Abstract

The rationale for recycling in the rotational molding community is arguably stronger than other sectors of the polymer industry since the process is more likely to produce extremely large parts and regardless of whether scrap is generated from an end-of-life situation or from off-spec production, this material is often too much and too valuable for diversion to landfill. It is therefore important for the community to establish test methods and knowledge on how to keep these polymeric materials within a circular economy. There is unfortunately little experimental data on recycling by rotomolding for processors to understand the feasibility of reclaiming scrap material in their production, for which this study aims to address. The molded parts of a commercial-grade and reactor-grade polyethylene were examined over several repeated molding cycles, in each case with between 10 and 50 % reclaim content, and then examined for quality indicators based on mechanical and rheological properties, part color and surface void content. The stabilized resin showed negligible changes over four recycle passes, except for yellowness, while the unstabilized resin showed minor signs of change on the second recycle pass. A narrow examination followed to understand the contributions of antioxidants versus UV stabilizers in the performance witnessed in the recycling trials. Overall, the study shows that robust recycling is very possible for the rotational molding industry with polyethylene grades, especially those intended for this process.

1 Introduction

Global demand for plastics is continually rising and in step with that growth, increasing environmental concerns are being voiced on how to handle products made from these materials when they are no longer useful. The rotational molding industry is particularly attuned to concerns related to their products’ end-of-life since molded parts can reach volumes as large as 80,000 L and disposal of these products is problematic from the viewpoint of occupying space in landfill sites as well as the loss of these valuable resins to the industry. Owing to the size of these parts and the relatively slow processing cycle attributed to rotomolding (Kelly-Walley et al. 2024), there is an urgent need to strategically identify feasible approaches to recycling (mechanical versus chemical) while also evaluating the validity over concerns of material damage associated with repeatedly exposing polymers to high temperatures and oxygen for prolonged periods of time (Cuadri and Martín-Alfonso 2017). Sustainability in this context would be in reference to the greater retention of polymer resins in the circular economy rather than being diverted to landfill. The present study is focused on mechanical recycling, seeking answers to these questions for the reclaim regrind generated from trimming or off-spec production, with the intention of keeping these materials as part of the global circular economy rather than treating them as waste. Approximately 30 % of rotational molding companies in North America will use recycled content in their normal operations with the percentage of reclaim regrind added varying from 10 to 50 %, making this a significant area of study since there is a strong belief that a high proportion of the remaining 70 % could be recycled but do not out of concerns over losses in part performance (Holguin 2024). The exact percentage of usable reclaim depends on both the quality of the recycled resin as well as the desired properties of the final product.

The principal concern associated with recyclability of polymers is their retention of original physical properties through each processing cycle which exposes the material to high temperatures, mechanical shear stresses, and oxygen. In the case of rotomolding, shear stresses are minimal, making the deterioration of properties being attributed to thermo-oxidative degradation. The hollow shaped molds inherent to rotational molding result in direct exposure of the polymer melt (often polyethylene) for prolonged periods of time to an oxygen-rich environment during heating, which initiates thermo-oxidative degradation and unsurprisingly, with more damage occurring to the inner part surfaces (Chen et al. 2019; Cramez et al. 2003). The dominant chain reaction resulting from thermo-oxidation for most families of polyethylenes is crosslinking and/or long-chain branching which have complex effects on the mechanical properties depending on the extent of these reactions (Oliveira et al. 1996); yellowing of the molded part is another common characteristic result of thermo-oxidative degradation, with its color intensity often thought to be relate to extent of damage (Allen et al. 2022). Both Oliviera et al. (1996) and Chen et al. (2019) conducted similar studies investigating the impact properties of degraded rotomolded polyethylene parts and both found that excessive crosslinking resulted in brittle failure with a significantly lower impact strength compared to samples where degradation was not evident. Quite often, the extent of degradation is linked to the peak internal air temperature (PIAT) for rotomolding since factors of time and high temperature are related to the extent of thermo-oxidative degradation (Gomes and Thompson 2018, Oliveira and Botelho 2008, Oliveira and Cramez 2001, Oliveira et al. 1996), with lower peak temperatures and faster heating cycles promoting less degradation but also often poorer sintering. Umbare and Arakerimath (2024) investigated the effect of various PIATs on mechanical properties of linear low density polyethylene (LLDPE) during rotomolding and noted that even a low PIAT of 200 °C resulted in polymer degradation where the flexural strength and flexural modulus were severely compromised. However, crosslinking can also provide a pathway to correcting material deficiencies, as found with off-spec post-consumer recycled feedstock, which was shown in a recent study exploring the use of free radical agents to tailor a molded part’s properties (Ahmad and Rodrigue 2024).

Studies on recycling have been very limited for rotational molding despite the environmental significance of its scrap rates. For all the studies mentioned above, the degradation commonly being discussed in the literature for rotomolding occurred during the initial cycle of molding a part, rather than from an examination of reprocessing the resins. The published recycling studies for this processing method have focused on introducing post-consumer waste as part of a charge to the mold (Ahmad and Rodrigue 2024; Cestari et al. 2021; Díaz et al. 2018; Dou and Rodrigue 2022; Pick et al. 2022; Shafigullin et al. 2022). In most cited cases, the recycled material was blended with a virgin resin (and potentially additives) using a twin-screw extruder to achieve a well dispersed composition and then ground up for rotomolding. Use of compounded blends minimizes the significance of materials variance on sintering otherwise seen using physical mixtures, which is better for correlating losses in mechanical properties to degradation, but it also introduces difficult questions about how extrusion contributed to the study results.

Comparably, the most common recycled content available to processors is their own scrap from off-spec parts or trimmings (industrial reclaim), and it is used as a physical mixture with virgin resin unless their business model is founded on handling post-consumer waste. Depending on the specifications and tolerances of a rotomolded product, processors may use between 10 and 50 % reclaim regrind content in a charge to their mold, and some fraction of polymer in that reclaim content may have experienced multiple cycles in a rotomolding unit, meaning that the potential impact of thermo-oxidative degradation on physical properties can be unknowingly high. The study by Song et al. (1992) gave a first-look at this ‘industrial regrind’ as recycled content and used a methodology identical to the one used by the present authors to more closely model the thermo-oxidative exposure conditions seen by industry. Those authors showed significant crosslinking by viscosity measurement which they reasoned kept their impact properties nearly constant after repeated heating cycles, though they could not explain why these properties dropped when molding under a nitrogen blanket; since absorbed oxygen is always present in polyethylene solids (Epacher et al. 2000), even under an inert gas blanket like nitrogen, the findings of their study are contrary to expectations since the same degradative reactions should be occurring (though to a lesser extent with no ambient oxygen).

The purpose of the present study was to examine the role of stabilizers using the recycling approach by Song et al. (1992), comparing a commercial resin to a reactor grade polyethylene with no stabilizer present; the term reactor grade refers to polyethylene collected at the polymerization reactor exit without being subsequently compounded with additives and pelletized like a commercial resin. The intent was to offer more insights on the recyclability of polyethylenes in rotomolding so that there was more comfort among companies using physical mixtures, and to understand the role of antioxidants versus UV stabilizers during recycling of industrial reclaim materials.

2 Experimental

2.1 Materials

Two resins were primarily under study for recyclability in this work, neither being rotational molding grades so that any stabilizer package present was not formulated for the process and there would be a greater chance of seeing thermo-oxidative degradation during the trials. The first resin was ExxonMobil™ LL 8555.25, a stabilized linear low-density polyethylene supplied by Imperial Oil Ltd (Sarnia, Ontario) with a melt index of 6.8 g/10 min (ASTM D-1238), denoted as “LL 8555.25” in the trials. The supplied resin had been commercially pulverized with a dominant particle size between 400 and 500 μm. The second resin was an unstabilized reactor grade high density polyethylene powder (675 μm nominally) supplied by Imperial Oil Ltd with a melt index of 2.0 g/10 min and referred to as “RG8660” in the trials. For reference, this reactor powder when formulated with a proprietary mixture of both antioxidants and UV stabilizers, makes a commercial rotomolding grade high density polyethylene (ExxonMobil™ HD 8660.29).

After initially detailed recycling trials with the two resins mentioned above, the effectiveness of the two main types of stabilizers in polyethylene resins were examined in minimizing degradation of RG8660. A UV stabilizer, Cyasorb Cynergy Solutions® M528 Light Stabilizer (Cyasorb), and antioxidant, Cyanox® 2777 Antioxidant (Cyanox) were donated by Cytec Canada Inc.

2.2 Compounding of stabilized resin

A total of three stabilized formulations were prepared by melt compounding prior to recycling trials. Formulations 1–3 consisted of 0.1 wt% Cyanox with RG8660, 0.1 wt% Cyasorb with RG8660 and finally 0.05 wt% of both Cyasorb and Cyanox with RG8660, respectively. The components of the three formulations along with their respective weight percentages are summarized in Table 1. A total of 500 g powder for each formulation was prepared by manually dry blending all components in a polyethylene bag and then feeding to the extruder at 1 kg/h with a K-Tron gravimetric feeder; this was the only use of an extruder in this study. An 18 mm 40 L/D MICRO18 co-rotating twin-screw extruder (Leistritz Extrusion; Somerville, NJ) was used to process each formulation. A barrel temperature profile gradually increased from 160 °C to 180 °C while a fixed screw speed of 250 RPM was used. The extruded material for each formulation was pelletized and bagged prior to recycling. The resin names used for the extruded formulations are listed in Column 5 of Table 1.

