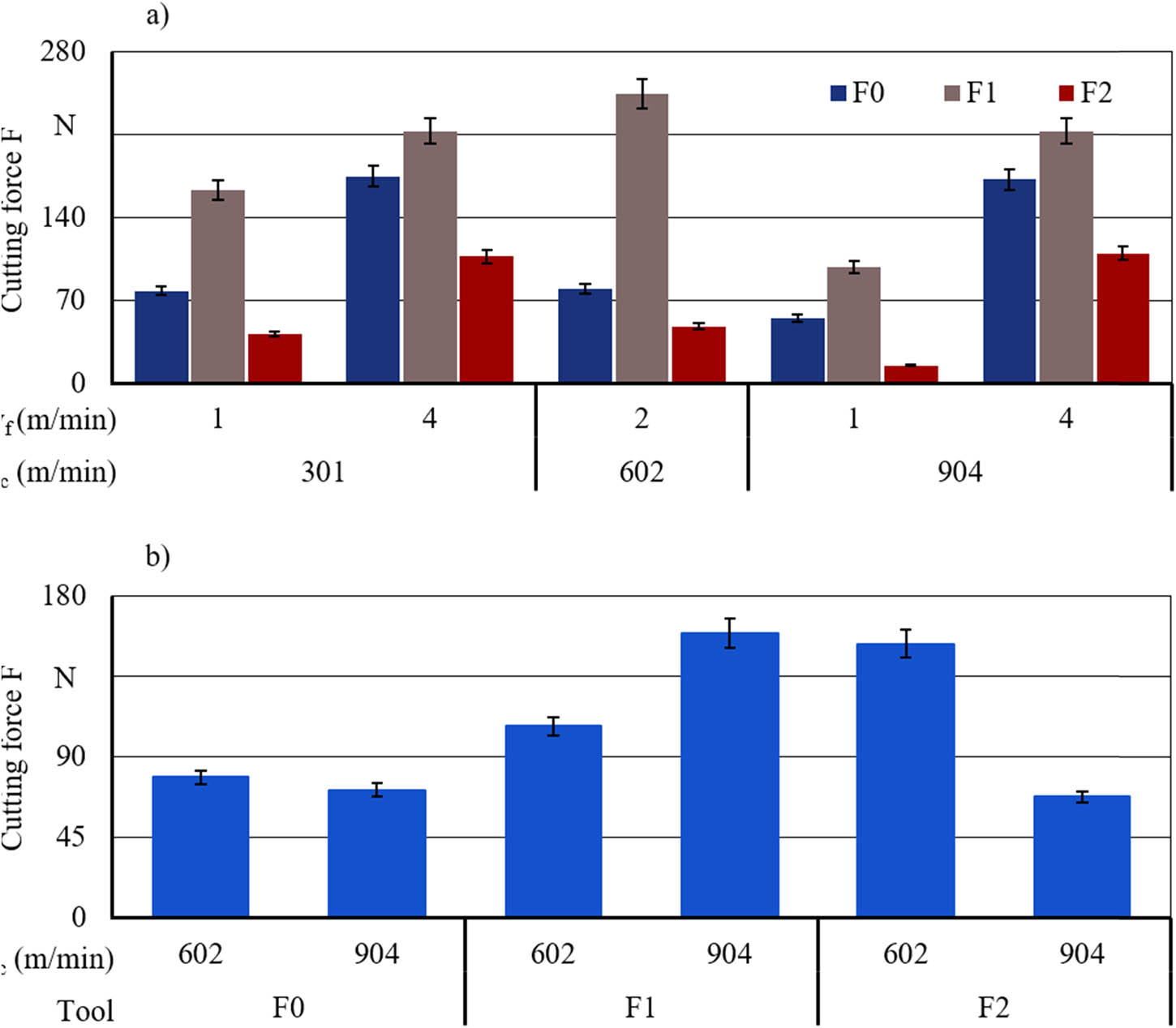

According to Kienzle [45], the force cutting F is mainly influenced by the feed rate. However, because of non-homogeneity and anisotropy of composite materials, other variables have a significant influence on the machining of these materials, such as the geometry of the cutting tool and the cutting speed. The cutting forces F show different patterns in different fiber orientations, unlike in metal cutting [11]. Figure 12 shows the cutting force of the three cutting tools and the cutting parameter combinations. The low pass filter was applied to generate the cutting force profile (black line in Figure 12). The cutting force profiles presented for the tests had a high initial force because of the cutting tool plunge strategy in the workpiece and during milling a harmonic behavior. The high cutting speeds can help smooth resultant force [12] even by increasing the feed rate by four times (see Figure 12). Regarding the cutting force, it can be observed that the increase in cutting speed v c has made it possible to gain the feed rate v f, in addition to maintaining or even reducing the cutting force. The cutting tool F0 showed a low oscillation of cutting force during the experiments for the combination of cutting parameters v c = 904 m/min and v f = 4 m/min (see Figure 12a), demonstrating excellent performance for extreme cutting parameters. On the contrary, the F1 cutting tool presented this type of performance for lower cutting parameters, v c = 301 m/min, and v f = 1 m/min (see Figure 12b). Besides, the cutting tool F1 has a high oscillation of the cutting force for the maximum cutting condition. This high oscillation generated a greater dimensional deviation, as presented previously. This is because of less instability generated in the tool path as the feed rate increases. This reiterates the influence not only of the feed rate v f, but also of the geometry of the cutting tool and the type of composite material. Both cutting tools have a similar geometry but different cutting force results. The cutting tool F2 showed high oscillation of cutting force for all experiments. Even so, it obtained the lowest cutting force values in unidirectional material milling. These results are because of the geometry of the cutting tool F2 which has narrow teeth with pyramidal edge, in which it helps to grind the composite matrix. In the wove material milling test, the feed rate was set constant v f = 2 m/min. As already mentioned, composite material has diverse structures that will directly affect its machinability. The performance of the cutting tools in the milling of wove material demonstrates this influence. According to Ahmad [46], the cutting force for multidirectional laminates was always greater than unidirectional