Abstract

Biomaterials from mushrooms and natural fibers have been used to reduce environmental impacts. This study aimed to develop the mycelium composite from four local mushrooms, Pleurotus ostreatus, Auricularia auricula-judae, Lentinus squarrosulus, and Lentinus polychrous and three substrates derived from agricultural wastes (coconut husk, rice husk, and rice straw). The mycelia of all mushrooms were cultured on potato dextrose agar and measured for the growth for 9 days. It showed that L. squarrosulus had a colony size significantly greater than the other species. Then, L. squarrosulus was selected to form the biocomposites and tested for material properties, e.g., morphology, compressive strength, water and moisture absorption, and biodegradability. Microscopically, the mycelium colonized almost all parts of the rice husk while it colonized less in the rice straw and coconut husk. However, the rice straw absorbed significantly more moisture than rice husk and coconut husk, but the coconut husk absorbed significantly more water than the rice husk and rice straw. Moreover, the rice straw composite showed the highest compressive strength value and the greatest biodegradability according to the highest weight loss. This research provided the results of the mycelium biocomposite production and mechanical tests for future biomaterials.

1 Introduction

The construction sector helps to develop the country and earn benefits, but construction waste is harmful to the environment and human society, and nonrenewable resources are also rapidly decreasing. This challenge has been taken for solutions. One of them is to create biocomposites from living organisms, e.g., algae, fungi, and bacteria to reduce the use of nonrenewable materials. Mycelium-based composite as an alternative is the result of the structure of filamentous fungi or mushroom species that grow on different natural fibers to produce biomaterials [1]. Mycelium is an association of interwoven and sting-like fungal hyphae which compose the vegetation part of mushroom growth by stretching and splitting their hyphae into substrates. Mycelium-based materials can be applied to industrial materials as a biodegradable alternative resource to develop a broad scope of production in the fields of architecture and industrial design, such as bricks [2].

Agriculture waste is defined as the non-product output of production from cultivating and agricultural activities such as grains, vegetables, or crops [3]. Agriculture has expanded three times over the past 50 years due to the development of land, agricultural needs, mechanical improvement, and population expansion which approximately result in 23.7 million tons of agriculture products per day globally [4]. Around 80% of solid waste is from farms in the form of organic decay, so agricultural waste such as straw, cotton stalks, sunflower shells, corn, rice hulls, coconut shells, and others are contributing varieties of helpful materials for many purposes [5]. Coconut production was estimated at around 1.8 million tons which gives coconut husk 80–85% of the total weight of coconut [6]. Production of rice husk was estimated at around 180 million tons worldwide while rice production was approximately 750 million tons [7]. Rice straw was the result of the rice production of lignocellulosic waste and estimated around 731 million tons [8]. There are biomaterials from living organisms such as fungi using these agricultural wastes as substrates.

Various types of mushrooms have been used to produce composites. For example, Pleurotus ostreatus was cultured with supplements for cultivating the mycelium on wheat bran and tested mycelium-based composite for compressive strength to produce materials as masonry units for architectural construction [9]. These mushroom species had already been used as mycelium composites to produce the biomaterials for replacing nonrenewable products, and there are more mushrooms locally found that are more interesting to study in this aspect. Therefore, this research aimed to make the mycelial biocomposites from four mushroom species: P. ostreatus, Auricularia auricula-judae, Lentinus squarrosulus, and Lentinus polychrous. Particularly, the Lentinus species are local to the region which allowed the study reporting the first record. Due to the effective promising properties of agriculture waste and mushrooms, the preparation of biocomposites of local mushroom mycelia using agricultural waste, rice husks, coconut husks, and rice straws as growth substrates was completed. Next, the effect of mushroom species and substrates on material properties of the mycelium composites was also evaluated to obtain the best biocomposite materials.

2 Materials and methods

2.1 Culture media preparation

Two different media were prepared in this experiment for growing mycelium. First, potato dextrose agar (PDA) was prepared: potatoes 200 g were diced into small pieces, mixed with dextrose 20 g, agar 20 g, and cooked with distilled H2O 1,000 mL until melting. Then they were poured into glass bottles and autoclaved for 30 min at 121°C to sterilize the medium. Next, PDA was poured into Petri dishes and solidified at room temperature. Secondly, potato dextrose broth (PDB) was prepared with the same process without agar. After that, PDB was poured 150 mL per glass bottle and autoclaved for 30 min at 121°C. Dextrose in PDB was added to be proportional to the quantities of potato and water.

2.2 Mushroom isolation and culture

Four mushroom species collected from the local markets in Muang, Khon Kaen, Thailand, P. ostreatus, A. auricula-judae, L. squarrosulus, and L. polychrous [10,11], were isolated for the pure mycelia. Small tissues (1 mm2 × 1 mm2) inside the fresh mushrooms were taken using sterile surgical blades. Then, the tissues were placed in Petri dishes containing PDA. The plates were kept at room temperature for 7 days to let the fungi grow under dark conditions. The mycelia growing from the mushroom tissues were isolated on the new PDA to obtain the pure culture for another 7 days and stored at room temperature for further experiment. A mycelium plug was inoculated in a Petri dish containing PDA (four mushroom species, five plates each). Then the plates were kept in the dark condition at room temperature. The radial growth of the mycelia was measured daily to determine which mushrooms exhibited the highest growth.

2.3 Production of mycelium biocomposites in substrates

Bottles containing the substrates (10 g), rice husk, rice straw, and coconut husk, were autoclaved for 30 min. Before the mushroom mycelia were transferred in substrate bottles, the mycelial plugs from the previous experiment were propagated in PDB and placed on the shaker (Brunswick Scientific) at 160 rpm for 7 days at room temperature. Next, the mycelia suspension in the broth (20 mL) was transferred to each screw top culture bottle containing the autoclaved substrates. After 3 months at room temperature, the mycelium composites from each substrate were formed as the blocks. Then, they were taken out from the bottles and dried in the hot air oven at 60°C for 2 days before testing the material properties.

2.4 Scanning electron microscopy (SEM)

Small pieces of the mycelium composites dissected from the blocks of each substrate were bounded over a carbon tape on the copper coins and transferred into Emitech sputter coater model: K500X to coat the surface of the specimen (gold-coated and voltage of 5.00 kV). Then, they were examined under the SEM, S-3000N. The samples were observed for the morphological characters of mycelium.

2.5 Moisture exposure

The blocks were added to a moisture chamber to control humidity with a UNI-T digital temperature humidity meter. Then, the mycelium blocks of each substrate were put in a moisture chamber to determine moisture uptake at 28°C under a relative humidity (RH) of 85% and the weight of the blocks were measured after 1, 2, 3, and 4 h to monitor the blocks’ rapid weight gain in the first few hours of moisture absorption. Then the blocks were measured every 24 h up to 12 days until the weight of the samples was stable. This part was conducted in three replicates. The moisture exposure was expressed in percentage of weight gain [12]: M (%) = [(W w – W d )/W d ] × 100, where M is the moisture content, W w is the sample mass after immersed moisture, and W d is the mass of the dry samples.

2.6 Water absorption

The prepared mycelium biocomposite blocks of each substrate were placed in three different chambers containing distilled H2O at 27°C to measure the different mass of mycelium blocks every 10 min of the first hour then 2, 3, 4, and 5 h to monitor the blocks’ rapid weight gain in the first few hours of water absorption. Next, the blocks were measured every 24 h up to 9 days to analyze the water absorption of composites until the weight of the samples was stable. Before the samples were weighed, they were wiped using filter paper to remove the excess water on the surface for 1 min. This part was conducted in four replicates. The water absorption was also expressed as a percentage derived from the formula [13]:

where W 1 and W 2 are the weights before and after soaking in water, respectively.

2.7 Compressive strength

Mycelium blocks of each substrate were performed for the compressive test on Universal Testing Machine, Model LR 30k with 1,000 N, the test speed was at a rate of 5 mm/min and stopped at 40% strain in the specimen. This part was conducted in three replicates. Then, the stress value was recorded and calculated using the formula [12]: compressive strength (σ) = F/A, where F is the compressive effort (N) and A is the specimen pattern cross-section (mm2).

2.8 Biodegradability

Mycelium biocomposite of each substrate was cut into small pieces and put into nylon bags and buried 6 cm underneath sand and natural soil mixture (1:1) at 24°C for 5 weeks. Then samples were cleaned with distilled H2O and dried overnight at 60°C and weighed to determine their weight loss using the formula [14]:

where W 0 is the sample weight before biodegradability testing and W 1 is the sample weight after biodegradability testing. This part was conducted in five replicates.