Composition of stabilized formulations 1–3 made in the extruder and their resin names.

| Formulation no. | RG8660 (wt%) | Cyanox (wt%) | Cyasorb (wt%) | Resin name |

|---|---|---|---|---|

| 1 | 99.9 | 0.1 | 0 | ANT |

| 2 | 99.9 | 0 | 0.1 | UV |

| 3 | 99.9 | 0.05 | 0.05 | ANTUV |

2.3 Recycling methodology

The standard methodology for studying degradation in polymer processes is to induce accelerated damage via multiple passes of a resin through a twin-screw extruder, with these results informing the industry on the viability of stabilization strategies, product defects, and resin recyclability (da Costa et al. 2007, Moss and Zweifel 1989, Zahavich et al. 1998). We elected in this study to use an evaluation method that more closely replicated the environment of recycling in a rotomolding unit (Song et al. 1992) rather than relying on the accelerated (and possibly unrealistic) damage produced by multi-pass testing.

For recyclability testing, all rotomolding cycles were carried out in a laboratory uniaxial rotomolding unit since it used less polymer powder to make a molded part (which meant less grinding between tests) and allowed easier measurement of PIAT. The oven temperature and PIAT were kept constant for each resin under study, as listed in Table 2; the PIAT indicated the temperature at which the heating cycle was stopped while the oven temperature influenced the heating rate during molding. The table includes the heating time, which was the duration to reach PIAT, and the cooling time, corresponding to the length of time that active cooling was applied to lower the mold temperature. PIAT varied for the different resins to reproducibly produce molded parts with ideally no porosity so that the quality of sintering would not be a factor in the later measured impact properties. The mold was charged with 100 g of a mixture, sealed closed with a transparent window to allow visual observation of the sintering, and mounted on an arm rotating at 4 RPM. A pre-heated oven was then placed over the mold and the trial started. Once PIAT was reached, the oven was removed, and the mold was cooled by blowing air at 3 m/s until the internal air temperature decreased below 70 °C.

Rotomolding conditionsa for the resin of study.

| Resin | Oven temperature (°C) | Heating time (min) | PIAT (°C) | Cooling time (min) |

|---|---|---|---|---|

| LL 8555.25 | 290 | 18 | 235 | 12 |

| RG8660 | 290 | 17 | 215 | 11 |

| ANT | 290 | 17 | 215 | 11 |

| UV | 290 | 17 | 215 | 11 |

| ANTUV | 290 | 17 | 215 | 11 |

-

aOven temperature and PIAT were optimized for each resin before the trials to produce the lowest void content for the shortest molding time and lowest ambient temperature.

The first molded box was made by one of the virgin resins, which was cut up into wall panels with half kept for physical characterization and the other half ground up into ‘reclaim’ regrind; the term reclaim is an industrial term referring to scrap left over at the end of production and never left the production facility. The reclaimed material for recycling was first fed into a plastic granulator (Rapid Granulator; Leetsdale, PA) to produce 3 mm polymer chunks and then further ground to size matching the virgin resin by using a 0.5 mm sieve in a grinding mill (Kinematica Polymix PX-MFC 90D, Switzerland). To keep the temperature from rising in the mill, a cooling fan forced air at 3 m/s over the outer metal faces of the mill and only small quantities of polymer could be milled at a time before stopping to let the unit cool down. A portion of the reclaim powder was then dry blended with virgin resin and a new box was molded. The box produced for this first recycling step is referred to as “Regrind 1”, while the sample would be referred to as “Regrind 1, 10 %” if the fraction of reclaim powder (in this case being 10 % of the 100 g charge to the rotomolding unit) was a variable of study. Reclaim content of 10 %, 30 %, and in some cases, 50 % were examined in this study. The recycling procedure continued by once again cutting up the box (now with a fraction of reclaim in its composition), keeping aside half of the wall panels for characterization and grinding up the other half. In total, recycling in this manner produced “Regrind 1”, “Regrind 2”, “Regrind 3” and “Regrind 4” boxes with between 10 % and 50 % reclaim from the earlier cycle in each case. Hence, a sample is described by the resin under analysis (LL 8555.25, RG8660, ANT, UV, ANTUV), its Regrind Number and the fraction of reclaim being recycled as regrind. Table 3 is provided to help clarify the naming convention of Regrind Number using an example of 30 % reclaim content, which can be applied to any resin under analysis. Multiple repeats were necessary to produce enough materials for the five processing cycles associated with these recycling trials for each resin.

Naming convention of a molded sample based on the composition of resins added to the mold for sintering demonstrated for 30 % reclaim content.

| Molding cycle | Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | Cycle 5 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Composition | Virgin resin (wt%) | Virgin resin (wt%) | Reclaim (wt%) | Virgin resin (wt%) | Reclaim (wt%) | Virgin resin (wt%) | Reclaim (wt%) | Virgin resin (wt%) | Reclaim (wt%) |

| Regrind 0 | 100 | ||||||||

| Regrind 1 | 70 | 30 from cycle 1 | |||||||

| Regrind 2 | 70 | 30 from cycle 2 | |||||||

| Regrind 3 | 70 | 30 from cycle 3 | |||||||

| Regrind 4 | 70 | 30 from cycle 4 | |||||||

2.4 Izod impact (unnotched) test

Though the industrial norm for physical characterization is dart impact testing, the unnotched Izod method was used instead because it requires less material for repeated testing and that was an important factor due to the extremely long time taken to produce even small amounts of testable materials for the higher molding cycles (like Regrind 3 and Regrind 4) of the recyclability trials. A Zwick-Roell HIT25P Pro Pendulum impact tester (Kennesaw, GA) was used to carry out the unnotched Izod Impact Tests as per ASTM D4812 standard to assess the impact strength of the rotationally molded boxes. Rectangular specimens were cut from the molded box walls with the dimensions of 64 × 13 × 3 mm and placed in a deep freezer to cool to −40 °C for at least 24 h prior to testing. A pendulum corresponding to 5.5 J was selected for the testing. Five specimens were tested for each rotomolded box and the average value was reported along with the standard deviation.

2.5 Polymer sintering analysis

The sintering behavior was assessed using a Polymer Analysis Vision System (Boyd et al. 2017) where 200 mg of polymer powder was evenly distributed across the surface area of a glass crucible and carefully tamped into place. The polymer powder used for the analysis was the same mixture of virgin and recycled powders that would be processed in the rotomolder. The glass crucible holding the polymer powder mixture was placed into a Heat Chamber and luminated from beneath. A microscope charge-coupled device (CCD) camera was used to collect images of the polymer powder during melting and recorded the number of bubbles present over time. The magnification level of the microscope used was 2× (corresponding to 211–213 pixels per mm). A sintering profile produced by the system recorded the number of bubbles present in the polymer melt every 30 s between melt temperatures of 120 °C and 230 °C. The heating rate of the system was approximately 5 °C/min.

2.6 Yellowness index (ASTM D-1925)

A standard method for calculating the yellowness index (YI) of plastics as per ASTM D-1925 was used to calculate the yellowness of the rotationally molded boxes. This method used tristimulus values obtained from a color sensor to compare the magnitude of yellowness to a magnesium oxide standard. Samples for testing were obtained from the same specimens used for Izod impact testing. A Nix Mini 3 portable color sensor (Hamilton, ON) was placed on top of an individual specimen, corresponding to the outer surface of the rotomolded box, and both were fully enclosed with a cardboard box to prevent any external light from penetrating. The sensor-calculated tristimulus values, XCIE, YCIE and ZCIE of the specimen gave YI according to Eq. (1):

where XCIE, YCIE and ZCIE are the tristimulus values for red, green and blue respectively. A positive YI value showed the presence and degree of yellowing, while a negative value showed a bluish appearance in the material. A total of three specimens were used to calculate YI for a sample and their averages and standard deviations were reported.