laminates. In addition, the rate of decrease in the cutting force depends also on fiber orientation. Diverging from what is proposed by Ahmad [46], the values of the cutting forces for the wove material were lower than those compared to the unidirectional material. It should be noted that only the F2 cutting tool has made significant gains by increasing the cutting speed. This is also explained by the geometry of its narrow teeth with pyramidal, which is able to grind the matrix. However, the cutting tool F1 showed an increase in the cutting force F with the increased cutting speed v c (see Figure 13b).

Result of cutting forces: (a) unidirectional material and (b) wove material.

4 Conclusion

The present work is focused on the analysis of CFRP milling by the application of the low payload IRs for two materials: unidirectional and wove. The experiments carried out involved the evaluation of cutting force, roughness surface, pull-out, delamination, and dimensional quality, considering the phenomena of the cutting tools and cutting parameters.

The surface roughness Ra for both materials was less than 8 µm in all tests. The down milling results in lower surface roughness Ra than up milling, regardless of the cutting tool used for unidirectional composite milling, demonstrating the preference for down milling when applying IR in CFRP milling.

The surface roughness Ra of wove material also showed non-standard results. All cutting tools showed similar results between down and up milling.

The unidirectional milling, the cutting tool F0 did not show any significant pull-out in down milling. Pull-out occurred for all combinations of up milling cutting parameters.

In the wove milling, only the cutting tool F0 did not have a pull-out in the down milling. The cutting tool F1 had the highest pull-out values for both materials. However, it was not possible to correlate this data in a uniform or standardized way neither for the cutting parameters nor for the cutting tools.

In general, no delamination occurs during CFRP milling. Delamination occurred only for F2 with extreme cutting condition.

The cutting tool F1 has the largest dimensional deviations, D max = 0.23 mm in robotic milling. On the contrary, only the combination of cutting tool F0 with v c = 602 m/min obtained a dimensional deviation of less than D = 0.14 mm for wove material milling.

The increased cutting speed for all experiments has negatively influenced the tool path.

The cutting tool F0 showed a low oscillation of cutting force during the experiments and excellent performance for extreme cutting parameters. On the contrary, the F1 cutting tool presented good performance for lower cutting parameters and high oscillation of the cutting force for the maximum cutting condition.

