Abstract

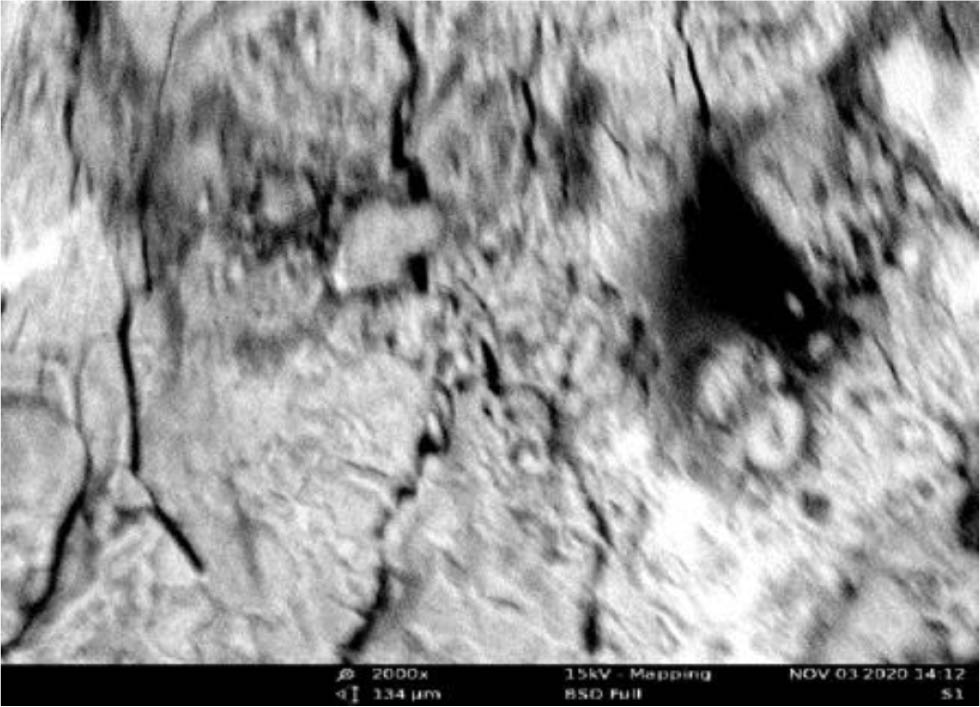

Waste control is a big challenge in industries. The aim of this study is to control degradation of farm structure using rice husk as corrosion inhibitor in pig dung, poultry dung and urea solution environment. The rice straw was subjected to phytochemical analysis. The four variables: rice straw, Pig dung, urea and poultry dung solutions were used to determine the best approach to reduce the corrosion rate of galvanized steel used for farm structures. Time variation used was 3–12 days. The result from the phytochemical analysis showed that rice husk has constituents of a good inhibitor. The result from the variables’ mix in S1: A: 40 cm3; B: 40 cm3; C: 10 cm3 and D: 10 cm3 has the highest inhibition efficiency of 88.59%. The SEM result from the best combination showed that passive film was formed which was attributed to the adsorption via rice straw extract. The rice straw used in this study was an effective inhibitor. It is an agricultural waste that was converted into a viable process which is of economic value.

1 Introduction

Farm wastes and slurries can also be significantly corrosive. Because there are so many different structures, machinery, and fittings used in farming, it's difficult to pinpoint exactly where rust can cause the most damage. The problem is further complicated by the various environments (rural, urban, and coastal), the local “microclimate”, the type of farming activity, the seasonal use of certain equipment and technology, and the storage methods used [1]. Galvanising of steel is generally beneficial in resisting corrosion. Maintaining product quality along with healthy environment at an optimal cost is a big challenge for the production engineers and researchers.

The following are some of the most significant advantages of galvanized steel: maintenance costs are lower, very durable, damage resistant and cheaper when compared with other most treated steels [2]. Corrosion failures often relate to the material selection and the environment. Furthermore; details of the material specifications, quality-assurance records, installation and maintenance records, and a history of the environment are all useful resources in resolving corrosion failures [3]. Advances in metallurgy like galvanized steel, is a keystone to modern farming operations by helping farmers to save time and money. Metallic materials play a critical part in a country 's economic development and long-term progress in the global economy [4]. Terms of waste management have been widely accepted as a sum of the measure and solution for waste prevention, treatment, recovery, reuse with regard to ecological and economic aspects. However, waste disposal to control landfills should only be a final option if further waste treatment is not economically or technically feasible [5]. Rising amounts of industrial waste are among the main challenges great concern in most cities, today. Based on the management concept "from cradle to grave," the reasonable starting point for solid waste management is to reduce the amount of garbage that needs to be managed (also known as Life Cycle Analysis). The benefits of incorporating waste reduction strategies into municipal solid waste management (MSWM) constitute the foundation of an emerging global strategy for solid waste management [6, 7, 8, 9]. Owing to the deterioration of metallic materials, the risk of corrosion has risen significantly. Chemicals from chickens and pigs can shorten the life of farm fencing by as much as 14 years on average. When used for fences and gates, galvanised steel has a longer life span than mild steel, according to [10]. Calcium orthoplumbate alkyd primers with a matching top-coat alkyd are much easier to apply to galvanized steel and have been proved to be effective in reducing corrosion. However, this type of inhibitor is expensive and there is need to find an alternative environmentally friendly inhibitor which will be cost effective. It has been found that hazardous concentration of hydrogen sulphide gas may be produced when a mixture of silage effluent and slurry promotes the production of corrosive acids under deposits. Slurries are dung and urine combinations that are composted with litter (usually a mixture of straw or wood shavings) to create farmyard manure. With naturally secreted animal chlorides, which are the principal corrosive components of slurries and farm yard manures, farm yard manure (FYM) ferments while releasing moisture, ammonia, and carbon dioxide [11]. Sulfates, nitrates, chlorides, hydrogen sulfide, and ammonia are among the corrosion-inducing compounds found in poultry, cow, and pig dung. However, the use of hybrid composites including sulfur, fly ash, silica fume, and nanoparticles such as silica can help to slow down the deterioration of concrete structures. Stalls for dairy cattle and piggery are often reinforced with cast-iron and galvanized steel. The cost-effective corrosion prevention approach must be integrated into agriculture to minimize the expense of fixing these farm facilities and also to save cost [13]. Corrosion losses in agriculture have not been quantified in the same manner that they have been in other fields. The first-order costs, including material losses and labor, have been projected to be significant. Although second-order losses caused by corrosion, such as crop loss owing to equipment failure and animal straying, might triple first-order expenditures. [10]. To evaluate the effectiveness of the corrosion prevention practices applied to agricultural equipment manufactured and used in Nigeria farms, it is important to identify the best method of corrosion prevention [1]. The risk of corrosion in the crude oil processing industry in Nigeria has been calculated using the engineering economy method and found to be 77 cents / barrel, and the cost of corrosion in the food and agro processing industries was determined by the costing of the life cycle and the total cost was N22,350,600 [13, 15, 16, 17]. It was reported by [14] that farm implements or equipment are mainly replaced because of wear and corrosion. Furthermore, agricultural crops produce significant volumes of residual residues, and crop residues are increasing in tandem with food production.