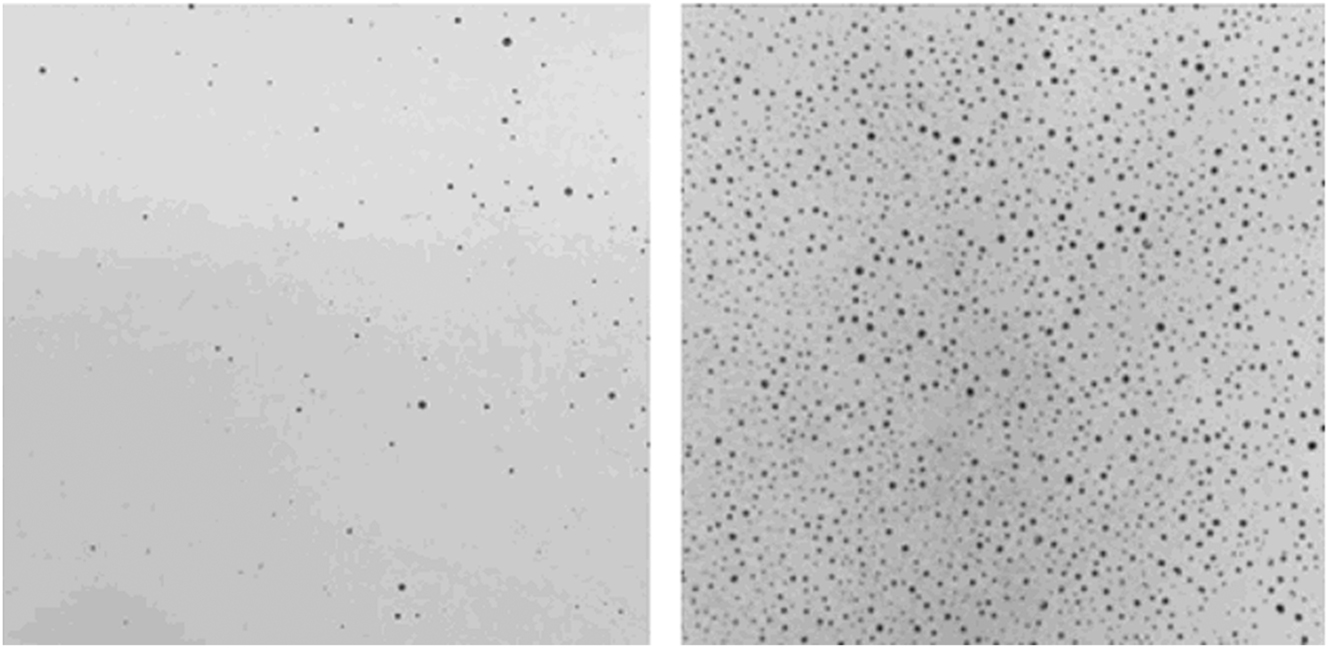

2.7 Surface void analysis

The frequency of bubbles in the outer surfaces of a rotomolded part was used to evaluate the completeness of sintering during processing. A copper-based lubricant was rubbed into the voids on the outer surface (mold side) of a rotomolded box panel to darken and accentuate their presence. Excess lubricant was wiped away and then the panel was photographed with a digital camera. Each image was analyzed using ImageJ (NIH, USA) by first cropping to a 40 mm by 40 mm section at the center of the wall face and then converting into an 8 bit image before the percentage of dark areas were calculated; less than 1 % void area was typically desirable. Two examples of a 40 mm by 40 mm lubricated section from the wall of a rotomolded part are shown in Figure 1, demonstrating a well sintered part with 0.5 % voids versus a poorly sintered part with 5.2 % voids.

Cropped images of the wall surface for rotomolded samples having either (left image) 0.5 % void area, or (right image) 5.2 % void area.

2.8 Rheological analysis

Rheology is an effective tool in characterizing degradation due to its sensitivity to changes in the molecular structure of a polymer melt. A Discovery HR-2 Hybrid rheometer (TA Instruments; New Castle, DE) equipped with 25 mm diameter parallel plates was used to assess rheological measurements of rotomolded materials. A specimen was directly cut from the wall of a rotomolded box. A strain of 5 % was found suitable for all experiments. A frequency sweep was conducted on the samples for an angular frequency (ω) range of 0.1–100 rad/s and a temperature of 215 °C. Zero shear viscosity was estimated by fitting the complex viscosity with the Cross model given in Eq. (2):

where η is complex viscosity, ηo is the zero shear viscosity, η∞ is the viscosity at infinite shear rate, C is a constitutive constant, n is the power-law index and

3 Results and discussion

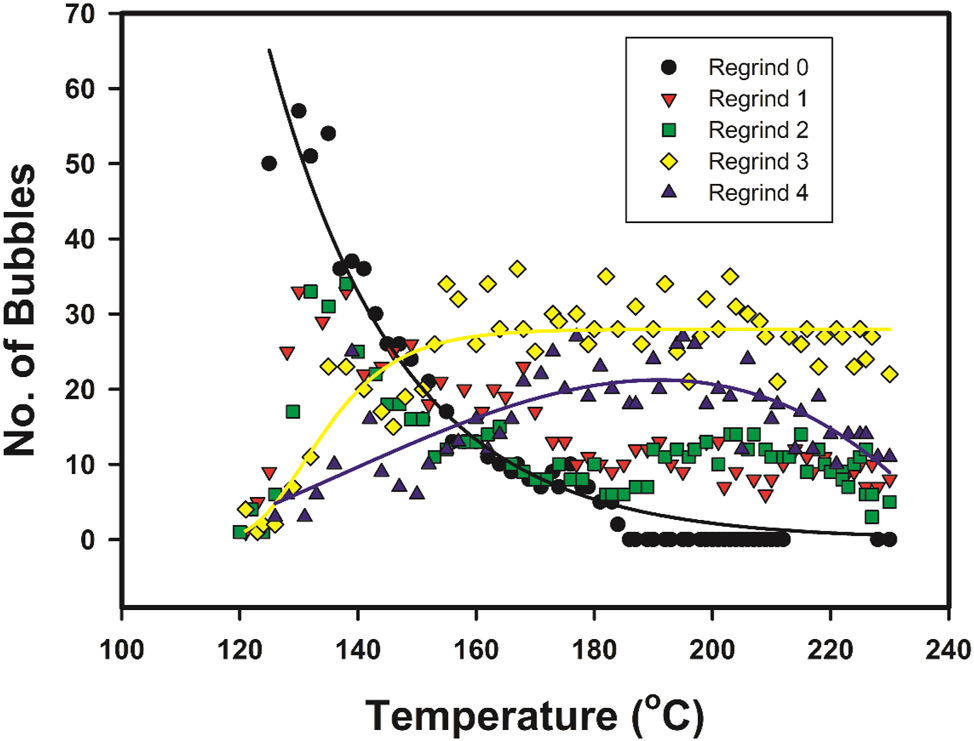

3.1 Powder sintering behavior

Sinter-ability was evaluated for the commercial resin, LL 8555.25 using the same powders charged to the rotomolding unit for producing Regrind 1–4 samples with 30 % reclaim, which were compared to Regrind 0 in Figure 2. This evaluation used our Polymer Analysis Vision System (PAVS) mentioned in Section 2.5, which examined how materials should perform during the heating cycle of rotomolding by automatically monitoring (and recording) the sizes of all bubbles seen with a custom-made hot stage microscopy setup in real-time as temperature increases. During sintering, bubbles were defined by the bridges forming between particles and then by melt coalescence, those voids ideally disappeared over time in accordance with the surface tension of the resin and its viscosity (Kontopoulou and Vlachopoulos 1999). The powder of the molded sample based on 100 % virgin resin (Regrind 0) showed approximately 60 well-formed bubbles at the melt temperature of 130 °C. As temperature increased, the number of bubbles steadily decreased until zero bubbles were present, implying complete sintering of the powder was possible by approximately 190 °C; this nature constitutes a good candidate for rotomolding. Comparatively, as temperature increased for the powders composed partially of reclaim regrind, the number of bubbles increased with Regrind number and never reached a completely sintered state as previously seen with Regrind 0; the gradual growth of bubbles at the lower temperatures with Regrind samples 1–4 indicate slowed bridging and melt coalescence due to hindered sinter-ability. This sensitive characterization method is showing changes to the polymer by recycling, which we attributed to thermo-oxidative degradation due to the tendency of linear low density polyethylene to experience an increase in viscosity by these free-radical reactions (Chen et al. 2019). Furthermore, we briefly note that when a sample with 50 % reclaim was tested for sinter-ability (Regrind 3), the frequency and nature of bubbles developed in the test did not statistically differ (data not shown).

Number of bubbles in the polymer melt plotted with temperature for Regrind 1–4 LL 8555.25 powdered material with 30 % recycled content compared with Regrind 0. Lines added to aid following the trends seen. Trends seen for Regrinds 1 and 2 were too complicated to fit, following Regrind 3 between 120 and 150 °C and then Regrind 0 at higher temperatures.

Since none of our later analysis methods could detect the change in chain structure nor did the porosity of the molded parts differ between the recycled samples (Regrind 1–4) versus Regrind 0, it was not considered worthwhile conducting this test for RG8660 as well. We accept the results of this analysis to be showing degradation occurred for LL 8555.25 but to such a small extent that the rotational molding environment did not display the same outcome – perhaps due to the rotating motion not being replicated in this test.