The material has diverse structures (fiber and matrix) that will directly affect its machinability. The performance of the cutting tools in the milling of wove material demonstrates this influence. In these experiments, the values of the cutting forces for the wove material were lower than those compared to the unidirectional material, diverging from another research.

The proposed cutting parameters for robotic machining, as well as the cutting tool geometry, have shown that there is no pattern of the results for pull-out, delamination, dimensional quality and cutting force. Reaffirming the need for more studies on the machinability of composite materials. But also demonstrating the technical feasibility of applying IRs in composite milling processes.

Acknowledgments

This work was supported by the Coordination for the Improvement of Higher Education Personnel – CAPES (grant number 88882.180844/2018-01); German Academic Exchange Service – DAAD (grant number 91744162); Institute for Production Systems and Design Technology – IPK; and Aeronautics Institute of Technology – ITA.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Geier N, Davim JP, Szalay T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: a review. Compos Part A Appl Sci Manuf. 2019;125:105552. 10.1016/j.compositesa.2019.105552.Suche in Google Scholar

[2] Lopresto V, Caggiano A, Teti R. High performance cutting of fibre reinforced plastic composite materials. Procedia CIRP. 2016;46:71–82. 10.1016/j.procir.2016.05.079.Suche in Google Scholar

[3] Davim JP, editor. Machining composite materials. London: ISTE; 2010.10.1002/9781118602713Suche in Google Scholar

[4] Heinrich JG, Aldinger F. Ceramic materials and components for engines. Wiley; 2008. ISBN:3-527-30416-9 - Book.Suche in Google Scholar

[5] Rosato DV, Rosato MG, Schott NR. Plastics technology handbook, volume 1: Introduction, properties, fabrication, processes. 1st edn. New York, NY (222 East 46th Street, New York, NY 10017): Momentum Press; 2010.Suche in Google Scholar

[6] Panchagnula KK, Palaniyandi K. Drilling on fiber reinforced polymer/nanopolymer composite laminates: a review. J Mater Res Technol. 2018;7(2):180–9. 10.1016/j.jmrt.2017.06.003.Suche in Google Scholar

[7] Abrão AM, Faria PE, Rubio JC, Reis P, Davim JP. Drilling of fiber reinforced plastics: a review. J Mater Process Technol. 2007;186(1–3):1–7. 10.1016/j.jmatprotec.2006.11.146.Suche in Google Scholar

[8] Vigneshwaran S, Uthayakumar M, Arumugaprabu V. Review on machinability of fiber reinforced polymers: a drilling approach. Silicon. 2018;10(5):2295–305. 10.1007/s12633-018-9764-9.Suche in Google Scholar

[9] Hejjaji A, Zitoune R, Crouzeix L, Le Roux S, Collombet F. Surface and machining induced damage characterization of abrasive water jet milled carbon/epoxy composite specimens and their impact on tensile behavior. Wear. 2017;376–377:1356–64. 10.1016/j.wear.2017.02.024.Suche in Google Scholar

[10] Haddad M, Zitoune R, Eyma F, Castanie B. Study of the surface defects and dust generated during trimming of CFRP: Influence of tool geometry, machining parameters and cutting speed range. Compos Part A Appl Sci Manuf. 2014;66:142–54. 10.1016/j.compositesa.2014.07.005.Suche in Google Scholar

[11] He Y, Qing H, Zhang S, Wang D, Zhu S. The cutting force and defect analysis in milling of carbon fiber-reinforced polymer (CFRP) composite. Int J Adv Manuf Technol. 2017;93(5–8):1829–42. 10.1007/s00170-017-0613-6.Suche in Google Scholar

[12] Grisol de Melo E, Klein TB, Reinkober S, Gomes JDO, Uhlmann E. Pocket milling of composite fibre-reinforced polymer using industrial robot. Procedia CIRP. 2019;85:183–8. 10.1016/j.procir.2019.09.006.Suche in Google Scholar

[13] Uhlmann E, Sammler F, Richarz S, Reucher G, Hufschmied R, Frank A, et al. Machining of carbon and glass fibre reinforced composites. Procedia CIRP. 2016;46:63–6. 10.1016/j.procir.2016.03.197.Suche in Google Scholar

