Abstract

Porous corundum ceramic samples were sintered at various temperatures in the range of 1350–1550°C. The effect of the sintering temperature on the porosity rate and compressive strength of corundum samples were investigated. The porosity rates were of the order of 3.3–38% and the high-density sample was obtained at a relatively high temperature. However, an increase of compressive strength by more than 6 times was observed with the sintering temperature rise. The Young’s modulus increased remarkably from 40.49 to 302.15 GPa, which is related to the corresponding decrease of porosity rate.

1 Introduction

Corundum, a form of alumina, is used to manufacture various components and mechanical, electrical and electronics parts. It is known for its relatively high hardness, high strength and low thermal conductivity compared to other ceramics, it has become a good material for sandpaper and grinding tools. Corundum products are usually made by sintering alumina powder at high temperature (>1300°C). It has been demonstrated that the sintering temperature has great influence on the properties of the alumina foamed ceramics [1]. As a consequence, the strength of corundum is not a strict material property but is dependent on the controlled sintering temperature [2], [3], [4]. On the other hand, many studies have reported that the decrement of strength relates directly to the microstructure of porous ceramics which is influenced by the fabrication methods [5], [6], [7], [8], [9].

The intention of the present work was to study the effect of sintering temperature variation on porosity rate and mechanical behavior, under nominal compression, of porous corundum ceramic.

2 Experimental

The sintering technique under high pressure was applied to fabricate bulk loads of alumina ceramics. This method typically consists of preparing a powder of 95 wt.% α-Al2O3 and 5 wt.% additives and then molding and sintering at different temperatures of 1350, 1400, 1500, and 1550°C, with which we had obtained samples of porous corundum at different rates of porosity of 38%, 32.7%, 7.7% and 3.3%. The measurement of porosity was done as a function of the presence of pores on a cross-section surface using Scion Image software (Scion Corporation, MD, USA) and then the percentages were estimated by the means of several surface measurements of the same sample. The samples obtained are summarized in Table 1.

A summary of the obtained samples.

| Samples no. | A | B | C | D |

|---|---|---|---|---|

| Sintered temperature (°C) | 1350 | 1400 | 1500 | 1550 |

| Rate of porosity (%) | 38 | 32.7 | 7.7 | 3.3 |

| Young’s modulus (GPa) | 40.49 | 94.93 | 249.37 | 302.15 |

| Strength (MPa) | 149.02 | 239.22 | 486.27 | 552.94 |

The study of the temperature effect on the mechanical behavior was accomplished by analyzing the variation of Young’s modulus of the samples. This is determined as a function of compression test results (stress and strain) by applying a uniaxial load at room temperature. The test measurements were conducted as follows: for every given rate of porosity, a compressive stress and strain were measured several times to determinate the maximum stress and strain supported by a material before rupture.

3 Results and discussion

3.1 Effect of the sintering temperature on the porosity rate

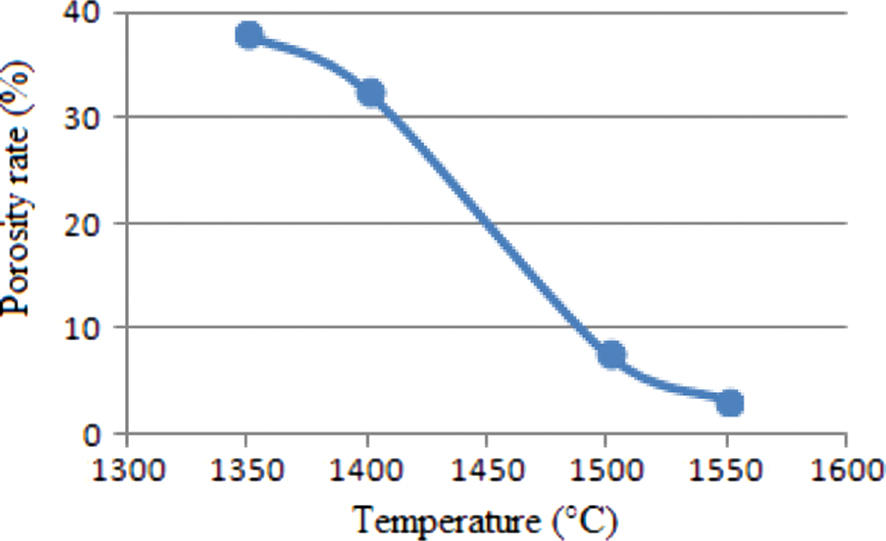

Figure 1 shows the variations of the porosity rate of corundum ceramics at different sintering temperatures in the range of 1350–1550°C. A high porosity of 38% was observed for samples sintered at low temperatures. However, an increase in sintering temperature was accompanied with a decrease in the average pore size, so the porosity rate was reduced due to the process of sintering densification that results in the gradual occupation of the pores by the grains of the corundum. The low porosity of 3.3% was obtained at high temperatures.