These unused residues represent not only a waste of resources, but also a missed opportunity for a farmer to increase his or her revenue. Crop leftovers are being used by researchers all over the world to tackle problems in domains such as textile, composite non-woven manufacturing processes (e.g. bamboo). [19]; olystyrene [20]; inhibitors: katemfe [21]; almond fruit extracts [22]; power generation, biogas production, animal feed, compost and manures.

Corrosion is the chemical attack or reaction of metals with their environment that causes them to corrode. It is a persistent and continuous problem, often hard to fully eradicate. The study of galvanized steel corrosion is of tremendous theoretical and practical concern, and has received considerable interest. The best choice for shielding metals and alloys from corrosion is the use of green inhibitors. Organic corrosion inhibitors’ environmental toxicity has inspired a search for green corrosion inhibitors, which are biodegradable and environmentally beneficial.[23]. Plant extracts have been successfully used by some academic researchers to prevent metal corrosion in acidic and alkaline environments, such as: Corchorus olitorium stem extract as corrosion inhibited the corrosion of mild steel in sulphuric acid [23]; oyewole et al. 2021; investigated the characterization of Ficus exasperata extract and the optimization of the process variables on inhibition of mild steel in seawater environment [24]; Delonix regia extracts reduced aluminum corrosion in hydrochloric acid solutions [25], rosemary leaves were explored as a corrosion inhibitor for the Al + 2.5Mg alloy in a 3 percent NaCl solution at 25°C [26], and El-Etre looked into the effects of opuntia extract on aluminum [27]. The inhibitive effect of the extract of khillah (Ammi visnaga) seeds on the corrosion of SX 316 steel in HCl solution was determined using weight loss measurements as well as potentiostatic technique. The formation of insoluble complexes as a result of interaction between iron cations and khellin is thought to constitute the mechanism of action [28]. The extracts described above have an inhibitory efficacy of 87–94 percent. Plant shutdowns, waste of important resources, product loss or contamination, decline in efficiency, costly maintenance, and expensive overdesign are all significant consequences of corrosion.

Corrosion often affects the metal's strength and movement and can result in a heavy bill for fixing or replacing the object [29]. Farm wastes and slurries contain many chemicals that often damage farm machinery and ancillary structures [30]. Chemical substances such as pesticides and elements such as manure also led to rust, creating high-risk areas on your farm or ranch. Before rust prevention advances, farmers and ranchers were left to conventional approaches such as using a wire brush to eliminate rust scaling. Products which are resistant to corrosion can reduce maintenance costs and extend the life of farm implements. [10, 31, 32] stated that no research has been done to estimate how much corrosion losses in agriculture can be avoided, while studies have shown that it may be as high as 50%. Mild steel corrodes more than galvanized steel in farmyard manure, according to results from laboratory studies conducted at ambient temperature [14]. Because galvanized steel is the most often used metallic material in agricultural constructions, it was chosen for this study. In the agricultural sector, it has been noted in the literature that there is a need to control or decrease corrosion attack on metallic components to the bare minimum. The use of rice straw extract as a corrosion inhibitor on galvanized steel in (poultry dung, cow dung, and urea conditions) was investigated in this study.

2 Materials and methods

2.1 Preparation of sample

Landmark University's Mechanical Engineering Laboratory provided the galvanized steel. It was cut into 22 coupons of 19 mm × 22 mm × 2 mm dimensions. The surface was cleaned with emery paper and then rinsed thoroughly with distilled water. It was later dried with acetone and placed in a desiccator. According to laboratory report findings by [14], mild steel corrodes more than galvanized steel at ambient temperature, this is the justification for using galvanized steel.

2.2 Extract preparation

The rice straw was obtained from Landmark University's Teaching and Research Farm in Omu-Aran, Kwara State. Then sun dried for 2 days to remove the moisture content, then milled to fine powder to increase the surface area and kept for further analysis.

2.3 Phytochemical analyses

The secondary metabolites tannins, saponins, flavonoids, and alkaloids were extracted from milled rice straw using phytochemical analysis.

2.4 Corrosive medium

The medium used were solution of: Pig, Urea and Poultry dung; added up to 100 cm3. The pH of pig dung was 7.50; Poultry dung with pH of 5.80 and Urea with pH of 5.0; respectively.

2.5 Weight loss analysis

Weight loss approach was used to test the protective efficiency of the rice straw extract in the acidic environments (urea piggery and poultry). This approach was adapted from [33]. According to Table 1, the coupons were immersed in pig dung, poultry dung, rice straw, and urea solution in beakers for 12 days with 3 days intervals. This was done in triplicate to avoid error.

The coupons immersed in composition of: pig dung, poultry dung, rice straw and urea solution contained in beakers for a period of 12 days with 3 days interval.

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | |

|---|---|---|---|---|---|---|---|

| A | 40 | 20 | 30 | 20 | 50 | 0 | 25 |

| B | 40 | 10 | 30 | 20 | 50 | 0 | 25 |

| C | 20 | 40 | 20 | 30 | 0 | 50 | 25 |

| D | 10 | 40 | 20 | 30 | 0 | 50 | 25 |

The initial weight and final weight before and after immersion was used to determine the weight loss as shown in Eq. (1);

While the corrosion rate (g/cm2h) was calculated using Eq. (2).

Where ΔW is the weight loss (g) after exposure time t (days), A is the area of the specimen (cm2) and t is the time of exposure in days and CR is the corrosion rate at each exposure time.

IE% is the inhibition efficiency which was calculated using Eq. (3)

IE% = X 100 (3)

Where, W1 and W0 are the weight loss values in presence and absence of inhibitor.

Where:

A represents pig dung,

B rice straw,

C urea,

D poultry dung,

S represents the mix of the 4 variables solution.