[14] Gonul B, Sapmaz OF, Tunc LT. Improved stable conditions in robotic milling by kinematic redundancy. Procedia CIRP. 2019;82:485–90. 10.1016/j.procir.2019.04.334.Suche in Google Scholar

[15] Schneider U, Ansaloni M, Drust M, Leali F, Verl A. Experimental investigation of sources of error in robot machining. In: Neto P, Moreira AP, editors. Robotics in smart manufacturing. Berlin Heidelberg: Springer; 2013. p. 14–26.10.1007/978-3-642-39223-8_2Suche in Google Scholar

[16] Iglesias I, Sebastián MA, Ares JE. Overview of the state of robotic machining: current situation and future potential. Procedia Eng. 2015;132:911–7. 10.1016/j.proeng.2015.12.577.Suche in Google Scholar

[17] Schneider U, Drust M, Ansaloni M, Lehmann C, Pellicciari M, Leali F, et al. Improving robotic machining accuracy through experimental error investigation and modular compensation. Int J Adv Manuf Technol. 2016;85(1–4):3–15. 10.1007/s00170-014-6021-2.Suche in Google Scholar

[18] Krzic P, Pušavec F, Kopac J. Kinematic constraints and offline programming in robotic machining applications. Tehnički Vjesn. 2013;20(1):117–24.Suche in Google Scholar

[19] Mejri S, Gagnol V, Le T-P, Sabourin L, Ray P, Paultre P. Dynamic characterization of machining robot and stability analysis. Int J Adv Manuf Technol. 2016;82(1–4):351–9. 10.1007/s00170-015-7336-3.Suche in Google Scholar

[20] Bisu C, Cherif M, Gerard A, K’nevez JY. Dynamic behavior analysis for a six axis industrial machining robot. Adv Mater Res. 2011;423:65–76. 10.4028/www.scientific.net/AMR.423.65.Suche in Google Scholar

[21] Slamani M, Joubair A, Bonev IA. A comparative evaluation of three industrial robots using three reference measuring techniques. Ind Robot. 2015;42(6):572–85. 10.1108/IR-05-2015-0088.Suche in Google Scholar

[22] Slamani M, Nubiola A, Bonev I. Assessment of the positioning performance of an industrial robot. Ind Robot. 2012;39(1):57–68. 10.1108/01439911211192501.Suche in Google Scholar

[23] Zaghbani I, Songmene V, Bonev I. An experimental study on the vibration response of a robotic machining system. Proc Inst Mech Eng Part B J Eng Manuf. 2013;227(6):866–80. 10.1177/0954405413477067.Suche in Google Scholar

[24] Zaghbani I, Lamraoui M, Songmene V, Thomas M, El Badaoui M. Robotic high speed machining of aluminum alloys. Adv Mater Res. 2011;188:584–9. 10.4028/www.scientific.net/AMR.188.584.Suche in Google Scholar

[25] Chen Y, Dong F. Robot machining: recent development and future research issues. Int J Adv Manuf Technol. 2013;66(9–12):1489–97. 10.1007/s00170-012-4433-4.Suche in Google Scholar

[26] Denkena B, Lepper T. Enabling an industrial robot for metal cutting operations. Procedia CIRP. 2015;35:79–84. 10.1016/j.procir.2015.08.100.Suche in Google Scholar

[27] Denkena B, Bergmann B, Lepper T. Design and optimization of a machining robot. Procedia Manuf. 2017;14:89–96. 10.1016/j.promfg.2017.11.010.Suche in Google Scholar

[28] Möller C, Schmidt HC, Koch P, Böhlmann C, Kothe SM, Wollnack J, et al. Machining of large scaled CFRP-Parts with mobile CNC-based robotic system in aerospace industry. Procedia Manuf. 2017;14:17–29. 10.1016/j.promfg.2017.11.003.Suche in Google Scholar

[29] Uhlmann E, Meier P, Hinzmann D. Application of niobium carbide based cutting materials for peripheral milling of CFRP. Procedia CIRP. 2019;85:108–13. 10.1016/j.procir.2019.09.009.Suche in Google Scholar