The porosity rate of samples obtained at different temperatures.

3.2 Effect of the sintering temperature on the Young’s modulus

The Young’s modulus, which describes the ceramic resistance to elastic deformation, exhibits almost linear dependence on the sintering temperature, as shown in Figure 2. The samples of corundum ceramics obtained at a higher sintering temperature of 1550°C, was characterized by a high Young’s modulus of 302.15 GPa. However, the values of this last was reduced relatively for samples sintered at relatively low temperatures from 1500 to 1350°C. It is worth reminding that the uniaxial compressive load is applied to the samples until the rupture moment takes place. It is clear that the quality of the compressive strength was improved to a good level with the increase of sintering temperature, and the material becomes less rigid with the decrease in temperature.

Variation of Young’s modulus as a function of temperature.

3.3 Variation of the compression strength as a function of the porosity rate

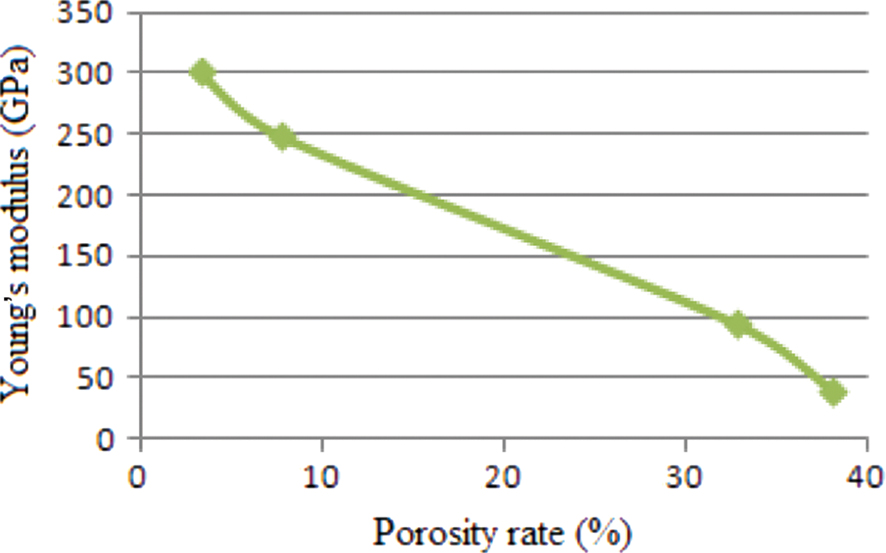

On the other hand, the variation curve, obtained after testing ceramics with different porosity levels in compression, showed that their behavior depended on the pore presence rate. The elastic modulus was almost linear depending on the porosity rate of ceramic samples, as shown in Figure 3. This dependence seems reasonable, as was discussed in previous curves, the sintering temperatures affect the porosity rate and Young’s modulus of ceramic samples, so consequently, it shows that Young’s modulus also depends on the porosity rate.

Variation of Young’s modulus as a function of porosity rate.

The samples with a high porosity of 3.3%, break down after reaching the compression strength limit and showed a low elastic modulus, of less than 50 GPa, compared to the samples with a low porosity rate of 38%, which provides a high compression strength limit and consequently a large Young’s modulus greater than 300 GPa.

4 Conclusion

Porous corundum ceramics sintered at various temperatures in the range of 1350–1550°C, were investigated. The sintering temperature significantly influenced the porosity rate and pore size distribution in the samples.

The analysis of elastic modulus curves of porous corundum ceramics (within the porosity range of 3.3%–38%) showed that the increase in sintering temperature affects the compression strength of ceramic samples and increases their Young’s modulus which varied between 40 and 300 GPa.

Therefore, it is possible to adjust the sintering temperature, to control the porosity rate and thus the compressive strength of porous corundum ceramics in order to reach the performance requirements both economically and efficiently.

Acknowledgments

This work was financially supported by LMNEPM Laboratory of Numerical and Experimental Modeling of Mechanical Phenomena and by university center of Relizane.

References

[1] Jia C, Liu J, Ding R, Teng D, Feng L. Effects of the Sintering Temperature on the Structure and Properties of the Alumina Foamed Ceramics. MATEC Web of Conferences, 67(SMAE 2016). DOI: https://doi.org/10.1051/matecconf/20166704011.Search in Google Scholar

[2] Ashby MK, Sammis CG. J. Pure Appl. Geophys. 1990, 133, 489–521.10.1007/BF00878002Search in Google Scholar

[3] Zouboulis ES, Grimsditch M. J. Appl. Phys. 1991, 70, 772–776.10.1063/1.349633Search in Google Scholar

[4] Keke K, Li Y, Zhao Y, Li S, Li Y, Sang S. J. Mater. Lett. 2016, 165, 19–21. DOI: 10.1016/j.matlet.2015.11.097.Search in Google Scholar

[5] Deng Z-Y, Yang J-F, Beppu Y, Ando M, Ohji T. J. Am. Ceram. Soc. 2002, 85, 1961–1965. DOI: 10.1111/j.1151-2916.2002.tb00388.x.Search in Google Scholar

[6] Kim H-W, Lee S-Y, Bae C-J, Noh Y-J, Kim H-E, Kim H-M, Ko JS. J. Biomater. 2003, 24, 3277–3284. DOI: 10.1016/S0142-9612(03)00162-5.Search in Google Scholar PubMed

[7] Jun I-K, Koh Y-H, Kim H-E. J. Mater. Lett. 2006, 60, 878–882. DOI: 10.1016/j.matlet.2005.10.037.Search in Google Scholar

[8] Rambo CR, Cao J, Sieber H. J. Mater. Chem. Phys. 2004, 87, 345–352. DOI: 10.1016/j.matchemphys.2004.05.031.Search in Google Scholar

[9] Tang F, Fudouzi H, Uchikoshi T, Sakka Y. J. Eur. Ceram. Soc. 2004, 24, 341–344. DOI: 10.1016/S0955-2219(03)00223-1.Search in Google Scholar

©2018 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Interaction between an edge dislocation near a circular void within the framework of the theory of strain gradient elasticity

- A gradient theory based on the Aifantis theory using the Gurtin-Anand strain gradient plasticity approach

- Comparative study on wear behavior of as cast and spray cast hypereutectic Al-Si alloy

- Experimental investigation of chicken feather fiber and crumb rubber reformed epoxy resin hybrid composite: mechanical and microstructural characterization

- Electrochemical corrosion behaviour of HVOF sprayed iron-based amorphous metallic coatings on AISI 316 stainless steel in an NaCl solution

- Study of the corrosion properties in a hot forged Cu-Al-Ni alloy with added Cr

- The effect of sintering temperature on the porosity and compressive strength of corundum

- Parametric studies on the workability and compressive strength properties of geopolymer concrete

- Flow analysis of materials in friction stir welding

- Effect of machine scatter on the rotating bending fatigue life of materials

- Topological optimization of the fork-end of a knuckle joint

- Mechanical response of marble epistyles under shear: numerical analysis using an experimentally validated model

Articles in the same Issue

- Interaction between an edge dislocation near a circular void within the framework of the theory of strain gradient elasticity

- A gradient theory based on the Aifantis theory using the Gurtin-Anand strain gradient plasticity approach

- Comparative study on wear behavior of as cast and spray cast hypereutectic Al-Si alloy

- Experimental investigation of chicken feather fiber and crumb rubber reformed epoxy resin hybrid composite: mechanical and microstructural characterization

- Electrochemical corrosion behaviour of HVOF sprayed iron-based amorphous metallic coatings on AISI 316 stainless steel in an NaCl solution

- Study of the corrosion properties in a hot forged Cu-Al-Ni alloy with added Cr

- The effect of sintering temperature on the porosity and compressive strength of corundum

- Parametric studies on the workability and compressive strength properties of geopolymer concrete

- Flow analysis of materials in friction stir welding

- Effect of machine scatter on the rotating bending fatigue life of materials

- Topological optimization of the fork-end of a knuckle joint

- Mechanical response of marble epistyles under shear: numerical analysis using an experimentally validated model