3 Results and discussion

3.1 Result of phytochemical analysis of RSE

The presence of metabolites such as saponins, tannins, flavonoids, and glycosides in the RSE made it a good inhibitor, according to the phytochemical study. This result validated [34, 35, 36, 37, 38, 39, 40, 41, 42]'s findings that plant extract is a good inhibitor, as indicated in Table 2.

Phytochemical constituents of RSE.

| S/N | Substances | Presence |

|---|---|---|

| 1 | saponins | ++ |

| 2 | tannis | + |

| 3 | flavonoids | + |

| 4 | alkanoids | – |

| 5 | phenolics | – |

| 6 | glycosides | ++ |

++ Highly present; + moderately present; – absent

3.2 Result of final weight after immersion

The result of the final weight observed is as shown in Table 3. The weight increases with time from 3 days till 12 days for the mix variation s in S1–S7, respectively. Table 3 is result observed. Table 4a–4b showed the results of the corrosion rate and weight loss respectively.

Result of final weight.

| S/N | Initial weight | Final weight | |||

|---|---|---|---|---|---|

| 3 days | 6 days | 9 days | 12 days | ||

| S1 | 5.4745 | 5.4680 | 5.4565 | 5.4689 | 5.4626 |

| S2 | 4.9236 | 4.9172 | 4.9167 | 5.4689 | 4.9065 |

| S3 | 5.4508 | 5.4459 | 5.4362 | 5.4359 | 5.4297 |

| S4 | 5.3044 | 5.2882 | 5.3026 | 5.2933 | 5.2871 |

| S5 | 5.4122 | 5.4956 | 5.3986 | 5.3961 | 5.3931 |

| S6 | 5.3852 | 5.3656 | 5.3641 | 5.3637 | 5.3558 |

| S7 | 5.3331 | 5.3179 | 5.3155 | 5.3086 | 5.2917 |

Corrosion rate (CR).

| S | 3 days | 6 days | 9 days | 12 days |

|---|---|---|---|---|

| S1 | 0.000524 | 0.000726 | 0.00151 | 0.00240 |

| S2 | 0.00516 | 0.00278 | 0.00409 | 0.00345 |

| S3 | 0.00395 | 0.00589 | 0.00401 | 0.00426 |

| S4 | 0.00131 | 0.00726 | 0.00299 | 0.00349 |

| S5 | 0.00530 | 0.00548 | 0.00433 | 0.00385 |

| S6 | 0.00158 | 0.00851 | 0.00578 | 0.00593 |

| S7 | 0.00122 | 0.00710 | 0.00659 | 0.00835 |

Weight loss αw.