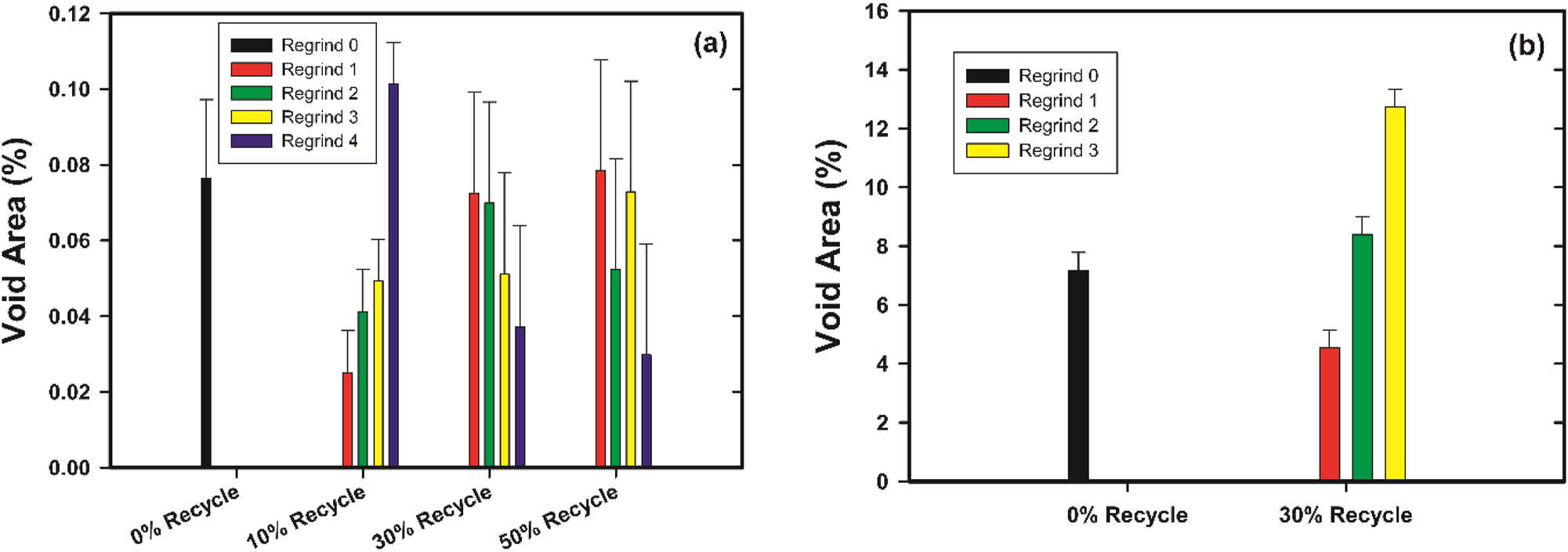

3.2 Surface void analysis

A surface void analysis was performed on Regrind 1–4 boxes with 10 %, 30 % and 50 % LL 8555.25 reclaim content in Figure 3(a) and Regrind 1–3 boxes with 30 % RG8660 reclaim content in Figure 3(b), made in comparison to sample rotomolded boxes made of only virgin resin (Regrind 0); all these conditions were tested in order to try to observe the effects of thermo-oxidative degradation on molded part properties as seen by Song et al. (1992) who noted changes immediately after recycling polyethylene only once.

Percentage of void area on the surface of the (a) LL 8555.25 rotationally molded boxes from Regrind 1–4 with 10, 30 and 50 % recycled content compared with virgin LL 8555.25 (pass 0), and (b) RG8660 Regrind 1–3 rotomolded samples compared with virgin RG8660 (Regrind 0).

In the case of LL 8555.25 resin, all rotomolded boxes displayed very little to no voids on their outer surfaces implying complete sintering of the particles during rotomolding. No trends could be interpreted from these results since this low void area differed at most by one bubble in the wall of a sample, meaning that all Regrind 1–4 boxes based on LL 8555.25 were considered equivalent. It is expected that particles will sinter better at the mold wall compared to the box interior due to the direct heat transfer from the mold promoting earlier melting and longer times to coalesce the particles present. Additionally, as the mold rotated, the particles along the molds surface experienced some compaction from the rotating particle layers above, promoting a better surface finish with less air pockets during melting. This may be why the surface void analysis suggested complete sintering of the particles for all samples while the sinter-ability test did not.

Since RG8660, with its absence of stabilizers, was more prone to thermo-oxidative reactions, testing only needed to evaluate the condition of 30 % reclaim content and only up to Regrind 3 to be able to see the effects on molded part properties. The total surface void area for a part with the virgin resin was approximately 7 %, significantly exceeding the desirable value for this study (set as less than 1 % for good sinter-ability). As the Regrind number increased for the RG8660 based samples, the trend showed an increase in surface void area and progressively poorer sintering behavior with repeated recycling; the rise in zero-shear viscosity with regrind number later reported in Section 3.5 explained the hinderance to sintering being seen. The decline in voids for Regrind 1 was expected since pre-study accelerated aging tests with HD 8660.29 produced a similar phenomenon of better melt coalescence (in that case without any change in viscosity). With only increased yellowing noted for HD 8660.29, the improvement in sintering was attributed to changed surface tension driving better melt coalescence and we believe the same effect was shown with Regrind 1 for RG8660, partially compensating for the slowed sintering due to increased viscosity.

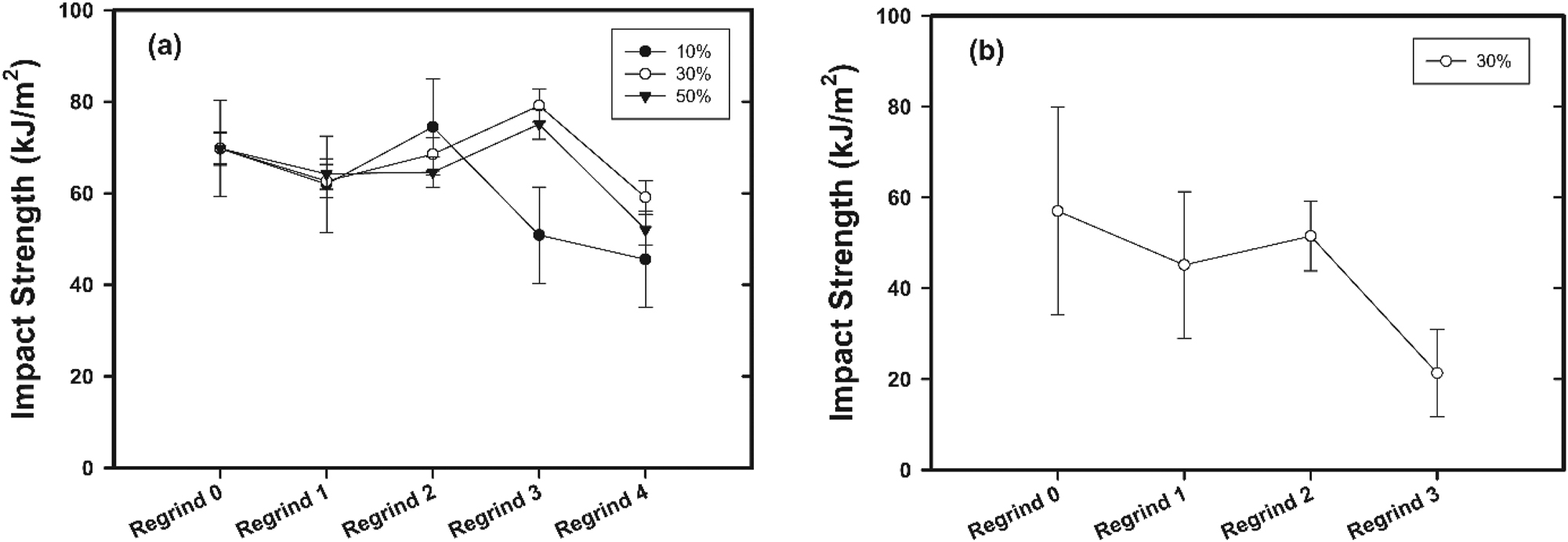

3.3 Izod impact test

The Izod impact strength was reported in Figure 4 for unnotched specimens taken from Regrind 1–4 boxes with 10 %, 30 % and 50 % recycled LL 8555.25 content (Plot (a)) and Regrind 1–3 boxes with 30 % recycled RG8660 content (Plot (b)), made in comparison to the virgin molded samples (Regrind 0). No sample failed in this test for LL 8555.25 resin.

Izod impact strength for unnotched specimens taken from (a) Regrind 1–4 LL 8555.25 rotomolded samples with 10, 30 and 50 % reclaim content and (b) Regrind 1–3 (30 %) RG8660 samples. Regrind 0 corresponds to the virgin resin in each case. Trend lines included for clarity.

Increasing recycled LL 8555.25 content as well as regrind number did not have a dramatic effect on impact strength for this resin. Only for Regrind 4 was there a consistent sign of loss in physical properties, and even then, after all these processing cycles, the change was only slight. A higher recycled content in samples with LL 8555.25 should theoretically amplify the influences of degradation in a part and even though more variability was noted with 10 % reclaim versus the higher amounts, we cannot conclude overall that there was any significant difference due to the repeatability of the measurement; the repeatability was affected by the fact that the inner surface of any molded wall varies due to the sintering method used by rotational molding, making significant thickness variation in test specimens. This finding is similar to the room temperature impact strength measurements reported by Song et al. (1992) but who concluded that degradation of LLDPE occurred after only one recycling pass by relying more on their viscosity measurements.