[30] M’Saoubi R, Axinte D, Soo SL, Nobel C, Attia H, Kappmeyer G, et al. High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann. 2015;64(2):557–80. 10.1016/j.cirp.2015.05.002.Suche in Google Scholar

[31] Ulhmann E. Machining of carbon and glass fibre reinforced composites. 7th HPC 2016 – CIRP Conference on High Performance Cutting; 2016. p. 63–6. 10.1016/j.procir.2016.03.197.Suche in Google Scholar

[32] Ulhmann E. High speed cutting of carbon fibre reinforced plastics. 16th Machining Innovations Conference for Aerospace Industry – MIC 2016/6(6); 2016. p. 113–23. 10.1016/j.promfg.2016.11.015.Suche in Google Scholar

[33] Uhlmann E, Richarz S, Sammler F, Hufschmied R. High speed cutting of carbon fibre reinforced plastics. Procedia Manuf. 2016;6:113–23. 10.1016/j.promfg.2016.11.015.Suche in Google Scholar

[34] Gao C, Xiao J, Xu J, Ke Y. Factor analysis of machining parameters of fiber-reinforced polymer composites based on finite element simulation with experimental investigation. Int J Adv Manuf Technol. 2016;83(5–8):1113–25. 10.1007/s00170-015-7592-2.Suche in Google Scholar

[35] The International Organization for Standardization. Geometrical product specifications (GPS) – Surface texture: profile method – terms, definitions and surface texture parameters. Available from: https://www.iso.org/standard/10132.html [cited 2020 February 3].Suche in Google Scholar

[36] Kalla D, Sheikh-Ahmad J, Twomey J. Prediction of cutting forces in helical end milling fiber reinforced polymers. Int J Mach Tools Manuf. 2010;50(10):882–91. 10.1016/j.ijmachtools.2010.06.005.Suche in Google Scholar

[37] Choudhury IA, Hashmi S. Finish machining and net-shape forming. Waltham MA: Elsevier; 2017.Suche in Google Scholar

[38] Sheikh-Ahmad J, El-Hofy M, Almaskari F, Kerrigan K, Takikawa Y. The evolution of cutting forces during slot milling of unidirectional carbon fiber reinforced polymer (UD-CFRP) composites. Procedia CIRP. 2019;85:127–32. 10.1016/j.procir.2019.09.043.Suche in Google Scholar

[39] Gara S, Tsoumarev O. Prediction of surface roughness in slotting of CFRP. Measurement. 2016;91:414–20. 10.1016/j.measurement.2016.05.016.Suche in Google Scholar

[40] Azmi AI, Lin RJT, Bhattacharyya D. Machinability study of glass fibre-reinforced polymer composites during end milling. Int J Adv Manuf Technol. 2013;64(1–4):247–61. 10.1007/s00170-012-4006-6.Suche in Google Scholar

[41] Jayaweera N, Webb P. Adaptive robotic assembly of compliant aero-structure components. Robot Comput Int Manuf. 2007;23(2):180–94. 10.1016/j.rcim.2006.04.002.Suche in Google Scholar

[42] Sreejith P, Krishnamurthy R, Malhotra S, Narayanasamy K. Evaluation of PCD tool performance during machining of carbon/phenolic ablative composites. J Mater Process Technol. 2000;104(1–2):53–8. 10.1016/S0924-0136(00)00549-5.Suche in Google Scholar

[43] Bolar G, Mekonen M, Das A, Joshi SN. Experimental investigation on surface quality and dimensional accuracy during curvilinear thin-wall machining. Mater Today Proc. 2018;5(2):6461–9. 10.1016/j.matpr.2017.12.259.Suche in Google Scholar

[44] Roesch O. Model-based on-line compensation of path deviations for milling robots. Adv Mater Res. 2013;769:255–62. 10.4028/www.scientific.net/AMR.769.255.Suche in Google Scholar

[45] Kienzle O. Die Bestimmung von Kraften und Leistungen an spanenden Werkzeugen und Werkzeugmaschinen. VDI-Zeitschrift Integriete Produktion. 1952;94(11–12):299–306.Suche in Google Scholar

