Data management of process plants as complex systems: systematic literature review and identification of challenges and opportunities

-

Max Layer

, Jonathan Leidich

, Sebastian Schwoch

, Bernhard Saske

, Sebastian Neubert

Abstract

Led by the manufacturing industry, virtual replicas of production systems also known as digital twins (DTs) are gradually moving into all areas of industry. Their advantages are characterized by the possibility of product optimization, simulations, improved monitoring and prediction of downtimes and optimized maintenance, to name just a few. The engineering, procurement and construction (EPC) of process plants as mechatronic systems is characterized by a high degree of project-specific modifications and interdisciplinary engineering effort with low reusability, in contrast to unit-production-driven areas such as automotive. This results in a high cost-benefit ratio for the creation of DTs over the life cycle of process plants, especially when suppliers are integrated into the value chain. The objective of this paper is to analyze the state of plant lifecycle management, data exchange and the possibilities of optimized supplier integration during the planning and EPC of process plants regarding DT creation and usage. Three research questions (RQs) were used to narrow down a total of 356 identified publications to 54, which were then examined. The papers covered a variety of topics, including combining discipline-specific models, plant management approaches and the combination of both.

1 Introduction and motivation

Process plants are complex systems that require integration and coordination of different engineering disciplines and suppliers to ensure efficient and effective operation. Currently, the majority of process plants are developed and erected on a customer-specific basis (Adamenko et al. 2019). For this purpose, the plant is detailed in different disciplines such as process technology, mechanical engineering, automation technology by different suppliers and prepared for installation. This complex process is carried out individually for each plant, resulting in a high number of variants with simultaneously low quantities up to batch size 1. The potential of standardized plant components for their use in several plants is not fully exploited. This makes it difficult to reuse development efforts and the associated information and data (Ripperger and Nikolaus 2020).

In addition, the interconnection of the development disciplines and the companies involved at the IT level and the harmonization of the engineering programs used are low. As a result, parallel, overlapping sub-models of the plant are created that are not merged into an overall model. The production and erection of the plants are mostly not carried out in a factory with a defined environment, IT connection, test stands and own employees. A large proportion of the value added such as steel construction, piping, cabling is provided on-site by suppliers under their responsibility (Ripperger and Nikolaus 2020). Often, the components installed are spontaneously adapted to the specific conditions at the construction site, resulting in deviations between the planned (should-build) and constructed (as-built) structure of the systems. This makes it difficult to provide data consistency and synchronize these processes.

The often-inconsistent documentation of the as-built structure in the original computer aided design (CAD) models (Weber et al. 2020) hinders the planning and execution of subsequent processes in the operating phase, such as maintenance. These processes in turn require changes to the plant, e.g., through component replacement or the restructuring of larger plant parts. Due to the interconnected nature of process plants as complex systems, maintenance and repair activities can be particularly challenging, as they often require coordination and cooperation between multiple stakeholders with specialized knowledge in different domains. This can lead to longer downtimes, higher costs and reduced availability of the plant. Therefore, effective strategies and tools for maintenance and repair of complex systems are critical for ensuring the reliable and efficient operation of process plants. Successful changes should be fed back into the models and structures of the plant development, since inconsistencies that arise between the digital model and the physical instance of the plant also block more potentials, e.g., the use of DTs. Based on these challenges, the need for a central access point for different kinds of information regarding the customer-specific plant such as

as-engineered data

as-built documentation

maintenance, repair and operations as well as

data analytics

The goal of this paper is to analyze the current state of the art of existing concepts for optimized data management during the life cycle of process plants. Section 2 illustrates the underlying methodology of the systematic literature analysis, while Section 3 consolidates the main concepts of interdisciplinary data management, system modeling and data exchange in related domains such as product development and production engineering. In Section 4 the systematically found papers are reviewed and analyzed, while in Section 5 the key findings are systemized and identified knowledge gaps are highlighted. Finally, in Section 6, a summary and direction for future research are given.

2 Research methodology

The derived methodology for this systematic review is based on existing approaches and recommendations for conducting systematic reviews (Kitchenham 2004). First, key research questions (RQs) were defined which then were transformed into search strings. The resulting literature was reduced by evaluating the title and abstract based on a voting system of all authors. To cover a broad field of references, the database IEEE Xplore and the two interdisciplinary indexes Scopus and Web of Science (WoS) were chosen.

2.1 Definition of key RQs

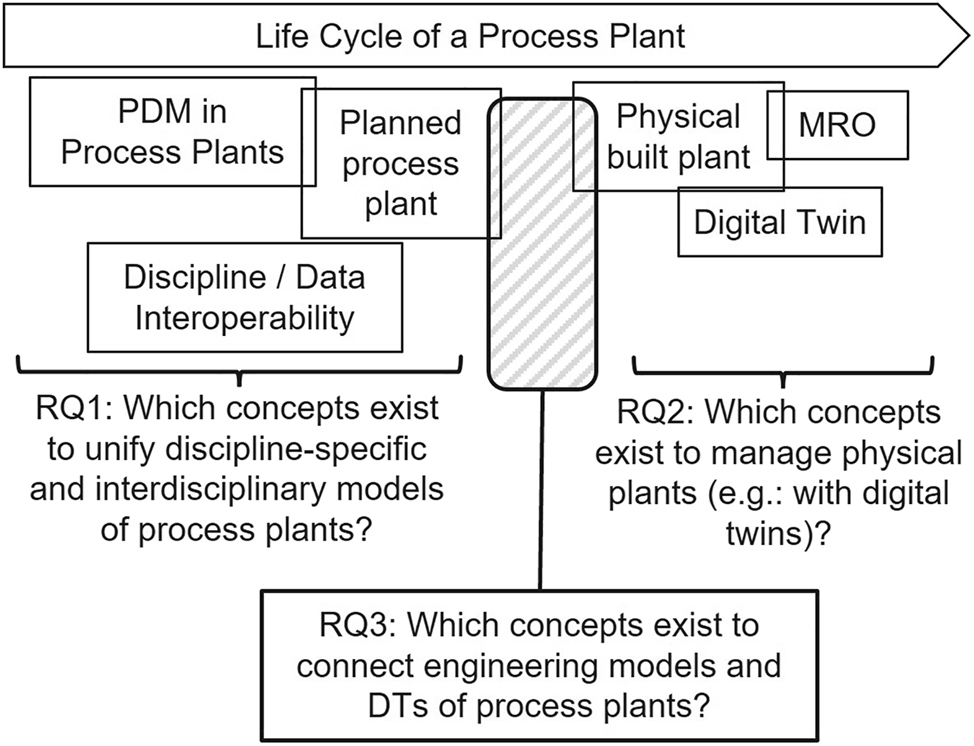

To identify precise RQs, the scope is first generally reduced to the field of the process industry. This reduction will later be represented by a prefilter. In addition, power plants are considered, as planning and construction are similarly complex, while a large part overlaps with systems of the process industry. RQs (Figure 1) are formulated in this context to understand existing methods for optimized data management during the life cycle of a process plant.

Visualization of key RQs.

Along the life cycle, three key RQs are derived:

RQ1: Which concepts exist to unify discipline-specific and interdisciplinary models of process plants?

RQ2: Which concepts exist to manage physical plants from a data perspective (e.g.: DTs)?

RQ3: Which concepts exist to connect engineering models and DTs of process plants?

2.2 Search string definition

The creation of the search strings for the literature queries is based on an initial literature database, which was set up in parallel with defining the three key RQs. The initial references were grouped according to the derived RQs and then the titles and keywords were analyzed by frequency of occurrence. For that, the titles were parsed into a python script and the data was prepared with the natural language processing toolkit (Bird et al. 2009) for removing stop words and tokenizing. Additionally, a systematic keyword extractor called YAKE (Campos et al. 2020) was utilized in different configurations to derive search strings from the titles. For each RQ, these different terms were diversified with synonyms and then combined into the search strings listed below:

RQ1: {("plant development" OR "product development" OR "product design" OR "plant design" OR "plantdesign" OR "plant eng*" OR "product engineering" OR "engineering-to-order" OR "eto" OR "model based system engineering" OR "mbse" OR "model based engineering" OR "sysml") AND ("unif*" OR "merge" OR "connect*" OR "exchang*" OR "silo" OR "intergrat*") AND ("interdisciplin*" OR "CAE" OR "disciplin*" OR "model*" OR "CAD" OR "interopera*" OR "CAX" OR "standard" OR "collabora*"OR "data consistency")}

RQ2: {("data") AND ("DT" OR "digital shadow" OR "digital repr*" OR "digital" OR "virtual twin" OR "virtual shadow" OR "virtual power plant") AND ("manag*" OR "administrat*" OR "operat*" framework OR "handl*" OR "control*" OR "govern*" OR "supervis*") AND ("physical" OR "real" OR "actual" OR "certain" OR "specific") AND("asset" OR "plant" OR "process" OR "system")}

RQ3: {("connect" OR "bridg*" OR "join*" OR "relate* " OR "unif*" OR "coupl*" OR "data consisten*") AND ("engineering model" OR "CAE" OR "PDM" OR "PLM" OR " data management" OR "CAD") AND ("digital" OR "virtual" OR "computational" OR "cyber") AND ("twin" OR "shadow" OR "representation" OR "model" OR "framework" OR "master")}

These RQs were each enhanced with one general NOT search string to exclude identified areas out of scope, such as the field of biology, cycle analysis, environmental analysis as well as grid and energy management studies:

NOT search string: ’("bio" OR "growing" OR "assessment*" OR "cycle analysis" OR "ornamental" OR "powertrain" OR "health" OR "emission" OR "ozone" OR "solar" OR "photovoltaic" OR "grid" OR "energy management " OR "energy")’

A prefilter on the title was integrated, to narrow the focus down to the process plant industry. The prefilter considers general terms from the process industry and identifiers of relevant international standards:

Prefilter: ’("Process plant" OR "Process industry" OR "power plant" OR "powerplant" OR "plant industry" OR "process engineering" OR "treatment plant" OR "reuse plant" OR "ocean plant" OR "plant 3D" OR ("brown?field" AND "plant") OR ("green?field" AND "plant") OR "plant design" OR "plantdesign" OR "15926" OR "10628" OR "62424" OR "16739" OR "generation plant")’

For Scopus, an additional preselection of subject area codes was used to further reduce the query time. The search was conducted on the subject areas engineering, computational, energy, chemical engineering, material science, mathematics, multidisciplinary, environmental sciences [’ENGI’, ’COMP’, ’ENER’, ’CENG’, ’MATE’, ’MATH’, ’MULT’, ’ENVI’] excluding fields such as economics or history.