The larger error bars reported with RG8660 resin were attributed to the greater void content in addition to the variation in specimen thickness mentioned above with LL 8555.25; depending on where the Izod impact hammer hit a specimen, these defects would have caused the large variability seen between repeats. The impact strength for the box molded with virgin RG8660 resin was approximately 55 kJ/m2, lower than LL 8555.25, and as the Regrind number increased, the impact strength decreased; a significant drop in impact properties was seen by Regrind 3 with this unstabilized high density polyethylene resin. Table 4 gives the percent of RG8660 specimens which displayed ductile versus brittle fractures upon impact for all recycled samples; no LL 8555.25 specimens fractured and hence, no data was included in the table. As recycling increased, the number of brittle failures increased. This trend matches that seen in the Han plot (in the next section) showing evidence of progressive crosslinking with increased time in the rotomolding unit.

Percentage of ductile and brittle fractures observed during unnotched Izod testing for RG8660 rotomolded samples.

| Rotomolded sample name | % ductile fractures | % brittle fractures |

|---|---|---|

| R0 | 80 | 20 |

| R1 | 80 | 20 |

| R2 | 60 | 40 |

| R3 | 20 | 80 |

3.4 Rheology results

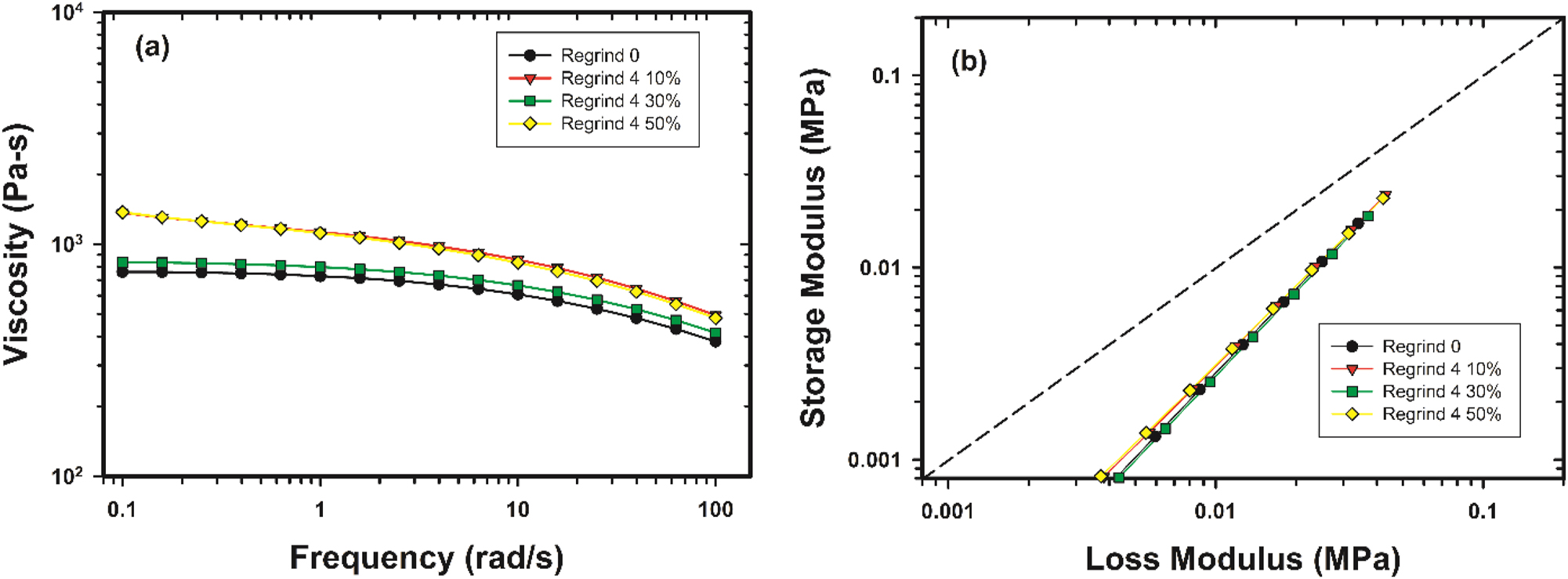

Figure 5 presents the shear viscosity and Han plots respectively for LL 8555.25 Regrind 4 samples containing 10, 30 and 50 % reclaim content compared with the virgin resin; only Regrind 4 samples were analyzed since it was the only recycling condition to show changes in the other physical properties and we sought to confirm the cause of the change. Due to the negligible shear present in rotomolding processes, it is the tendency of the field to more closely note changes in viscosity due to degradation that are found in the Newtonian plateau region; quoted zero shear viscosities (η0) in this section were estimated using the Cross model. The 10 % and 50 % reclaim regrind contents showed a minor increase in shear viscosity (η0 = 1,500 Pa-s and η0 = 1,562 Pa-s respectively) while the 30 % regrind content (η0 = 856 Pa-s) matched the virgin resin (η0 = 779 Pa-s); these results do not suggest significant degradation occurred with LL 8555.25 and also match the impact strength data where samples with 10 % and 50 % recycled content showed slightly more (though not significant) stiffening compared to the 30 % condition. In order to help our analysis of molecular change, the Han plot is usually a superior rheological tool for detecting branching and crosslinking (Lachtermacher and Rudin 1995). The plots showed almost identical viscoelastic behavior, with all samples being below the G′ = G″ line, indicating no change in the elasticity had occurred. Considering all results together, there does not appear to be significant thermo-oxidative degradation via recycling to affect the physical properties of LL 8555.25, even over all cycles of reprocessing.

Rheological analysis of LL 8555.25 Regrind 4 samples with 10, 30 and 50 % recycled content compared to a rotomolded sample with virgin LL 8555.25; (a) Shear viscosity and (b) Han plot. Trend lines included for clarity whereas the dashed 45° line is meant as a visual aid on how the G′ versus G″ curves are shifting based on reclaim content.

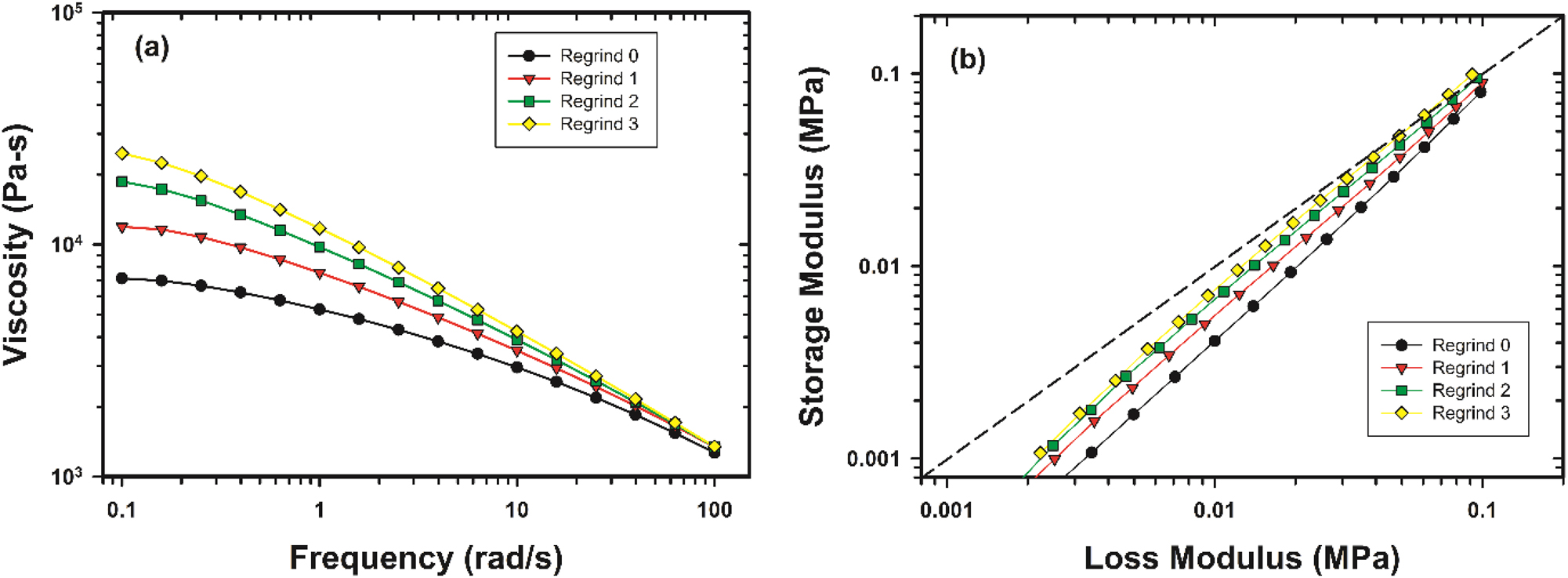

Comparably, the shear viscosity and Han plots for RG8660 rotomolded samples with 30 % recycled content are shown in Figure 6 for Regrind 1–3 samples versus the virgin resin (Regrind 0) to establish the degradative sensitivity of polyethylene to recycling when no stabilizers are present. The absence of a clear Newtonian plateau and progressive increase in shear viscosity with Regrind number for RG8660 showed the evolution of a more complex microstructure, specifically the inclusion of crosslinking and LCB which effectively restrict chain mobility and result in an increase in shear viscosity. The zero shear viscosity of RG8660 was estimated to be η0 = 8,995 Pa-s (Regrind 0), increasing to η0 = 15,423 Pa-s (Regrind 1), η0 = 28,123 Pa-s (Regrind 2) and finally η0 = 39,663 (Regrind 3). The Han curve for the molded sample with virgin RG8660 resin lies completely below the G′ = G″ line, showing a dominant viscous behavior similar to LL 8555.25. However, as the Regrind number increased for RG8660, the Han curves shifted closer to the G′ = G″ line and then crossed by Regrind 3, showed a progression to dominant elastic behavior. This shift is indicative of restricted chain mobility due to branching and crosslinking which enhance the material’s ability to store elastic energy. Since Regrind 3 was the first condition for significant changes to be seen in impact strength, the rheological analysis revealed how substantive the changes in molecular structure needed to be before degradation affected the recyclability of the tested polyethylenes. It was surprising that this polyethylene showed less thermo-oxidative sensitivity than might be expected for an unstabilized resin subjected to a long heating history in the presence of air.