2.9 Statistical analysis

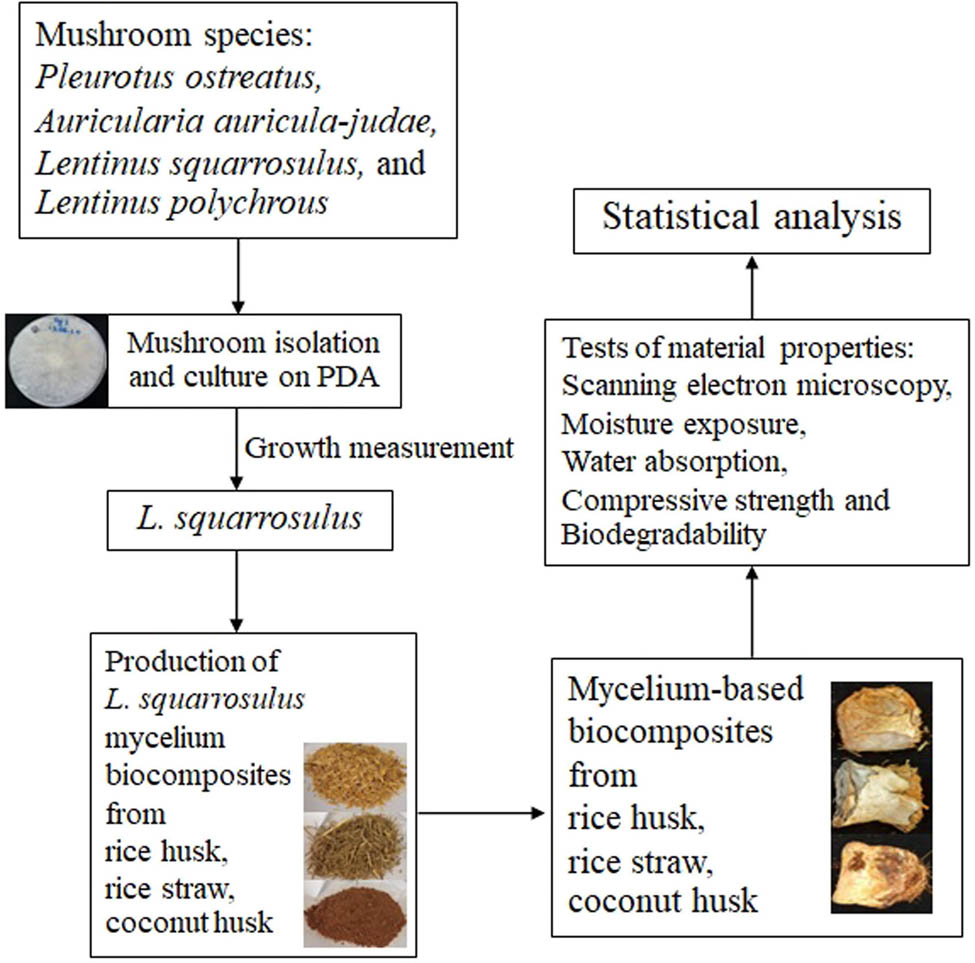

Data derived from the mushroom growth were compared using ANOVA (p < 0.01). The values derived from material property tests were compared using ANOVA (p < 0.05) to find significant differences. The summary of research methodology is shown in Figure 1.

Research methodology employed in this study.

3 Results

3.1 Growth evaluation and production of mycelium biocomposites

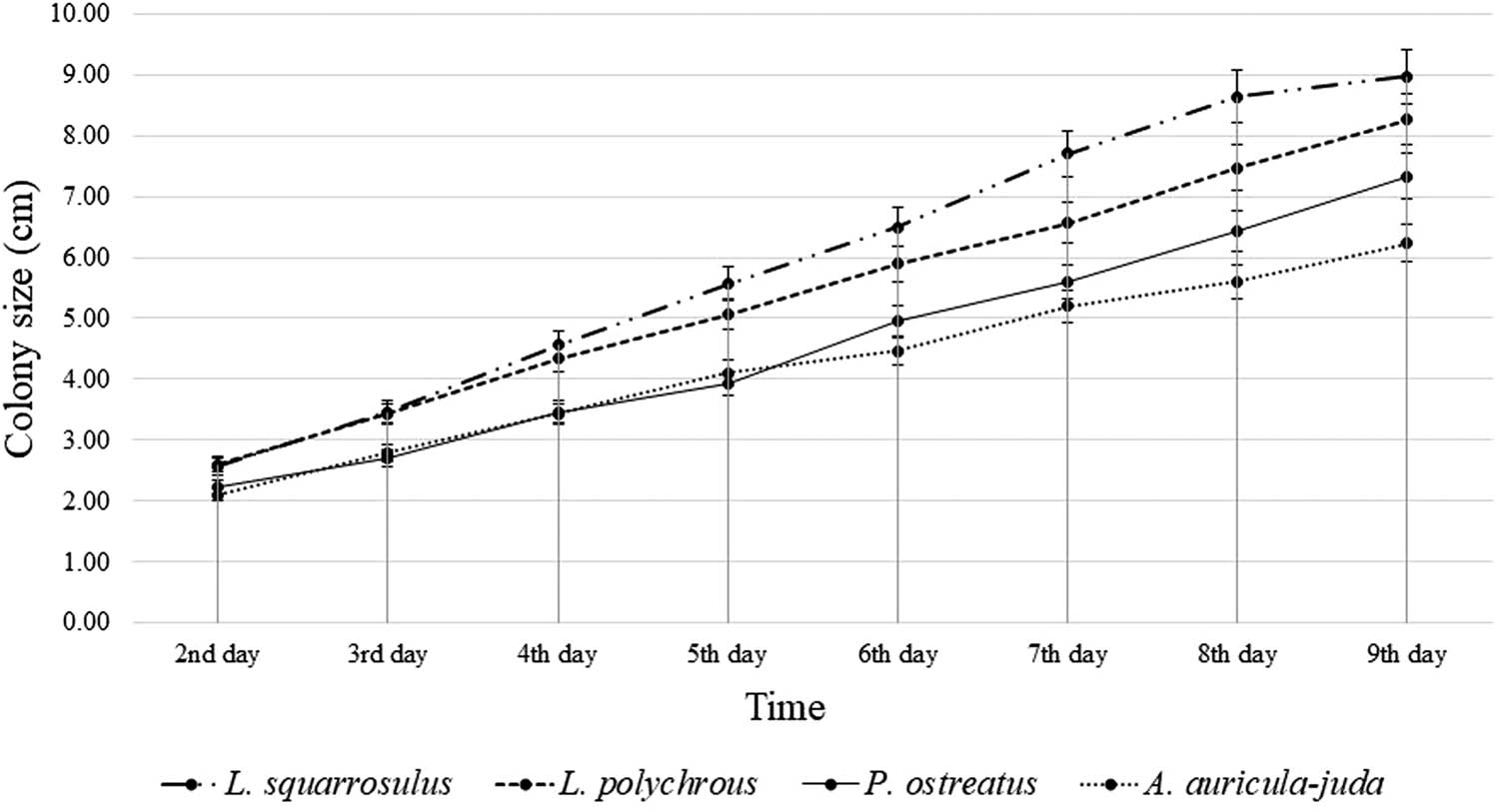

Four mushroom species were isolated on the PDA plate and measured for their growth from the second day until the ninth day. Among the four mushroom species, L. squarrosulus, L. polychrous, P. ostreatus, and A. auricula-judae showed different growth (Figure 2). Based on ANOVA, L. squarrosulus (8.96 ± 0.4 cm) was significantly greater than L. polychrous (8.26 ± 0.2 cm), P. ostreatus (7.33 ± 0.28 cm), and A. auricula-judae (6.23 ± 0.32 cm) (p < 0.01) on the ninth day. It can be said that L. squarrosulus proved to be a significantly better grower than the other three species. Therefore, L. squarrosulus was chosen to grow with substrates to produce the biocomposites for testing the material properties.

Average growth of four mushroom species in PDA plates from the second day to the ninth day.