[46] Ahmad J. Machining of polymer composites. Boston, MA: Springer US; 2009.10.1007/978-0-387-68619-6Suche in Google Scholar

© 2021 Ever Grisol de Melo et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Effects of Material Constructions on Supersonic Flutter Characteristics for Composite Rectangular Plates Reinforced with Carbon Nano-structures

- Processing of Hollow Glass Microspheres (HGM) filled Epoxy Syntactic Foam Composites with improved Structural Characteristics

- Investigation on the anti-penetration performance of the steel/nylon sandwich plate

- Flexural bearing capacity and failure mechanism of CFRP-aluminum laminate beam with double-channel cross-section

- In-Plane Permeability Measurement of Biaxial Woven Fabrics by 2D-Radial Flow Method

- Regular Articles

- Real time defect detection during composite layup via Tactile Shape Sensing

- Mechanical and durability properties of GFRP bars exposed to aggressive solution environments

- Cushioning energy absorption of paper corrugation tubes with regular polygonal cross-section under axial static compression

- An investigation on the degradation behaviors of Mg wires/PLA composite for bone fixation implants: influence of wire content and load mode

- Compressive bearing capacity and failure mechanism of CFRP–aluminum laminate column with single-channel cross section

- Self-Fibers Compacting Concrete Properties Reinforced with Propylene Fibers

- Study on the fabrication of in-situ TiB2/Al composite by electroslag melting

- Characterization and Comparison Research on Composite of Alluvial Clayey Soil Modified with Fine Aggregates of Construction Waste and Fly Ash

- Axial and lateral stiffness of spherical self-balancing fiber reinforced rubber pipes under internal pressure

- Influence of technical parameters on the structure of annular axis braided preforms

- Nano titanium oxide for modifying water physical property and acid-resistance of alluvial soil in Yangtze River estuary

- Modified Halpin–Tsai equation for predicting interfacial effect in water diffusion process

- Experimental research on effect of opening configuration and reinforcement method on buckling and strength analyses of spar web made of composite material

- Photoluminescence characteristics and energy transfer phenomena in Ce3+-doped YVO4 single crystal

- Influence of fiber type on mechanical properties of lightweight cement-based composites

- Mechanical and fracture properties of steel fiber-reinforced geopolymer concrete

- Handcrafted digital light processing apparatus for additively manufacturing oral-prosthesis targeted nano-ceramic resin composites

- 3D printing path planning algorithm for thin walled and complex devices

- Material-removing machining wastes as a filler of a polymer concrete (industrial chips as a filler of a polymer concrete)

- The electrochemical performance and modification mechanism of the corrosion inhibitor on concrete

- Evaluation of the applicability of different viscoelasticity constitutive models in bamboo scrimber short-term tensile creep property research

- Experimental and microstructure analysis of the penetration resistance of composite structures

- Ultrasensitive analysis of SW-BNNT with an extra attached mass

- Active vibration suppression of wind turbine blades integrated with piezoelectric sensors

- Delamination properties and in situ damage monitoring of z-pinned carbon fiber/epoxy composites

- Analysis of the influence of asymmetric geological conditions on stability of high arch dam

- Measurement and simulation validation of numerical model parameters of fresh concrete

- Tuning the through-thickness orientation of 1D nanocarbons to enhance the electrical conductivity and ILSS of hierarchical CFRP composites

- Performance improvements of a short glass fiber-reinforced PA66 composite

- Investigation on the acoustic properties of structural gradient 316L stainless steel hollow spheres composites

- Experimental studies on the dynamic viscoelastic properties of basalt fiber-reinforced asphalt mixtures

- Hot deformation behavior of nano-Al2O3-dispersion-strengthened Cu20W composite

- Synthesize and characterization of conductive nano silver/graphene oxide composites

- Analysis and optimization of mechanical properties of recycled concrete based on aggregate characteristics

- Synthesis and characterization of polyurethane–polysiloxane block copolymers modified by α,ω-hydroxyalkyl polysiloxanes with methacrylate side chain

- Buckling analysis of thin-walled metal liner of cylindrical composite overwrapped pressure vessels with depressions after autofrettage processing

