Abstract

The service conditions of rubber seals are primarily in the dynamic sliding state, with a high coefficient of friction, which can seriously compromise the equipment’s safety and the services’ lifespan. Diamond-like carbon (DLC) films have been the ideal candidate for tribological modification of rubber surfaces due to their excellent tribological properties over the last two decades. This field can be widely discussed as a hard film on soft substrates, where the challenge is the mismatch of mechanical properties, leading to the exfoliation of DLC films in friction. Early work developed the DLC films with a segment structure to solve this critical issue, illustrating the possibility of wear-resistant rubber. In recent years, researchers have paid attention to further increasing the coated rubber’s lifetime in friction, focusing on adhesion. These research achievements were reviewed on the aspects of structurization, adhesion, and doping in this article. It proposed an alternative direction of understanding the surface wear mechanism for designing wear-resistant DLC films on rubber.

1 Introduction

Wear is inevitable in most mechanical components, e.g., bearings, gears, brakes, and piston rings [1]. Rubber is routinely used with prominent oil-resistant features to seal rods, pistons, and valves in engineering applications. However, when seals work primarily in dynamic sliding conditions [2], rubber exhibits high friction characteristics when interacting with other engineering materials (steel counterparts, etc.) that can easily lead to rubber wear and tear, while the frictional heat generated by high friction can intensify the process, prompting premature failure of rubber seals and leakage, which seriously affects the safety and reliable service of equipment [3]. Therefore, it is essential to conduct anti-wear tests on rubber materials to reduce friction and increase the wear resistance of rubber seals.

Surface physical modification is a green methodology to modify the surface of rubber. In most cases, the rubber surface macromolecules undergo a chemical structure change after physical treatment, which is still a chemical modification. For example, plasma treatment was applied to change the physical and chemical properties of the rubber surface to improve friction and wear performance [4,5]. However, the chemical and physical treatments of the rubber surface have limitations on enhancing the tribological performance of rubber due to the high coefficient of friction (CoF) of the modified layer, which cannot meet the low friction requirement yet.

A film is a layer with unique functions attached to the rubber substance after depositing the film on the rubber surface. The rubber surface macromolecules still maintain their original structure, which is a physical modification of the surface. The formation of a selected protective film on the rubber surface can reduce the CoF between the rubber and its counterpart, thus reducing the wear of the rubber. So far, various films, including organic polymers and inorganic hard ones, have been used on the rubber to modify the tribological performance. Polytetrafluoroethylene films were prepared on acrylonitrile-butadiene rubber substrates, possessing high stability in the friction process with low CoFs [6]. Tashlykov et al. used their ion-assisted ion plating to deposit metal films (Ti, Cr, Mo, etc.) on the rubber surface to improve its tribological properties [7,8]. It was found that the high adhesion characteristics of metal films and steel counterparts have a significant influence on the improvement of the tribological properties of the rubber surface. Cadambi and Ghassemieh deposited ceramic film (tungsten carbide) on the rubber surface and found that the ceramic film can effectively reduce hysteresis friction [9].

Diamond-like carbon (DLC) is a class of amorphous materials possessing superior chemical inertness, corrosion resistance, and low CoF [10]. The superlow CoF of DLC could reach 0.001 [11], making it one of the most promising solid lubricants in engineering. The research on DLC/rubber has been activated over the last two decades due to its good chemical compatibility (the main components are carbon and hydrogen). The value of DLC films on rubber substrates is actively explored [12,13,14]. The application of DLC films deposited on rubber substrates is considered promising in O-rings for zoom cameras, ball bearings, and rubber seals in the aerospace, automotive, and rural water supply industries [15,16,17]. Considering the mismatch in mechanical properties between rigid films and soft substrates, earlier work developed DLC films with segmented structures to address this critical issue and is reviewed in related review articles [18,19]. In recent years, researchers have noted that the focus for further improving the service life of coated rubber in friction is adhesion, and to address this vital issue, researchers have discussed the improvement of adhesion properties from different aspects, such as the influence of substrate [20], the choice of plasma pretreatment gas [21], the optimization of film formation methods [22,23], intermediate transition layers [24], and doping [25], and some progress has been made.

This review summarized the typically updated processes of modified DLC films on rubber surfaces in recent years, categorized into structurization, adhesion, and doping. It proposes an alternative direction of understanding the surface wear mechanism for designing wear-resistant DLC films on rubber, reveals the critical problems of current studies, and discusses potential future research trends that still need to be resolved.

2 DLC and its tribology

DLC is composed of sp2 and sp3 carbon bonds (which may also contain a small amount of sp1), where different bonds are cross-linked to form an amorphous carbon network [26]. Based on the elemental composition of DLC, it can be divided into hydrogen-free DLC and hydrogen-containing H-DLC. As shown in Figure 1a, hydrogen-free DLC films include tetrahedral amorphous carbon films (ta-C) and graphite-like amorphous carbon films (a-C). Hydrogenated DLC films can be prepared by the physical-assisted chemical vapor deposition method using hydrocarbon gases (C2H2, CH4, etc.) as carbon precursors, which have low friction and wear [27]. The sp3 and sp2 content and hydrogen ratio affect DLC films’ physicochemical and mechanical properties. The higher the proportion of sp3/sp2 DLC within a specific range, the higher the hardness of the DLC coating will get [12]. While preparing DLC films, the carbon structure in the DLC films can be adjusted by controlling the deposition method and conditions, which determines the mechanical properties of the films.

The DLC films were found to have a low CoF due to their wear-induced graphitization [28]. Erdemir et al. accomplished a breakthrough in superlubricity in highly hydrogenated amorphous carbon films [29]. By comparing the function of hydrogen in DLC films, the non-hydrogenated DLC films are constantly subjected to high CoF and wear rates, which is usually attributed to the solid interactions between the carbon dangling bonds and their counterpart [30]. In terms of the microscale (Figure 1b), Erdemir proposed that the redistribution of charge density and the repulsive forces generated between two positively charged hydrogen protons along the sliding interface are the origins of suppression adhesive interactions and hence friction [31]. This hydrogen passivation interface is satisfactory to cancel out the friction forces and avoid material wear. Maintaining the hydrogen-covered surface is vital due to the inevitable loss of hydrogen.

The surface topology plays a crucial role in tribology. Mechanical interlocking can occur among surface asperities and lead to high frictional losses (especially during sliding tests’ run-in or initial stages) [32]. Typically, the roughness of amorphous DLC films relies on their substrate topology. Thus, the rubber substrate raises the difficulty of reaching an ultralow CoF. The tribochemical interactions between DLC and its surroundings have been intensively investigated [33]. Under dynamic sliding contacts, DLC surfaces may interact with counterparts and gaseous molecules in the surroundings. The interaction will remain stable along with substrate changes. The transfer layers on the sliding surfaces commonly affect the frictional behavior of DLC films [34], which comes from DLC counterparts’ debris. This debris will react with the surface and result in tribochemical interactions.

3 Development of DLC films on rubber

Early studies date back to around 2004 when Nakahigashi et al. in Japan used radio frequency plasma assisted chemical vapor deposition to deposit flexible DLC films on rubber and started the application of DLC in rubber seals [12], and in the same year, Takikawa et al. [14] and Miyakawa et al. [37] used T-filtered arc deposition system in the preparation of DLC films on ethylene propylene diene monomer substrates without introducing gas. They also investigated the tribological properties of the rubber surface after depositing DLC films and compared them with uncoated rubber, but only at low loads. After that, Japanese scholars generally agreed that the presence of surface cracks in DLC films on rubber surfaces was the main reason for their flexibility, but the mechanism of crack formation was not described in detail. Since then until 2008, a large number of relevant studies have been conducted in this area, Yoshida et al. [38], Martinez-Martinez and De Hosson [19], Lubwama et al. [18], and Pei et al. [13] contributed to the study of DLC-coated modified rubber. It was found that film flaking did not occur even in the deformation of soft substrates. However, the cracks generated in the films affected the final frictional properties. Martinez-Martinez et al. [39] investigated the effect of different plasma pretreatment and film deposition bias on the DLC film bonding on the rubber surface. They found that both affected the film crack formation density by changing the temperature difference before and after the film deposition. They obtained the temperature difference and film crack density by controlling the temperature difference before and after the film deposition. Lubwama et al. [40] investigated the tribological behavior of DLC and Si-doped DLC films coated on the surface of nitrile butadiene rubber (NBR). The prepared films exhibited a crack-like microstructure with hydrophobic properties and a dense non-columnar microstructure under a certain negative bias pressure. The dry and wet environments and the presence or absence of the Si–C interlayer had significant effects on the tribological properties and bond strength of the coatings. The presence of the Si–C interlayer greatly enhanced the bonding force of the films and provided general design rules for depositing ultra-low friction DLC films on rubber. The loss of the protective layer due to wear in long-term friction leads to an increase in CoF, as researchers have been working to further reduce the CoF of coated rubber materials and improve their service life in harsh friction environments.