2.3 Reduction methodology

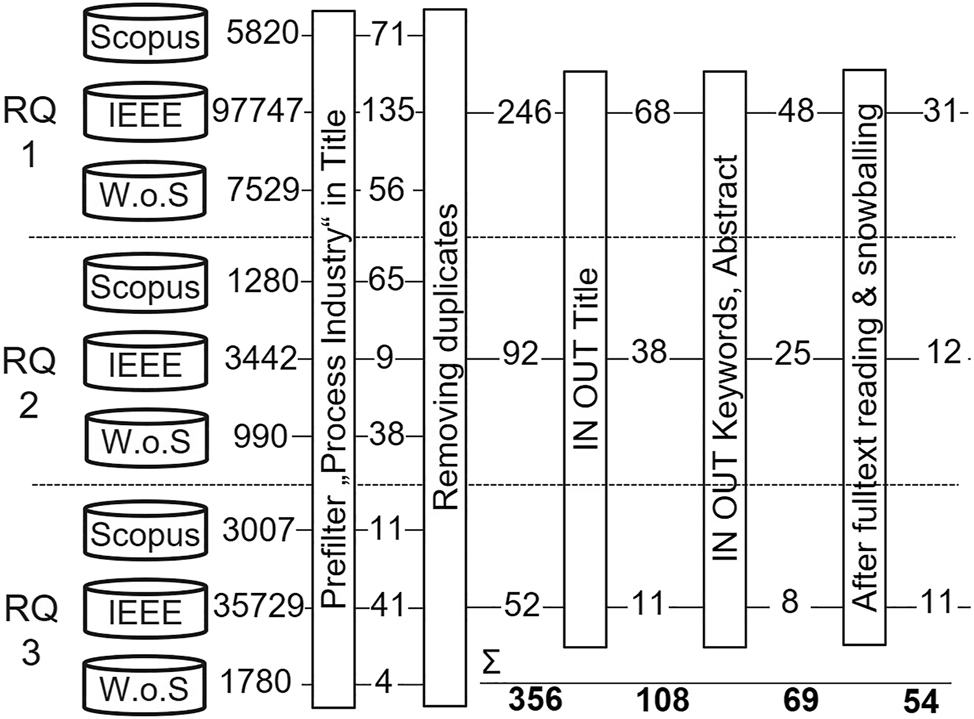

For the queries, the “advanced search” of Scopus, IEEE and WoS was used to search for all indexed publications. Additionally, a prefilter was defined to scope the topic into the process plant industry. This prefilter was set on “Document Title” for IEEE and on “Title” for both Scopus and WoS. For the combination with the RQs, the search was conducted on “TITLE-ABSTRACT-KEYWORDS” for Scopus and for IEEE and WoS on “all Metadata”. This consists of all bibliographic information including the abstract. The search returned 348 papers after Level 1, which were then evaluated by the authors following the method derived in Figure 2.

Visualization of methodology.

In levels 2 and 3 all remaining literature was scanned regarding its relevance to the RQs. This was done by a voting system in which each author had to decide whether a paper was in or out of scope of the formulated RQs. Papers with more than 50 % agreement were further considered. Papers with even choices were decided by discussion. This method led to 64 papers for detailed reading and analysis. Finally, the references in the analyzed papers were used to find further fitting literature not covered by the initial search generally referred to as the snowballing method.

3 Related studies

Before the found literature is analyzed in Section 4, the existing state of art of life-cycle data management, system modeling, DTs and data exchange are taken into consideration.

3.1 Product Data Management and Product Lifecycle Management

Product lifecycle management (PLM) emerged from the need for consistent management and storage of development data in the aviation and automotive industry (Eigner and Stelzer 2009; Stark 2022). Its well-developed strategies, methods and tools aim at providing all necessary information at each time over the whole product lifecycle. Therefore, PLM integrates concepts to manage development data of different disciplines within relational databases. PLM emerged from product data management (PDM), which was primarily used to manage data from mechanical engineering with part- and document structures. With a product centric vision, the PLM approach requires an understanding of the role of information within the enterprise along the value-creation chain (Terzi et al. 2010). This includes the management of bill-of-materials and the geometrical description of parts and assemblies e.g. within CAD models. Additionally, documents associated with the geometry are also included within PDM-systems, like models and results from FEM simulations.

PLM expands the functionalities of PDM to a strategy that covers the whole product lifecycle. This implies a horizontal scaling over the different phases of the product lifecycle from the product idea over its creation, production and usage until it is recycled at the end of the lifecycle. Furthermore, vertical scaling is necessary to integrate all involved disciplines and stakeholders and their respective IT-systems for authoring e.g., CAX-tools and data management (Enterprise Resource Management – ERP, Maintenance, Repair and Operations – MRO, etc.). Although very mature in its fundamental concepts, the integration of the various systems is still an ongoing topic in the science and economy. Recent research for example evaluates the use of the asset administration shell (ASS) for integrating PLM and application lifecycle management (ALM) (Deuter and Imort 2020). Other research in PLM focuses on:

Ontology-based methodologies for exchanging information between PLM systems (Sriti et al. 2015),

a concept, where meta-models of PLM are utilized to create a Systems of Systems (SoS) framework for mechatronic systems (Hehenberger et al. 2016),

reconfiguration approaches in smart products (Savarino et al. 2018) and their virtual representation (Abramovici et al. 2018),

Data mining, AI and big data use cases in PLM (Dekhtiar et al. 2018),

the integration of data from the industrial internet of things (Barrios et al. 2019),

the application of virtual reality for information exchange (Adwernat et al. 2020),

the role of PLM in supporting the concepts within a circular economy (Cholewa and Minh 2021),

the rising complexity of products and related business processes affecting the complexity of PLM-concepts (Deuter and Imort 2021).

3.2 Model-Based Systems Engineering

Model-based systems engineering (MBSE) is based on the principles and concepts of systems engineering. It comprises strategies, methods and tools for the creation and analysis of models of technical systems (Micouin 2014). MBSE represents a paradigm shift from the document-centric to a model-centric specification of system (Micouin 2014).

One key concern of MBSE is the utilization of the formalized modeling language systems modeling language (SysML) to create descriptive models of technical systems. Originally published in 2007 as a derivate of the unified modeling language, SysML is currently undergoing a major update to version 2.0 (Object Management Group Inc 2017).

The models built with SysML consist of a wide variety of entity and relation types to form the model and different diagram types to visualize the structure of the model. A technical system is mostly modeled in terms of a requirements structure, system structure and system behavior (Friedenthal et al. 2015). Typically the system modeling is conducted at early development stages to create an interdisciplinary model which then serves discipline-specific development as a reference (VDI 2206 2021). Additionally, simulation models may make use of the system model via interfaces to ensure that simulation parameter align with the real parameter set for their computations (Aiello et al. 2021).

The following trends in MBSE research can be extracted from literature:

Investigation of methods for definition of semantics and ontologies, which serve as meta-models for a consistent modeling of systems (Biffl et al. 2017; Schafer et al. 2017),

Linking and integration of MBSE and PLM for a lifecycle-spanning management and provision of system models for all stakeholders of the system (Brovar et al. 2022),

Supporting the development of sustainable products via a transparent integration of sustainability aspects within the system models (Halstenberg et al. 2019).

3.3 Digital Twins

The origin of the term “digital twin” was first introduced by Dr Michael Grieves in 2002 as a concept for the formation of a PLM center (Grieves and Vickers 2016). On a presentation slide (Conceptual Ideal for PLM) real space, virtual space and the linked data flow were set into context (Grieves and Vickers 2016). There are many different definitions of the DT and numerous authors have already set out to combine them into a single one (Eigner et al. 2021; Jones et al. 2020; Liu et al. 2021; VanDerHorn and Mahadevan 2021). VanDerHorn and Mahadevan (2021) consolidate 46 Definitions of DT to “a virtual representation of a physical system (and its associated environment and processes) that is updated through the exchange of information between the physical and virtual systems”, which will be used in the following paper as a foundation.

Nonetheless, the term DT is not sufficiently differentiated from many existing concepts throughout the whole lifecycle of products. There are overlapping definitions with concepts from PLM like as-designed, should-build, as-built, as-maintained-bill-of-materials. Furthermore, various virtualization concepts like CAX-tools, behavioral simulations, digital mockup and virtual reality (VR) or augmented reality (AR) concepts partially exist for several decades now (Grieves 2022). This fuzzy terminology bears the risk of preventing a conceptual differentiation between the DT and established concepts (Stark et al. 2020).

Still, some main trends can be identified in the area of DTs. For example, Perno, Hvam et al. (Perno et al. 2022) derive artificial intelligence (AI), internet of things (IoT), industrial internet of things (IIoT), VR/AR, hardware, communication technologies, knowledge building, design process and development technologies as the main enablers of DTs in the process industry. In contrast to that, system integration issues, security issues, performance issues, organizational issues, data quality issues and environmental issues were identified as main barriers (Perno et al. 2022). In addition to these aspects, managing the rising complexity of DTs following the complexity of their represented products is subject to current research (Orlova 2022).

Existing norms and standards on DTs and their creation currently exist in context of manufacturing systems defined by the International Organization for Standardization (ISO) as ISO 23247-1 (2021). Following the concept of linking virtual and physical space via a data connection the standard focusses on the definition of a framework for development, deployment and usage of DTs in the manufacturing context. It gives a comprehensive view on different domains and entities that form and use DTs in manufacturing. These entities are the observable manufacturing elements, the device communication entity, the DT entity, the user entity and a cross system entity. For each of them distinct requirements, objectives, necessary information and interface specifications are given. Although specialized on manufacturing systems this standard might be a template for adaption of DT utilization in other domains such as the process industry.

Building high-fidelity DTs is a challenging and time-consuming process. There are various approaches to constructing and maintaining DTs, each with its own advantages and disadvantages. Physics-based DTs, for example, use physical models to describe the behavior of a real system. The advantage is that these models are based on scientific principles and can therefore provide a high level of accuracy and predictive capability. This enables accurate simulations of system behavior and optimization of system performance in various applications such as engineering, manufacturing, and energy. Another example is data-driven DTs, which rely on machine learning algorithms to learn from data collected from the system (Erikstad 2017). The approach chosen depends on the specific requirements of the system and the goals of the DT. The different approaches have advantages and disadvantages. It is important to consider which approach is best suited to the context.

3.4 Data exchange standards

Product data or data of plants are usually located in different and heterogeneous management systems and searching the individual systems for information is time-consuming (Assouroko et al. 2014). To optimize information accessibility and to exchange data between native authoring systems and data management systems multiple standards have been developed over the years. The standard mostly used to exchange product-related data in the industrial environment is the standard ISO 10303 „Industrial automation systems and integration – Product data representation and exchange“, better known as standard for the exchange of product model data (STEP) (ISO 10303-1 2021). STEP includes a basic definition to describe models of product-related data. Using this underlying definition, multiple standards are derived focusing on different aspects. These concretized standards are referred to as application protocols (AP). APs can be understood as more general concepts, like AP 239 – product life cycle support (ISO 10303-239 2012) and AP 233 – systems engineering (ISO 10303-233 2012), or are specified for a specific topic like AP 215 – ship arrangement (ISO 10303-215 2004).

Some APs are explicitly related to process plants. “AP 227 – plant spatial configuration” defines a standard to exchange information about features and structure of geometrical elements of process plants via STEP-files (ISO 10303-227 2005). “AP 221 – functional data and schematic representation of process plants” describes how the functional design of systems and the engineering specifications of its components can be exchanged with STEP-files (ISO 10303-221 2007) or Jupiter-Tesselation files (ISO 14306 2017).