| S/N | 3 days αW | 6 days αW | 9 days αW | 12 days αW |

|---|---|---|---|---|

| S1 | 0.0065 | 0018 | 0.0056 | 0.0119 |

| S2 | 0.0064 | 0.0069 | 0.0152 | 0.0171 |

| S3 | 0.0049 | 0.0146 | 0.0149 | 0.0211 |

| S4 | 0.0162 | 0.0018 | 0.0111 | 0.0173 |

| S5 | 0.0066 | 0.0136 | 0.0161 | 0.0191 |

| S6 | 0.0196 | 0.0211 | 0.0215 | 0.0294 |

| S7 | 0.0152 | 0.0176 | 0.0245 | 0.0414 |

3.3 Result of weight loss, corrosion rate and inhibition efficiency

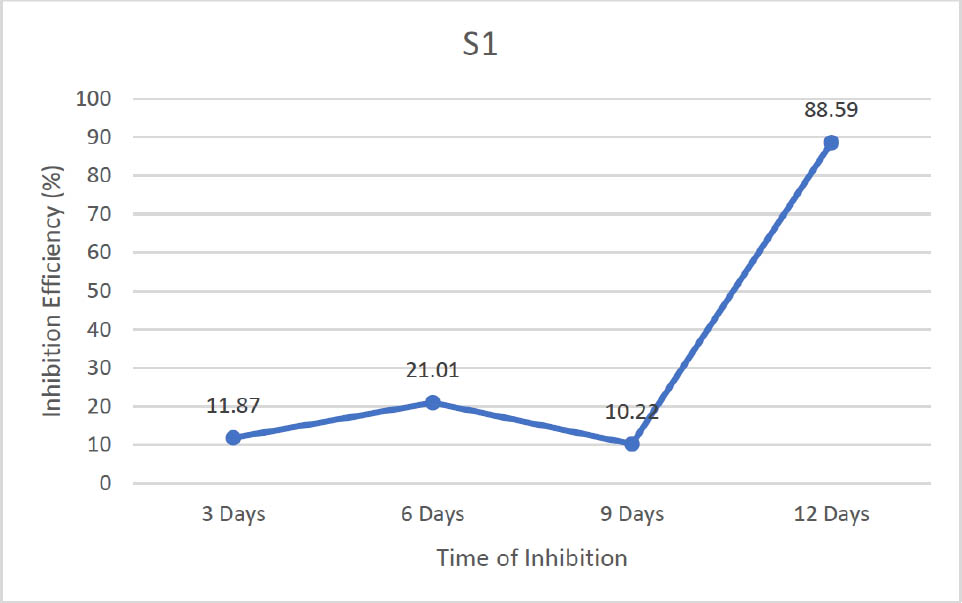

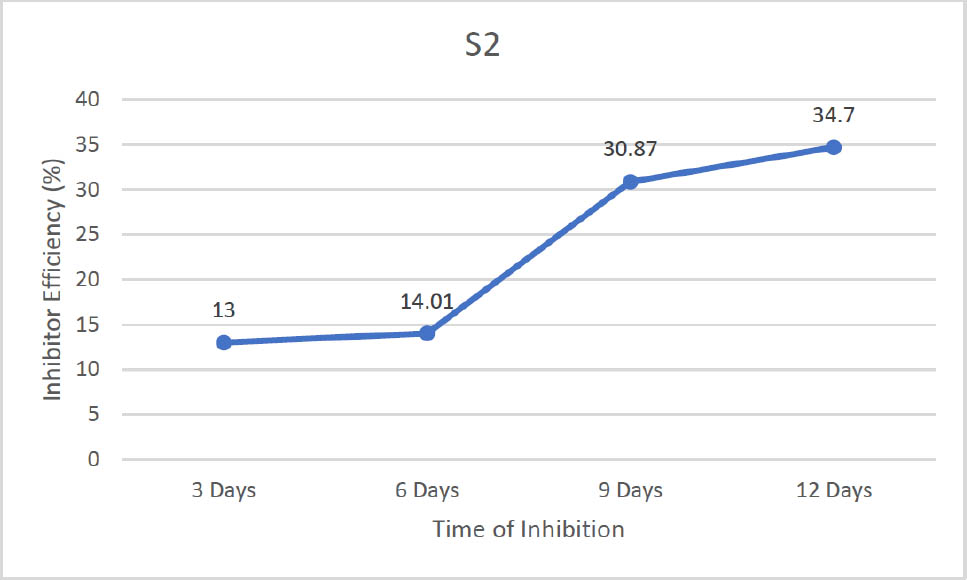

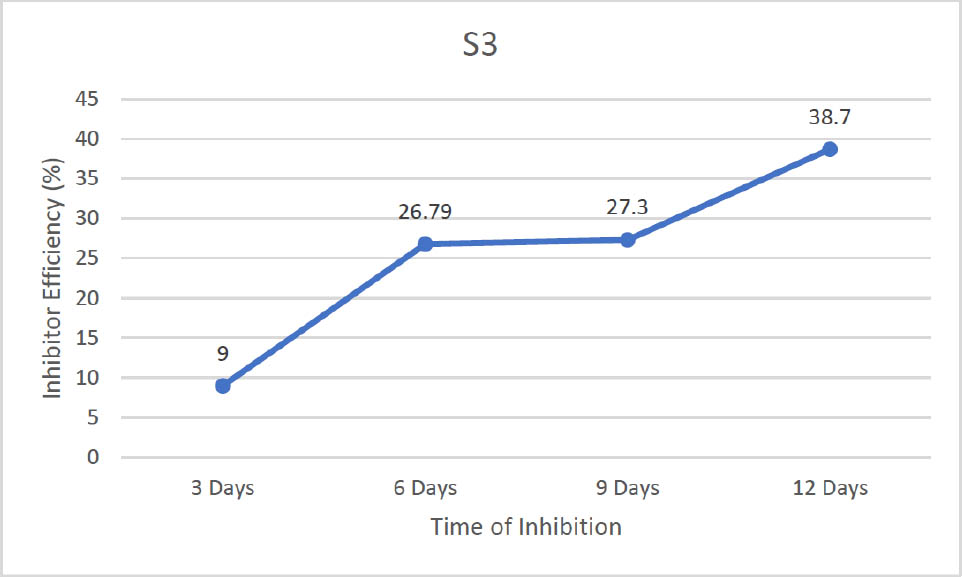

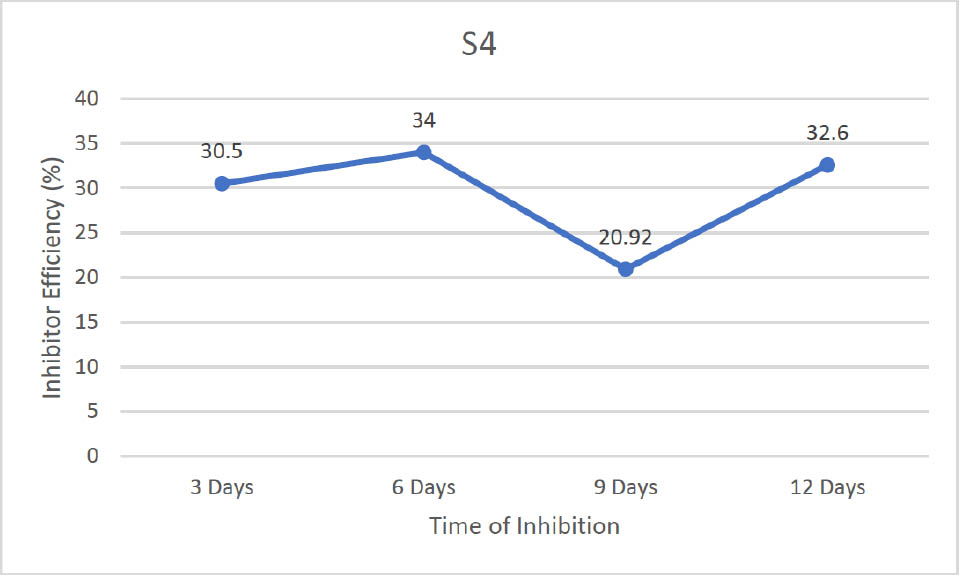

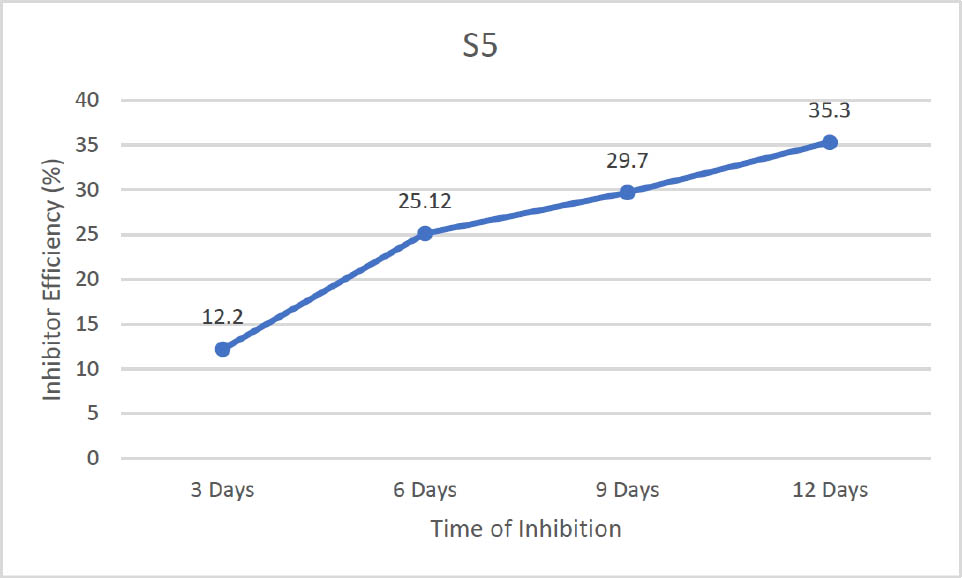

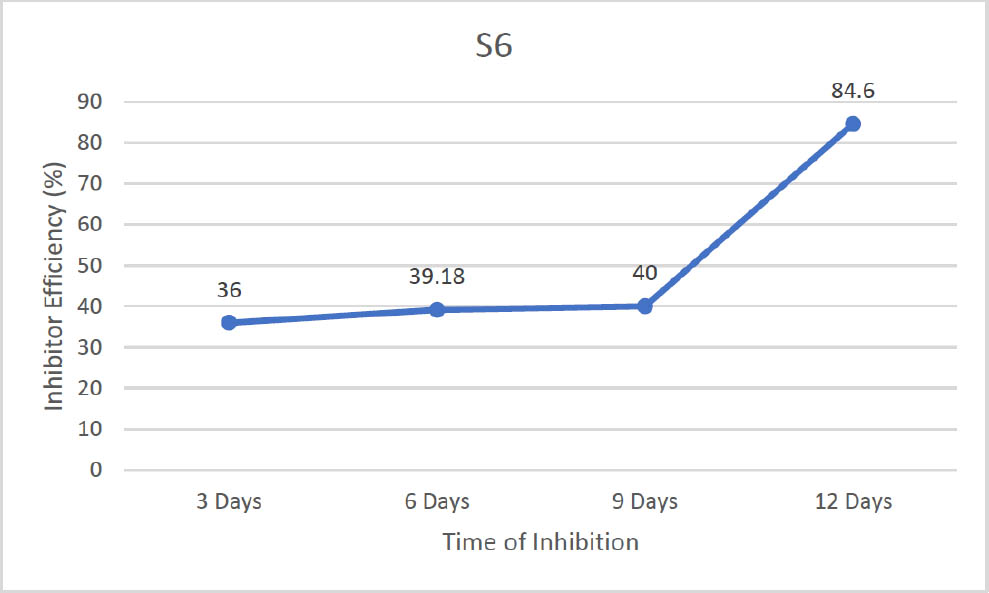

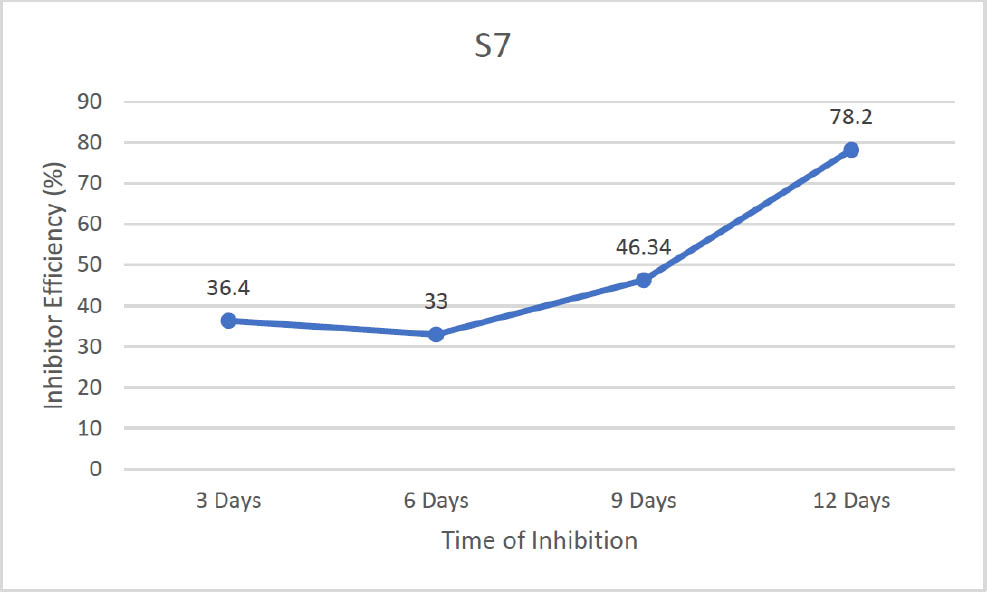

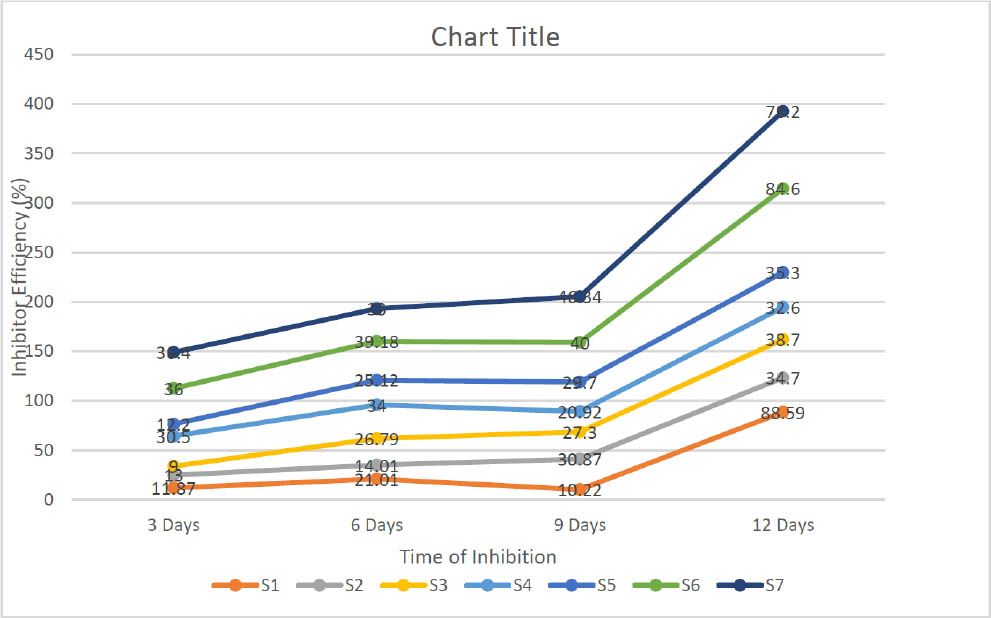

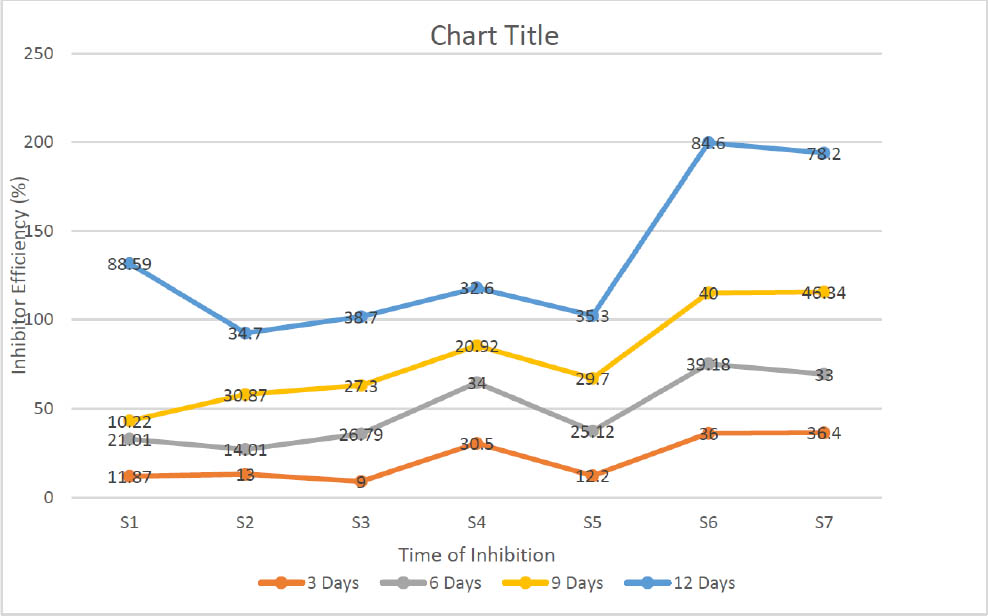

Most corrosive environment as observed form the result was Mix S3 at 3 days of immersion. The result of the inhibition efficiency is as shown in Table 5. The inhibition efficiency increases with time of inhibition from 3 days till 12 days respectively. The highest inhibition efficiency of 88.59% was observed in S1 (A=40 cm3, B=40 cm3, C= 10 cm3. D=10 cm3) at 12 days. Figures 1–6 indicated the plots of S1–S7 for inhibition efficiency versus time of inhibition while Figures 8 and 9 are for plots of Inhibition efficiency versus S(S1–S7) and Plot of inhibition efficiency versus time of inhibition, respectively. However; in mix S1 and S4, Inhibition efficiency increases with temperature from 3 days to 6 days but reduced at 9 days while highest inhibition efficiency was in 12 days. It was reported by [42, 43, 44] that infusing silica fumes into the steel rods during the production phase of the galvanized steel has proven to have more protective benefits compared to steel rods, without silica fumes. This supported the findings in this study since silica is one of the major proximate constituent of rice straw as reported in the literature. This means this study can be replicated and used by agricultural sector, to combat corrosion on farm structures in Nigeria; since it is a cost-effective approach.

Result of inhibition efficiency (%).

| S/N | 3 days | 6 days | 9 days | 12 days |

|---|---|---|---|---|

| S1 | 11.87 | 21.01 | 10.22 | 88.59 |

| S2 | 13.00 | 14.01 | 30.87 | 34.70 |

| S3 | 9.0 | 26.79 | 27.30 | 38.70 |

| S4 | 30.5 | 34.00 | 20.92 | 32.60 |

| S5 | 12.20 | 25.12 | 29.70 | 35.30 |

| S6 | 36.00 | 39.18 | 40.00 | 84.60 |

| S7 | 36.40 | 33.00 | 46.34 | 78.20 |

Plot of S1 (Inhibition efficiency versus Time of inhibition (days).

Plot of S2 (Inhibition efficiency (%) versus Time of inhibition (days).

Plot of S3 (Inhibition efficiency versus Time of inhibition (days).

Plot of S4 (Inhibition efficiency versus Time of inhibition (days).

Plot of S5 (Inhibition efficiency versus Time of inhibition (days).

Plot of S6 (Inhibition efficiency versus Time of inhibition (days).

Plot of S7 (Inhibition efficiency versus Time of inhibition (days).

Plot of Inhibition efficiency (%) versus Time of inhibition (days).

Plot of Inhibition efficiency versus Time of inhibition (days).

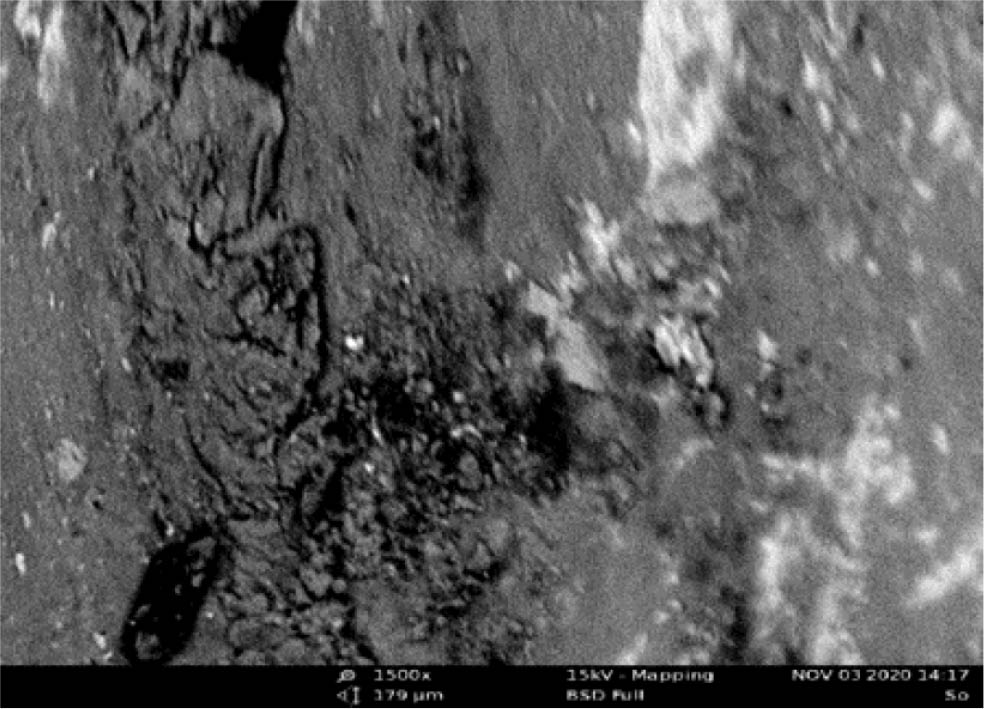

SEM Result of the blank mild steel.

SEM result of the mild steel with the highest IE.

Inhibition efficiency increases with time from 3 till 12 days in S2; S3; S5 and S6 respectively. Furthermore, in S7 Inhibition decreases from what was observed in 3 days with the result in 6 days and then it increases in 9 and 12 days, respectively.

4 Conclusion

Rice straw contained the major constituents, which made it a good inhibitor. The SEM result showed that outer film layer was formed on the mix S1 after the immersion time for 12 days with the highest inhibition. The mix S3 gave the lowest inhibition efficiency because it contained more concentration of the corrosive constituents which would have contributed to higher corrosion of the test mix. The level of sensitivity to corrosion and degradation of a material used in the building of farm structures affects their service life. Degradation of agricultural constructions is unavoidable, but it can be managed through material selection. It can be concluded that the mix of S1 was the best composition for solving corrosion challenges on farm structures.

Funding information: The authors state no funding involved.

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

Conflict of interest: The authors state no conflict of interest.

References

[1] Halpern SD, Ubel PA, Caplan AL. Solid-organ transplantation in HIV-infected patients. N Engl J Med. 2002;347(4):284–7.10.1056/NEJMsb020632Search in Google Scholar

[2] Bertron A, Lavigne MP, Patapy C, Erable B. Biodeterioration of concrete in agricultural, agro-food and biogas plants: state of the art and challenges. RILEM Technical Letters. 2017 Dec 30;2:83–9.10.21809/rilemtechlett.2017.42Search in Google Scholar

[3] Abdelrazek AH, Choudhury IA, Nukman Y, Kazi SN. Metal cutting lubricants and cutting tools: a review on the performance improvement and sustainability assessment. The International Journal of Advanced Manufacturing Technology. 2020 Feb;106(9):4221–45.10.1007/s00170-019-04890-wSearch in Google Scholar

[4] Amanchukwu CV, Yu Z, Kong X, Qin J, Cui Y, Bao Z. A new class of ionically conducting fluorinated ether electrolytes with high electrochemical stability. Journal of the American Chemical Society. 2020 Apr 1;142(16):7393–403.10.1021/jacs.9b11056Search in Google Scholar

[5] Bilitewski, B., Härdtle, G., Marek, K., Weissbach, A., Boeddicker, H. waste management. 1994: Springer-Verlag Berlin Heidelberg. ISBN 3-540-59210-5Search in Google Scholar

[6] United Nations Environment Programme. Asian Tsunami Disaster Task Force. Seychelles: post-tsunami environmental assessment. UNEP/Earthprint; 2005.Search in Google Scholar

[7] Jones RG, Ando W, Chojnowski J, editors. Silicon-containing polymers: the science and technology of their synthesis and applications. Springer Science & Business Media; 2013 Nov 11.Search in Google Scholar

[8] Quadrio Curzio A, Prosperetti L, Zoboli R. The Management of Municipal Solid Waste in Europe: Economic, Technological and Environmental Perspectives.Search in Google Scholar

[9] Daskalopoulos E, Badr O, Probert SD. Municipal solid waste: a prediction methodology for the generation rate and composition in the European Union countries and the United States of America. Resources, conservation and recycling. 1998 Nov 1;24(2):155–6610.1016/S0921-3449(98)00032-9Search in Google Scholar

[10] Lay JJ, Li YY, Noike T, Endo J, Ishimoto S. Analysis of environmental factors affecting methane production from high-solids organic waste. Water science and technology. 1997 Jan 1;36(6–7):493–500.10.2166/wst.1997.0628Search in Google Scholar

[11] Jekayinfa SO, Ojediran JO, Okekunle PO. An evaluation of corrosion prevention practices in agricultural equipment manufactured and used in Nigeria. Anti-Corrosion Methods and Materials. 2003 Oct 1.10.1108/00035590310492289Search in Google Scholar

[12] Loto CA, Popoola AP. Environmental surface degradation of galvanised and mild steels in cattle and poultry wastes and urea solution. International Journal of Physical Sciences. 2011 Jul 31;6(13):3074–81.Search in Google Scholar

[13] Loto CA, Popoola AP. Environmental surface degradation of galvanised and mild steels in cattle and poultry wastes and urea solution. Inter J Phy Sci. 2011 Jul 31;6(13):3074–81.Search in Google Scholar

[14] Eker B, Yuksel E. Solutions to corrosion caused by agricultural chemicals. Trakia Journal of Sciences. 2005;3(7):1–6.Search in Google Scholar

[15] Severnyi AÉ, Efimov IA, Ivanova LP, Eniseiskii NL. Corrosion protection of agricultural equipment by microcrystalline wax compositions. Chemistry and Technology of Fuels and Oils. 1985 Oct;21(10):505–7.10.1007/BF00726696Search in Google Scholar

[16] Yi Q, editor. Point Sources of Pollution: Local Effects and their Control-Volume II. EOLSS Publications; 2009 Aug 17.Search in Google Scholar

[17] Grause G, Buekens A, Sakata Y, Okuwaki A, Yoshioka T. Feedstock recycling of waste polymeric material. Journal of Material Cycles and Waste Management. 2011 Dec;13(4):265–82.10.1007/s10163-011-0031-zSearch in Google Scholar

[18] Mitan NM, Brebu M, Bhaskar T, Muto A, Sakata Y, Kaji M. Co-processing of DVDs and CDs with vegetable cooking oil by thermal degradation. J Mater Cyc Wast Manag 2007 Mar;9(1):62–810.1007/s10163-006-0160-ySearch in Google Scholar

[19] Akinyemi BA, Omoniyi TE. Effect of experimental wet and dry cycles on bamboo fibre reinforced acrylic polymer modified cement composites. J Mech Beh Mater. 2020 Sep 22;29(1):86–93.10.1515/jmbm-2020-0009Search in Google Scholar

[20] Akinyemi BA, Ojediran J, Olawale O, Ayanwola S. Efficacy of expanded polystyrene as fine aggregate in cement mortars modified with latex paint as an alternative to polymer admixture. J Mech. Beh. Mater. 2020 Jan 1;29(1):163–8.10.1515/jmbm-2020-0016Search in Google Scholar

[21] Olawale O, Ogunsemi BT, Abayomi SJ, Uguru-Okorie DC, Okunola AA, Oni SO, Kolawole OD, Ikpotokin I. Optimization of Katemfe Seed Extract as A Corrosion Inhibitor for Mild-Steel in 0.5 M Hcl. Inter J. Civ. Eng. Tech. 2018; Dec. 9(13):1394–402.Search in Google Scholar