- Use of polypropylene fibres to increase the resistance of reinforcement to chloride corrosion in concretes

- Oblique penetration mechanism of hybrid composite laminates

- Comparative study between dry and wet properties of thermoplastic PA6/PP novel matrix-based carbon fibre composites

- Experimental study on the low-velocity impact failure mechanism of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Preparation, optical properties, and thermal stability of polyvinyl butyral composite films containing core (lanthanum hexaboride)–shell (titanium dioxide)-structured nanoparticles

- Research on the size effect of roughness on rock uniaxial compressive strength and characteristic strength

- Research on the mechanical model of cord-reinforced air spring with winding formation

- Experimental study on the influence of mixing time on concrete performance under different mixing modes

- A continuum damage model for fatigue life prediction of 2.5D woven composites

- Investigation of the influence of recyclate content on Poisson number of composites

- A hard-core soft-shell model for vibration condition of fresh concrete based on low water-cement ratio concrete

- Retraction

- Thermal and mechanical characteristics of cement nanocomposites

- Influence of class F fly ash and silica nano-micro powder on water permeability and thermal properties of high performance cementitious composites

- Effects of fly ash and cement content on rheological, mechanical, and transport properties of high-performance self-compacting concrete

- Erratum

- Inverse analysis of concrete meso-constitutive model parameters considering aggregate size effect

- Special Issue: MDA 2020

- Comparison of the shear behavior in graphite-epoxy composites evaluated by means of biaxial test and off-axis tension test

- Photosynthetic textile biocomposites: Using laboratory testing and digital fabrication to develop flexible living building materials

- Study of gypsum composites with fine solid aggregates at elevated temperatures

- Optimization for drilling process of metal-composite aeronautical structures

- Engineering of composite materials made of epoxy resins modified with recycled fine aggregate

- Evaluation of carbon fiber reinforced polymer – CFRP – machining by applying industrial robots

- Experimental and analytical study of bio-based epoxy composite materials for strengthening reinforced concrete structures

- Environmental effects on mode II fracture toughness of unidirectional E-glass/vinyl ester laminated composites

- Special Issue: NCM4EA

- Effect and mechanism of different excitation modes on the activities of the recycled brick micropowder

Artikel in diesem Heft

- Effects of Material Constructions on Supersonic Flutter Characteristics for Composite Rectangular Plates Reinforced with Carbon Nano-structures

- Processing of Hollow Glass Microspheres (HGM) filled Epoxy Syntactic Foam Composites with improved Structural Characteristics

- Investigation on the anti-penetration performance of the steel/nylon sandwich plate

- Flexural bearing capacity and failure mechanism of CFRP-aluminum laminate beam with double-channel cross-section

- In-Plane Permeability Measurement of Biaxial Woven Fabrics by 2D-Radial Flow Method

- Regular Articles

- Real time defect detection during composite layup via Tactile Shape Sensing

- Mechanical and durability properties of GFRP bars exposed to aggressive solution environments

- Cushioning energy absorption of paper corrugation tubes with regular polygonal cross-section under axial static compression

- An investigation on the degradation behaviors of Mg wires/PLA composite for bone fixation implants: influence of wire content and load mode

- Compressive bearing capacity and failure mechanism of CFRP–aluminum laminate column with single-channel cross section

- Self-Fibers Compacting Concrete Properties Reinforced with Propylene Fibers

- Study on the fabrication of in-situ TiB2/Al composite by electroslag melting

- Characterization and Comparison Research on Composite of Alluvial Clayey Soil Modified with Fine Aggregates of Construction Waste and Fly Ash

- Axial and lateral stiffness of spherical self-balancing fiber reinforced rubber pipes under internal pressure

- Influence of technical parameters on the structure of annular axis braided preforms

- Nano titanium oxide for modifying water physical property and acid-resistance of alluvial soil in Yangtze River estuary

- Modified Halpin–Tsai equation for predicting interfacial effect in water diffusion process

- Experimental research on effect of opening configuration and reinforcement method on buckling and strength analyses of spar web made of composite material

- Photoluminescence characteristics and energy transfer phenomena in Ce3+-doped YVO4 single crystal

- Influence of fiber type on mechanical properties of lightweight cement-based composites