The ISO-standard ISO 15926 “Industrial automation systems and integration – Integration of life-cycle data for process plants including oil and gas production facilities” defines a data model which is, in conjunction with so called reference data, capable of managing data throughout the whole life-cycle of process plants (ISO 15926-1 2004). Based on ISO 15926 multiple exchange standards have emerged, like Proteus developed by the “Data Exchange in the Process Industry” consortium (DEXPI) (Papakonstantinou et al. 2019), iRingTools (Jeon et al. 2013) and the capital facilities information handover specification (CFIHOS) (van der Bijl 2018).

4 Results and analysis of resulting literature

4.1 Filtering relevant sources

The methodology presented in Section 2 resulted in 356 papers after level 1, which were evaluated by the authors following the systematic illustrated in Figure 2. IN and OUT scanning considered only papers, where at least 3 out of the 4 authors voted positively, without knowing the evaluation of the others. In Level 4, a snowballing method included referenced papers which were not detected by the query. After Level 2, 3 and 4, 69 publications remained to be further analyzed in Section 4, as shown in Figure 3. Papers identified as relevant by multiple RQs have been considered separately for each RQ, thus slightly distorting the overall total. After full text reading and snowballing, 54 publications are presented and analyzed in this section.

Visualization of resulting literature.

Both the absolute results (Figure 3) and plotted against the year of publication (Figure 4) show that there is constant research in the area of merging discipline-specific models (RQ1).

Analyzed research by year and RQs.

The use of DTs or similar to control process and power plants (RQ2) has increased in recent years due to advancements in industry 4.0 and the industrial internet of things. Literature for RQ3 dealing with the linking of RQ1 and RQ2 is scarce.

4.2 RQ1: existing concepts for unifying discipline-specific and interdisciplinary models of process plants

A model is a representation of something abstract or concrete that helps individuals to understand something or describe something. In the following, current possibilities and concepts are considered to unite the interdependent models of different disciplines in plant engineering. Making these models consistent with each other usually still involves a large amount of manual work (Rahm et al. 2017). The approaches to uniting different disciplines exist in different forms such as standards (Holm et al. 2012), software (Boy et al. 2016), text-based formats (Li 2010), graph grammar (Rahm et al. 2017, 2021), digital mockups (Oppelt et al. 2015) and is research subject in the interdisciplinary field of study of “computer supported cooperative work” (Boy et al. 2016). There is also research that addresses collaboration between different disciplines in creating and working with DTs in a 3D collaborative environment (Beisheim et al. 2022).

The interest group for automation technology in the process industry, originally named “Normenarbeitsgemeinschaft für Meß- und Regeltechnik in der chemischen Industrie” (NAMUR), defines processes, system requirements and advice that often form the basis for international standards. These development advances and findings are recorded in the form of NAMUR recommendations (NE – german for “NAMUR Empfehlung”). Some of these NEs deal with the description of interfaces between individual life phases and thus indirectly disciplines in plant engineering. NAMUR provides a recommendation for the synchronization network of data models in the process industry (Rahm et al. 2021)

Based on VDI/VDE 2658 Part 2 (2019), Wiedau et al. (2019) and Rahm et al. (2021) Figure 5 shows the data exchange interfaces proposed by NAMUR between individual disciplines in the life cycle of a process plant.

Exchange formats between disciplines across the plant lifecycle, based on Rahm et al. (2021), VDI/VDE 2658 Part 2 (2019) and Wiedau et al. (2019).

At the functional requirements stage, there is currently no formally standardized model, which means that data cannot be exchanged between automated interpretation systems (Rahm et al. 2021). In the functional design phase, on the other hand, a dominant data exchange concept already exists. NAMUR is not alone in considering DEXPI to be the leading pioneer in the exchange of design data in plant engineering. The international initiative DEXPI has set itself the goal of enabling interoperability between different partners involved in a plant project (Wiedau et al. 2019). Companies using plant data management systems, research partners (such as universities), ISO standardization bodies and various software manufacturers are involved in this development (Wiedau 2018). DEXPI’s research activities to date have focused on the development of an Extensible Markup Language (XML) standard for the exchange of flow diagrams in the form of P&IDs (Wiedau et al. 2019). This enables the import and export of piping and instrumentation diagrams (P&IDs) from computer aided engineering (CAE) software such as “COMOS” or “intergraph smart”. The name of this XML standard is Proteus as mentioned in Section 3.4 (Proteus XML 2018; Wiedau et al. 2019).

In the phase in which the asset is specified in more detail or is given a customer reference (Figure 5), NAMUR provides NE 159. At this point, plant development or design is brought together with the actual plant design planning or engineering. This is a potential way to generate a customized plant model from a customer-independent reference plant. Process and design variables of the sensors and actuators as well as the requirements derived from the process information are defined in this interface description (Rahm et al. 2021)

NAMUR and numerous other papers use automation markup language (AutomationML) as the serialization markup language in this process step (Holm et al. 2012; Rahm et al. 2021). Based on the automation-driven approach defined in the International Electrotechnical Commission (IEC) as IEC 62424, this standard defines a metamodel for describing and serializing plant data. AutomationML uses existing standard data formats and is based on IEC 62714 standardization. AutomationML includes the representation of the hierarchical structures of the plant using the computer aided engineering exchange (CAEX), which is based on the XML-format. CAEX was originally developed for data exchange between trades or disciplines of process planning. It was created because none of the data formats were uniform or established. The kinematics and geometry are described in the AutomationML context by collaborative design activity, abbreviated as COLLADA. This is an open standard to be established for the interdisciplinary exchange of 3D data (Drath 2021; Holm et al. 2012).

Commissioning is the start of the operation phase in the life cycle of a plant. The asset, or in this case the plant, now has a physical representation from which, for example, real measurement and quality data as well as live sensor data can be assigned. NE 150 describes the exchange of engineering data between CAE System and Process Control Systems. NE 100 describes the exchange of process control data with other disciplines. For this purpose, concrete information on the data to be exchanged and their use is defined (Rahm et al. 2021).

To prepare information from different disciplines for use in the automation sector in a logical and user-friendly way, the module type package (MTP) was developed. The MTP system provides access to many different functions by connecting to the modular plant’s process orchestration layer (VDI/VDE 2658 Part 2 2019).

Its attributes include access to services, parameters, instrumentation and the human machine interface (HMI). All components are categorized using an eCl@ss classification. MTP also uses AutomationML for its serialization (Hoernicke et al. 2022; Rahm et al. 2021).

The recommendations of NAMUR and other initiatives such as DEXPI or the neutral exchange formats are often based on standards. In the context of the RQ1, two standards should be mentioned here. IEC 62424 (IEC 62424 2016), which describes CAEX as a neutral data format in plant engineering and ISO 15926 (ISO 15926-1 2004), which promotes the shared use of data across disciplines. The generic data model defined within ISO 15926 contains various entities that can be used to integrate wide variety of data from different disciplines during a plant life cycle which can be represented and linked. In addition, the standard follows the approach of the 1:n relationship between an abstract object and a possible individual instance, which is widely used in computer science. This means that there is an implicit link between the domains that do not yet have a customer reference, such as research and development and the domains that relate specifically to existing projects and thus later real physical process plants (Holm et al. 2012).

Scientific work exists that addresses the use of the asset administration shell (AAS) in combination with the ISO 15926 standard to facilitate the exchange of data about the condition and health of equipment in a process plant. The AAS acts as a framework for integrating data, allowing heterogeneous data sources to be accessed and provided in a consistent format (Kim et al. 2022).

The standard series defines semantic relationships between the defined entities and maps these in the web ontology language (OWL) using the resource description framework (RDF) (ISO 15926-7 2011; ISO 15926-8 2011). Like the AAS, which is based on AutomationML (Bader et al. 2022), the RDF is a data technology option for addressing and communicating an asset across disciplines (Gašević et al. 2009). All data associated with the asset are assigned from the most diverse disciplines (Ma et al. 2016).

Creating discipline-specific data models for a process plant requires a lot of time and manual effort during planning (Rahm et al. 2017). To counteract this, the triple graph grammar (TGG) has been created to map discipline-specific data models to each other (Cicchetti et al. 2011; Rahm et al. 2017; Samimi-Dehkordi et al. 2016).

The various models of the disciplines involved have a considerable semantic overlap. Changes in one model inevitably lead to changes in another. By using the TGG transformation language, formal rules are created and the models are connected with each other (Rahm et al. 2021). Figure 6 describes the correspondence between the data model of a P&ID and an HMI. The data from the data models are first put into XML form and then mapped to each other using a source graph and target graph (Rahm et al. 2017).

Correspondence between a P&ID and HMI model (Rahm et al. 2017).

Like the research just described, Kremer et al. (2022) explore the cross-discipline connection between P&ID and 3D models. If something changes in the P&ID, this is consistently adjusted in the 3D model and vice versa. This connection allows for a consistent representation of mechanical and process engineering models that were previously developed in separate disciplines (Kremer et al. 2022).

The results are models with the highest possible degree of consistency (Schürr 1994). Another methodology for describing the relationship between two or more models is the query/view/transformation (QVT). Here, like TGG, the relationship is made describable by rules, which are the basis for model transformation (Greenyer and Kindler 2010).

The linked data technology creates a single data access point. Metadata can be pulled from many heterogeneous sources to be combined into a linked data cloud using specialized converters. The semantics of each individual source can be transferred into a higher-level logic with appropriate effort (Figure 7) (Graube et al. 2011).

Different disciplines use different concepts that can be harmonized by Linked Data technology (Graube et al. 2011).

Furthermore, Mun et al. (2008) categorize studies on the exchange of product data between systems into three research areas. Firstly, the exchange of feature-based CAD models between different CAD systems in different organizations. Secondly, the exchange of product data between different PDM systems in a distributed environment and finally, the exchange of product data between CAD systems and their downstream applications such as computer-aided process planning and Computer-aided manufacturing across product lifecycle (Mun et al. 2008).

Zhang et al. (2015) present an asymmetric strategy to enrich the theory of feature-based interoperability of CAD data in the context of collaborative product development (CPD). Due to the growing technical complexity within a company, there are often several CAD systems coexisting that are predestined for individual disciplines. The approach of Zhang et al. (2015) describes methods to keep this CAD model interoperable across disciplines.