[22] Olawale O, Ogunsemi BT, Bello JO, Ikubanni PP, Ogundipe SJ, Abayomi TS. Optimization and modelling of aluminium corrosion inhibition using Almond (Prunus amydgdalus) fruit leaves extract as green inhibitor in HCl acidic medium. Inter. J. Mech. Eng. Technol. 2018:Dec. 9(13):1274–1285Search in Google Scholar

[23] Oyewole O, Oshin TA, Atotuoma BO. Corchorus olitorius stem as corrosion inhibitor on mild steel in sulphuric acid. Heli. 2021 Apr 1;7(4):e06840.10.1016/j.heliyon.2021.e06840Search in Google Scholar

[24] Oyewole O, Aondoakaa E, Abayomi TS, Ogundipe SJ, Oshin TA. Characterization and optimization study of Ficus exasperata extract as corrosion inhibitor for mild steel in seawater. Wor Scie New. 2021;151:78–94.Search in Google Scholar

[25] Abiola OK, Oforka NC, Ebenso EE, Nwinuka NM. Eco-friendly corrosion inhibitors: the inhibitive action of Delonix Regia extract for the corrosion of aluminium in acidic media. Anti-Corr Meth Mater. 2007 Jul 3. 54(4):219–224.10.1108/00035590710762357Search in Google Scholar

[26] Kliškić M, Radošević J, Gudić S, Katalinić V. Aqueous extract of Rosmarinus officinalis L. as inhibitor of Al–Mg alloy corrosion in chloride solution. J Appl Electro 2000 Jul;30(7):823–30.10.1023/A:1004041530105Search in Google Scholar

[27] El-Etre AY. Inhibition of aluminum corrosion using Opuntia extract. Corr Sci. 2003 Nov 1;45(11):2485–95.10.1016/S0010-938X(03)00066-0Search in Google Scholar

[28] El-Etre AY. Khillah extract as inhibitor for acid corrosion of SX 316 steel. Appl Surf Sci. 2006 Oct 15;252(24):8521–5.10.1016/j.apsusc.2005.11.066Search in Google Scholar

[29] Orisanmi BO, Afolalu SA, Adetunji OR, Salawu EY, Okokpujie IP, Abioye AA, Akinyemi O, Abioye OP. Cost of corrosion of metallic products in Federal University of Agriculture, Abeokuta. Inter J Appl Eng. 2017;12(24):14141–7.Search in Google Scholar

[30] Koch GH, Brongers MP, Thompson NG, Virmani YP, Payer JH. Corrosion cost and preventive strategies in the United States. 2002 Mar. Nat.Acad.Sci.Eng.Med.Search in Google Scholar

[31] Orisanmi BO, Afolalu SA, Adetunji OR, Salawu EY, Okokpujie IP, Abioye AA, Akinyemi O, Abioye OP. Cost of corrosion of metallic products in Federal University of Agriculture, Abeokuta. Inter J Appl Eng. 2017;12(24):14141–7.Search in Google Scholar

[32] Rani BE, Basu BB. Green inhibitors for corrosion protection of metals and alloys: an overview. Inter J cor. 2012 Jun. 1–1510.1155/2012/380217Search in Google Scholar

[33] Augustin M, Ščerbejová M. Anticorrosive efficiency of preservants for farming machinery. Res in Agri Eng. 2003; 49:22–26.10.17221/4947-RAESearch in Google Scholar

[34] Oki M, Anawe PA. A review of corrosion in agricultural industries. Phys Sci Inter J. 2015 Jan 1:216–22.10.9734/PSIJ/2015/14847Search in Google Scholar

[35] Obot IB, Obi-Egbedi NO, Eseola AO. Anticorrosion potential of 2-mesityl-1H-imidazo [4, 5-f][1, 10] phenanthroline on mild steel in sulfuric acid solution: experimental and theoretical study. Ind Eng Chem Res. 2011;50(4):2098–110.10.1021/ie102034cSearch in Google Scholar

[36] Oguize EE, Okolue BN, Ogukwe CE, Onuchukwu AI. Studies on the inhibitive action of methylene blue dye on aluminium corrosion in KOH solution. J Corr Sci. Techn. 2004;1(1):88–91.Search in Google Scholar

[37] Okafor PC, Osabor VI, Ebenso EE. Eco-friendly corrosion inhibitors: inhibitive action of ethanol extracts of Garcinia kola for the corrosion of mild steel in H2SO4 solutions. Pig and Res Tech. 2007. Sept.18; 36 (5) : 299–30510.1108/03699420710820414Search in Google Scholar

[38] Pacheco J, Polder RB, Fraaij AL, Mol JM. Short-term benefits of cathodic protection of steel in concrete. Conc. Solu. 2012 Jan 1:147–56.10.1201/b11570-24Search in Google Scholar

[39] Obi-Egbedi NO, Obot IB, Umoren SA. Spondias mombin L. as a green corrosion inhibitor for aluminium in sulphuric acid: Correlation between inhibitive effect and electronic properties of extracts major constituents using density functional theory. Arab J Chem. 2012 Jul 1;5(3):361–73.10.1016/j.arabjc.2010.09.002Search in Google Scholar

[40] Hart K, James AO. The inhibitive effect of aloe vera barbadensis gel on copper in hydrochloric acid medium. J Emer Tren Eng Appl Sci. 2014 Feb 1;5(1):24–9.Search in Google Scholar

[41] Emembolu LN, Onukwuli OD, Okafor VN. Characterization and Optimization study of Epiphyllum oxypetalum extract as corrosion inhibitor for mild steel in 3 M H2SO4 solutions. Wor Sci Ne. 2020;145:256–73.Search in Google Scholar

[42] Faiz M, Zahari A, Awang K, Hussin H. Corrosion inhibition on mild steel in 1 M HCl solution by Cryptocarya nigra extracts and three of its constituents (alkaloids). RSC Adv. 2020;10(11):6547–62.10.1039/C9RA05654HSearch in Google Scholar PubMed PubMed Central

[43] Maraveas C. Concrete Silos: Failures, Design Issues and Repair/Strengthening Methods. Appl Sci. 2020 Jan;10(11):3938.10.3390/app10113938Search in Google Scholar

[44] Abdelmseeh VA, Jofriet J, Hayward G. Sulphate and sulphide corrosion in livestock buildings, Part II: Reinforcing steel corrosion. Biosys Engi. 2008 Mar 1;99(3):382–9.10.1016/j.biosystemseng.2007.11.005Search in Google Scholar

© 2021 Olamide Oyewole et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**