Rheological analysis of RG8660 Regrind 1–3 samples compared with virgin RG8660; (a) shear viscosity and (b) Han plot for RG8660 Regrind 1–3 samples compared with a virgin RG8660 sample (Regrind 0). Trend lines included for clarity.

3.5 Yellowness index results

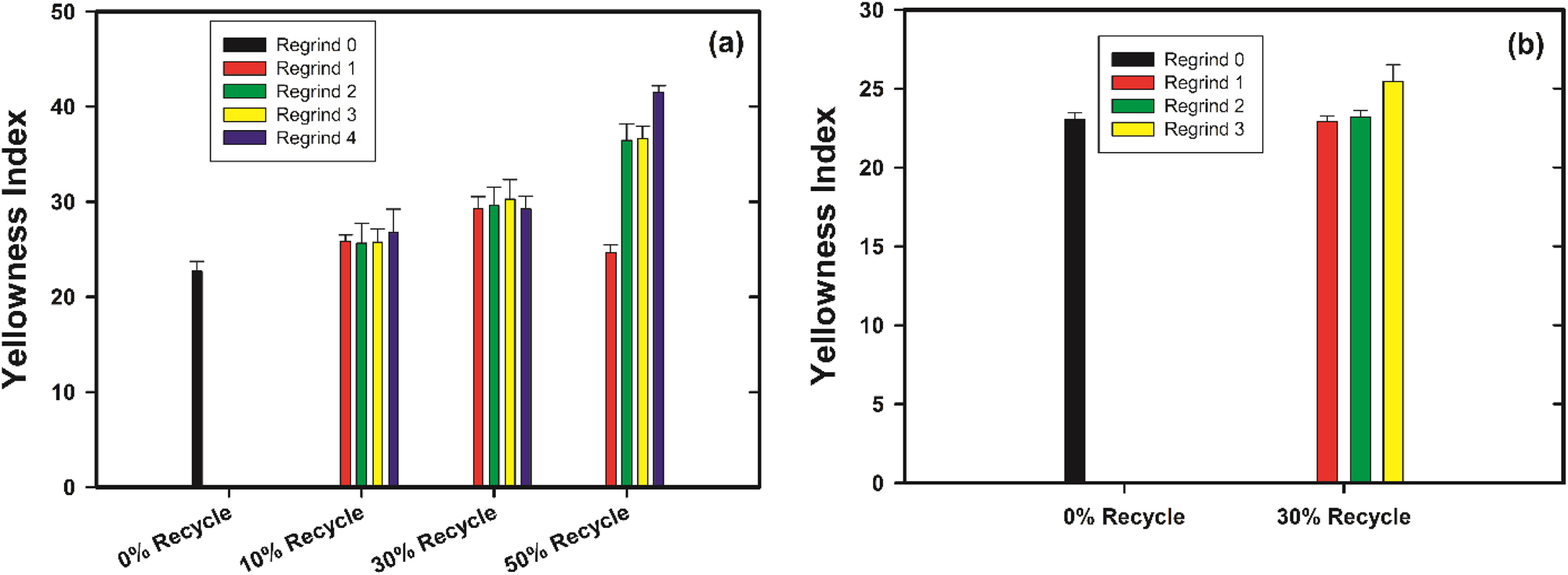

The YI values are given in Figure 7 for Regrind 1–4 rotomolded samples for LL 8555.25 containing 10 %, 30 % and 50 % reclaim content (Plot (a)) as well as unstabilized RG8660 Regrind 1–3 rotomolded samples (Plot (b)), both in comparison to a molded box made with their respective virgin resins (Regrind 0).

Yellowness index for (a) LL 8555.25 Regrind 1–4 rotomolded samples with 10, 30 and 50 % recycled content compared with a virgin LL 8555.25 (Regrind 0) sample; and (b) RG8660 Regrind 1–3 rotomolded samples compared with a rotomolded virgin RG8660 sample (Regrind 0).

The molded sample with virgin LL 8555.25 displayed a YI of around 23. The samples with 10 % reclaim content had no significant color change. With 30 % reclaim content, there was a slight increase in YI for all Regrind numbers compared to the virgin material and at 50 % reclaim content, yellowing increased significantly for Regrinds 2–4.

The YI for RG8660 Regrind 0 through Regrind 2 remained steady at 23 (like LL 8555.25) and it was only increased slightly to 25 for Regrind 3. Despite the notable evidence of thermo-oxidation reaction occurring for RG8660 during recycling, any oxidation functionalities added to the polymer chains produced minimal changes to the yellowness of a molded part.

The significantly greater shift in yellowness for LL 8555.25 is explored more deeply in the next section, being attributed to the stabilizers present in that resin and their nature in trapping/terminating free radical attributed to thermo-oxidative reactions (Allen et al. 2022).

3.6 Influence of antioxidant and UV stabilizers

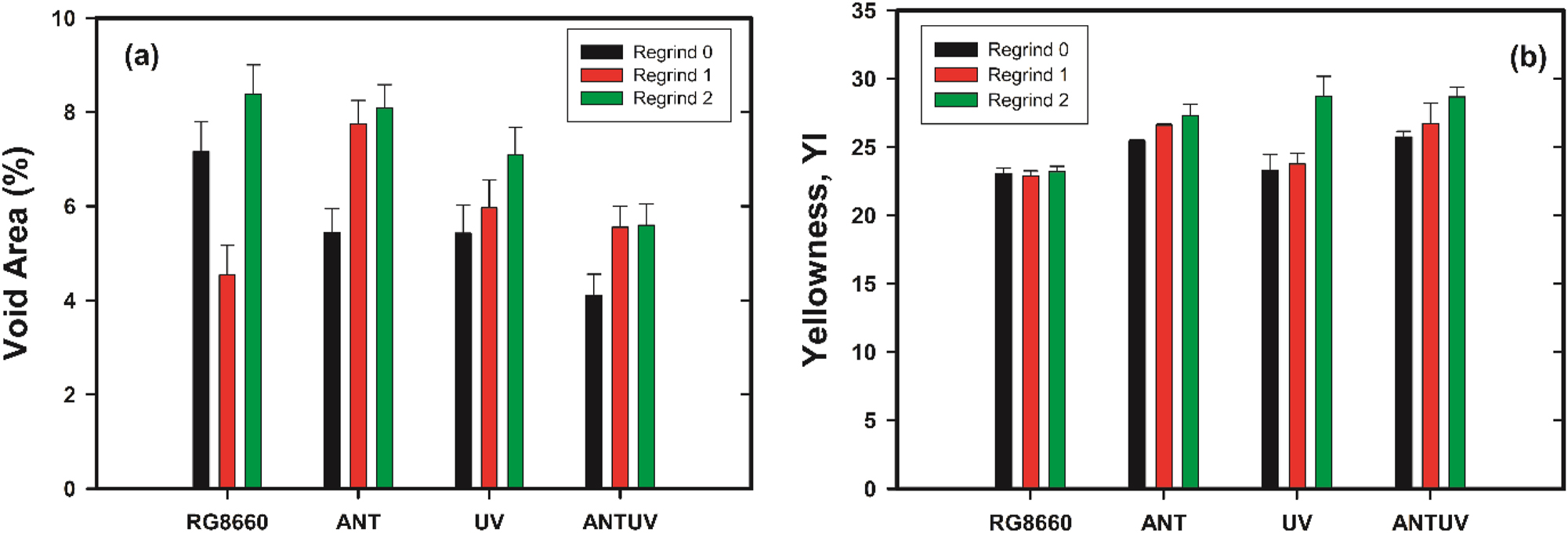

The goal of this part of the study was to more closely examine the roles of key stabilizers used in rotomolding resins with respect to recycling. The recyclability of compounded polyethylene examples with UV and/or antioxidant stabilizer in the reactor-grade RG8660 was considered up to Regrind 2 where results in the earlier section showed evidence of microstructural changes. The three compounded resins (UV, ANT, ANTUV) constituted as ‘virgin’ resins in their respective recycling trial and were compared to results with unstabilized RG8660. This means that there were four Regrind 0, Regrind 1, and Regrind 2 samples to analyze, though the focus was on Regrind 2 where prior sections had established the unstabilized resin started to show significant evidence of degradation.

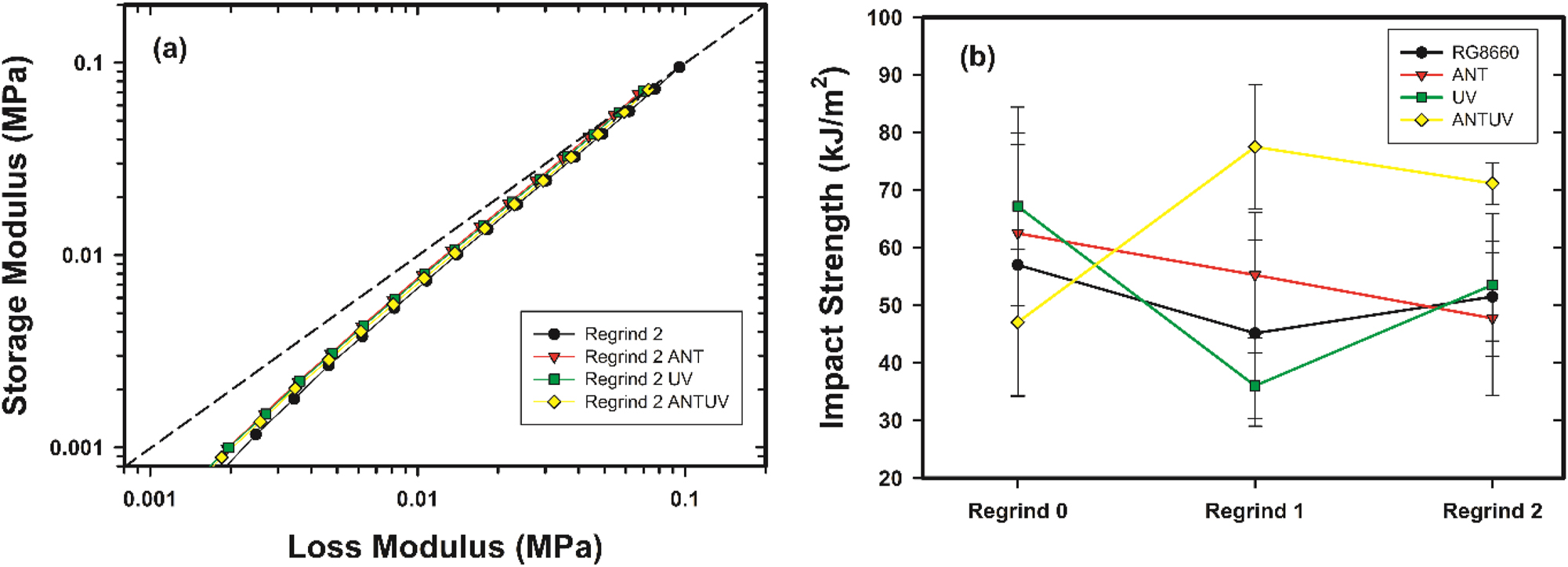

Physical differences due to the type of stabilizer present were examined in Figure 8(a), showing the Han plot of Regrind 2 with 30 % reclaim regrind samples versus unstabilized Regrind 2 and impact strength results for Regrind 0–2 samples with 30 % reclaim regrind. Rheologically, the addition of antioxidant or UV stabilizer reduced the shear viscosity of Regrind 2 from η0 = 28,617 Pa-s (no stabilizer added, RG8660) to η0 = 20,340-24,170 Pa-s for UV, ANT, or ANTUV. For reference, Regrind 0 with the virgin RG8600 had a zero-shear viscosity of η0 = 8,995 Pa-s, showing that some crosslinking or branching had occurred even with these stabilizers over the course of compounding and recycling. The Han plot showed no distinctive differences among samples with the different stabilizer compositions but in turn, they showed more chain mobility compared to the unstabilized resin; the higher mobility was noted by the lower G′ relative to G″ at high oscillatory frequencies.

Physical properties of recycled rotomolded samples with 30 % reclaim regrind with compounded stabilizers compared with the unstabilized RG8660; (a) Han plot of Regrind 2 samples, and (b) impact strength of all Regrind cycles. Trend lines included for clarity.

Results for impact strength given in Figure 8(b) showed a distinctive increase in impact strength for ANTUV, containing both UV and antioxidant additives, with recycling though this property did not change between Regrind 1 and Regrind 2. This improvement in physical property was not explained by the rheological analysis, indicating the likelihood of a different crystalline structure during cooling, though neither density nor enthalpy (via DSC) measurements could detect any change, which meant these changes were small. Further testing with a greater number of concentrations and blend ratios would be required to establish a trend in impact properties but this was beyond the scope of this study. But for the moment, the commercial approach to include both stabilizer types seemed beneficial to the recyclability of their resins.

The appearance of the recycled parts using these compounded resins (ANT, UV, ANTUV) versus the unstabilized resin (RG8660) samples for Regrind 0–2 are summarized in Figure 9, reporting surface void area and yellowness index. The void areas shown in Plot (a) were significantly lower in the compounded resins for Regrind 0 (virgin condition), but that difference disappeared in Regrind 1 or Regrind 2. Of the three stabilized resins, ANTUV was more likely than the others to have less voids in the molded part and if the void value for RG8660 Regrind 1 is to be considered an outlier, then we can consider ANTUV as the only resin in this test to improve recyclability of polyethylene in rotomolding.

Appearance of the rotomolded samples for the compounded resins with stabilizer blended at 30 % as reclaim regrind compared with RG8660 samples: (a) surface void area, and (b) yellowness.

Regarding yellowness, Plot (b) of Figure 9 showed that any resin with antioxidant had a higher YI, even for Regrind 0; the intermediate products formed by phenolic antioxidants are associated with this yellowness. Since even Regrind 0 involved polymer exposure to the degradative environments of both extrusion and rotomolding (which the unstabilized sample did not), there is some uncertainty about how much of the yellowing observed for this initial case is attributed to rotomolding, but it will be assumed to be wholly attributed to recycling for the purposes of this examination. The UV stabilizer did not contribute to the yellowness of a part until Regrind 2. The YI values for RG8660 never increased up to Regrind 2, confirming the yellow color in the molded parts throughout this study was negligibly attributed to oxidation functionalities on the polyethylene chains but rather, due to the stabilizers performing their function in trapping or terminating free radicals arising from thermo-oxidation. The YI value was only as high at 29 by Regrind 2 for these compounded resins, below the 36 reported for LL 8555.25 likely because a commercial stabilization package can be made up of many different additives.

4 Conclusions

The recyclability of different polyethylene grades was examined using a method comparable to industrial practices for recycling in-house reclaim. The method was confirmed to cause significant crosslinking when the resin is not suitably protected, as proven in this case with a reactor grade high density polyethylene (RG8660). By this validation of the test method to produce degradation, it was found that a commercial polyethylene resin without an optimized stabilizer package for rotomolding, LL 8555.25 resin, shows excellent resistance to thermo-oxidative degradation for at least three out of five processing cycles (counting both the initial molding and two cycles with reclaim) with up to 50 % regrind content. The only negative to the protection offered by the commercial stabilizer package was the steady increase in yellowness found by recycling that was not seen in the reactor grade material, which was subsequently attributed to antioxidants in the molded parts; this yellowness increased by 78 % (YI value) after five processing cycles as the recycled reclaim fraction increased to 50 %. Examining the nature of stabilizer species separately revealed the UV stabilizer would eventually contribute to the yellowing of a recycled part but not as immediately as seen with the antioxidant. The testing in this study also showed that protection of physical properties during recycling favors a combination of antioxidant and UV stabilizer. Further work is needed to understand the synergy shown between these two types of stabilizers in hindering oxidation during molding.

Acknowledgments

The authors thank Imperial Oil Ltd. for their funding of this work. The authors want to especially thank Tammy Boesche at Imperial Oil for her advice, supply of materials, and review of our results throughout the study. We wish to further thank Heera Marway at the McMaster Manufacturing Research Institute (MMRI) for assisting with the rotomolding unit and training on the different characterization techniques used in this study.

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: The authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: Not applicable.

-

Conflict of interest: The authors state no competing interests.

-

Research funding: Imperial Oil Ltd Imperial Research Grant.

-

Data availability: Data available on request from the authors.