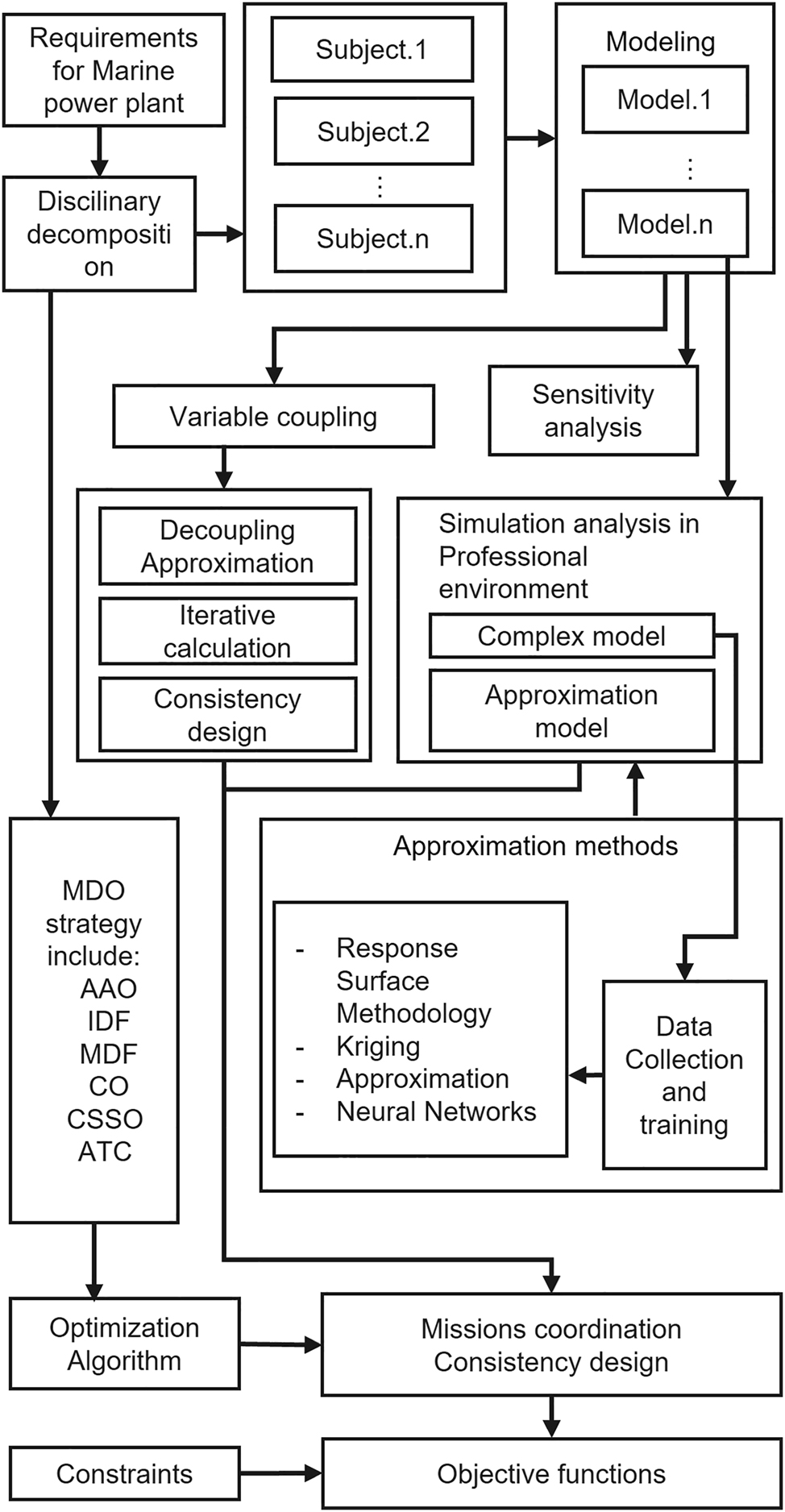

Yin et al. (2017) investigate multi-disciplinary design optimization (MDO) for marine power plant. Multi-disciplinary design optimization solves design problems by combining many disciplines. It uses methods from multiple fields of expertise to create a global optimum solution. Using the example of a shaft design containing shaft alignment and lateral vibration, the MDO for shaft system is studied as shown in Figure 8.

MDO frame for marine power plant design acc. to Yin et al. (2017).

First, the requirements for the marine power plant are divided into requirements within the different technical disciplines. Subsequently, discipline-specific models are generated. Different MDO strategies are applied such as all-at-once (AAO), individual disciplinary feasible (IDF) and multidisciplinary feasible method (MDF). By combining different variables across disciplines, cross-disciplinary optimization can be performed. A sensitivity analysis describes how strongly individual variables depend on each other.

In summary NAMUR already describes many recommendations on how interfaces between life cycle phases and disciplines in plant engineering can be designed. The IEC 62424 (2016) and ISO 15926-1 (2004) standards are relevant for the data-related consolidation of different disciplines in plant engineering. To connect data models from these different disciplines with each other, the bidirectional model transformation TGG and QVT can be used. DEXPI is the leading initiative for the interdisciplinary exchange of design data in plant engineering. In addition, many strategies exist to optimize data exchange and data consistency across disciplines.

4.3 RQ2: existing concepts for managing physical plants (e.g.: DTs)

This RQ concentrates on existing implementations of managing or controlling physical plants during operation. While there are many applications which introduce DT as stated in Section 3, this RQ focuses on the integration of DT in control and management of plants during operation.

Geddes (1998) developed a real-time simulation model of a 200 Mega Watt (MW) thermal power plant for optimizing combustion control. A computer power plant model was designed and validated using data collected by a data server. This plant model formed the basis of a virtual plant system that included an industrial standard distributed control system with multiple operator screens on a local area network.

Research is found in the context of the “virtual power plant” (VPP), which was first introduced as a “virtual utility” in 1997 by Awerbuch and Preston (1997). VPP facilitate the integration of distributed energy resources in the power system (Sarmiento-Vintimilla et al. 2022). She et al. (2017) use the concept of the VPP for an operation and scheduling model based on an energy blockchain network. The combination of this network and the VPP leads to an optimized model, which can reflect the real-time information of the electricity demand. This enables the environmentally friendly and transparent stable scheduling of the plant while improving data and storage security (She et al. 2017).

Chemnitz et al. (2021) focus on the central role of virtual power plants in flexible electricity networks. They define a set of principles for data governance models within the VPP:

“Collective bargaining: The asset owners should be able to bargain collectively about the conditions and purposes of the data flows. This includes which supplementary data flows to include and how to utilize them.

Representation: The asset owners should be represented in a central organizational governing body, which is in charge of defining and overseeing the data principles.

Disruptive measures: The asset owners should be able to limit or halt core data flow, allowing them to assert power and symmetry in the relation with the aggregator.

Accountability: Transparency measures should be put in place to ensure the asset-owners ability to audit the data usage performed by the aggregator, in order to detect misuse and assign accountability” (Chemnitz et al. 2021).

Within this work, Khatri and Brown (2010) are cited for their five decision domains of data governance consisting of data principles, data quality, data lifecycle, metadata and data access.

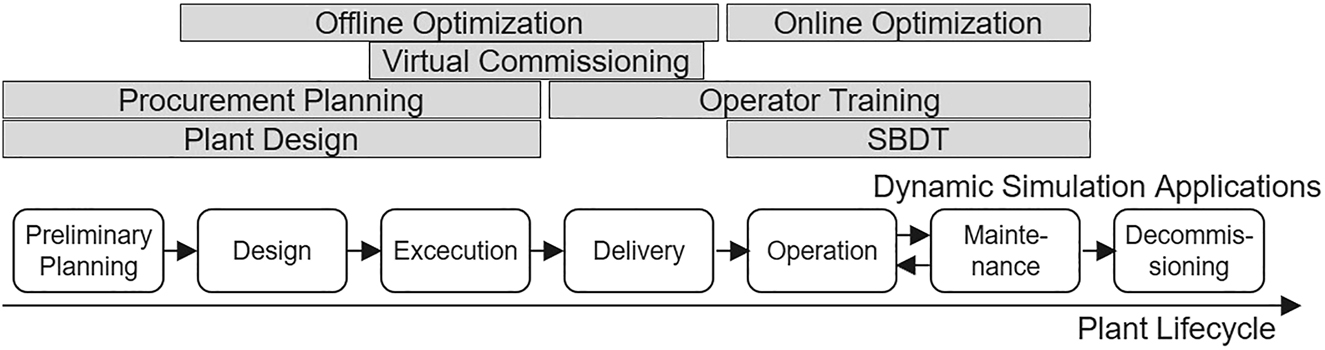

Martinez et al. (2018a) propose the automatic generation of so-called simulation-based DT (SBDT) of industrial process plants. As the main obstacles for the wider industrial adoption of SBDTs they identify laborious development of their underlying first-principles simulation model and a lack of integrated lifecycle-wide implementation methods and simulation architectures (Martinez et al. 2018a). The architecture of an SBDT can be seen in Figure 9.

SBDT over the plant lifecycle according to Martinez et al. (2018a).

Martinez et al. (2018b) similarly develop a method to derive a process simulation model from a 3D plant model. This is due to its proximity to RQ3 further analyzed in Section 4.3.

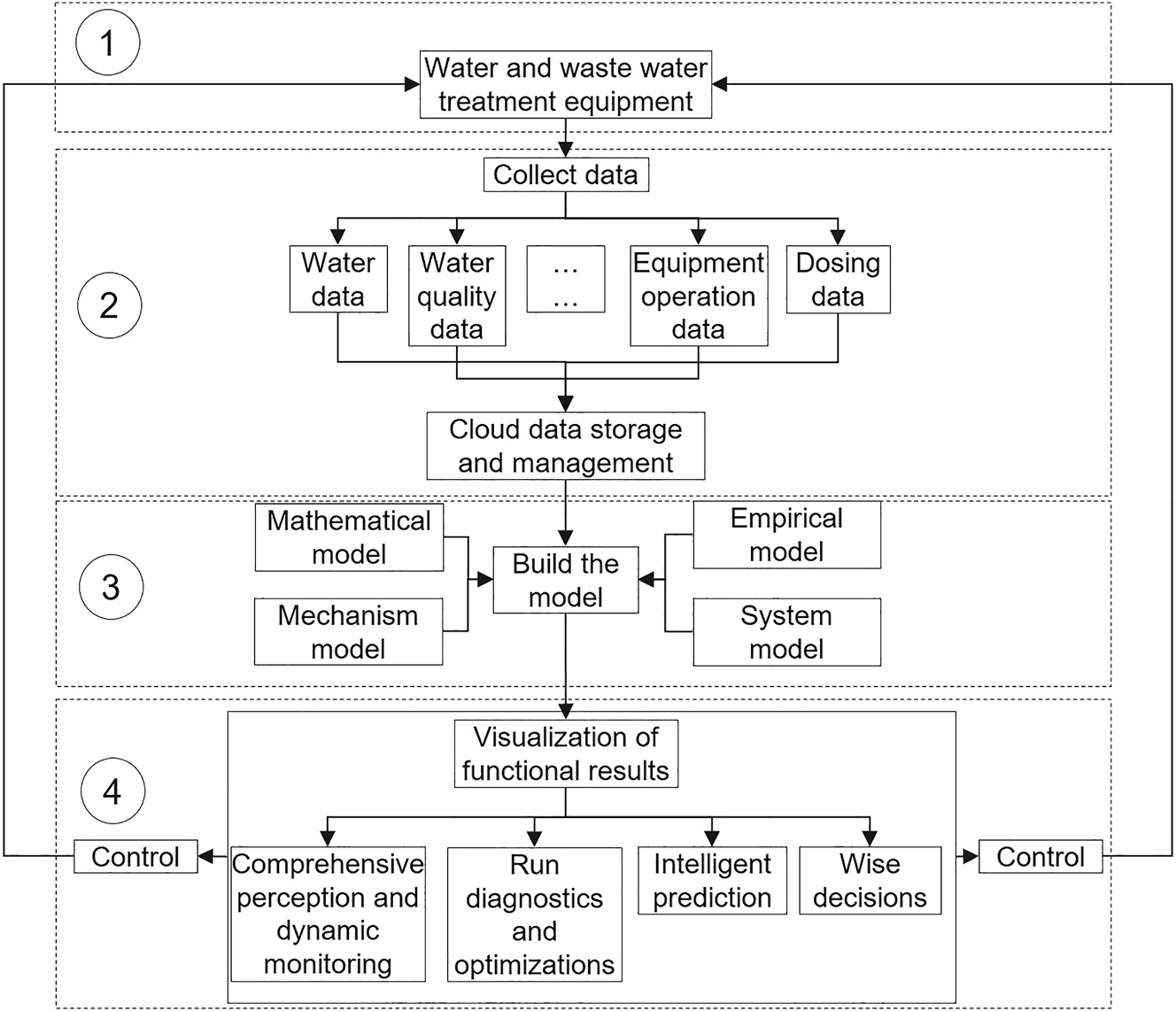

Ji et al. (2021) took a chemical water production system as an example aiming on early fault warning and fault diagnosis with the help of DT. A model shown in Figure 10 is derived with the ability of self-adaptive optimization, self-learning diagnosis, self-recovery processing and self-organization management (Ji et al. 2021).

Model for water production data management by Ji et al. (2021).

Their final architecture is visualized in Figure 11 and is separated in the four layers physical (1), data (2), model (3) and functional (4) (Ji et al. 2021).

Architecture of an intelligent management system by Ji et al. (2021).

Sleiti et al. (2022) propose a robust DT for power plants and other complex capital-intensive large engineering systems and derive the following requirements for the DT architecture:

“The DT must have the up-to-date physical dimensions and model (System Genome or SGenome) of the physical twin – The DT must age” as the physical twin does

The DT must accept and process continuous data stream from a multitude of sensors (referred to as distributed sensor network (DSN) – just as a human brain does.

Must include a low-order, physics-based, dynamic system model (DSM) that can run in real-time. This is essentially the cyber–physical model or system of the physical twin.

Must be able to detect, in real-time, anomalies based on data received from DSN, to apply machine learning or deep learning principles to identify the serious anomalies. This feature is referred to an anomaly detection and deep learning (ADL).

Must be able to refer to a look-up table of previously performed localized, in-depth simulation (LDS) solutions to explain differences between ADL and DSM and update system genome.

Must be able to trigger alarms and warnings in real-time that would lead to maintenance schedules and/or suggest off-line, new LDS in case of unexplained disagreements.

Must be able to answer what–if scenarios for transient operation or changes.” (Sleiti et al. 2022)

Junior et al. (2021) present a DT design for a thermal power plant cooling system based on sensor data. A combination of an automatic rules extraction approach to form the model’s knowledge database, the principal component analysis technique and an algorithm for automatic update of rules during the operation is used, enabling the model to learn during the operation without the need for retraining while reducing errors of the model’s response. The data of all sensors are stored in the database using plant information management systems (PIMS) software (Junior et al. 2021).

Lei et al. (2022) develop a web-based interactive model of a power plant with five different aspects, enabling the monitoring and control of the power plant via web browsers. The five aspects consist of real-time monitoring, visualization, real-time interaction, virtual reality and algorithm design. Furthermore, the potential of overcoming issues such as cyber-attack, communication and interdisciplinary collaboration constraints is shown. This interactive model can also be used for education and training purposes (Lei et al. 2022).

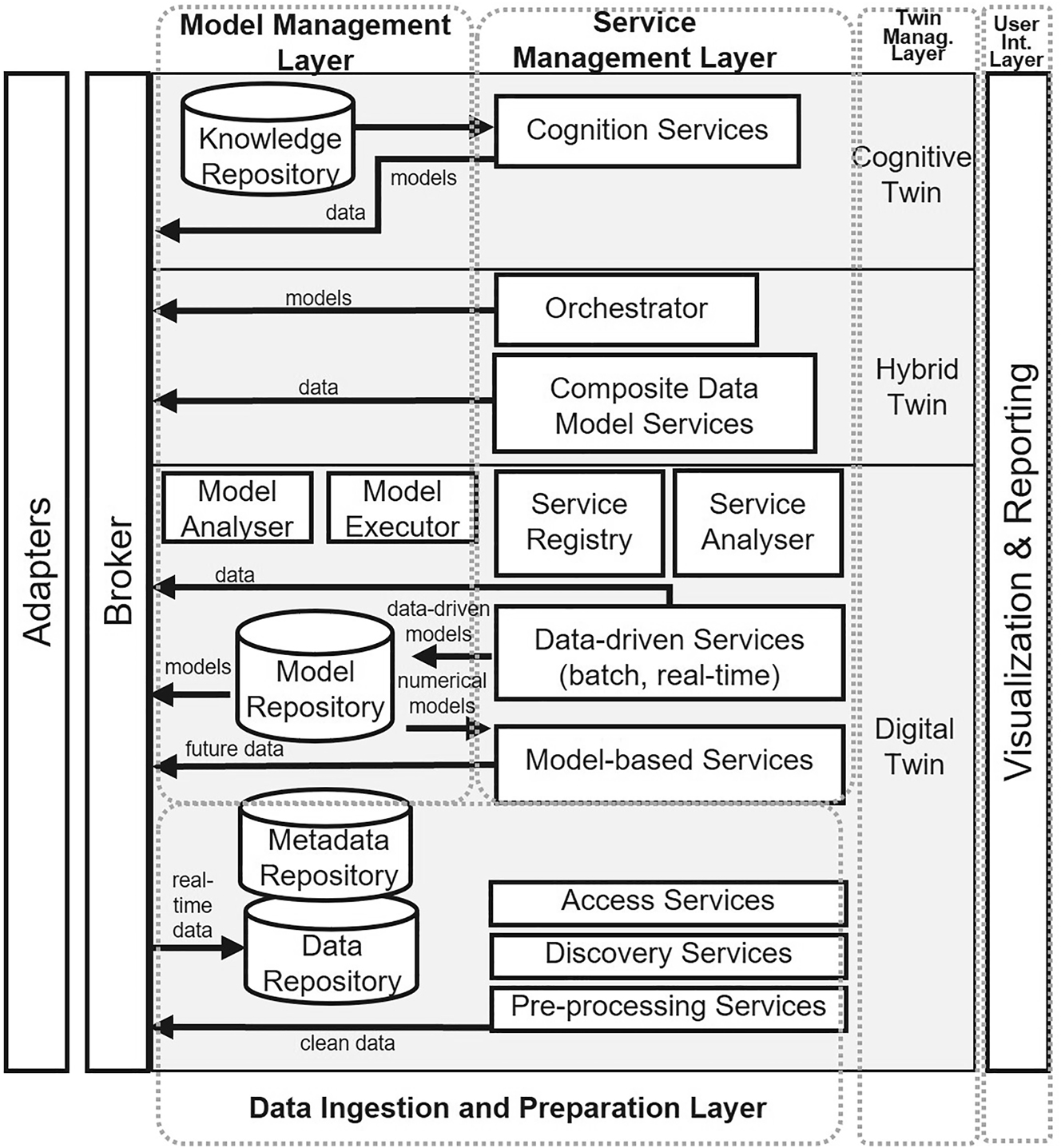

Abburu et al. (2020) propose a conceptual approach to improving the functionality of DTs by introducing them around the notions of hybrid and cognitive twins and describe a toolbox-based solution called COGNITWIN to realize this vision. This toolbox (Figure 12), focused on the process industry, is intended to provide methods and tools that support the entire lifecycle of a twin, from modeling, generation, connection, operation, reuse, sharing and continuous improvement.

Architecture and layers of Cognitwin toolbox acc. to Abburu et al. (2020).

They focus on the interfaces to external tools for data exchange and model execution and to other DTs. Also, they focus on the need to represent the internal structure of a DT in a standardized way to avoid vendor lock-in was shown. Finally, for the meta-model the following requirements considering metadata, data and references to other DT are mentioned: (Abburu et al. 2020)

“Metadata:

Static data: asset, manufacturer, location, etc.

Dynamic data: a list of relevant multimodal parameters including the metadata about the parameters (e.g., unit of measurement, frequency, quality, etc.).

Models: a list of relevant models including a model type, the input/output parameters, etc.

Data: a local or remote storage of the multimodal data.

Models: for each model a local or a remote storage of the model as well as a service (or a reference to it) for the model execution.

References to other DTs: association, inclusion, etc.” (Abburu et al. 2020)

The proposal of instantiating a concrete DT for a given system is stated (Abburu et al. 2020). According to Abburu et al., there are three options to do this. Firstly, this can be done manually by filling in a template, secondly by writing code to extract the needed information from relevant software systems or hardware systems. By combining/reusing existing DTs, while conformance checking should be always applied to ensure that the created DT model conforms to the metamodel.

4.4 RQ3: existing concepts for connecting engineering models and DTs of process plants

This RQ focuses on application and research results in the process industry, where the engineering models from development and detail planning are used during operation of the plant. This can be in the form of different use cases such as monitoring and optimization or as foundation for different DTs.

Romero-Jimenez et al. (2009) develop a 25 MW geothermal power plant full scope simulator based on a control system graphical modeling. The Cerro Prieto-IV simulator is a replica of the real power plant thanks to main characteristics of the main graphical model of the distributed control system (DCS).

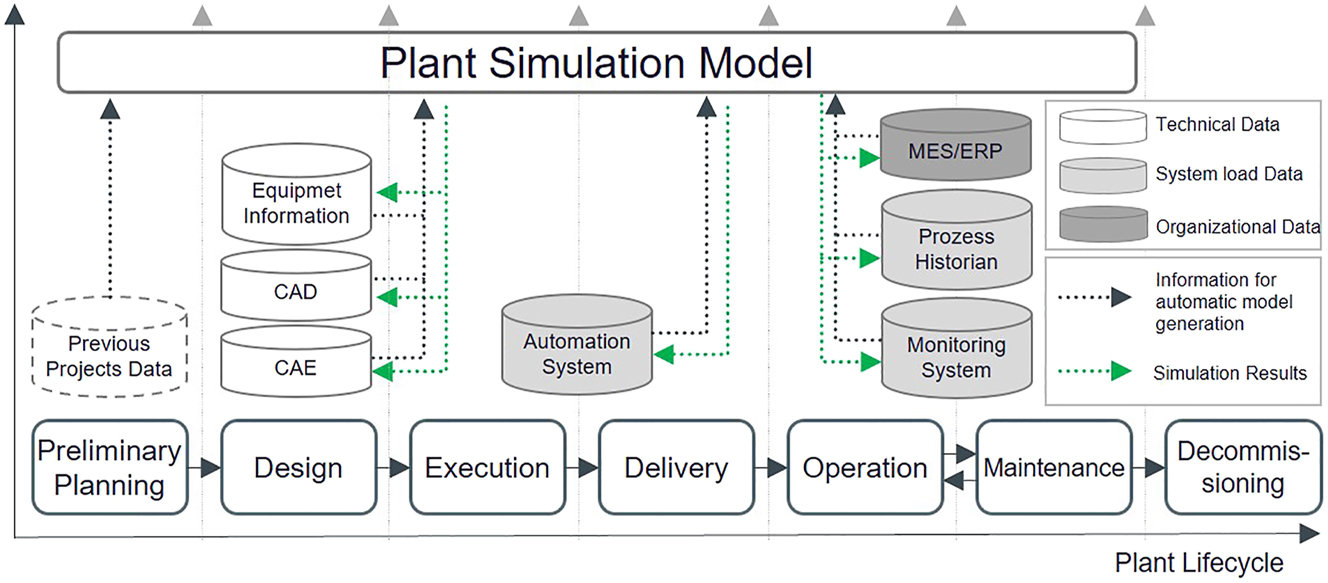

Martinez et al. (2018b) present a method for automatic generation of a thermal-hydraulic process simulation model from a 3-D plant model. Detailed 3-D plant models, which are developed during early plant engineering for process design, are used as a source of information to enable rapid development of high-fidelity simulation models. As an example, information about the piping dimensions and elevations is retrieved from the 3-D plant model and used to calculate head loss coefficients of the pipelines and configure the piping network model visualized in Figure 13 (Martinez et al. 2018b).