3.1 Examples of DLC films on rubber

Different vapor deposition techniques have been used to deposit DLC films on various types of rubber [41]. Table 1 summarizes the classification and characteristics of typical deposition techniques for DLC films on different rubber surfaces and reviews information on the corresponding deposition techniques over the past two decades. It illustrates that CVD and physical vapor deposition (typical magnetron sputtering) are two prevalent methods due to their relatively low deposition temperatures. In general, the elastomers cannot withstand high temperatures, a critical limitation on the synthesis methods of films on rubber. Meanwhile, temperature control, the crucial factor influencing the film quality, becomes unavailable in DLC films on rubber.

Deposition details and characteristics of DLC coatings on rubber

| Technique category | Classical deposition process | Characteristics | Deposition details | References | |||

|---|---|---|---|---|---|---|---|

| Substrates | Film | Gases and precursors | Interlayer | ||||

| PVD | MS | Substrate diversification | FKM, HNBR, ACM | W–DLC | Ar + C2H2 | W–C | [47] |

| Low deposition temperature | FKM, HNBR | W–DLC | Ar + C2H2 | Cr (optional)W–C | [48] | ||

| Large deposition area | NBR | DLC | Ar (Graphite) | [22] | |||

| Stable deposition rate | NBR | DLC | Ar (Graphite) | Ti–C | [24] | ||

| Uniform film layer | HNBR | DLC | Ar + C2H2 | [49] | |||

| Stable process | HNBR | Ti–DLC | Ar + C2H2 | [50] | |||

| Good repeatability | TPU | DLC | Ar, C4H10, C2H2 | [51] | |||

| PLD | Fast film growth | MVQ | DLC | Frozen C5H11OH | [38] | ||

| High-resolution film deposition | |||||||

| Easy to realize micro-zone deposition | |||||||

| CVD | Low deposition temperature | CR, NBR, MVQ | DLC | CH4 | [12] | ||

| Good winding property | |||||||

| PECVD | Uniform film layer | ||||||

| PACVD | Low internal film stress | ||||||

| Good adhesion\linefeed\High cost | |||||||

| Challenging to obtain pure products | |||||||

| Most of the reaction substances are flammable, explosive, and toxic | |||||||

| Butyl rubber | DLC | CH4 | [52] | ||||

| ACM | DLC | Ar + C2H2 | [16,39,53,54,55] | ||||

| NBR | DLC | Ar + C4H10 | Si–C (optional) | [15,40,44,56] | |||

| Si–DLC | |||||||

| NBR, FKM, TPU | DLC | Ar + C2H2 | [42] | ||||

| NBR | DLC | Ar + C2H2 | [57,58] | ||||

| HNBR | DLC | Ar + C2H2 | [13,17,46,59,60,61] | ||||

| T-FAD | EPDM, MVQ | DLC | None, H2, Ar, C2H2, C2H4, CH4 | [14,37] | |||

| PBII | FKM | Si–DLC | Si (CH3)4 | [62] | |||

Abbreviations: ACM, acrylic rubber; CR, chloroprene rubber; EPDM, ethylene propylene diene monomer; FKM, fluororubber; HNBR, hydrogenated nitrile butadiene rubber; MVQ, silicone rubber; MS, magnetron sputtering; NBR, nitrile butadiene rubber; PACVD, plasma-assisted chemical vapor deposition; PBII, plasma-based ion implantation; PECVD, plasma-enhanced chemical vapor deposition; PLD, pulsed laser deposition; PVD, physical vapor deposition; T-FAD, T-shaped filtered arc deposition; TPU, thermoplastic polyurethane.

As for the rubber substrate, it plays a vital role in the ultimate tribological performance. The NBR and fluororubber present excellent tribological performance after coating DLC films [42]. The surface interaction between rubber and counterpart is modified with the coating of DLC. Therefore, the CoF dramatically decreases. However, the mechanical property of rubber determines the degree of deformation being loaded, which also affects the tribological behavior based on the contact area [43]. Besides, the surface roughness of coated rubber relies on the original roughness of the rubber substrate. In most studies, one typical way to estimate the surface roughness is via an atomic force microscope, with an analyzed area of less than 10 μm2 × 10 μm2. It should be noted that the actual contact area between rubber and counterparts is significantly larger than this size. The contact area at around millimeter level should be considered according to the size of the friction counterpart.

As for the category of DLC films, most cases are hydrogenated DLC films due to the merit in the frictional interactions. However, the interlayers and doping strategies have been rarely used in the DLC films on rubber. Lubwama et al. [44] systematically studied the function of Si–C interlayers between DLC films and rubber and suggested that interlayers can enhance adhesion. The doping technique has been used to modify the hardness, tribological properties, internal stress, and adhesion of DLC films on hard substrates [45]. It has enormous potential to apply doping on the DLC films to rubber substrates due to the prominent issues related to the film adhesion and internal stress between the DLC and soft rubber materials. The doped DLC films on the rubber substrate are discussed in the latter part.

The tribological properties of films are generally evaluated by tribotests, consisting of repeated movements of the film in contact with the counterpart (usually a ball) under a specific load, speed, and atmospheric conditions. Table 2 summarizes the test conditions and CoF of DLC films deposited on rubber substrate surfaces. The coated rubber exhibits a low CoF (∼0.2) compared with the raw rubber (∼0.8), which benefits from the excellent tribological properties of DLC films. However, the various friction conditions make it difficult to make comparisons. Pei et al. [46] proposed an analytical model to simulate the viscoelastic behavior of rubber in cyclic friction tests, as shown in Figure 2. It reveals the variation law of two friction elements in friction tests under different conditions. The adhesive friction mainly depends on the frictional contact area. In contrast, hysteresis friction relies on the contact surface force (or torque magnitude), which reveals the adhesive and hysteresis contributions to friction in the rubber tribology. According to the proposed theory, the tribotest condition can be briefly understood. The loading force has both effects on the contact area and the contact surface force. Thus, it is critical for CoF value. The contact area could also be determined by the rubber deformation (hardness), the size of the counterpart, and surface roughness. The morphology of coated rubber is shown in Table 2. The deposition method and rubber category lead to different morphology, which has a distinct influence on friction. As a result, it is necessary to control these parameters for comparing the tribology performance fairly.

Characteristics of DLC films on kinds of rubbers

| Substrate | Technique | Morphology | Performance | References |

|---|---|---|---|---|

| NBR | PACVD + DC–MS |

|

100Cr6 stainless steel ball | [42] |

| 10,000 cycles; load 1 N | ||||

| CoF ∼0.3 | ||||

| NBR | PACVD |

|

Brass counterpart (reciprocating) | [63] |

| 645 cycles; load 10 N | ||||

| CoF ∼0.5 | ||||

| NBR | MS |

|

GCr-15 stainless-steel ball | [20] |

| 10,000 cycles; load 1 N | ||||

| CoF ∼0.2 | ||||

| HNBR | CVD |

|

100Cr6 stainless steel ball | [60] |

| 10,000 cycles; load 1 N | ||||

| CoF ∼0.14 | ||||

| ACM | PACVD |

|

100Cr6 stainless steel ball | [16] |

| 10,000 cycles; load 1 N | ||||

| CoF ∼0.22 | ||||

| ACM | PECVD |

|

100Cr6 stainless steel ball | [55] |

| 30,000 cycles; load 1 N | ||||

| CoF ∼0.08 (oil) | ||||

| NBR | MS + PACVD |

|

100Cr6 stainless steel ball | [58] |

| 10,000 cycles; load 1 N | ||||

| CoF ∼0.2 | ||||

| PU | PCAD |

|

Annual chrome steel disk | [64] |

| Load 50 N | ||||

| CoF ∼0.3 | ||||

| NBR | MS |

|

Tungsten carbide ball | [22] |

| 7,500 cycles; load 0.3 N | ||||

| CoF ∼0.25 | ||||

| NBR | PECVD |

|

GCr15 steel ball | [65] |

| 12,000 cycles; load 3 N | ||||

| CoF ∼0.2 |

![Figure 2

(a) Sketch of the mattress model composed of standard linear solid (SLS) units under deformation by a ball. The detailed SLS arrangement is enclosed. (b) Strain evolution of an SLS under static loading. (c) Strain evolution of an SLS under cyclic loading. (d) A closer view of a loading–unloading cycle in the steady state. Schematic overview of the influence of the increase in shear strength (from (e) to (f)), normal load (from (f) to (g)) on the contact area, and friction contributions of DLC film-coated rubber (a–g) [46].](/document/doi/10.1515/ntrev-2022-0481/asset/graphic/j_ntrev-2022-0481_fig_002.jpg)