- Mechanical and fracture properties of steel fiber-reinforced geopolymer concrete

- Handcrafted digital light processing apparatus for additively manufacturing oral-prosthesis targeted nano-ceramic resin composites

- 3D printing path planning algorithm for thin walled and complex devices

- Material-removing machining wastes as a filler of a polymer concrete (industrial chips as a filler of a polymer concrete)

- The electrochemical performance and modification mechanism of the corrosion inhibitor on concrete

- Evaluation of the applicability of different viscoelasticity constitutive models in bamboo scrimber short-term tensile creep property research

- Experimental and microstructure analysis of the penetration resistance of composite structures

- Ultrasensitive analysis of SW-BNNT with an extra attached mass

- Active vibration suppression of wind turbine blades integrated with piezoelectric sensors

- Delamination properties and in situ damage monitoring of z-pinned carbon fiber/epoxy composites

- Analysis of the influence of asymmetric geological conditions on stability of high arch dam

- Measurement and simulation validation of numerical model parameters of fresh concrete

- Tuning the through-thickness orientation of 1D nanocarbons to enhance the electrical conductivity and ILSS of hierarchical CFRP composites

- Performance improvements of a short glass fiber-reinforced PA66 composite

- Investigation on the acoustic properties of structural gradient 316L stainless steel hollow spheres composites

- Experimental studies on the dynamic viscoelastic properties of basalt fiber-reinforced asphalt mixtures

- Hot deformation behavior of nano-Al2O3-dispersion-strengthened Cu20W composite

- Synthesize and characterization of conductive nano silver/graphene oxide composites

- Analysis and optimization of mechanical properties of recycled concrete based on aggregate characteristics

- Synthesis and characterization of polyurethane–polysiloxane block copolymers modified by α,ω-hydroxyalkyl polysiloxanes with methacrylate side chain

- Buckling analysis of thin-walled metal liner of cylindrical composite overwrapped pressure vessels with depressions after autofrettage processing

- Use of polypropylene fibres to increase the resistance of reinforcement to chloride corrosion in concretes

- Oblique penetration mechanism of hybrid composite laminates

- Comparative study between dry and wet properties of thermoplastic PA6/PP novel matrix-based carbon fibre composites

- Experimental study on the low-velocity impact failure mechanism of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Preparation, optical properties, and thermal stability of polyvinyl butyral composite films containing core (lanthanum hexaboride)–shell (titanium dioxide)-structured nanoparticles

- Research on the size effect of roughness on rock uniaxial compressive strength and characteristic strength

- Research on the mechanical model of cord-reinforced air spring with winding formation

- Experimental study on the influence of mixing time on concrete performance under different mixing modes

- A continuum damage model for fatigue life prediction of 2.5D woven composites

- Investigation of the influence of recyclate content on Poisson number of composites

- A hard-core soft-shell model for vibration condition of fresh concrete based on low water-cement ratio concrete

- Retraction

- Thermal and mechanical characteristics of cement nanocomposites

- Influence of class F fly ash and silica nano-micro powder on water permeability and thermal properties of high performance cementitious composites

- Effects of fly ash and cement content on rheological, mechanical, and transport properties of high-performance self-compacting concrete

- Erratum

- Inverse analysis of concrete meso-constitutive model parameters considering aggregate size effect

- Special Issue: MDA 2020

- Comparison of the shear behavior in graphite-epoxy composites evaluated by means of biaxial test and off-axis tension test

- Photosynthetic textile biocomposites: Using laboratory testing and digital fabrication to develop flexible living building materials

- Study of gypsum composites with fine solid aggregates at elevated temperatures

- Optimization for drilling process of metal-composite aeronautical structures

- Engineering of composite materials made of epoxy resins modified with recycled fine aggregate

- Evaluation of carbon fiber reinforced polymer – CFRP – machining by applying industrial robots

- Experimental and analytical study of bio-based epoxy composite materials for strengthening reinforced concrete structures

- Environmental effects on mode II fracture toughness of unidirectional E-glass/vinyl ester laminated composites

- Special Issue: NCM4EA

- Effect and mechanism of different excitation modes on the activities of the recycled brick micropowder