3.2 SEM

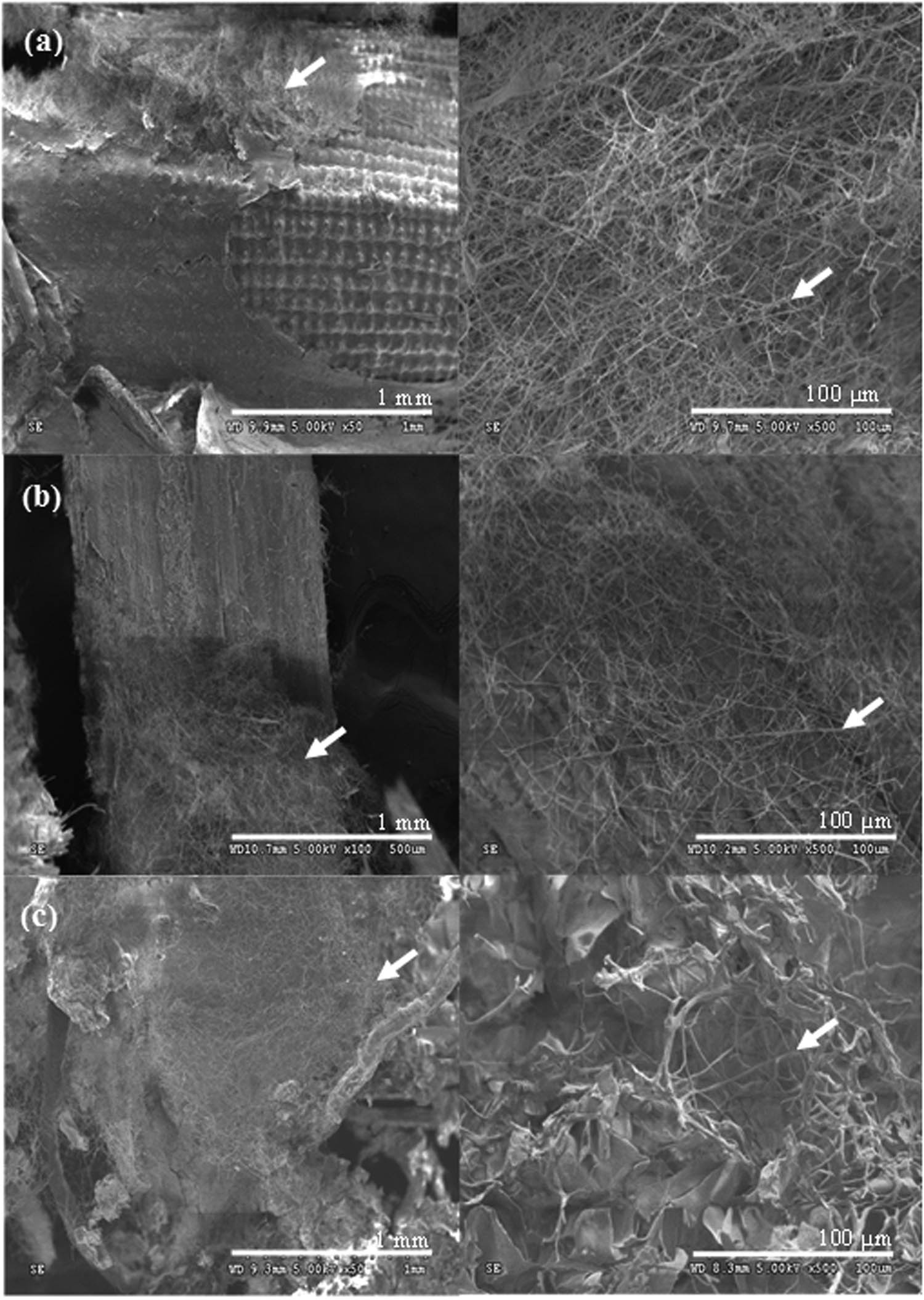

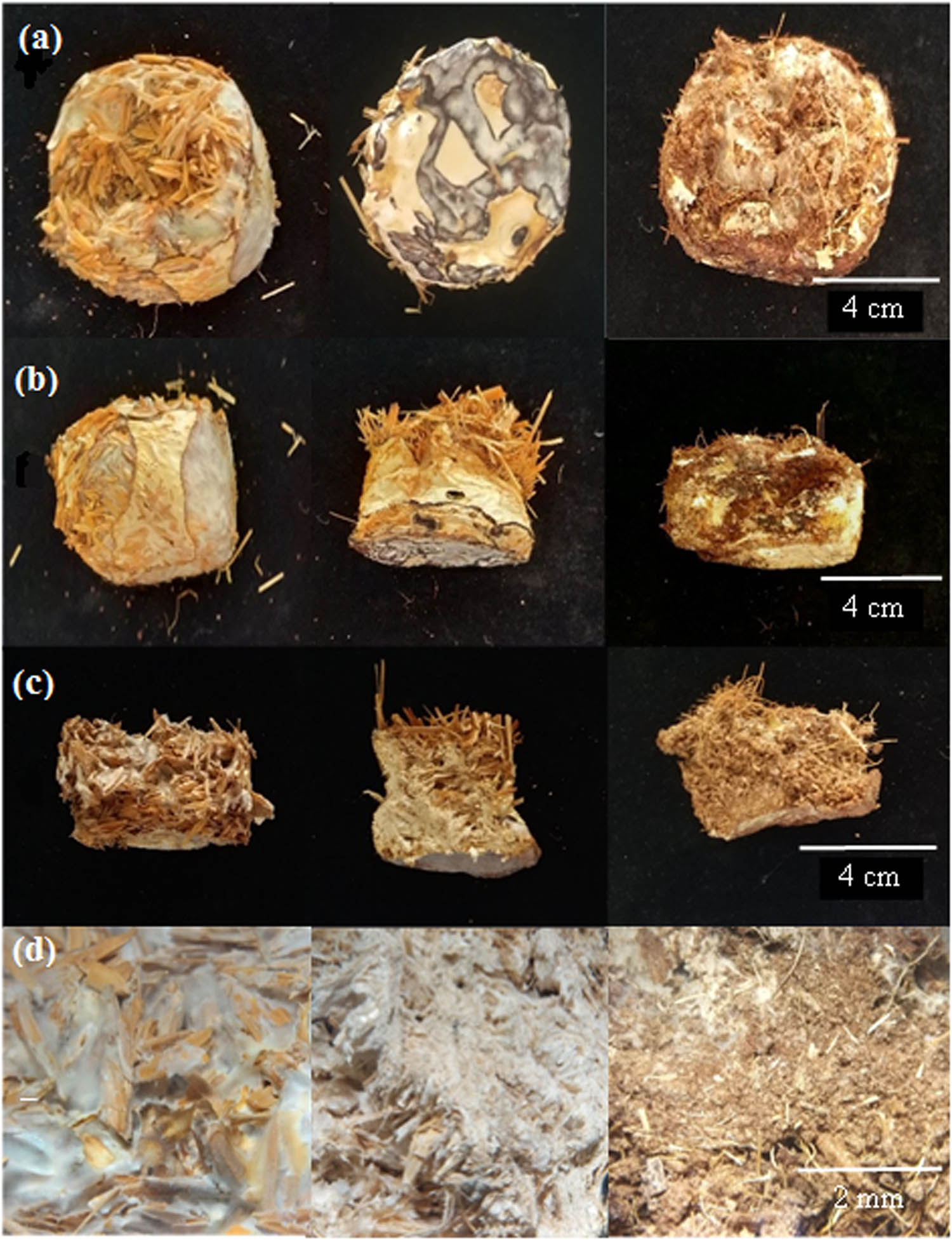

The surface of rice husk, rice straw, and coconut husk of L. squarrosulus mycelium composites are portrayed in Figure 3. The right pictures represent the micrograph of mycelium which colonized each substrate differently in the images. The pictures show the highest growth density of mycelium on the rice husk compared to the other substrates. The mycelia also spread on the coconut husk, but the growth was weak and limited to the surface. Due to the filamentous structure of the mushroom mycelia extending throughout the substrates, it could bind the substrate parts together to form mycelium blocks (Figure 4).

SEM micrographs of L. squarrosulus mycelium on the substrates (arrow heads): (a) rice husk, (b) rice straw, and (c) coconut husk.

Mycelium composites from L. squarrosulus using rice husk (left), rice straw (middle), and coconut husk (right) in different dimensions: (a) top view, (b) side view, (c) inner view, and (d) stereomicroscopic images.