(a) Sketch of the mattress model composed of standard linear solid (SLS) units under deformation by a ball. The detailed SLS arrangement is enclosed. (b) Strain evolution of an SLS under static loading. (c) Strain evolution of an SLS under cyclic loading. (d) A closer view of a loading–unloading cycle in the steady state. Schematic overview of the influence of the increase in shear strength (from (e) to (f)), normal load (from (f) to (g)) on the contact area, and friction contributions of DLC film-coated rubber (a–g) [46].

3.2 Structured DLC films on rubber

When the DLC films are deposited onto the rubber, the deformation of the soft substrate tends to cause catastrophic failures of the DLC films [66]. Extensive works focus on the segment-structured DLC films addressing the incongruous deformation between hard films and soft substrates [52]. The mesh wire was employed to fabricate the segment-structured DLC films on a substrate (Figure 3a1). The wear resistance of the new structure was significantly improved compared with that of the conventional unsegmented DLC films due to effective stress relaxation (Figure 3a2).

![Figure 3

(a1) Film method for producing segment-structured DLC films. (a2) Schematic illustration of segment-structured DLC film, (a1 and a2) [52]. (b1) Evolution of measured substrate temperature versus time of plasma cleaning (open symbols) and deposition (close marks), with the solid fitted curves. (b2) Sizes of film segments as measured and predicted versus temperature variation ΔT during deposition. (b3) Surface morphology of DLC films on hydrogenated nitrile butadiene rubber (HNBR) deposited at temperature variations: ΔT = –46.3 °C. (b4) CoF of 300 nm thick DLC films on HNBR with segment sizes indicated, (b1–b4) [13]. Sketch of the segmentation mechanism in different regimes of temperature variation during deposition: (b5) positive ΔT and (b6) negative ΔT. The length of the arrow pairs indicates the rubber substrate’s thermal expansion or contraction rate at different moments of deposition from t

1 to t

4. The cooling phase after deposition is from t

4 to t

f, (b5 and b6) [59].](/document/doi/10.1515/ntrev-2022-0481/asset/graphic/j_ntrev-2022-0481_fig_003.jpg)

(a1) Film method for producing segment-structured DLC films. (a2) Schematic illustration of segment-structured DLC film, (a1 and a2) [52]. (b1) Evolution of measured substrate temperature versus time of plasma cleaning (open symbols) and deposition (close marks), with the solid fitted curves. (b2) Sizes of film segments as measured and predicted versus temperature variation ΔT during deposition. (b3) Surface morphology of DLC films on hydrogenated nitrile butadiene rubber (HNBR) deposited at temperature variations: ΔT = –46.3 °C. (b4) CoF of 300 nm thick DLC films on HNBR with segment sizes indicated, (b1–b4) [13]. Sketch of the segmentation mechanism in different regimes of temperature variation during deposition: (b5) positive ΔT and (b6) negative ΔT. The length of the arrow pairs indicates the rubber substrate’s thermal expansion or contraction rate at different moments of deposition from t 1 to t 4. The cooling phase after deposition is from t 4 to t f, (b5 and b6) [59].

Pei et al. developed another approach to deposit flexible DLC films on rubber via self-segmentation based on the unique structural design [61]. They tuned the substantial thermal mismatch between the DLC film and rubber substrate to form a dense network of cracks in the DLC film, contributing to its flexibility. The size of the micro-segments can be controlled by tuning the substrate temperature variation during deposition by varying the bias voltage (Figure 3b1 and b2). When DLC films are deposited on the rubber surface, cracks are initialized due to the mismatch of thermal stresses and form a dendritic network of cracks, dividing the films into micron-scale areas (Figure 3b3). The decreased size of the film segments and the opening gap between the segments give rise to excellent tribological performance (Figure 3b4). This method exhibited a creative mentality for designing structures with excellent tribology. A reasonable estimation of the less size of film segments, such as nanoscale, will provide better tribology performance. Because the property of rubber limits the temperature range, the other strategy should be considered.

The mechanism of crack formation is schematically depicted in Figure 3. Under a positive temperature difference (the difference between the plasma cleaning temperature and the deposition temperature is above zero; Figure 3b5), the films are separated from each other due to the thermal expansion of the rubber substrate. As the temperature tends to be stable, the expansion rate of the films decreases, while the growth rate of films remains constant throughout the deposition process. Therefore, the film continuously grows from a certain point. As the temperature increases, the rubber substrate expands, resulting in cracks in the films due to tensile stress.

In contrast, the negative temperature difference (Figure 3b6) does not affect the continuous growth of the film. The compressive stress acts from the beginning of the deposition, which promotes the formation of continuous films, resulting in a higher crack density and smaller size patches on the surface after cooling. The inward shrinkage of the rubber occurs during the final cooling, which causes the inward bending of the crack edges. Hence, the film formed at the positive temperature difference is relatively flatter than at the negative temperature difference. The cracks in the DLC film on the rubber surface bend inward regardless of the positive or negative temperature difference. This inwardly curved and closed crack avoids the interaction between the patches and the severe wear caused by the generated abrasive chips.

3.3 Adhesion between DLC films and rubber

The adhesion between film and substrate critically determines the reliability and service lifespan of the film application and is also a common concern in the manufacturing process. The primary damage to the films during wear is the inconsistent deformation between the film and substrate, resulting in exfoliation of the films. Therefore, the key to improving DLC films’ tribological performance on rubber substrate lies in enhancing the adhesion. So far, there are two common ways to enhance adhesion.

3.3.1 Plasma pretreatment

A clean surface fosters good adhesion between the films and the substrate. The strict temperature limitation of rubber makes plasma cleaning an alternative method to obtain a clean surface. An argon plasma was used to treat the rubber surface before the deposition of DLC films [49]. The morphology difference under strain between plasma-treated and untreated rubber reveals that plasma treatment strengthens interfacial adhesion (Figure 4). When the stress is released, all cracks return to their initial microstructure. Thus, no delamination of the film patches was observed. It indicates that the DLC film adheres well to the rubber substrate after plasma treatment. The modification of the rubber morphology and changing the temperature at the start of the deposition are responsible for enhanced adhesion. If the adhesion between the rubber substrate and the DLC films is sufficiently high, many cracks could form on the surface after stretching; the film flakes off at the crack edges to release the stress. A method to quantify the adhesion of DLC films on rubber surfaces was also developed based on the in situ tensile tests [53]. During the strain, the film breaks, and the patch size decreases until it reaches the maximum adhesion value; the patch size keeps constant. Therefore, the relationship between the final patch size (

where

![Figure 4

Morphology of DLC film deposited on untreated (left column) and −400 V Ar plasma pretreated HNBR (right column) after being stretched to: (a and d) 20% strain; (b and e) 50% strain; and (c and f) unloaded from the maximum strain. A pair of arrows indicates the stretch direction (a–f) [49].](/document/doi/10.1515/ntrev-2022-0481/asset/graphic/j_ntrev-2022-0481_fig_004.jpg)

Morphology of DLC film deposited on untreated (left column) and −400 V Ar plasma pretreated HNBR (right column) after being stretched to: (a and d) 20% strain; (b and e) 50% strain; and (c and f) unloaded from the maximum strain. A pair of arrows indicates the stretch direction (a–f) [49].