Applications of the derived process simulation model by Martinez et al. (2018b).

Furthermore, an overview of available data sources for the model generation is given in Figure 14 differentiating in technical, system load and organizational data (Martinez et al. 2018b).

Availability and classification of data sources for model generation acc. to Martinez et al. (2018b).

Mun et al. (2008) utilize a neutral model to share product data of nuclear power plants across their lifecycle. With the goal of establishing an information bridge between design and operation and maintenance (O&M) phases, the generic product model (GPM) introduced by Hitachi (Koizumi et al. 2004) in 2004 is extended. With the construction of a neutral data warehouse the Korean nuclear power plant information sharing system (KNPISS) was developed. They identify three major objectives. Firstly, many types of application systems are used in different departments at different phases across a plant lifecycle, each having their own native models that provide a certain level of automation capabilities. Secondly, operators of process plants receive and maintain design and construction information in a variety of different formats, including electronic files and hard copies. This results in data interoperability and maintenance problems. Finally, even though each organization reaches a certain level of automation for itself, data sharing among multiple collaborating organizations remains a challenge (Mun et al. 2008). To overcome these objectives, the developed architecture of KNPISS (Figure 15) consists of a neutral model, a design interface, an intelligent browser and an O&M-interface. The main users of this framework consist of the plant developer, which is graphical represented by Korea Plant Engineering Co. (KOPEC) and the plant operator, represented by Korea hydraulic and nuclear power (KHNP).

System architecture of KNPISS (Mun et al. 2008).

Naciri et al. (2011) also enhance the Hitachi GPM model (Koizumi et al. 2004) for enterprise resource planning (ERP) data. This is done by developing a data sharing framework based on converting flat excel files to structured GPM data (Naciri et al. 2011).

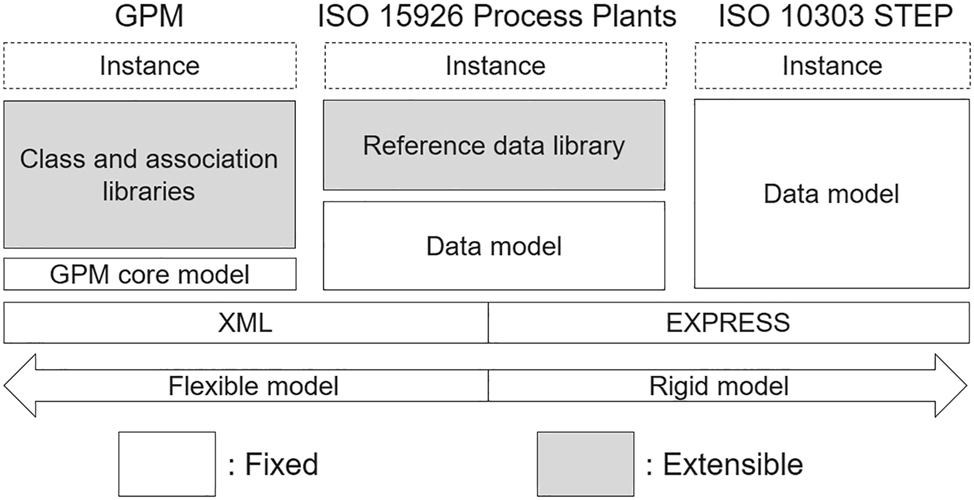

Mun and Yang (2010) develop an integrated translation of design data of a nuclear power plant from a specification-driven plant design system to neutral model data. Due to their translation into neutral model data in an integrated manner, various kinds of data created in the design phase, such as 2-D schematic diagrams and 3-D solid data, logical configuration information and plant items specification information, can be used for effective operation and maintenance in plants with a long-term lifecycle (Mun and Yang 2010). They also visualize the differences between GPM, ISO 15926 and data exchange with STEP format in Figure 16.

Comparison of GPM, ISO 15926 and STEP acc. to Mun and Yang (2010).

Kim et al. (2020) propose an ISO 15926–based integration method of process plant life-cycle information including maintenance activity. They develop a data model, which covers the entire lifecycle of a facility from concept to operation and maintenance. This model is a high-level data structure as a backbone from which detailed life-cycle data at each stage are populated and linked.

To keep this data model consistent, information objects at each state are instantiated with persistent identifiers and are integrated with other information objects. Detailed data generated from commercial engineering systems can be linked to those information objects. With this method they enable the combination and integration of life-cycle data for a process plant in different formats from different IT-systems. In this case the synchronization of life-cycle data is possible based on the data model when life-cycle objects are changed according to maintenance activities. With this, consistency and availability of life-cycle data in process planning and the control for the operation and maintenance of a process plant are secured (Kim et al. 2020).

Barszcz and Czop (2012a) introduce the optimized usage of the concepts of VPPs (introduced in Section 4.3) in a derived environment where the novelty is the combination of first-principle and data-driven models of power plant components that allows absorbing and utilizing of different forms of existing knowledge concerning parameters of the modeled system. Their VPP is characterized by

“a flexible structure enabling multiple configurations to be defined,

an ability to import data acquired at the object,

the possibility to store models of each component in different versions,

for models of moderate complexity, an ability to achieve performance close to the real time and

an ability to present results in either an advanced or a simplified form, for experts and operational staff of power plants, respectively.” (Barszcz and Czop 2012a)

The software infrastructure and the applicability of the method is also demonstrated on an existing coal-fired steam turbogenerator (Barszcz and Czop 2012b). The VPP project connects data-driven models of the power plant and is therefore allowing the absorbing and utilizing of different forms of existing knowledge regarding the parameters of the modeled system. The feedwater heater model of the coal-fired steam turbogenerator is presented in detail, starting from design data, through equations, implementation details in the first part of the work, to end at the component-based validation presented in this part of the work. In short, the VPP is a virtual laboratory for model-based diagnostics of power plant components (Barszcz and Czop 2012b).

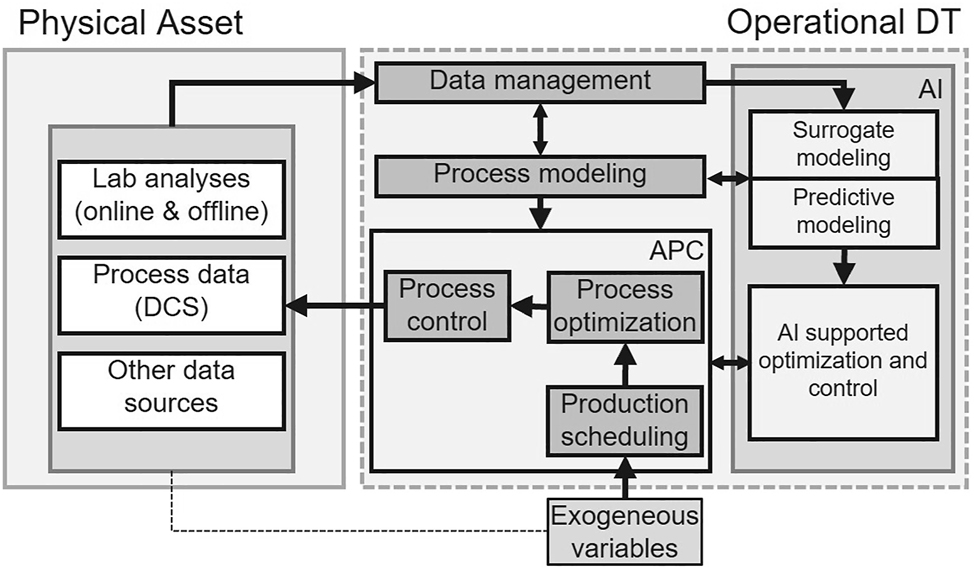

Örs et al. (2020) propose a conceptual framework for an AI-based operational DT (ODT) in chemical process engineering. The main building blocks of this ODT consist of data management, process modeling, advanced process control (APC) and AI-supported optimization and control as shown in Figure 17. They strongly emphasize, that the establishment of a data historian is a must-have prerequisite for the successful implementation of an ODT (Örs et al. 2020).

ODT framework acc. to Örs et al. (2020).

A hybrid modeling framework combining physical mechanism and operation data to develop gray-box models of thermal systems is proposed by Yu et al. (2022) and used for an in-service thermal power plant. Using historical operation data for a gray-box model, a high precision (0.79 % error) of the modeling method is demonstrated (Yu et al. 2022).

Ospina-Bohórquez et al. (2023) use DTs during the construction of a wind farm. By comparing the as-designed models and the as-built models they thereby help to control deviations that may occur during construction. With a video game-type interactive application and a timeline tool, their allow going through the construction stages recorded in the as-built models and comparing them to the as-designed model (Ospina-Bohórquez et al. 2023).

5 Key findings and identified knowledge gaps

While Section 3 provided an overview of different state-of-the-art topics such as PLM, MBSE, DTs and data exchange, the focus of Section 4 is set on examining the results of the search strings and snowballing of the three RQs, respectively. In Section 5 the key findings and knowledge gaps are summarized.

5.1 Key findings

The analysis of RQ1 states that Namur has already described numerous recommendations on how interfaces between life cycle phases and disciplines in plant engineering should be designed. TGG and QVT is used for bidirectional model transformation between two disciplines. DEXPI is the leading initiative for the interdisciplinary exchange of design data in the plant engineering industry. IEC 62424 and ISO 15926 are relevant for the data-related consolidation of different disciplines. Multi-disciplinary design optimization is a method used to optimize all discipline-specific models of a process plant according to certain optimization criteria.

Derived from RQ2, various DT applications focusing on condition monitoring, maintenance and the overall control of plants are investigated. These models are mostly referred to as DTs defined in Section 3.2. For model development, VPP is used as they already represent the plant in a virtual form. Another concept is shown where simulations were consistently generated and compared with live data. A web-based interactive model of a power plant can enable real-time monitoring, visualization, real-time interaction, virtual reality applications and algorithm optimization. The concept of the Cognitwin supports the entire lifecycle of a DT, from modeling, generation, connection, operation, reuse, sharing and continuous improvement.

Both the concept of the GPM model and the VPP are adapted to fulfill the need of consistent data along the lifecycle of the process plant. These ideas are integrated with standards such as ISO 15926. While many publications cite the need to create a data historian to enable the analysis of earlier versions of the process plant, this is extended by the need for instantiation. Kim et al. (2020) and Abburu et al. (2020) identify the requirement to “instantiate” information objects and therefore enable a link to native engineering systems.

5.2 Identified knowledge gaps

Although the Namur initiative provides an interface for semi-automatic, bidirectional, data exchange between CAE-tools and process systems engineering (PSE) engineering tools such as NE 159 or NE 150, the lack of a standardized method for the structured exchange of customer requirements is noted. No sources are identified on how to capture customer requirements in a standardized way so that they can be used seamlessly in the plant engineering data model. Furthermore, it is not clearly defined in the literature according to which generally valid rules or criteria it can be decided which discipline is dominant when information from different disciplines is described differently.

Even though there are use cases, where the engineering models resulting from plant development are further utilized in the control and management of the plant, most presented solutions are created individually. The foundation for these is partly provided by standards used in the industry, such as the GPM model or the VPP.

Furthermore, process plants are becoming more and more part of the energy grid as e.g. electrolyzer consume electricity and need to be further connected into classical power plants with recent developments in power-to-X (Rego de Vasconcelos and Lavoie 2019).

In the field of process plant engineering, safety and risk management are crucial aspects that need to be carefully considered throughout the entire lifecycle of a plant. However, the review finds a gap in the literature regarding the incorporation of these aspects into the existing interdisciplinary models and DTs of process plants. The authors identify a lack of clear guidance or standard practices for how safety and risk management should be done in an interdisciplinary and digital context. Future research should focus on developing new methods and tools for modeling and analyzing safety and risk in process plants, and for integrating these aspects into existing models. This could include exploring the use of artificial intelligence, machine learning, and other advanced technologies. Ultimately, such research could lead to the development of more comprehensive and effective tools for managing safety and risk in process plants, and to improved overall plant performance.

Furthermore, it became apparent that there is little research regarding the integration of sustainability and circular economy principles in plant design and operation. While some literature references touch on this topic, there is a lack of systematic approaches that integrate these principles throughout the entire plant lifecycle. Additionally, there is no consensus on how to quantify the sustainability performance of a plant, or how to benchmark performance against industry-specific standards. To address this gap, future research should focus on developing methods to incorporate sustainability and circular economy principles in plant design and operation, including the selection of materials, energy efficiency, waste reduction, and environmental impact. This should also identify metrics and standards to assess the sustainability performance of plants, as well as potential opportunities for improving plant sustainability through technology innovation and policy intervention.

While there is research on how to increase efficiency and cost-effectiveness in the plant engineering process in general, the authors identify few articles taking this to a multidisciplinary level. While some existing solutions utilize digital models to improve collaboration and reduce errors, few address the full lifecycle of the plant design and construction process. Further research is needed to identify methods for optimizing the process from early design stages through to commissioning and handover, with a focus on reducing overall construction time and costs while maintaining safety and quality standards.

Additionally, more work is needed to investigate how digital technologies such as virtual commissioning and simulation can be used to further optimize plant design and construction, ultimately improving the economic viability and sustainability of process plants.

Not one given research or solution utilized the methods and tools of MBSE to create an interdisciplinary model of process plants. Hence, the advantages of MBSE which are evident in other domains such as aerospace and automotive remain unused for process plants. Further research should be conducted to evaluate the benefits of MBSE for process plant design and subsequent lifecycle-phases.

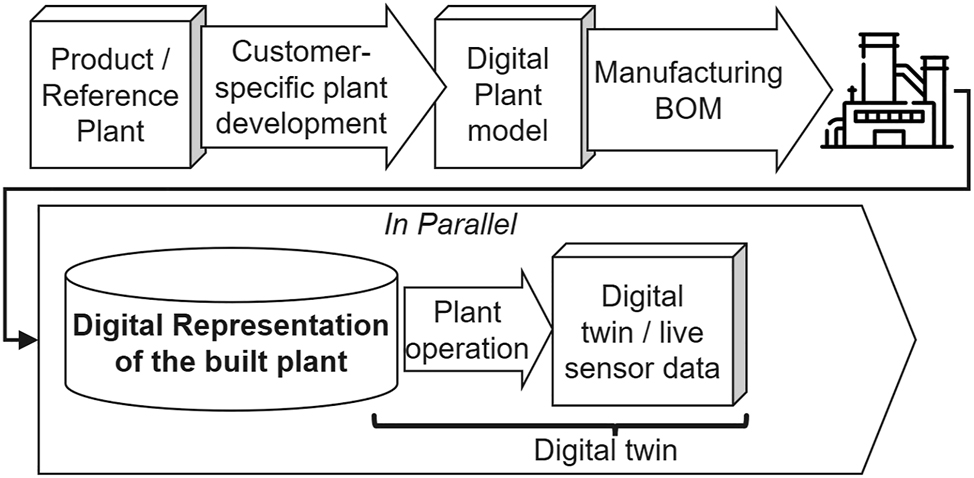

While various approaches and literature could be found for the first two RQs, the authors recognize that the question of linking engineering models to DTs should be investigated further. The creation of a so-called “reference plant”, a “digital plant model” and a “digital representation” of the plant is proposed by Saske et al. (2022) visualized in Figure 18. This plant lifecycle management concept can bridge information exchange limits throughout the lifecycle and disciplines.

Proposed concept for a derived and reduced “Digital Representation” of the process plant in acc. with Saske et al. (2022).

As one central key finding, plant data is usually located in different and heterogeneous management systems and searching the individual systems for information is time-consuming. An interdisciplinary digital representation of a process plant requires that all relevant data can be accessed centrally. For this purpose, a superordinate middleware can be an approach that integrates the heterogeneous data sources of the individual systems and thus presents data of the process plant or its assemblies and individual parts in a consolidated form.

To keep information consistent and avoid redundancy, information should be instantiated in parallel to the engineering and construction of the plant. The resulting digital representation of a plant should bundle all relevant information by linking it to the native data systems of the disciplines. For analysis of the plant in operation, the as-built status can thus serve as the basis for various DTs. The authors will focus on linking the instantiation of the digital representation with its respective customer requirements and the EPC phase.

6 Summary and outlook

Based on a comprehensive literature review, a current overview of different approaches to data management for process plants is given. Special attention is paid to the questions of which concepts exist to unify discipline-specific and interdisciplinary models of process plants, which concepts exist to manage physical plants from a data perspective (e.g.: DTs) and which concepts exist to connect engineering models and DTs of process plants. The authors are proposing the construction of a digital representation bridging information between disciplines and lifecycle phases as stated in Section 5.2.

For future research, questions arise on how modularization approaches such as module type package or similar can be integrated into a new integrative plant lifecycle management such as the digital representation for process plants. The open question is, how requirements engineering will be connected to the existing functional-references and how the automated creation of different DT applications can benefit from the proposed digital representation of the plant. Also, an optimized approach to identify relevant information depending on the subsequent usage is required.

The DT, which brings together different disciplines and allows them to collaborate, is one of the technical trends of recent years. While this promising technology has already become widespread in product development or vehicle construction, the process industry is not yet as advanced in many aspects. The analysis within this paper describes the potential of this technology and which gaps the authors aim to close with their current and future developments.

The concept of DT has the potential to transform the way multidisciplinary systems are developed and used. Development in the process industry is still in its infancy. However, current research and development efforts are progressing at a rapid pace and have the potential to make the future of DT in multidisciplinary systems transferable to and further developed for other domains and industries.

-

Author contributions: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: The research is being carried out as part of the research project “DIAA-H2 – Digitale Abbilder für Anlagen zur H2-Gewinnung” and is funded by the German Federal Ministry for Economic Affairs and Climate Action under grant number 03EI3067.

-

Conflict of interest statement: The authors declare no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Abbreviations

- AAS

-

Asset Administration Shell

- AAO

-

All-at-Once

- AI

-

Artificial Intelligence

- AP

-

Application Protocol

- APC

-

Advanced Process Control

- AR

-

Augmented Reality

- AutomationML

-

Automation Markup Language

- CAD

-

Computer Aided Design

- CAE

-

Computer Aided Engineering

- CAEX

-

Computer Aided Engineering Exchange

- CFIHOS

-

Capital Facilities Information Handover Specification

- COLLADA

-

Collaborative Design Activity

- CPD

-

Collaborative Product Development

- DCS

-

Distributed Control System

- DEXPI

-

Data Exchange in the Process Industry

- DIAA-H2

-

Digitale Abbilder für Anlagen zur H2-Gewinnung

- DSM

-

Dynamic System Model

- DSN

-

Distributed Sensor Network

- DT

-

Digital Twin

- EPC

-

Engineering, Procurement and Construction

- ERP

-

Enterprise Resource Planning

- GPM

-

Generic Product Model

- HMI

-

Human Machine Interface

- IDF

-

Individual Disciplinary Feasible

- IEC

-

International Electrotechnical Commission

- IIoT

-

Industrial Internet of Things

- IoT

-

Internet of Things

- KHNP

-

Korea Hydraulic and Nuclear Power

- KNPISS

-

Korean Nuclear Power Plant Information Sharing System

- KOPEC

-

Korea Plant Engineering Co.

- LDS

-

Localized, In-Depth Simulation

- MBSE

-

Model-Based Systems Engineering

- MDF

-

Multidisciplinary Feasible methode

- MDO

-

Multi-disciplinary Design Optimization

- MTP

-

Module Type Package

- MW

-

Mega Watt

- NAMUR

-

Normenarbeitsgemeinschaft für Meß- und Regeltechnik in der chemischen Industrie

- NE

-

NAMUR Empfehlung

- ODT

-

Operational Digital Twin

- OWL

-

Web Ontology Language

- O&M

-

Operation and Maintenance

- PDM

-

Product Data Management

- PIMS

-

Plant Information Management Systems

- PLM

-

Product Lifecycle Management

- PSE

-

Process Systems Engineering

- P&ID

-

Piping and Instrumentation Diagram

- QVT

-

Query/View/Transformation

- RQ

-

Research Question

- RDF

-

Resource Description Framework

- SBDT

-

Simulation-Based Digital Twin

- STEP

-

Standard for the Exchange of Product model data

- SysML

-

Systems Modeling Language

- TGG

-

Triple Graph Grammar

- VPP

-

Virtual Power Plant

- VR

-

Virtual Reality

- WoS

-

Web of Science

- XML

-

Extensible Markup Language

References

Abburu, S., Berre, A.J., Jacoby, M., Roman, D., Stojanovic, L., and Stojanovic, N. (2020). COGNITWIN – hybrid and cognitive digital twins for the process industry. In: 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, pp. 1–8.10.1109/ICE/ITMC49519.2020.9198403Search in Google Scholar

Abramovici, M., Savarino, P., Göbel, J.C., Adwernat, S., and Gebus, P. (2018). Systematization of virtual product twin models in the context of smart product reconfiguration during the product use phase. Proc. CIRP 69: 734–739, https://doi.org/10.1016/j.procir.2017.11.025.Search in Google Scholar

Adamenko, D., Kunnen, S., Pluhnau, R., and Nagarajah, A. (2019). An approach for knowledge-based requirements definition for re-engineering of the process plant. In: 2019 IEEE International Systems Conference (SysCon), 8–11 April, Orlando, FL, USA, pp. 1–8.10.1109/SYSCON.2019.8836865Search in Google Scholar

Adwernat, S., Wolf, M., and Gerhard, D. (2020). Optimizing the design review process for cyber-physical systems using virtual reality. Proc. CIRP 91: 710–715, https://doi.org/10.1016/j.procir.2020.03.115.Search in Google Scholar

Aiello, O., Del Kandel, D.S.R., Chaudemar, J.-C., Poitou, O., and Saqui-Sannes, P.de (2021). Populating MBSE models from MDAO analysis. In: 2021 IEEE International Symposium on Systems Engineering (ISSE), 13 September – 13 October, Vienna, Austria, pp. 1–8.10.1109/ISSE51541.2021.9582519Search in Google Scholar

Assouroko, I., Ducellier, G., Boutinaud, P., and Eynard, B. (2014). Knowledge management and reuse in collaborative product development – a semantic relationship management-based approach. Int. J. Prod. Lifecycle Manag. 7: 54, https://doi.org/10.1504/IJPLM.2014.065460.Search in Google Scholar

Awerbuch, S., and Preston, A.M. (Eds.) (1997). The virtual utility: accounting, technology & competitive aspects of the emerging industry. Kluwer Academic, Boston, London.10.1007/978-1-4615-6167-5Search in Google Scholar

Bader, S., Barnstedt, E., Bedenbender, H., Billmann, M., Boss, B., Braunmandl, A., Clauer, E., Deppe, T., Diedrich, C. and Flubacher, B. (2022). Details of the asset administration Shell: Part 1. The exchange of information between partners in the value chain of industrie 4.0 (Version 3.0 RC02). Available at: <https://www.plattform-i40.de/IP/Redaktion/DE/Downloads/Publikation/Details_of_the_Asset_Administration_Shell_Part1_V3.pdf?__blob=publicationFile&v=10>.Search in Google Scholar

Barrios, P., Eynard, B., and Danjou, C. (2019). Towards a digital thread between industrial internet of things and product lifecycle management: experimental work for prototype implementation. In: Product lifecycle management in the digital twin era. Springer International Publishing, Cham, pp. 273–282.10.1007/978-3-030-42250-9_26Search in Google Scholar

Barszcz, T. and Czop, P. (2012a). Presentation of a virtual power plant environment and its application with combined first-principle and data-driven models intended for the diagnostics of a power plant – Part 1. Simulation 88: 139–166, https://doi.org/10.1177/0037549711398718.Search in Google Scholar

Barszcz, T. and Czop, P. (2012b). Presentation of a virtual power plant environment and its application with combined first-principle and data-driven models intended for the diagnostics of a power plant – Part 2. Simulation 88: 167–179, https://doi.org/10.1177/0037549711399007.Search in Google Scholar

Beisheim, N., Rädle, M., Reichwald, J., Linde, M., Ott, T., Amann, S., and Kastner, K. (2022). Simultaneous interdisciplinary teamwork on digital twins in a 3D collaborative environment. In: Proceedings of the 29th International Society of Transdisciplinary Engineering (ISTE) Global Conference, July 5–July 8. IOS Press, Cambridge, MA, USA.10.3233/ATDE220667Search in Google Scholar

Biffl, S., Lüder, A., and Gerhard, D. (2017). Multi-disciplinary engineering for cyber-physical production systems: data models and software solutions for handling complex engineering projects. Springer, Cham, Switzerland.10.1007/978-3-319-56345-9Search in Google Scholar

Bird, S., Klein, E., and Loper, E. (2009). Natural language processing with Python: analyzing text with the natural language toolkit. O’Reilly Media, Inc, Sebastopol, CA.Search in Google Scholar

Boy, G.A., Jani, G., Manera, A., Memmott, M., Petrovic, B., Rayad, Y., Stephane, L., and Suri, N. (2016). Improving collaborative work and project management in a nuclear power plant design team: a human-centered design approach. Ann. Nucl. Energy 94: 555–565, https://doi.org/10.1016/j.anucene.2015.12.039.Search in Google Scholar

Brovar, Y., Menshenin, Y., Knoll, D., and Fortin, C. (2022). Modelling of engineering and manufacturing data structures through a DSM-based approach. In: Product lifecycle management. Green and blue technologies to support smart and sustainable organizations. Springer International Publishing, Cham, pp. 96–109.10.1007/978-3-030-94399-8_8Search in Google Scholar

Campos, R., Mangaravite, V., Pasquali, A., Jorge, A., Nunes, C., and Jatowt, A. (2020). YAKE! Keyword extraction from single documents using multiple local features. Inf. Sci. 509: 257–289, https://doi.org/10.1016/j.ins.2019.09.013.Search in Google Scholar

Chemnitz, N.Ø., Bonnet, P., Büttrich, S., Shklovski, I., and Watts, L. (2021). Unionized data governance in virtual power plants. In: Proceedings of the twelfth ACM international conference on future energy systems, e-Energy ‘21: the twelfth ACM international conference on future energy systems, 28 06 2021 02 07 2021, Virtual Event Italy. ACM, New York, NY, USA, pp. 282–283.Search in Google Scholar

Cholewa, M. and Minh, L.H.B. (2021). PLM solutions in the process of supporting the implementation and maintenance of the circular economy concept in manufacturing companies. Sustainability 13: 10589, https://doi.org/10.3390/su131910589.Search in Google Scholar

Cicchetti, A., Di Ruscio, D., Eramo, R., and Pierantonio, A. (2011). JTL: a bidirectional and change propagating transformation language. In: Software language engineering. Springer, Berlin, Heidelberg, pp. 183–202.10.1007/978-3-642-19440-5_11Search in Google Scholar

Dekhtiar, J., Durupt, A., Bricogne, M., Eynard, B., Rowson, H., and Kiritsis, D. (2018). Deep learning for big data applications in CAD and PLM – research review, opportunities and case study. Comput. Ind. 100: 227–243, https://doi.org/10.1016/j.compind.2018.04.005.Search in Google Scholar

Deuter, A. and Imort, S. (2020). PLM/ALM integration with the asset administration shell. Proc. Manuf. 52: 234–240, https://doi.org/10.1016/j.promfg.2020.11.040.Search in Google Scholar

Deuter, A. and Imort, S. (2021). Product lifecycle management with the asset administration shell. Computers 10: 84, https://doi.org/10.3390/computers10070084.Search in Google Scholar

Drath, R. (Ed.) (2021). Automationml: a practical guide. De Gruyter Oldenbourg, Boston.10.1515/9783110746235Search in Google Scholar

Eigner, M. and Stelzer, R. (2009). Product lifecycle management: ein Leitfaden für product development und life cycle management. Springer Science & Business Media, Berlin, Heidelberg.10.1007/b93672Search in Google Scholar

Eigner, M., Detzner, A., Schmidt, P.H., and Tharma, R. (2021). Holistic definition of the digital twin. Int. J. Prod. Lifecycle Manag. 13: 343–357, https://doi.org/10.1504/ijplm.2021.119527.Search in Google Scholar

Erikstad, S.O. (2017). Merging physics, big data analytics and simulation for the next-generation digital twins. In: HIPER 2017, High-Performance marine vehicles, Zevenwacht, South-Africa, 11-13 September 2017, pp. 141–151.Search in Google Scholar

Friedenthal, S., Moore, A., and Steiner, R. (2015). A practical guide to SysML: the systems modeling language. Elsevier MK, Amsterdam, Boston.Search in Google Scholar

Gašević, D., Djurić, D., and Devedžić, V. (2009). An MDA based ontology platform: AIR. Model Driven Archit. Ontol. Dev. 299–309, https://doi.org/10.1007/978-3-642-00282-3_12.Search in Google Scholar

Geddes, D.J. (1998). A real-time simulation of a 200 MW thermal power plant for optimising combustion control. In: UKACC international conference on control (CONTROL ‘98), 1–4 Sept. 1998, Swansea, UK. IEEE, pp. 859–864.10.1049/cp:19980341Search in Google Scholar

Graube, M., Pfeffer, J., Ziegler, J., and Urbas, L. (2011). Linked data as integrating technology for industrial data. In: 2011 14th international conference on network-based information systems (NBiS), 7–9 September, Tirana, Albania. IEEE, pp. 162–167.10.1109/NBiS.2011.33Search in Google Scholar

Greenyer, J. and Kindler, E. (2010). Comparing relational model transformation technologies: implementing query/view/transformation with triple graph grammars. Software & Syst. Model. 9: 21–46, https://doi.org/10.1007/s10270-009-0121-8.Search in Google Scholar

Grieves, M. (2022). Intelligent digital twins and the development and management of complex systems. Digital Twin 2: 8, https://doi.org/10.12688/digitaltwin.17574.1.Search in Google Scholar

Grieves, M. and Vickers, J. (2016). Origins of the digital twin concept, Available at: <https://www.researchgate.net/publication/307509727_Origins_of_the_Digital_Twin_Concept>.Search in Google Scholar

Halstenberg, F.A., Lindow, K., and Stark, R. (2019). Leveraging circular economy through a methodology for smart service systems engineering. Sustainability 11: 3517, https://doi.org/10.3390/su11133517.Search in Google Scholar

Hehenberger, P., Bricogne, M., Le Duigou, J., and Eynard, B. (2016). Meta-model of PLM for design of systems. In: Product lifecycle management in the era of internet of things. Springer International Publishing, Cham, pp. 301–310.10.1007/978-3-319-33111-9_28Search in Google Scholar

Hoernicke, M., Stark, K., Schoch, N., Jeske, R., Markaj, A., and Fay, A. (2022). Modular engineering of conventional plants. atp Magazin 63: 62–68, https://doi.org/10.17560/atp.v63i4.2587.Search in Google Scholar

Holm, T., Christiansen, L., Goring, M., Jager, T., and Fay, A. (2012). ISO 15926 vs. IEC 62424 — comparison of plant structure modeling concepts, pp. 1–8, Available at: https://doi.org/10.1109/ETFA.2012.6489662.Search in Google Scholar

IEC 62424 (2016). Representation of process control engineering: requests in P&I diagrams and data exchange between P&ID tools and PCE-CAE tools. IEC Central Office (IEC 62424:2016), Geneva, Switzerland.Search in Google Scholar

ISO 10303-1 (2021). Industrial automation systems and integration: Product data representation and exchange – Part 1: overview and fundamentals. ISO Copyright Office (ISO 10303-1:2021), Switzerland.Search in Google Scholar