References

Ahmad, H. and Rodrigue, D. (2024). Upcycling of recycled polyethylene for rotomolding applications via dicumyl peroxide crosslinking. J. Appl. Polym. Sci. 141: e56236, https://doi.org/10.1002/app.56236.Search in Google Scholar

Allen, N.S., Edge, M., and Hussain, S. (2022). Perspectives on yellowing in the degradation of polymer materials: inter-relationship of structure, mechanisms and modes of stabilisation. Polym. Degrad. Stab. 201: 109977, https://doi.org/10.1016/j.polymdegradstab.2022.109977.Search in Google Scholar

Boyd, J., West, W., Wu, S., Takacs, E., Vlachopoulos, J., and Thompson, M. (2017). Automated image analysis to characterize the melt densification stage of polymer sintering processes. Polym. Test. 60: 242–249, https://doi.org/10.1016/j.polymertesting.2017.04.008.Search in Google Scholar

Cestari, S.P., Martin, P.J., Hanna, P.R., Kearns, M.P., Mendes, L.C., and Millar, B. (2021). Use of virgin/recycled polyethylene blends in rotational moulding. J. Polym. Eng. 41: 509–516, https://doi.org/10.1515/polyeng-2021-0065.Search in Google Scholar

Chen, L.L., Sun, X., Ren, Y., Liang, W., and Wang, K. (2019). Effects of thermo-oxidative aging on structure and low temperature impact performance of rotationally molded products. Polym. Degrad. Stab. 161: 150–156, https://doi.org/10.1016/j.polymdegradstab.2019.01.016.Search in Google Scholar

Cramez, M.C., Oliveira, M.J., and Crawford, R.J. (2003). Optimization of the rotational moulding process for polyolefins. Proc. Inst. Mech. Eng. Part B 217: 323–334, https://doi.org/10.1243/095440503321590497.Search in Google Scholar

Cuadri, A.A. and Martín-Alfonso, J.E. (2017). The effect of thermal and thermo-oxidative degradation conditions on rheological, chemical and thermal properties of HDPE. Polym. Degrad. Stab. 141: 11–18, https://doi.org/10.1016/j.polymdegradstab.2017.05.005.Search in Google Scholar

da Costa, H., Ramos, V., and Oliveira, M. (2007). Degradation of polypropylene (PP) during multiple extrusions: thermal analysis, mechanical properties and analysis of variance. Polym. Test. 26: 676–684, https://doi.org/10.1016/j.polymertesting.2007.04.003.Search in Google Scholar

Díaz, S., Ortega, Z., McCourt, M., Kearns, M.P., and Benítez, A.N. (2018). Recycling of polymeric fraction of cable waste by rotational moulding. Waste Manag. 76: 199–206, https://doi.org/10.1016/j.wasman.2018.03.020.Search in Google Scholar PubMed

Dou, Y. and Rodrigue, D. (2022). Morphological, thermal and mechanical properties of recycled HDPE foams via rotational molding. J. Cell. Plast. 58: 305–323, https://doi.org/10.1177/0021955x211013793.Search in Google Scholar

Epacher, E., Tolvéth, J., Kröhnke, C., and Pukánszky, B. (2000). Processing stability of high density polyethylene: effect of adsorbed and dissolved oxygen. Polymer 41: 8401–8408, https://doi.org/10.1016/S0032-3861(00)00191-9.Search in Google Scholar

Gomes, F.P.C. and Thompson, M.R. (2018). Nondestructive evaluation of sintering and degradation for rotational molded polyethylene. Polym. Degrad. Stab. 157: 34–43, https://doi.org/10.1016/j.polymdegradstab.2018.09.013.Search in Google Scholar

Holguin, M. (2024). Understanding recycled materials for rotomolding. SPE Plast. Eng. October 19: 007055.Search in Google Scholar

Kelly-Walley, J., Martin, P., Ortega, Z., Pick, L., and McCourt, M. (2024). Recent advancements towards sustainability in rotomoulding. Materials 17: 2607, https://doi.org/10.3390/ma17112607.Search in Google Scholar PubMed PubMed Central

Kontopoulou, M. and Vlachopoulos, J. (1999). Bubble dissolution in molten polymers and its role in rotational molding. Polym. Eng. Sci. 39: 1189–1198, https://doi.org/10.1002/pen.11505.Search in Google Scholar

Lachtermacher, M.G. and Rudin, A. (1995). Reactive processing of LLDPES in corotating intermeshing twin-screw extruder. II. Effect of peroxide treatment on processability. J. Appl. Polym. Sci. 58: 2433–2449, https://doi.org/10.1002/app.1995.070581311.Search in Google Scholar

Moss, S. and Zweifel, H. (1989). Degradation and stabilization of high density polyethylene during multiple extrusions. Polym. Degrad. Stab. 25: 217–245, https://doi.org/10.1016/S0141-3910(89)81009-2.Search in Google Scholar

Oliveira, M.J. and Botelho, G. (2008). Degradation of polyamide 11 in rotational moulding. Polym. Degrad. Stab. 93: 139–146, https://doi.org/10.1016/j.polymdegradstab.2007.10.004.Search in Google Scholar

Oliveira, M.J. and Cramez, M.C. (2001). Rotational molding of polyolefins: processing, morphology, and properties. J. Macromol. Sci.-Phys. B40: 457–471, https://doi.org/10.1081/Mb-100106170.Search in Google Scholar

Oliveira, M.J., Cramez, M.C., and Crawford, R.J. (1996). Structure-property relationships in rotationally moulded polyethylene. SPE ANTEC ’96 Tech. Papers: Plast. – Racing Fut. I-I, 42: 2096–2100.Search in Google Scholar

Pick, L., Hanna, P.R., and Gorman, L. (2022). Assessment of processibility and properties of raw post-consumer waste polyethylene in the rotational moulding process. J. Polym. Eng. 42: 374–383, https://doi.org/10.1515/polyeng-2021-0212.Search in Google Scholar

Shafigullin, L.N., Romanova, N.V., Erofeev, V.T., Gabdrakhmanov, A.T., and Bobryshev, A.A. (2022). Using products of polyethylene recycling for the production of holding tanks. Mater. Phys. Mech. 50: 266–274, https://doi.org/10.18149/Mpm.5022022_7.Search in Google Scholar

Song, S.S., Nagy, T., and White, J.L. (1992). A basic study of applicability of regrind polyethylene in rotational molding. Intern. Polym. Proc. 7: 274–282, https://doi.org/10.3139/217.920274.Search in Google Scholar

Umbare, V. and Arakerimath, R. (2024). Investigating the influence of peak internal air temperature (PIAT) on material characteristics of linear low-density polyethylene (LLDPE) during rotational moulding. Eng. Res. Exp. 6, https://doi.org/10.1088/2631-8695/ad1d22.Search in Google Scholar

Zahavich, A., Latto, B., Takacs, E., and Vlachopoulos, J. (1998). The effect of multiple extrusion passes during recycling of high density polyethylene. Adv. Poly. Technol. 16: 11–24, https://doi.org/10.1002/(SICI)1098-2329(199721)16:1<11::AID-ADV2>3.0.CO;2-M.10.1002/(SICI)1098-2329(199721)16:1<11::AID-ADV2>3.0.CO;2-MSearch in Google Scholar

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Review Article

- Corrosion resistive conducting polymeric nanocomposite-based coatings on steel: a mechanistic insight

- Research Articles

- Effect of compatibilizer type on the properties of thermoplastic elastomers based on recycled polyethylene at high ground tire rubber content

- Analyzing the effects of solid fraction and heat treatment on the mechanical properties of 3D printed polymer lattices

- Effect of polyvinyl acetate on the properties of biodegradable thermoplastic starch/polyethylene glycol blends

- A color masterbatch assistance system for optimizing product color by masterbatch addition in injection molding of post-industrial recyclates

- Enhancing 3D printing with composite filaments incorporating electronic waste: a study on flexural and compression strength

- Development of enhanced co-continuous PVDF/PET nanocomposites via synergistic effects of graphite particle size, hybrid systems, and reduced graphene oxide

- Integration of nanographene and action of fiber sequences on functional behaviour of composite laminates

- Effect of chain branching on the rheological properties of HDPE/LLDPE and HDPE/LDPE blends under shear and elongational flows and evaluation of die swell and flow instabilities

- Effect of graphene nanoplatelets (GnPs) on low velocity impact properties of hybrid kevlar/basalt fiber reinforced epoxy based composites

- Sustainability in rotational molding: a study on recycling and the influence of additives

Articles in the same Issue

- Frontmatter

- Review Article

- Corrosion resistive conducting polymeric nanocomposite-based coatings on steel: a mechanistic insight

- Research Articles

- Effect of compatibilizer type on the properties of thermoplastic elastomers based on recycled polyethylene at high ground tire rubber content

- Analyzing the effects of solid fraction and heat treatment on the mechanical properties of 3D printed polymer lattices

- Effect of polyvinyl acetate on the properties of biodegradable thermoplastic starch/polyethylene glycol blends

- A color masterbatch assistance system for optimizing product color by masterbatch addition in injection molding of post-industrial recyclates

- Enhancing 3D printing with composite filaments incorporating electronic waste: a study on flexural and compression strength

- Development of enhanced co-continuous PVDF/PET nanocomposites via synergistic effects of graphite particle size, hybrid systems, and reduced graphene oxide

- Integration of nanographene and action of fiber sequences on functional behaviour of composite laminates

- Effect of chain branching on the rheological properties of HDPE/LLDPE and HDPE/LDPE blends under shear and elongational flows and evaluation of die swell and flow instabilities

- Effect of graphene nanoplatelets (GnPs) on low velocity impact properties of hybrid kevlar/basalt fiber reinforced epoxy based composites

- Sustainability in rotational molding: a study on recycling and the influence of additives