Furthermore, various gas combinations for plasma treatment have been investigated recently. Four plasma gases were used to treat the rubber surface before deposition, and the adhesion difference was studied [21]. The X-cut method was utilized to estimate the adhesion, revealing that NBR with N2 and Ar plasma pretreatment has the optimal adhesion with DLC films (Figure 5a–d). The X-cut method uses a blade to cut X-shaped cuts on the sample’s surface and then utilizes a specific tape to adhere and tear the cuts. The peeled films are evaluated qualitatively in the X-cut region using microscopy to assess the adhesion level of the films [69,70]. Furthermore, the observed stable friction curve with a CoF of 0.2 is ascribed to forming a compact layer on the rubber surface, originating from the Ar pretreatment (Figure 5e).

![Figure 5

SEM images of X-cuts after peel tests for DLC/rubber with different plasma pretreatments: (a) Ar–O2; (b) Ar–H2; (c) Ar–N2; and (d) Ar–Ar. (e) CoF of virgin NBR and DLC/rubber with different plasma pretreatments, (a–e) [21]. The carbon and oxygen element mapping images of NBR rubber pretreated by Ar plasma at the various times of (f) 0, (g) 15, (h) 30, and (i) 75 min. (j) CoF and acoustic signal function as the DLC film’s loading force (f–j) [71].](/document/doi/10.1515/ntrev-2022-0481/asset/graphic/j_ntrev-2022-0481_fig_005.jpg)

SEM images of X-cuts after peel tests for DLC/rubber with different plasma pretreatments: (a) Ar–O2; (b) Ar–H2; (c) Ar–N2; and (d) Ar–Ar. (e) CoF of virgin NBR and DLC/rubber with different plasma pretreatments, (a–e) [21]. The carbon and oxygen element mapping images of NBR rubber pretreated by Ar plasma at the various times of (f) 0, (g) 15, (h) 30, and (i) 75 min. (j) CoF and acoustic signal function as the DLC film’s loading force (f–j) [71].

The effects of separate treatment times were investigated to clarify more structure information caused by Ar pretreatment [71]. The two main influences of Ar pretreatment were proposed: One is the removal of surface contaminants; the other is the creation of free radicals on the surface. The following method was used to investigate the surface-free radicals well: Comparing the captured molecular O2 and H2O from the air atmosphere. The results of element mapping (Figure 5f–i) reveal that the free radicals increase with the prolonged pretreatment time. Meanwhile, the other method, the scratch test, was used to adjust the critical adhesion quantitatively (Figure 5j). Therefore, the optimal time for Ar pretreatment was established. The scratch test is simple, intuitive, quantitative, and can simulate the actual working conditions to a certain extent. The acoustic signal renders the estimation of critical adhesion more reliable.

3.3.2 Interlayers

Designing an intermediate transition layer can also be an effective way to improve adhesion by decreasing residual stress. The interlayers should have good adhesion to both rubber and DLC films. Typically, the hardness of interlayers needs to be in between rubber and DLC films so that there is a gradient deformation, which is beneficial for eliminating stress. Considering the element composition of rubber and DLC, the carbon-based interlayer is favorable.

The Ti–C films were interlayers between DLC and the rubber substrate to enhance the tribological performance [24]. Compared to the wear tracks after the friction test, the samples with Ti–C interlayers exhibit better abrasion performance (Figure 6a), attributed to improved adhesion. Meanwhile, the structure of interlayers is also essential. The interlayers under higher bias voltage possess lower I D/I G and strong adhesion, supporting superior tribological performance.

![Figure 6

(a) SEM images showing the wear tracks of NBR, DLC coated on NBR (DLC, DT1, DT2, DT3, and DT4). The DLC films with a Ti–C interlayer under substrate bias voltages of 0, −50, −100, and −150 V are referred to as DT1, DT2, DT3, and DT4, respectively [24]. (b) Process design for DLC and Si–DLC films deposited on NBR substrate. Vickers hardness (at 147.1 mN indentation load) and adhesion levels for DLC and Si–DLC films without and with Si–C interlayer [56]. (c) The residual stress of films deposited on NBR and Si wafer substrates. The terms “DLC-1 film, DLC-2 film, DLC-3 film, DLC-4 film” were used to denote the Si–DLC films on different Si interlayers with a deposition time of 0, 5, 15, and 35 min [25].](/document/doi/10.1515/ntrev-2022-0481/asset/graphic/j_ntrev-2022-0481_fig_006.jpg)

(a) SEM images showing the wear tracks of NBR, DLC coated on NBR (DLC, DT1, DT2, DT3, and DT4). The DLC films with a Ti–C interlayer under substrate bias voltages of 0, −50, −100, and −150 V are referred to as DT1, DT2, DT3, and DT4, respectively [24]. (b) Process design for DLC and Si–DLC films deposited on NBR substrate. Vickers hardness (at 147.1 mN indentation load) and adhesion levels for DLC and Si–DLC films without and with Si–C interlayer [56]. (c) The residual stress of films deposited on NBR and Si wafer substrates. The terms “DLC-1 film, DLC-2 film, DLC-3 film, DLC-4 film” were used to denote the Si–DLC films on different Si interlayers with a deposition time of 0, 5, 15, and 35 min [25].

The Si–C interlayers were also investigated on the NBR substrate [56]. The DLC films with Si–C interlayers give rise to better adhesion levels than bare DLC films. In contrast, this kind of interlayer induces a decrease in hardness simultaneously (Figure 6b). Eventually, the Si–C interlayer does not improve tribological performance. The thickness of the interlayer is also very sensitive to tribological performance. The thick interlayer will cause enormous residual stress, while the thin interlayer will only result in negligible residual stress. The thickness-related research was conducted on the Si interlayers [25]. It was found that there was an optimal thickness for the lowest residual stress (Figure 6c). Therefore, the thickness of the interlayer is a critical factor to consider when introducing an interlayer.

3.4 Doped DLC films on rubber

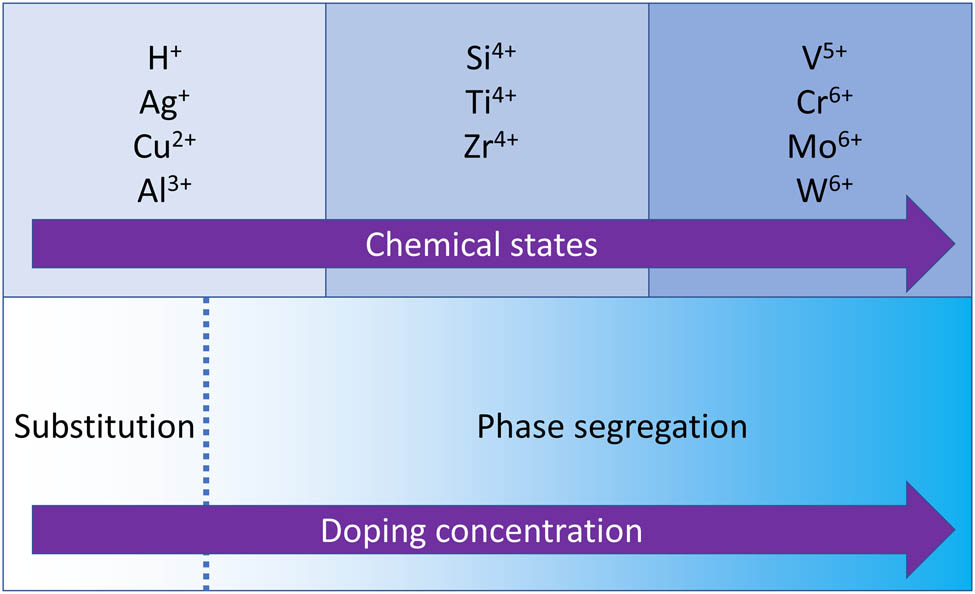

Incorporating certain doping elements into DLC films may significantly affect the tribochemical mechanisms [72]. These different elements can participate in various reactions and tune the tribological action of DLC films. From the mechanics’ aspect, doping can modify the sp2 and sp3 structures, leading to changes in the mechanical properties. Due to the mismatching mechanical properties between rubber and DLC films, it is critical to decrease the internal stress to enhance tribological performance. Many dopants have been used to decorate DLC films, achieving excellent friction performance [73,74,75]. The typical strategies related to the DLC films are summarized in Figure 7. The doping elements can be divided into three groups according to different chemical states. The difference in the valence electrons’ number will induce different types of potential for electrons. As far as we know, the research on electrostatic tribology, like hydrogenated DLC [36], is limited. Most research suggests that incorporating doping elements changes the environment of C, leading to changes in hardness and stress [76,77]. Besides, doping concentration is also vital for the tribological performance of DLC films. When the doping concentration is low, the doping atoms will substitute the C sites or enter interstitial sites [78]. However, phase segregation occurs as the doping concentration rises. The elements with valencies lower than 4 typically form the metal nanocrystalline [79] rather than the carbide phases when the doping elements have high chemical states [80,81]. Phase segregation is a disadvantage for tribology due to the rough interface and abrasive wear [82]. Therefore, doping with low concentration is promising for optimizing the tribological performance of DLC films.