3.3 Moisture exposure and water absorption

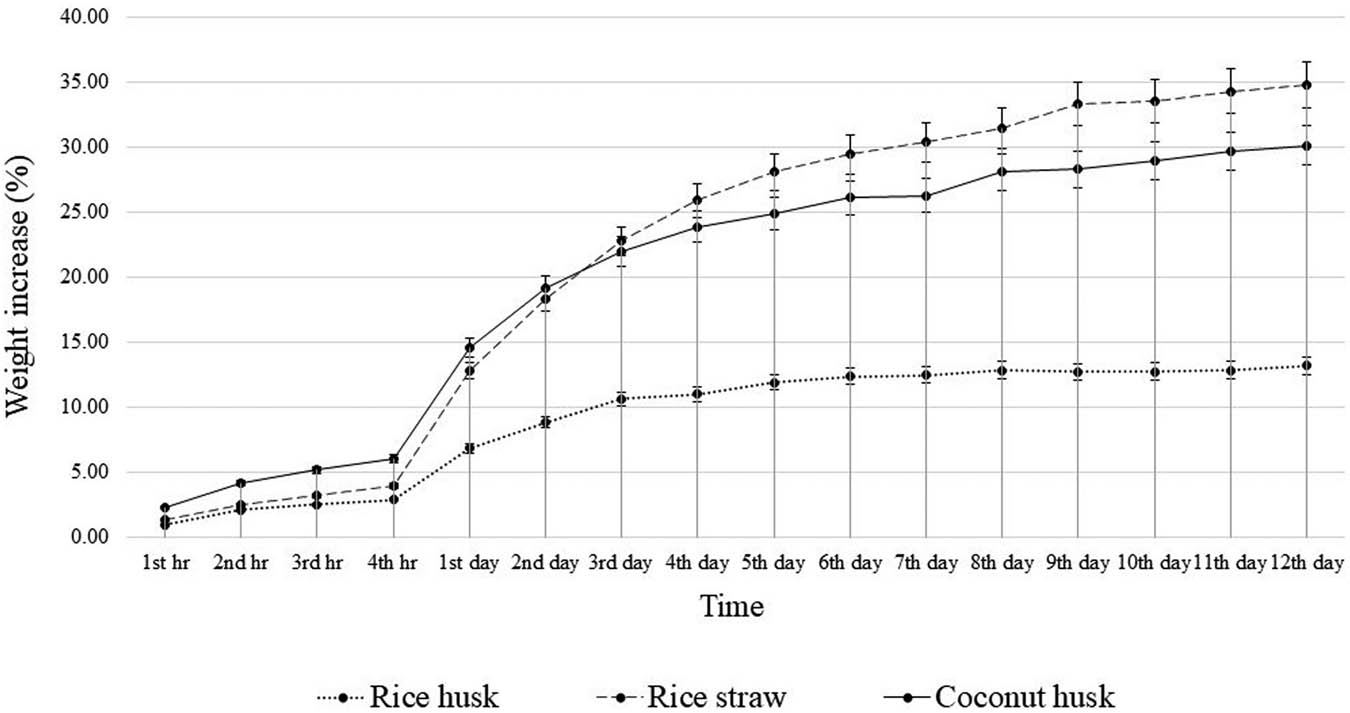

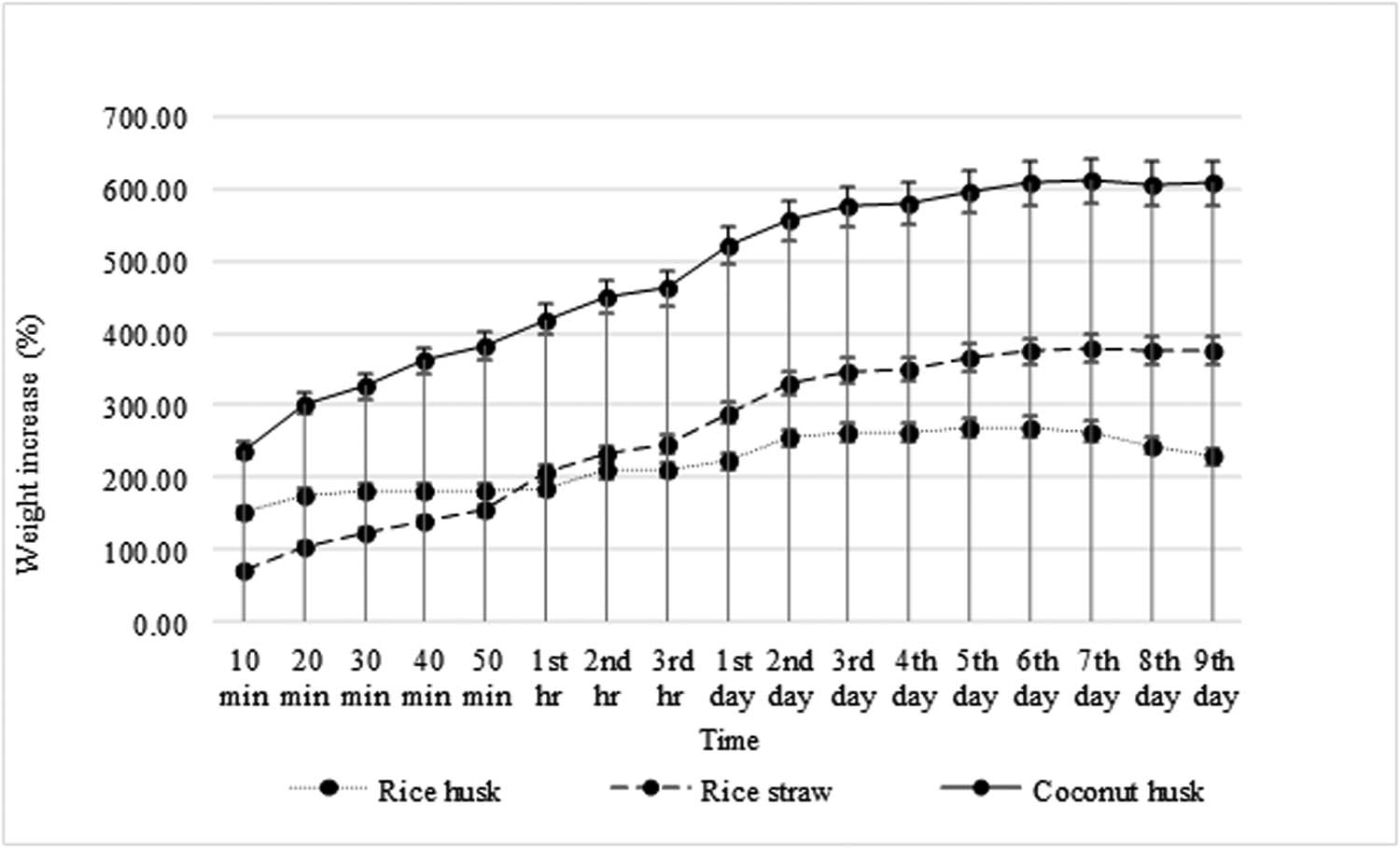

The mycelium blocks of each substrate with L. squarrosulus were measured before and after the moisture exposure at 85% RH to calculate the increased weight. The result suggested that after the first hour of moisture exposure until the twelfth day (Figure 5), the rice straw block had the significant increased weight (34.76 ± 1.74%) compared to the rice husk (13.19 ± 1.95%) and coconut husk (30.11 ± 2.84%), p < 0.05. The weight increased rapidly in the first 3 days and kept increasing slowly. The rate of water absorption of L. squarrosulus mycelium of different substrates is shown in Figure 6. It shows the increase in weight of the substrates after immersed in water from the first 10 min until the ninth day. The graph shows the water absorption as percentages of coconut husk (609 ± 58.62%) was statistically better than the rice husk (229.08 ± 68.77%) and the rice straw (229.08 ± 44.00%), p < 0.05. Therefore, the coconut husk (237.90 ± 113.18%) absorbed water and its weight increased more significantly than the rice husk blocks (150.92 ± 38.37%) and the rice straw blocks (69.94 ± 43.35%) from the first 10 min, p < 0.05. The rice straw (206.45 ± 50.93%) started increasing more weight than the rice husk (184.88 ± 40.29%) at the first hour while the weight of the rice husk dropped (264.08 ± 57.37%) on the seventh day because it could no longer hold water and broke into pieces.

Average weight increase of L. squarrosulus mycelium-based composite of each substrate when exposed to moisture at 85% at 28°C from the first hour to the twelfth day.

Average weight increase (%) of L. squarrosulus mycelium composite after placed in water at 27°C from the first 10 min until the ninth day.

3.4 Compressive strength

The results regarding the compressive strength of L. squarrosulus mycelium composites using rice husk, rice straw, and coconut husk are shown in Table 1. It revealed the force resistance of the samples. The rice straw blocks showed the highest compressive strength (0.54 ± 0.06 MPa) while the rice husk (0.46 ± 0.10 MPa) and coconut husk (0.47 ± 0.20 MPa) had a similar value due to the statistical analysis (p < 0.05). The rice husk and coconut husk blocks were fractured into pieces after testing while the rice straw blocks could maintain the block shape.

Compressive strength of L. squarrosulus mycelium blocks on rice husk, rice straw, and coconut husk

| Substrates | Compressive strength (MPa) |

|---|---|

| Rice husk | 0.46 ± 0.10b |

| Rice straw | 0.54 ± 0.06a |

| Coconut husk | 0.47 ± 0.20b |

Different letters indicate significant differences (p < 0.05).

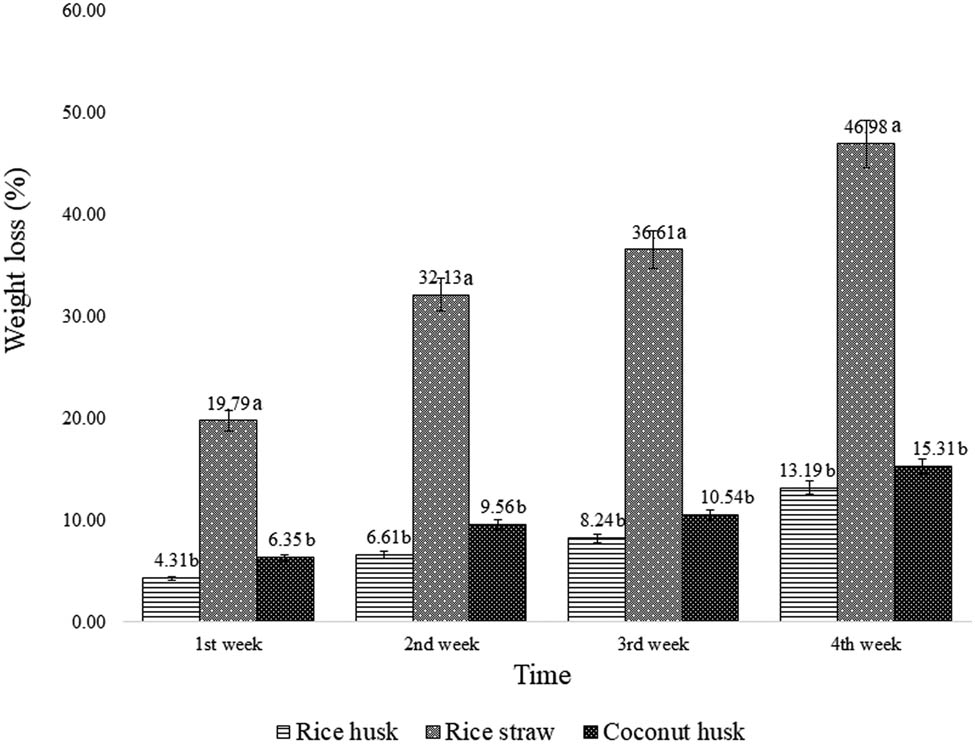

3.5 Biodegradability

The biodegradability is determined from the loss of the weight of the blocks. This study determined the weight loss (%) of the blocks after being buried in the soil mixture for 4 weeks. The result suggested that the rice straw’s weight loss was significantly higher (46.98 ± 4.03%) than that of the rice husk (13.19 ± 3.13%) and coconut husk (15.31 ± 7.81%) as shown in Figure 7. After 4 weeks underneath the soil mixture, the rice husk and coconut husk blocks were shattered into small fragments, but the rice straw still could retain its shape.

Average weight loss (%) of L. squarrosulus mycelium composites using three substrates after buried in the soil mixture for 4 weeks. Different letters indicate significant differences (p < 0.05).

4 Discussion

According to the results, L. squarrosulus was the mushroom among the four species exhibiting the highest growth performance. It continued to produce the mycelium blocks with three different substrates. The visual observation (Figure 4) showed the appearances of mycelium blocks of each substrate. The rice husk had large particles to provide oxygen and contained amorphous silica (20%) and organic substances such as cellulose and lignin (80%). They then became the nutrients for the mycelia to grow and colonize in the rice husk particles more efficiently [15,16]. Rice straw contains a favorable source of carbon for mushrooms such as cellulose (39%), lignin (12%), and dust (11%), which show potential for mycelium growth [17]. The coconut husk contains lignin (45.8%), cellulose (43.4%), hemicellulose (10.25%), and pectin (3%), which are similar to that found in the mushroom’s natural habitat and also can keep humidity for the mycelia to grow [18]. These conditions of rice husk, rice straw, and coconut husk improved L. squarrosulus mycelium growth and formed the network with these three substrates as the block composites. The mushroom mycelia were successful growing into the inner parts of the substrates, especially in the rice husk (Figure 4). The rice husk had appropriate particles which let the mycelia attach to and bond inner parts with the nutrients from the substrate to improve the growth [16]. A study by Yang et al. [19], reports about the physical nature and high carbon to nitrogen ratio of rice straw with lower biological efficiency, and it states that the mycelium could not colonize the inner parts of rice straw very well. Also, the coconut husk would affect the mycelium yield and colonization, so mycelium could not bond the inner parts of this substrate [20]. The property and condition of rice husk allowed mycelium to colonize into the inner parts and were better than rice straw and coconut husk due to the visual observation (Figure 4). However, these conditions did not suggest that the rice husk composite was better than the other two substrates in terms of properties.

As a result of the moisture exposure, Figure 5 shows the increase in weight of the rice straw blocks; it was greater than the coconut husk and rice husk because the rice straw had a low lignin content which is key to the durability and stability including storing and binding the moisture [21]. Meanwhile, the coconut husk structure had the characteristic of high water detention [22]. In contrast to water absorption, coconut husk could maintain water longer than the rice husk and rice straw because it is a natural fiber that has a high content of lignin and hemicellulose. It is able to absorb water and store for a longer time, so the weight increases more than the other two substrates after being immersed into water [23]. The rice straw was reported as a lignocellulosic fiber, leading to a reduction in water absorption by the reason of hydrophobic properties which repel the mass of water from the substrate [24]. Comparatively, the rice husk was a cellulose-based fibrous material with low bulk dimension, toughness, and water resistance. For this reason, this agricultural waste could not absorb water and moisture fast [25]. The coconut husk has cellulose, hemicellulose, and lignin which are able to absorb a high amount of water [26]. Accordingly, the biocomposites from the coconut husk are favorable to applications associated with the water absorption but they are not an option as the materials used to protect water or moisture unless the waterproof ability of the blocks is further enhanced.

The conclusion of the compressive test among the three substrates showed that the rice straw took a lead (0.54 MPa) compared to rice husk (0.46 MPa) and coconut husk (0.47 MPa). Three of them were known as the lignocellulosic materials, but their properties were different during the compressive test, i.e., the composite blocks of rice husk and coconut husk were broken after compressing, and their compressive strength was lower than the rice straw because the rice husk had small and thick particles and the coconut husk body was similar to powder which could be shattered easily. In contrast to the rice straw blocks, they had longer and thinner components to maintain the shape with higher stress strength during compression. This study is compared to the article by Elsacker et al. [12], in which Taramites versicolor mycelia was grown on different substrates like hemp, pine wood, and flax waste, and tested for the compressive strength to measure the resistance of composite. The combination of the mycelia and hemp received the highest compressive stiffness (0.51 MPa) which is similar to the finding in this study, followed by flax waste (0.31 MPa) and pine wood (0.14 MPa). The article also described that the small-sized fiber of hemp had an influence on the ability to tolerate the compression. Rice straw and hemp had similar fiber conditions and also gave the highest compressive strength among the following substrates. Also, the wood fiber composite had the highest compressive strength (39.78 ± 8.71 MPa) [27]. Moreover, a study by Bamigboye et al. [28] evaluated the compressive strength on concrete cubes incorporated in coconut husk, cement, and sand. The value strength of the specimen was obtained at 25.59 N/mm2. Due to the results, the blocks produced in this study were obviously not as strong as other materials in the literature. Therefore, the improvement of the block related to this issue should be sought out.

The biodegradability test conducted in sand and soil mixture was determined by the weight loss of the mycelium biocomposites [29]. The rice straw lost more weight than the rice husk and coconut husk because the microbes in the soil mixture could degrade this type of cellulosic substrate better [30]. The rice husk structure was bigger, and the coconut husk structure was in a powder-like form [31]. They both contained lignin as a hydrophobic component which reduced the rate of biodegradation in the soil. These three natural fibers had similar components, but they had different abilities to be degraded in soil. In this study, it can be said that the most biodegradable biocomposite was the rice straw. Similarly, the kenaf composites were buried in organic soil for 22 days and the degradation rate of kenaf composite was at 43% [32].

5 Conclusion

The finding of this research provided important information on structure, water and moisture absorption, and other properties. The mycelium-based biocomposite was achieved from the mushroom species and different substrates. As the results, it could be concluded that L. squarrosulus was the most favorable mushroom species to form the biocomposite with rice straw as the most suitable substrate because of its potential properties including biodegradability. Also, the mycelium composite from this study could be used as an economical, degradable, and sustainable alternative material to reduce the solid wastes causing pollution to the environment.

Acknowledgments

Authors would like to thank the Department of Plant Sciences and Agricultural Resources, Plant Pathology Division and Horticulture Division, Faculty of Agriculture, Khon Kaen University for kindly providing the laboratory and equipment.

-

Funding information: The APC was funded by Research Administration Division, Khon Kean University and International College, Khon Kaen University.

-

Author contributions: LL: literature search, methodology, experiments, data analysis, original draft; WJ: conceptualization, supervision, original draft, review and editing.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Appels FVW, Camere S, Montalti M, Karana E, Jansen KMB, Dijksterhuis J, et al. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater Des. 2020;161:64–71.10.1016/j.matdes.2018.11.027Search in Google Scholar

[2] Karana E, Blauwhoff D, Hultink EJ, Camere S. When the material grows: a case study on designing (with) mycelium-based materials. Int J Des. 2018;12:119–36.Search in Google Scholar

[3] Obi F, Ugwuishiwu B, Nwakaire J. Agricultural waste concept, generation, utilization and management. Niger J Technol. 2016;35:957.10.4314/njt.v35i4.34Search in Google Scholar

[4] Duque-Acevedo M, Belmonte-Ureña LJ, Cortés-García FJ, Camacho-Ferre F. Agricultural waste: review of the evolution, approaches and perspectives on alternative uses. Glob Ecol Conserv. 2020;22:1–22.10.1016/j.gecco.2020.e00902Search in Google Scholar

[5] Nguyen H, Jamali-Moghadam M, Moayedi H. Agricultural wastes preparation, management, and applications in civil engineering: a review. J Mater Cycles Waste Manag. 2019;21:1039–51.10.1007/s10163-019-00872-ySearch in Google Scholar

[6] Cabral MMS, Abud de S, Silva de F, Almeida RMRG. A produção de bioetanol a partir de fibra de casca de coco. Cienc Rural. 2016;46:1872–7.10.1590/0103-8478cr20151331Search in Google Scholar

[7] Vaskalis I, Skoulou V, Stavropoulos G, Zabaniotou A. Towards circular economy solutions for the management of rice processing residues to bioenergy via gasification. Sustainability. 2019;11:1–21.10.3390/su11226433Search in Google Scholar

[8] Verhé R, Echim C, De Greyt W, Stevens C. Production of biodiesel via chemical catalytic conversion. In: Luque R, Campelo J, Clark J, editors. Handbook of biofuels production. UK: Woodhead Publishing; 2011. p. 97–133.10.1533/9780857090492.2.97Search in Google Scholar

[9] Ghazvinian A, Farrokhsiar P, Vieira F, Pecchia J, Gursoy B. Mycelium-based bio-composites for architecture: assessing the effects of cultivation factors on compressive strength. In: Sousa JP, Henriques GC, Xavier JP, editors. Proceedings of 37th eCAADe and XXIII SIGraDi Joint Conference, Architecture in the Age of the 4th Industrial Revolution. Porto, Portugal, São Paulo: Blucher; 2019 Sep 11–13. p. 505–14.10.5151/proceedings-ecaadesigradi2019_465Search in Google Scholar

[10] Chandrasrikul A, Suwanarit P, Sangwanit U, Morinaga T, Nishizawa Y, Murakami Y. Diversity of mushrooms and macrofungi in Thailand. Bangkok, Thailand: Kasetsart University Press; 2008.Search in Google Scholar

[11] Hermawan R. Study of Lentinus squarrosulus from West Java on the basis of molecular and morphological data. J Biota. 2020;7(1):1–9.10.19109/Biota.v7i1.6378Search in Google Scholar

[12] Elsacker E, Vandelook S, Brancart J, Peeters E, De Laet L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS One. 2019;14:1–20.10.1371/journal.pone.0213954Search in Google Scholar PubMed PubMed Central

[13] Das G, Biswas S. Physical, mechanical and water absorption behaviour of coir fiber reinforced epoxy composites filled with Al2O3 particulates. Mater Sci Eng. 2015;115:1–7.10.1088/1757-899X/115/1/012012Search in Google Scholar

[14] Ochi S. Durability of starch based biodegradable plastics reinforced with manila hemp fibers. Materials. 2010;4:457–68.10.3390/ma4030457Search in Google Scholar PubMed PubMed Central

[15] Hossain SKS, Mathur L, Roy PK. Rice husk/rice husk ash as an alternative source of silica in ceramics: a review. J Asian Ceram Soc. 2018;6:299–313.10.1080/21870764.2018.1539210Search in Google Scholar

[16] Sekifuji R, Tateda M. Study of the feasibility of a rice husk recycling scheme in Japan to produce silica fertilizer for rice plants. Sustain Environ Res. 2019;1:1–9.10.1186/s42834-019-0011-xSearch in Google Scholar

[17] Utami CP, Susilawati PR. Rice straw addition as sawdust substitution in oyster mushroom Pleurotus ostreatus planted media. AIP Conf Proc. 2017;1868:090002. 10.1063/1.4995194.Search in Google Scholar

[18] Christita M. Economical and ecological friendly of growth media for edible mushroom Pleurotus ostreatus made of the coconut waste. J Biol Udayana. 2018;2018(22):35–41.10.24843/JBIOUNUD.2018.v22.i01.p05Search in Google Scholar

[19] Yang WJ, Guo FL, Wan ZJ. Yield and size of oyster mushroom grown on rice/wheat straw basal substrate supplemented with cotton seed hull. Saudi J Biol Sci. 2013;20:333–8.10.1016/j.sjbs.2013.02.006Search in Google Scholar PubMed PubMed Central

[20] Vetayasuporn S. The feasibility of using coconut residue as a substrate for oyster mushroom cultivation. Biotechnology. 2007;6:578–82.10.3923/biotech.2007.578.582Search in Google Scholar

[21] Gill N, Dogra R, Dogra B. Influence of moisture content, particle size, and binder ratio on quality and economics of rice straw briquettes. Bioenergy Res. 2018;11:54–68.10.1007/s12155-017-9877-9Search in Google Scholar

[22] Fernando M, Amarasinghe S. Drying kinetics and mathematical modeling of hot air drying of coconut coir pith. SpringerPlus. 2016;5:1–12.10.1186/s40064-016-2387-ySearch in Google Scholar PubMed PubMed Central

[23] Pandey MR, Pokharel S, Karn NK. Water absorption study of the coconut coir fibre after surface modification by different chemicals for varied duration. Proceedings of International Conference on Soil and Environment. Bangalore, India: 2016 Jul 22–23.Search in Google Scholar

[24] Ismail MR, Yassen AAM, Afify MS. Mechanical properties of rice straw fiber-reinforced polymer composites. Fibers Polym. 2011;12:648–56.10.1007/s12221-011-0648-5Search in Google Scholar

[25] Arjmandi R, Hassan A, Majeed K, Zakaria Z. Rice husk filled polymer composites. Int J Polym Sci. 2015;2015:32.10.1155/2015/501471Search in Google Scholar

[26] Bui H, Sebaibi N, Boutouil M, Levacher D. Determination and review of physical and mechanical properties of raw and treated coconut fibers for their recycling in construction materials. Fibers. 2020;8:1–18.10.3390/fib8060037Search in Google Scholar

[27] Muthuraj R, Lacoste C, Lacroix P, Bergeret A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: elaboration and performances evaluation. Ind Crop Prod. 2019;135:238–45.10.1016/j.indcrop.2019.04.053Search in Google Scholar

[28] Bamigboye G, Ngene B, Aladesuru O, Mark O, Adegoke D. Reinforced concrete at elevated temperatures. Fibers. 2020;1:1–12.Search in Google Scholar

[29] Trongchuen K, Ounkaew A, Kasemsiri P, Hiziroglu S, Mongkolthanaruk W, Wannasutta R, et al. Bioactive starch foam composite enriched with natural antioxidants from spent coffee ground and essential oil. Starch/Staerke. 2018;70:1–9.10.1002/star.201700238Search in Google Scholar

[30] Stella M, Emmyrafedziawati AK. Identification of rice straw degrading microbial consortium. J Trop Agric Food Sci. 2015;43:119–27.Search in Google Scholar

[31] Yussuf AA, Massoumi I, Hassan A. Comparison of polylactic acid/kenaf and polylactic acid/rice husk composites: the mechanical, thermal and biodegradability properties. J Polym Environ. 2010;18:422–9.10.1007/s10924-010-0185-0Search in Google Scholar

[32] Won JS, Lee JE, Jin D, Lee SG. Mechanical properties and biodegradability of the kenaf/soy protein isolate-PVA biocomposites. Int J Polym Sci. 2015;2015:11.10.1155/2015/860617Search in Google Scholar

© 2022 Lina Ly and Wuttiwat Jitjak, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Foliar application of boron positively affects the growth, yield, and oil content of sesame (Sesamum indicum L.)

- Impacts of adopting specialized agricultural programs relying on “good practice” – Empirical evidence from fruit growers in Vietnam

- Evaluation of 11 potential trap crops for root-knot nematode (RKN) control under glasshouse conditions

- Technical efficiency of resource-poor maize farmers in northern Ghana

- Bulk density: An index for measuring critical soil compaction levels for groundnut cultivation

- Efficiency of the European Union farm types: Scenarios with and without the 2013 CAP measures

- Participatory validation and optimization of the Triple S method for sweetpotato planting material conservation in southern Ethiopia

- Selection of high-yield maize hybrid under different cropping systems based on stability and adaptability parameters

- Soil test-based phosphorus fertilizer recommendation for malting barley production on Nitisols

- Effects of domestication and temperature on the growth and survival of the giant freshwater prawn (Macrobrachium rosenbergii) postlarvae

- Influence of irrigation regime on gas exchange, growth, and oil quality of field grown, Texas (USA) olive trees

- Present status and prospects of value addition industry for agricultural produce – A review

- Competitiveness and impact of government policy on chili in Indonesia

- Growth of Rucola on Mars soil simulant under the influence of pig slurry and earthworms

- Effect of potassium fertilizer application in teff yield and nutrient uptake on Vertisols in the central highlands of Ethiopia

- Dissection of social interaction and community engagement of smallholder oil palm in reducing conflict using soft system methodology

- Farmers’ perception, awareness, and constraints of organic rice farming in Indonesia

- Improving the capacity of local food network through local food hubs’ development

- Quality evaluation of gluten-free biscuits prepared with algarrobo flour as a partial sugar replacer

- Effect of pre-slaughter weight on morphological composition of pig carcasses

- Study of the impact of increasing the highest retail price of subsidized fertilizer on rice production in Indonesia

- Agrobiodiversity and perceived climatic change effect on family farming systems in semiarid tropics of Kenya

- Influences of inter- and intra-row spacing on the growth and head yield of cabbage (Brassica oleracea var. capitata) in western Amhara, Ethiopia

- The supply chain and its development concept of fresh mulberry fruit in Thailand: Observations in Nan Province, the largest production area

- Toward achieving sustainable development agenda: Nexus between agriculture, trade openness, and oil rents in Nigeria

- Phenotyping cowpea accessions at the seedling stage for drought tolerance in controlled environments

- Apparent nutrient utilization and metabolic growth rate of Nile tilapia, Oreochromis niloticus, cultured in recirculating aquaculture and biofloc systems

- Influence of season and rangeland-type on serum biochemistry of indigenous Zulu sheep

- Meta-analysis of responses of broiler chickens to Bacillus supplementation: Intestinal histomorphometry and blood immunoglobulin

- Weed composition and maize yield in a former tin-mining area: A case study in Malim Nawar, Malaysia

- Strategies for overcoming farmers’ lives in volcano-prone areas: A case study in Mount Semeru, Indonesia

- Principal component and cluster analyses based characterization of maize fields in southern central Rift Valley of Ethiopia

- Profitability and financial performance of European Union farms: An analysis at both regional and national levels

- Analysis of trends and variability of climatic parameters in Teff growing belts of Ethiopia

- Farmers’ food security in the volcanic area: A case in Mount Merapi, Indonesia

- Strategy to improve the sustainability of “porang” (Amorphophallus muelleri Blume) farming in support of the triple export movement policy in Indonesia

- Agrarian contracts, relations between agents, and perception on energy crops in the sugarcane supply chain: The Peruvian case

- Factors influencing the adoption of conservation agriculture by smallholder farmers in KwaZulu-Natal, South Africa

- Meta-analysis of zinc feed additive on enhancement of semen quality, fertility and hatchability performance in breeder chickens

- Meta-analysis of the potential of dietary Bacillus spp. in improving growth performance traits in broiler chickens

- Biocomposites from agricultural wastes and mycelia of a local mushroom, Lentinus squarrosulus (Mont.) Singer

- Cross transferability of barley nuclear SSRs to pearl millet genome provides new molecular tools for genetic analyses and marker assisted selection

- Detection of encapsulant addition in butterfly-pea (Clitoria ternatea L.) extract powder using visible–near-infrared spectroscopy and chemometrics analysis

- The willingness of farmers to preserve sustainable food agricultural land in Yogyakarta, Indonesia

- Transparent conductive far-infrared radiative film based on polyvinyl alcohol with carbon fiber apply in agriculture greenhouse

- Grain yield stability of black soybean lines across three agroecosystems in West Java, Indonesia

- Forms of land access in the sugarcane agroindustry: A comparison of Brazilian and Peruvian cases

- Assessment of the factors contributing to the lack of agricultural mechanization in Jiroft, Iran

- Do poor farmers have entrepreneurship skill, intention, and competence? Lessons from transmigration program in rural Gorontalo Province, Indonesia

- Communication networks used by smallholder livestock farmers during disease outbreaks: Case study in the Free State, South Africa

- Sustainability of Arabica coffee business in West Java, Indonesia: A multidimensional scaling approach

- Farmers’ perspectives on the adoption of smart farming technology to support food farming in Aceh Province, Indonesia

- Rice yield grown in different fertilizer combination and planting methods: Case study in Buru Island, Indonesia

- Paclobutrazol and benzylaminopurine improve potato yield grown under high temperatures in lowland and medium land

- Agricultural sciences publication activity in Russia and the impact of the national project “Science.” A bibliometric analysis

- Storage conditions and postharvest practices lead to aflatoxin contamination in maize in two counties (Makueni and Baringo) in Kenya

- Relationship of potato yield and factors of influence on the background of herbological protection

- Biology and life cycle Of Diatraea busckella (Lepidoptera: Crambidae) under simulated altitudinal profile in controlled conditions

- Evaluation of combustion characteristics performances and emissions of a diesel engine using diesel and biodiesel fuel blends containing graphene oxide nanoparticles

- Effect of various varieties and dosage of potassium fertilizer on growth, yield, and quality of red chili (Capsicum annuum L.)

- Review Articles

- Germination ecology of three Asteraceae annuals Arctotis hirsuta, Oncosiphon suffruticosum, and Cotula duckittiae in the winter-rainfall region of South Africa: A review

- Animal waste antibiotic residues and resistance genes: A review

- A brief and comprehensive history of the development and use of feed analysis: A review

- The evolving state of food security in Nigeria amidst the COVID-19 pandemic – A review

- Short Communication

- Response of cannabidiol hemp (Cannabis sativa L.) varieties grown in the southeastern United States to nitrogen fertilization

- Special Issue on the International Conference on Multidisciplinary Research – Agrarian Sciences

- Special issue on the International Conference on Multidisciplinary Research – Agrarian Sciences: Message from the editor

- Maritime pine land use environmental impact evolution in the context of life cycle assessment

- Influence of different parameters on the characteristics of hazelnut (var. Grada de Viseu) grown in Portugal

- Organic food consumption and eating habit in Morocco, Algeria, and Tunisia during the COVID-19 pandemic lockdown

- Customer knowledge and behavior on the use of food refrigerated display cabinets: A Portuguese case

- Perceptions and knowledge regarding quality and safety of plastic materials used for food packaging

- Understanding the role of media and food labels to disseminate food related information in Lebanon

- Liquefaction and chemical composition of walnut shells

- Validation of an analytical methodology to determine humic substances using low-volume toxic reagents

- Special Issue on the International Conference on Agribusiness and Rural Development – IConARD 2020

- Behavioral response of breeder toward development program of Ongole crossbred cattle in Yogyakarta Special Region, Indonesia

- Special Issue on the 2nd ICSARD 2020

- Perceived attributes driving the adoption of system of rice intensification: The Indonesian farmers’ view

- Value-added analysis of Lactobacillus acidophilus cell encapsulation using Eucheuma cottonii by freeze-drying and spray-drying

- Investigating the elicited emotion of single-origin chocolate towards sustainable chocolate production in Indonesia

- Temperature and duration of vernalization effect on the vegetative growth of garlic (Allium sativum L.) clones in Indonesia

- Special Issue on Agriculture, Climate Change, Information Technology, Food and Animal (ACIFAS 2020)

- Prediction model for agro-tourism development using adaptive neuro-fuzzy inference system method

- Special Issue of International Web Conference on Food Choice and Eating Motivation

- Can ingredients and information interventions affect the hedonic level and (emo-sensory) perceptions of the milk chocolate and cocoa drink’s consumers?

Articles in the same Issue

- Regular Articles

- Foliar application of boron positively affects the growth, yield, and oil content of sesame (Sesamum indicum L.)

- Impacts of adopting specialized agricultural programs relying on “good practice” – Empirical evidence from fruit growers in Vietnam

- Evaluation of 11 potential trap crops for root-knot nematode (RKN) control under glasshouse conditions

- Technical efficiency of resource-poor maize farmers in northern Ghana

- Bulk density: An index for measuring critical soil compaction levels for groundnut cultivation

- Efficiency of the European Union farm types: Scenarios with and without the 2013 CAP measures

- Participatory validation and optimization of the Triple S method for sweetpotato planting material conservation in southern Ethiopia

- Selection of high-yield maize hybrid under different cropping systems based on stability and adaptability parameters

- Soil test-based phosphorus fertilizer recommendation for malting barley production on Nitisols

- Effects of domestication and temperature on the growth and survival of the giant freshwater prawn (Macrobrachium rosenbergii) postlarvae

- Influence of irrigation regime on gas exchange, growth, and oil quality of field grown, Texas (USA) olive trees

- Present status and prospects of value addition industry for agricultural produce – A review

- Competitiveness and impact of government policy on chili in Indonesia

- Growth of Rucola on Mars soil simulant under the influence of pig slurry and earthworms

- Effect of potassium fertilizer application in teff yield and nutrient uptake on Vertisols in the central highlands of Ethiopia

- Dissection of social interaction and community engagement of smallholder oil palm in reducing conflict using soft system methodology

- Farmers’ perception, awareness, and constraints of organic rice farming in Indonesia

- Improving the capacity of local food network through local food hubs’ development

- Quality evaluation of gluten-free biscuits prepared with algarrobo flour as a partial sugar replacer

- Effect of pre-slaughter weight on morphological composition of pig carcasses

- Study of the impact of increasing the highest retail price of subsidized fertilizer on rice production in Indonesia

- Agrobiodiversity and perceived climatic change effect on family farming systems in semiarid tropics of Kenya

- Influences of inter- and intra-row spacing on the growth and head yield of cabbage (Brassica oleracea var. capitata) in western Amhara, Ethiopia

- The supply chain and its development concept of fresh mulberry fruit in Thailand: Observations in Nan Province, the largest production area

- Toward achieving sustainable development agenda: Nexus between agriculture, trade openness, and oil rents in Nigeria

- Phenotyping cowpea accessions at the seedling stage for drought tolerance in controlled environments

- Apparent nutrient utilization and metabolic growth rate of Nile tilapia, Oreochromis niloticus, cultured in recirculating aquaculture and biofloc systems

- Influence of season and rangeland-type on serum biochemistry of indigenous Zulu sheep

- Meta-analysis of responses of broiler chickens to Bacillus supplementation: Intestinal histomorphometry and blood immunoglobulin

- Weed composition and maize yield in a former tin-mining area: A case study in Malim Nawar, Malaysia

- Strategies for overcoming farmers’ lives in volcano-prone areas: A case study in Mount Semeru, Indonesia

- Principal component and cluster analyses based characterization of maize fields in southern central Rift Valley of Ethiopia

- Profitability and financial performance of European Union farms: An analysis at both regional and national levels

- Analysis of trends and variability of climatic parameters in Teff growing belts of Ethiopia

- Farmers’ food security in the volcanic area: A case in Mount Merapi, Indonesia

- Strategy to improve the sustainability of “porang” (Amorphophallus muelleri Blume) farming in support of the triple export movement policy in Indonesia

- Agrarian contracts, relations between agents, and perception on energy crops in the sugarcane supply chain: The Peruvian case

- Factors influencing the adoption of conservation agriculture by smallholder farmers in KwaZulu-Natal, South Africa

- Meta-analysis of zinc feed additive on enhancement of semen quality, fertility and hatchability performance in breeder chickens

- Meta-analysis of the potential of dietary Bacillus spp. in improving growth performance traits in broiler chickens

- Biocomposites from agricultural wastes and mycelia of a local mushroom, Lentinus squarrosulus (Mont.) Singer

- Cross transferability of barley nuclear SSRs to pearl millet genome provides new molecular tools for genetic analyses and marker assisted selection

- Detection of encapsulant addition in butterfly-pea (Clitoria ternatea L.) extract powder using visible–near-infrared spectroscopy and chemometrics analysis

- The willingness of farmers to preserve sustainable food agricultural land in Yogyakarta, Indonesia

- Transparent conductive far-infrared radiative film based on polyvinyl alcohol with carbon fiber apply in agriculture greenhouse

- Grain yield stability of black soybean lines across three agroecosystems in West Java, Indonesia

- Forms of land access in the sugarcane agroindustry: A comparison of Brazilian and Peruvian cases

- Assessment of the factors contributing to the lack of agricultural mechanization in Jiroft, Iran

- Do poor farmers have entrepreneurship skill, intention, and competence? Lessons from transmigration program in rural Gorontalo Province, Indonesia

- Communication networks used by smallholder livestock farmers during disease outbreaks: Case study in the Free State, South Africa

- Sustainability of Arabica coffee business in West Java, Indonesia: A multidimensional scaling approach

- Farmers’ perspectives on the adoption of smart farming technology to support food farming in Aceh Province, Indonesia

- Rice yield grown in different fertilizer combination and planting methods: Case study in Buru Island, Indonesia

- Paclobutrazol and benzylaminopurine improve potato yield grown under high temperatures in lowland and medium land

- Agricultural sciences publication activity in Russia and the impact of the national project “Science.” A bibliometric analysis

- Storage conditions and postharvest practices lead to aflatoxin contamination in maize in two counties (Makueni and Baringo) in Kenya

- Relationship of potato yield and factors of influence on the background of herbological protection

- Biology and life cycle Of Diatraea busckella (Lepidoptera: Crambidae) under simulated altitudinal profile in controlled conditions

- Evaluation of combustion characteristics performances and emissions of a diesel engine using diesel and biodiesel fuel blends containing graphene oxide nanoparticles

- Effect of various varieties and dosage of potassium fertilizer on growth, yield, and quality of red chili (Capsicum annuum L.)

- Review Articles

- Germination ecology of three Asteraceae annuals Arctotis hirsuta, Oncosiphon suffruticosum, and Cotula duckittiae in the winter-rainfall region of South Africa: A review

- Animal waste antibiotic residues and resistance genes: A review

- A brief and comprehensive history of the development and use of feed analysis: A review

- The evolving state of food security in Nigeria amidst the COVID-19 pandemic – A review

- Short Communication

- Response of cannabidiol hemp (Cannabis sativa L.) varieties grown in the southeastern United States to nitrogen fertilization

- Special Issue on the International Conference on Multidisciplinary Research – Agrarian Sciences

- Special issue on the International Conference on Multidisciplinary Research – Agrarian Sciences: Message from the editor

- Maritime pine land use environmental impact evolution in the context of life cycle assessment

- Influence of different parameters on the characteristics of hazelnut (var. Grada de Viseu) grown in Portugal

- Organic food consumption and eating habit in Morocco, Algeria, and Tunisia during the COVID-19 pandemic lockdown

- Customer knowledge and behavior on the use of food refrigerated display cabinets: A Portuguese case

- Perceptions and knowledge regarding quality and safety of plastic materials used for food packaging

- Understanding the role of media and food labels to disseminate food related information in Lebanon

- Liquefaction and chemical composition of walnut shells

- Validation of an analytical methodology to determine humic substances using low-volume toxic reagents

- Special Issue on the International Conference on Agribusiness and Rural Development – IConARD 2020

- Behavioral response of breeder toward development program of Ongole crossbred cattle in Yogyakarta Special Region, Indonesia

- Special Issue on the 2nd ICSARD 2020

- Perceived attributes driving the adoption of system of rice intensification: The Indonesian farmers’ view

- Value-added analysis of Lactobacillus acidophilus cell encapsulation using Eucheuma cottonii by freeze-drying and spray-drying

- Investigating the elicited emotion of single-origin chocolate towards sustainable chocolate production in Indonesia

- Temperature and duration of vernalization effect on the vegetative growth of garlic (Allium sativum L.) clones in Indonesia

- Special Issue on Agriculture, Climate Change, Information Technology, Food and Animal (ACIFAS 2020)

- Prediction model for agro-tourism development using adaptive neuro-fuzzy inference system method

- Special Issue of International Web Conference on Food Choice and Eating Motivation

- Can ingredients and information interventions affect the hedonic level and (emo-sensory) perceptions of the milk chocolate and cocoa drink’s consumers?