The typical doping strategy of DLC films.

The doped DLC films have been less applied on the rubber substrate. In the early days, Ti–DLC [50], W–DLC [48], and Si–DLC [62] were fabricated on the rubber, exhibiting enhanced tribological performance compared with bare rubber. However, the structural changes caused by doping have not been thoroughly investigated. Lubwama et al. reported the Raman analysis (Figure 8) of Si–DLC compared with DLC [40]. The residual stress was calculated as follows [83]:

where

![Figure 8

Raman spectra at 488 and 325 nm for (a) DLC, (b) Si–DLC, (c) DLC with Si–C, and (d) Si–DLC with Si–C films deposited on nitrile rubber (a–d) [40].](/document/doi/10.1515/ntrev-2022-0481/asset/graphic/j_ntrev-2022-0481_fig_008.jpg)

Raman spectra at 488 and 325 nm for (a) DLC, (b) Si–DLC, (c) DLC with Si–C, and (d) Si–DLC with Si–C films deposited on nitrile rubber (a–d) [40].

Another Si–DLC film on rubber was studied by Liu et al. [85]. The various Si compositions were designed to investigate the structure of Si–DLC films. It was found that the incorporated Si probably exists in the form of Si–C bonds [86] at a high Si concentration (Si–DLC1) (Figure 9). As the Si concentration decreases further, the Si 2p peak could be fitted into two peaks at ∼100.3 eV for Si–C bonds and ∼101.3 eV for SiO x C y bonds [87], indicating that the incorporated Si probably exists in the form of SiC and SiO x C y at relatively low Si concentration. The Si–DLC films with appropriate Si content produce excellent tribological performance, attributed to the counterpart’s protection, even with relatively low hardness.

![Figure 9

(a) The Si 2p spectra of the Si–DLC films deposited at different CH4 flow rates on NBR, and the fitted Si 2p spectrum of (b) Si–DLC1 film, (c) Si–DLC2 film, (d) Si–DLC3 film, (e) Si–DLC4 film, and (f) Si–DLC5 film. The Si concentration gradually decreases from Si–DLC1 to Si–DLC5 films [85].](/document/doi/10.1515/ntrev-2022-0481/asset/graphic/j_ntrev-2022-0481_fig_009.jpg)

(a) The Si 2p spectra of the Si–DLC films deposited at different CH4 flow rates on NBR, and the fitted Si 2p spectrum of (b) Si–DLC1 film, (c) Si–DLC2 film, (d) Si–DLC3 film, (e) Si–DLC4 film, and (f) Si–DLC5 film. The Si concentration gradually decreases from Si–DLC1 to Si–DLC5 films [85].

Some other materials were also used to modify the DLC films. The F-DLC was fabricated by introducing the C4F8 gas precursor [88], wherein the mass loss was measured to compare with the wear resistance. The results show that the incorporation of fluorine has little influence on the CoF (Figure 10a). Furthermore, as a solid lubricant, transition metal dichalcogenides (TMDs) such as MoS2 or WS2 have been widely used to accompany DLC [89,90]. Various DLC/MoS2 ratios were deposited on elastomeric substrates, and the tribological performance was compared. The thick films keep intact after friction compared to the severely damaged thin films (Figure 10b and c).

4 Summary and perspective

Rubber has been widely used as a common sealing material in the environment of friction. The DLC film significantly improves the friction and wear performance of the rubber surface, which dramatically reduces the CoF of the rubber surface. However, applying hard films to a soft substrate is still challenging. The deformation in the soft rubber induces the fracture of hard films, and afterward, the exfoliation of DLC films may cause severe wear. The structured films, plasma pretreatment, and interlayers yield satisfying results in improved tribological performance. Film adhesion is a focal point in improving the tribology performance of DLC-coated rubber to avoid DLC films’ peel-off. Meanwhile, the doped DLC films exhibit the potential to eliminate residual stress, which is also beneficial for adhesion. The doped DLC films could be well utilized on the rubber substrate according to the comprehensive mechanism.

Even though the DLC films exhibit the low CoF on the rubber surface, the wear consumption of DLC layers is the main factor determining the lifetime of protection. The increased thickness is an alternative way to prolong the lifetime of DLC films. Nevertheless, considerable stress will be generated with the increase in thickness. In this case, the advantage of the doping method in eliminating stress is significant. Besides, further decreasing the wear despite the evident deformation should be the other pathway in this field. The wear mechanism of DLC films is responsible for designing more wear-resistant films [92]. Due to the lack of sophisticated investigation of surface revolution in the friction process on a rubber substrate, a method for enhancing the wear-resistant property needs to be developed. With the development of characteristic technology, the in situ structure characteristic combining the tribotest is promising to explore the wear mechanism of DLC films on rubber, such as in situ XPS and Raman.

After enhancing the wear-resistant property, the increasing loading force might not be a challenge for DLC-coated rubber. Thus, the rubber can bear severe harsh friction conditions. Due to the extensive application of soft materials in the friction environment, this field is vital in decreasing the waste caused by friction.

-

Funding information: This work was supported by the Key Projects of Hainan Province (ZDYF2019206) and the Natural Science Foundation of Hainan Province (420RC525).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Rosenkranz A, Costa HL, Baykara MZ, Martini A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear – A review. Tribol Int. 2021;155:106792.10.1016/j.triboint.2020.106792Search in Google Scholar

[2] Ke Y, Yao X, Yang H, Liu X. Kinetic friction characterizations of the tubular rubber seals. Tribol Int. 2014;72:35–41.10.1016/j.triboint.2013.12.004Search in Google Scholar

[3] Bakolas V, Roedel P, Koch O, Pausch M. A first approximation of the global energy consumption of ball bearings. Tribol Trans. 2021;64(5):883–90.10.1080/10402004.2021.1946227Search in Google Scholar

[4] Wolthuizen DJ, Martinez-Martinez D, Pei YT, De, Hosson JTM. Influence of plasma treatments on the frictional performance of rubbers. Tribol Lett. 2012;47(2):303–11.10.1007/s11249-012-9985-9Search in Google Scholar

[5] Zhang ZX, Shen MX, Xiong GY. Time-dependent effect on wetting and tribological properties of plasma-modified acrylonitrile-butadiene rubber (NBR) surface. Int J Mod Phys B. 2019;33:1940050 (3rd International Conference on Materials Science and Nanotechnology (ICMSNT)). 10.1142/S0217979219400502Search in Google Scholar

[6] Liu Z, Zhou B, Rogachev AV, Yarmolenko MA. Growth feature of PTFE coatings on rubber substrate by low-energy electron beam dispersion. Polym Adv Technol. 2016;27(6):823–9.10.1002/pat.3723Search in Google Scholar

[7] Tashlykov IS, Kasperovich VI, Shadrukhin MG, Kasperovich AV, Wolf GK, Wesch W. Elastomer treatment by arc metal deposition assisted with self-ion irradiation. Surf Coat Technol. 1999;116–119(Complete):848–52.10.1016/S0257-8972(99)00205-4Search in Google Scholar

[8] Tashlykov IS, Kasperovich AV, Wolf GK. Elastomer surface modification by means of SIAD of metal-based layers. Surf Coat Technol. 2002;158–159:498–502.10.1016/S0257-8972(02)00287-6Search in Google Scholar

[9] Cadambi RM, Ghassemieh E. Hard coatings on elastomers for reduced permeability and increased wear resistance. Plast Rubber Compos. 2012;41(4–5):169–74.10.1179/1743289811Y.0000000048Search in Google Scholar

[10] Tyagi A, Walia RS, Murtaza Q, Pandey SM, Tyagi PK, Bajaj B. A critical review of diamond like carbon coating for wear resistance applications. Int J Refract Met Hard Mater. 2019;78:107–22.10.1016/j.ijrmhm.2018.09.006Search in Google Scholar

[11] Chen X, Zhang C, Kato T, Yang X, Wu S, Wang R, et al. Evolution of tribo-induced interfacial nanostructures governing superlubricity in a-C:H and a-C:H:Si films. Nat Commun. 2017;8(1):1675.10.1038/s41467-017-01717-8Search in Google Scholar PubMed PubMed Central

[12] Nakahigashi T, Tanaka Y, Miyake K, Oohara H. Properties of flexible DLC film deposited by amplitude-modulated RF P-CVD. Tribol Int. 2004;37(11–12 SPEC.ISS.):907–12.10.1002/9780470294802.ch84Search in Google Scholar

[13] Pei YT, Bui XL, De, Hosson JTM. Flexible protective diamond-like carbon film on rubber. Scr Mater. 2010;63(6):649–52.10.1016/j.scriptamat.2010.05.036Search in Google Scholar

[14] Takikawa H, Miyakawa N, Minamisawa S, Sakakibara T. Fabrication of diamond-like carbon film on rubber by T-shape filtered-arc-deposition under the influence of various ambient gases. Thin Solid Films. 2004;457(1):143–50.10.1016/j.tsf.2003.12.029Search in Google Scholar

[15] Lubwama M, McDonnell KA, Kirabira JB, Sebbit A, Sayers K, Dowling D, et al. Characteristics and tribological performance of DLC and Si-DLC films deposited on nitrile rubber. Surf Coat Technol. 2012;206(22):4585–93.10.1016/j.surfcoat.2012.05.015Search in Google Scholar

[16] Martinez-Martinez D, Schenkel M, Pei YT, De Hosson JTM. Microstructural and frictional control of diamond-like carbon films deposited on acrylic rubber by plasma assisted chemical vapor deposition. Thin Solid Films. 2011;519(7):2213–7.10.1016/j.tsf.2010.11.006Search in Google Scholar

[17] Pei YT, Bui XL, De Hosson JTM. Deposition and characterization of hydrogenated diamond-like carbon thin films on rubber seals. Thin Solid Films. 2010;518(21):S42–5.10.1016/j.tsf.2010.03.018Search in Google Scholar

[18] Lubwama M, Corcoran B, Sayers K. DLC films deposited on rubber substrates: A review. Surf Eng. 2015;31(1):1–10.10.1179/1743294414Y.0000000379Search in Google Scholar

[19] Martinez-Martinez D, De Hosson JTM. On the deposition and properties of DLC protective coatings on elastomers: A critical review. Surf Coat Technol. 2014;258:677–90.10.1016/j.surfcoat.2014.08.016Search in Google Scholar

[20] Xu Y, Jia J, Zhang G, Li H, Chen T. Effect of rubber substrates on the flexibility and tribological properties of diamond-like carbon coatings. Surf Coat Technol. 2021;422:127526.10.1016/j.surfcoat.2021.127526Search in Google Scholar

[21] Bai C, Gong Z, An L, Qiang L, Zhang J, Yushkov G, et al. Adhesion and friction performance of DLC/rubber: The influence of plasma pretreatment. Friction. 2021;9(3):627–41.10.1007/s40544-020-0436-6Search in Google Scholar

[22] Liu JQ, Li LJ, Wei B, Wen F, Cao HT, Pei YT. Effect of sputtering pressure on the surface topography, structure, wettability and tribological performance of DLC films coated on rubber by magnetron sputtering. Surf Coat Technol. 2019;365:33–40.10.1016/j.surfcoat.2018.05.012Search in Google Scholar

[23] Liu JQ, Wu ZY, Cao HT, Wen F, Pei YT. Effect of bias voltage on the tribological and sealing properties of rubber seals modified by DLC films. Surf Coat Technol. 2019;360:391–9.10.1016/j.surfcoat.2018.12.100Search in Google Scholar

[24] Wu YM, Liu JQ, Cao HT, Wu ZY, Wang Q, Ma YP, et al. On the adhesion and wear resistance of DLC films deposited on nitrile butadiene rubber: A Ti-C interlayer. Diam Relat Mater. 2020;101:107563.10.1016/j.diamond.2019.107563Search in Google Scholar

[25] Qiang L, Bai C, Gong Z, Liang A, Zhang J. Microstructure, adhesion and tribological behaviors of Si interlayer/Si doping diamond-like carbon film developed on nitrile butadiene rubber. Diam Relat Mater. 2019;92:208–18.10.1016/j.diamond.2019.01.005Search in Google Scholar

[26] Robertson J. Amorphous carbon. Adv Phys. 1986;35(4):317–74.10.1080/00018738600101911Search in Google Scholar

[27] Fukui H, Irie M, Utsumi Y, Oda K, Ohara H. An investigation of the wear track on DLC (a-C:H) film by time-of-flight secondary ion mass spectroscopy. Surf Coat Technol. 2001;146–147:378–83.10.1016/S0257-8972(01)01422-0Search in Google Scholar

[28] Liu Y, Erdemir A, Meletis EI. An investigation of the relationship between graphitization and frictional behavior of DLC coatings. Surf Coat Technol. 1996;86–87:564–8.10.1016/S0257-8972(96)03057-5Search in Google Scholar

[29] Erdemir A, Eryilmaz OL, Fenske GR. Synthesis of diamondlike carbon films with superlow friction and wear properties. J Vac Sci Technol. 2000;18:1987–92.10.1116/1.582459Search in Google Scholar

[30] Donnet C, Fontaine J, Grill A, Mogne TL. The role of hydrogen on the friction mechanism of diamond-like carbon films. Tribol Lett. 2001;9(3–4):137–42.10.1023/A:1018800719806Search in Google Scholar

[31] Erdemir A. Genesis of superlow friction and wear in diamondlike carbon films. Tribol Int. 2004;37(11):1005–12.10.1016/j.triboint.2004.07.018Search in Google Scholar

[32] Erdemir A, Donnet C. Tribology of diamond-like carbon films: Recent progress and future prospects. J Phys D Appl Phys. 2006;39:R311.10.1088/0022-3727/39/18/R01Search in Google Scholar

[33] Dickrell PL, Sawyer WG, Heimberg JA, Singer IL, Wahl KJ, Erdemir A. A gas-surface interaction model for spatial and time-dependent friction coefficient in reciprocating contacts: Applications to near-frictionless carbon. J Tribol. 2005;127(1):82–8.10.1115/1.1829719Search in Google Scholar

[34] Murashima M, Oyama S, Kousaka H, Tokoroyama T, Lee WY, Umehara N. New in situ low-friction technology for diamond-like carbon coatings using surface discharge treatment in ambient air. Tribol Int. 2022;165:107306.10.1016/j.triboint.2021.107306Search in Google Scholar

[35] Robertson J. Diamond-like amorphous carbon. Mater Sci Eng R Rep. 2002;37(4–6):129–281.10.1016/S0927-796X(02)00005-0Search in Google Scholar

[36] Erdemir A, Eryilmaz O. Achieving superlubricity in DLC films by controlling bulk, surface, and tribochemistry. Friction. 2014;2(2):140–55.10.1007/s40544-014-0055-1Search in Google Scholar

[37] Miyakawa N, Minamisawa S, Takikawa H, Sakakibara T. Physical–chemical hybrid deposition of DLC film on rubber by T-shape filtered-arc-deposition. Vacuum. 2004;73(3–4):611–7.10.1016/j.vacuum.2003.12.079Search in Google Scholar

[38] Yoshida S, Okoshi M, Inoue N. Femtosecond-pulsed laser deposition of diamond-like carbon films onto silicone rubber. J Phys Conf Ser. 2007;59(1):368–71.10.1088/1742-6596/59/1/077Search in Google Scholar

[39] Martinez-Martinez D, Schenkel M, Pei YT, Sánchez-López JC, De Hosson JTM. Microstructure and chemical bonding of DLC films deposited on ACM rubber by PACVD. Surf Coat Technol. 2011;205(SUPPL. 2):75–8S.10.1016/j.surfcoat.2011.02.067Search in Google Scholar

[40] Lubwama M, Corcoran B, Rajani KV, Wong CS, Kirabira JB, Sebbit A, et al. Raman analysis of DLC and Si-DLC films deposited on nitrile rubber. Surf Coat Technol. 2013;232:521–7.10.1016/j.surfcoat.2013.06.013Search in Google Scholar

[41] Li Q, Bin Z, Yuanlie Y, Junyan Z. Research progress on wear resistance modification of carbon-based film on rubber. China Surf Eng. 2021;34(2):25–34.Search in Google Scholar

[42] Thirumalai S, Hausberger A, Lackner JM, Waldhauser W, Schwarz T. Effect of the type of elastomeric substrate on the microstructural, surface and tribological characteristics of diamond-like carbon (DLC) coatings. Surf Coat Technol. 2016;302:244–54.10.1016/j.surfcoat.2016.06.021Search in Google Scholar

[43] Bayrak S, Paulkowski D, Stöckelhuber KW, Staar B, Mayer B. A comprehensive study about the role of crosslink density on the tribological behavior of DLC coated rubber. Mater (Basel, Switz). 2020;13(23):5460.10.3390/ma13235460Search in Google Scholar PubMed PubMed Central

[44] Lubwama M, Corcoran B, McDonnell KA, Dowling D, Kirabira JB, Sebbit A, et al. Flexibility and frictional behaviour of DLC and Si-DLC films deposited on nitrile rubber. Surf Coat Technol. 2014;239:84–94.10.1016/j.surfcoat.2013.11.023Search in Google Scholar

[45] Sánchez-López JC, Fernández A. Doping and alloying effects on DLC coatings. Tribology of diamond-like carbon films. Boston, MA: Springer US; p. 311–38.10.1007/978-0-387-49891-1_12Search in Google Scholar

[46] Pei YT, Martinez-Martinez D, Van Der Pal JP, Bui XL, Zhou XB, De, et al. Flexible diamond-like carbon films on rubber: Friction and the effect of viscoelastic deformation of rubber substrates. Acta Mater. 2012;60(20):7216–25.10.1016/j.actamat.2012.09.031Search in Google Scholar

[47] Pei Y, Bui XL, Zhou XB, De Hosson JTM. Microstructure and tribological behavior of tungsten-containing diamondlike carbon coated rubbers. J Vac Sci Technol A Vac Surf Film. 2008;26:1085–92.10.1116/1.2889443Search in Google Scholar

[48] Pei YT, Bui XL, Zhou XB, De Hosson JTM. Tribological behavior of W-DLC coated rubber seals. Surf Coat Technol. 2008;202(9):1869–75.10.1016/j.surfcoat.2007.08.013Search in Google Scholar

[49] Bui XL, Pei YT, Mulder EDG, De Hosson JTM. Adhesion improvement of hydrogenated diamond-like carbon thin films by pre-deposition plasma treatment of rubber substrate. Surf Coat Technol. 2009;203(14):1964–70.10.1016/j.surfcoat.2009.01.027Search in Google Scholar

[50] Bui XL, Pei YT, De, Hosson JTM. Magnetron reactively sputtered Ti-DLC coatings on HNBR rubber: The influence of substrate bias. Surf Coat Technol. 2008;202(20):4939–44.10.1016/j.surfcoat.2008.04.078Search in Google Scholar

[51] Lackner JM, Major R, Major L, Schöberl T, Waldhauser W. RF deposition of soft hydrogenated amorphous carbon coatings for adhesive interfaces on highly elastic polymer materials. Surf Coat Technol. 2009;203(16):2243–8.10.1016/j.surfcoat.2009.02.012Search in Google Scholar

[52] Aoki Y, Ohtake N. Tribological properties of segment-structured diamond-like carbon films. Tribol Int. 2004;37(11):941–7.10.1016/j.triboint.2004.07.011Search in Google Scholar

[53] Schenkel M, Martinez-Martinez D, Pei YT, De Hosson JTM. Tribological performance of DLC films deposited on ACM rubber by PACVD. Surf Coat Technol. 2011;205(20):4838–43.10.1016/j.surfcoat.2011.04.072Search in Google Scholar

[54] Martinez-Martinez D, Van Der Pal JP, Pei YT, De, Hosson JTM. Performance of diamond-like carbon-protected rubber under cyclic friction. I. Influence of substrate viscoelasticity on the depth evolution. J Appl Phys. 2011;110:124906.10.1063/1.3665443Search in Google Scholar

[55] Martinez-Martinez D, van der Pal JP, Schenkel M, Shaha KP, Pei YT, De Hosson JTM. On the nature of the coefficient of friction of diamond-like carbon films deposited on rubber. J Appl Phys. 2012;111(11):114902.10.1063/1.4723830Search in Google Scholar

[56] Lubwama M, Corcoran B, Sayers K, Kirabira JB, Sebbit A, McDonnell KA, et al. Adhesion and composite micro-hardness of DLC and Si-DLC films deposited on nitrile rubber. Surf Coat Technol. 2012;206(23):4881–6.10.1016/j.surfcoat.2012.05.079Search in Google Scholar

[57] Pei YT, Eivani AR, Zaharia T, Kazantzis AV, Van de Sanden MCM, De Hosson JTM. High throughput deposition of hydrogenated amorphous carbon coatings on rubber with expanding thermal plasma. Surf Coat Technol. 2014;245:74–83.10.1016/j.surfcoat.2014.02.043Search in Google Scholar

[58] Thirumalai S, Hausberger A, Lackner JM, Waldhauser W, Schwarz T. Anode layer source plasma-assisted hybrid deposition and characterization of diamond-like carbon coatings deposited on flexible substrates. Thin Solid Films. 2018;655:54–61.10.1016/j.tsf.2018.04.012Search in Google Scholar

[59] Pei YT, Bui XL, Van Der Pal JP, Martinez-Martinez D, Zhou XB, De, et al. Flexible diamond-like carbon films on rubber: On the origin of self-acting segmentation and film flexibility. Acta Mater. 2012;60(15):5526–35.10.1016/j.actamat.2012.07.017Search in Google Scholar

[60] van der Pal JP, Martinez-Martinez D, Pei YT, Rudolf P, De Hosson JTM. Microstructure and tribological performance of diamond-like carbon films deposited on hydrogenated rubber. Thin Solid Films. 2012;524:218–23.10.1016/j.tsf.2012.10.005Search in Google Scholar

[61] Pei YT, Bui XL, Van Der Pal JP, Martinez-Martinez D, De, Hosson JTM. Flexible diamond-like carbon film coated on rubber. Prog Org Coat. 2013;76(12):1773–8.10.1016/j.porgcoat.2013.05.015Search in Google Scholar

[62] Masami I, Haruho M, Tatsuya M, Junho C. Low temperature Si-DLC coatings on fluoro rubber by a bipolar pulse type PBII system. Surf Coat Technol. 2011;206(5):999–1002.10.1016/j.surfcoat.2011.04.011Search in Google Scholar

[63] Martínez L, Nevshupa R, Álvarez L, Huttel Y, Méndez J, Román E, et al. Application of diamond-like carbon coatings to elastomers frictional surfaces. Tribol Int. 2009;42(4):584–90.10.1016/j.triboint.2008.06.016Search in Google Scholar

[64] Zhang L, Zong X, Yuan X, Xing X. Effects of polyurethane substrate pre-treatment on pulsed cathodic arc deposited DLC Films. Coatings. 2020;10(6):545.10.3390/coatings10060545Search in Google Scholar

[65] Bai C, Qiang L, Zhang B, Gao K, Zhang J. Optimizing the tribological performance of DLC-coated NBR rubber: The role of hydrogen in films. Friction. 2022;10(6):866–77.10.1007/s40544-021-0498-0Search in Google Scholar

[66] Begley MR, Evans AG, Hutchinson JW. Spherical impression of thin elastic films on elastic–plastic substrates. Int J Solids Struct. 1999;36(18):2773–88.10.1016/S0020-7683(98)00128-0Search in Google Scholar

[67] Isono Y, Namazu T, Terayama N, Tanaka T. Mechanical characterization of sub-micrometer thick DLC films by AFM tensile testing for surface modification in MEMS. Technical Digest MEMS 2002 IEEE International Conference Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (Cat No02CH37266). IEEE; 2002. p. 431–410.1109/MEMSYS.2002.984295Search in Google Scholar

[68] Ollivier B, Dowey SJ, Young SJ, Matthews A. Adhesion assessment of DLC films on PET using a simple tensile tester: Comparison of different theories. J Adhes Sci Technol. 1995;9(6):769–84.10.1163/156856195X00662Search in Google Scholar

[69] Guo YB, Chau-Nan Hong F. Adhesion improvements for diamond-like carbon films on polycarbonate and polymethylmethacrylate substrates by ion plating with inductively coupled plasma. Diam Relat Mater. 2003;12(3):946–52.10.1016/S0925-9635(02)00320-5Search in Google Scholar

[70] Trakhtenberg IS, Bakunin OM, Korneyev IN, Plotnikov SA, Rubshtein AP, Uemura K. Substrate surface temperature as a decisive parameter for diamond-like carbon film adhesion to polyethylene substrates. Diam Relat Mater. 2000;9(3):711–4.10.1016/S0925-9635(99)00254-XSearch in Google Scholar

[71] Bai C, Liang A, Cao Z, Qiang L, Zhang J. Achieving a high adhesion and excellent wear resistance diamond-like carbon film coated on NBR rubber by Ar plasma pretreatment. Diam Relat Mater. 2018;89:84–93.10.1016/j.diamond.2018.08.013Search in Google Scholar

[72] Donnet C. Recent progress on the tribology of doped diamond-like and carbon alloy coatings: A review. Surf Coat Technol. 1998;100–101:180–6.10.1016/S0257-8972(97)00611-7Search in Google Scholar

[73] Khanmohammadi H, Wijanarko W, Cruz S, Evaristo M, Espallargas N. Triboelectrochemical friction control of W- and Ag-doped DLC coatings in water-glycol with ionic liquids as lubricant additives. RSC Adv. 2022;12(6):3573–83.10.1039/D1RA08814ASearch in Google Scholar

[74] Shakil A, Amiri A, Polycarpou AA. Effect of carbon configuration on mechanical, friction and wear behavior of nitrogen-doped diamond-like carbon films for magnetic storage applications. Tribol Lett. 2021;69:151.10.1007/s11249-021-01525-8Search in Google Scholar

[75] Zeng Q, Ning Z. High-temperature tribological properties of diamond-like carbon films: A review. Rev Adv Mater Sci. 2021;60(1):276–92.10.1515/rams-2021-0028Search in Google Scholar

[76] Yetim AF, Kovacı H, Kasapoğlu AE, Bozkurt YB, Çelik A. Influences of Ti, Al and V metal doping on the structural, mechanical and tribological properties of DLC films. Diam Relat Mater. 2021;120:108639.10.1016/j.diamond.2021.108639Search in Google Scholar

[77] Manninen NK, Ribeiro F, Escudeiro A, Polcar T, Carvalho S, Cavaleiro A. Influence of Ag content on mechanical and tribological behavior of DLC coatings. Surf Coatings Technol. 2013;232:440–6.10.1016/j.surfcoat.2013.05.048Search in Google Scholar

[78] Goto M. Preparations and tribological properties of soft-metal/DLC composite coatings by RF magnetron sputter using composite targets. Int J Mech Mater Des. 2018;14(3):313–27.10.1007/s10999-017-9376-3Search in Google Scholar

[79] Gayathri S, Kumar N, Krishnan R, Ravindran TR, Amirthapandian S, Dash S, et al. Influence of transition metal doping on the tribological properties of pulsed laser deposited DLC films. Ceram Int. 2015;41(1):1797–805.10.1016/j.ceramint.2014.09.125Search in Google Scholar

[80] Cao L, Liu J, Wan Y, Pu J. Corrosion and tribocorrosion behavior of W doped DLC coating in artificial seawater. Diam Relat Mater. 2020;109:108019.10.1016/j.diamond.2020.108019Search in Google Scholar

[81] Tang XS, Wang HJ, Feng L, Shao LX, Zou CW. Mo doped DLC nanocomposite coatings with improved mechanical and blood compatibility properties. Appl Surf Sci. 2014;311:758–62.10.1016/j.apsusc.2014.05.155Search in Google Scholar

[82] Zhou Y, Li L, Shao W, Chen Z, Wang S, Xing X, et al. Mechanical and tribological behaviors of Ti-DLC films deposited on 304 stainless steel: Exploration with Ti doping from micro to macro. Diam Relat Mater. 2020;107:107870.10.1016/j.diamond.2020.107870Search in Google Scholar

[83] Narayan RJ. Laser processing of diamond-like carbon–metal composites. Appl Surf Sci. 2005;245(1):420–30.10.1016/j.apsusc.2004.11.026Search in Google Scholar

[84] Nakamatsu K, Nagase M, Igaki J, Namatsu H, Matsui S. Mechanical characteristics and its annealing effect of diamondlike-carbon nanosprings fabricated by focused-ion-beam chemical vapor deposition. J Vac Sci Technol B Microelectron Nanom Struct Process Meas Phenom. 2005;23(6):2801–5.10.1116/1.2132329Search in Google Scholar

[85] Liu G, Wen Z, Chen K, Dong L, Wang Z, Zhang B, et al. Optimizing the microstructure, mechanical, and tribological properties of Si-DLC coatings on NBR rubber for its potential applications. Coatings. 2020;10(7):671.10.3390/coatings10070671Search in Google Scholar

[86] Nakazawa H, Miura S, Nakamura K, Nara Y. Impacts of substrate bias and dilution gas on the properties of Si-incorporated diamond-like carbon films by plasma deposition using organosilane as a Si source. Thin Solid Films. 2018;654:38–48.10.1016/j.tsf.2018.03.075Search in Google Scholar

[87] Wu Y, Zhang S, Yu S, Zhu L, Shen Y, Zhou B, et al. A self-lubricated Si incorporated hydrogenated amorphous carbon (a-C:H) film in simulated acid rain. Diam Relat Mater. 2019;94:43–51.10.1016/j.diamond.2019.02.011Search in Google Scholar

[88] Zhang L, Zong X, Guo F, He B, Yuan X. Effect of fluorine incorporation on DLC films deposited by pulsed cathodic arc deposition on nitrile butadiene rubber and polyurethane rubber substrates. Coatings. 2020;10(9):878.10.3390/coatings10090878Search in Google Scholar

[89] Zhao X, Lu Z, Wu G, Zhang G, Wang L, Xue Q. Preparation and properties of DLC/MoS2 multilayer coatings for high humidity tribology. Mater Res Exp. 2016;3(6):66401.10.1088/2053-1591/3/6/066401Search in Google Scholar

[90] Wu Y, Liu Y, Yu S, Zhou B, Tang B, Li H, et al. Influences of space irradiations on the structure and properties of MoS2/DLC lubricant film. Tribol Lett. 2016;64(2):24.10.1007/s11249-016-0759-7Search in Google Scholar

[91] Wang C, Hausberger A, Nothdurft P, Lackner JM, Schwarz T. The potential of tribological application of DLC/MoS2 coated sealing materials. Coatings. 2018;8(8):267.10.3390/coatings8080267Search in Google Scholar

[92] Okubo H, Tadokoro C, Sumi T, Tanaka N, Sasaki S. Wear acceleration mechanism of diamond-like carbon (DLC) films lubricated with MoDTC solution: Roles of tribofilm formation and structural transformation in wear acceleration of DLC films lubricated with MoDTC solution. Tribol Int. 2019;133:271–87.10.1016/j.triboint.2018.12.029Search in Google Scholar

© 2022 Jiaqi Liu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites