Abstract

This overview traces the modern history of wood science and technology, particularly from the European perspective. It begins with the early forestry schools in 18th-century Germany, which influenced the founding of similar institutions worldwide. These schools introduced technical subjects, including wood physics, to meet industrial demand, especially from the mining sector. Before formal studies began, early research on wood properties, including moisture relations and strength, appeared in encyclopaedias. With the Industrial Revolution, interest in wood as a construction material grew, linking wood research to engineering and materials science. In the early 20th century, dedicated wood technology institutes marked the birth of wood science as a distinct discipline. Today, key research fields include wood-water relations, mechanical and rheological behaviour, wood modification, and structure-property modelling. The future of wood science lies in sustainability and the efficient use of resources. As interest in renewable, bio-based alternatives to steel and concrete grows, further research on wood functionalisation and modification will be vital. Extensive literature is available for deeper study of advances in wood physics.

1 The pre-scholastic period of wood science

The pre-scholastic period of knowledge in the use of wood refers to the time before formal scientific or academic study, roughly from prehistoric times up to the early Middle Ages. Still, for wood science, the period is at least until the 1600s. During this era, knowledge about wood was empirical and based on hands-on experience, observation, and oral tradition. People learned which types of wood were best for tools, shelter, fire, and transport through trial and error. Hardwoods like oak and ash were favoured for their strength, while softwoods like pine were used for their ease of shaping. This knowledge was passed down through generations of craftsmen, hunters, and builders, forming the basis for later scholarly study. Such a system of knowledge allowed realisations of high technological value, and it has accompanied the development of scientific knowledge in the field for a very long time and is probably still present in some instances or places without a single word having been written down.

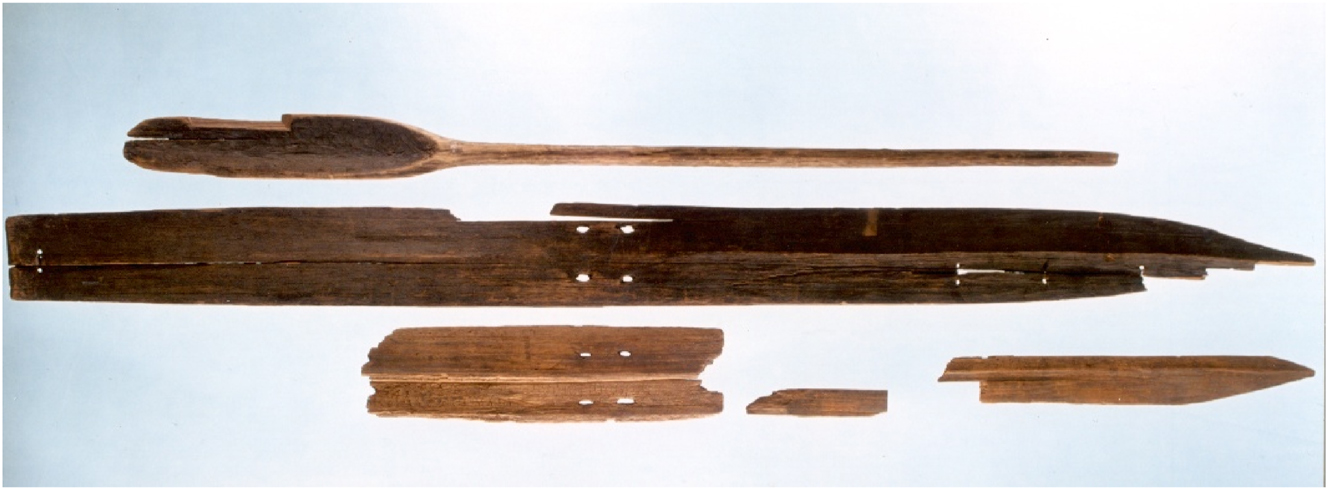

A very early example of a product made of wood that has survived to this day is the Kalvträsk ski, which can be seen in Figure 1 (Navi and Sandberg 2012). Such skis were used ca 5,200 years ago and have been preserved by lying in a swamp in northern Sweden (Åström 1993). The wood for the ski was split in a way that allowed for vertical growth rings in the cross-section of the timber, providing better skiing on icy snow. The front tip of the ski was bent into a curved shape with the help of heat, probably from an open fire. The Saami have practised using heat and water to give skis the right shape up to the present day (Insulander 1998). The wood was selected for its so-called compression wood, a special kind of wood structure that arises in conifers and is processed to achieve the typical arc shape, considerably improving ski performance.

A 5200-year-old ski made of wood with vertical annual rings formed by a thermo-hydro-mechanical-like process. (Photo by Sune Jonsson, Västerbotten Museum, Sweden).

The earliest treatises are often a transposition, a recodification of such systems of knowledge, which is worth mentioning, starting with the early works of Theophrastus, Pliny the Elder and Vitruvius, all of which already contain a great deal of information on wood species and their technological uses.

The pre-scholastic period of wood science has yielded knowledge that is both interesting and important for the development of new insights. Despite this, we have chosen to focus on a chronological presentation of the early development of forestry schools and how these inspired the establishment of the field of research on wood material properties. This means that the period from the second half of the 18th century to around 2000 is in focus, but later essential research results are also mentioned.

2 Forestry schools serve as the cradle of wood science

Wood physics, a key component of material research in wood science, is a multidisciplinary field that draws on anatomy, chemistry, classical mechanics, physics, and the principles of strength of materials. It focuses on testing and researching material properties and the fundamental interactions between the structure and properties of wood and wood-based materials, including the influence of climate conditions.

This review aims to provide a concise and accessible overview of the evolution of wood research, with a particular emphasis from the European perspective.

2.1 The Industrial Revolution drastically increased the exploitation of forest resources

As is well known, the economic uses of forest resources underwent radical changes as industrialisation spread throughout the Western world. In Early Modern Europe, wood was a crucial element in the economy, serving as the primary energy source for daily life and the operation of many industries (Iriarte-Goñi and Ayuda 2012). It was also the essential raw material in the manufacture of many products. In the approximately 150 years following the start of the Industrial Revolution, there was a growing desire to utilise more materials from forest resources. The steam saws of the mid-19th century became a significant technological breakthrough. Thanks to them, the sawmills in the forestry-dense Nordic countries, specifically Finland, Norway and Sweden, could be located near the coast, where the sawn timber was loaded onto ships for export throughout Europe. Paper pulp was produced from the sawmill waste, and spirits and fuel were extracted from the waste streams of pulp production. Paper was the main product from the pulp, but with Alfred Nobel as an interested pioneer, artificial silk also began to be made from cellulose. Glued-laminated timber, a straight or curved wooden beam composed of several laminations bonded with adhesive, was patented in 1901 and 1905 by the German carpenter, entrepreneur and inventor Otto Karl Friedrich Hetzer (1846−1911) and used to carry heavy loads over long spans in construction. Wood was used as a fuel, building material and material for machines, ships and later, until the First and Second World Wars, also for aeroplanes and automobiles. Particularly in times of shortage, the locally available raw material, wood, was often used as a construction material, as well as a chemical raw material and a base in food for livestock. However, there was soon competition from concrete, plastics and other non-biobased materials.

As the demand for wood grew, tree harvesting became so extensive in some regions that it led to large-scale deforestation. By the late 19th century, many European countries began to organise reforestation efforts in response. The pioneer was Johann (Hannß) Carl von Carlowitz (1645–1714), a member of the Royal Polish and electoral Saxon chamber, mining councillor, and chief mining administrator of the Ore Mountains (German: Erzgebirge), Germany. Education was arranged to support professional forestry. In the first phase of the education structure, the forestry colleges were often located in mining faculties, as the mining industry required large quantities of wood for mining and smelting the ore. With the publication of Sylvicultura oeconomica, Carlowitz wrote the first comprehensive work on forestry, considered a crucial step in formulating the concept of forest sustainability (Carlowitz 1713).

2.2 New types of forests require new knowledge and training

In the 18th and 19th centuries, following extensive deforestation in earlier periods, Germany – dominated initially by deciduous forests – underwent large-scale reforestation, with Norway spruce and Scots pine becoming the predominant species, developing extensive coniferous forest stands. These pine and spruce forests yielded higher timber volumes and proved more cost-effective than traditional deciduous or mixed forests with a high proportion of deciduous species. However, new forest types also required new knowledge in forestry to handle these, which were, until then, less common species in Germany. Notably, the previously described trend is now reversing, with current forestry practices increasingly favouring mixed forests containing a higher proportion of deciduous tree species.

The first formal education programs for foresters were the so-called “Forstmeister” (master) schools, starting in Wernigerode, Germany, as early as 1763 by Hans Dietrich v. Zanthier (1717−1768), later transferred to the close-situated Ilsenburg, ending with his death (Fernow 1911). Heinrich Cotta (1763−1844) and Georg Ludvig Hartig (1764−1837) were considered to be those who introduced modern forestry and instituted their own Forstmeister schools in 1785 and 1789, respectively. The school by Cotta was afterwards transferred to Tharandt, where Cotta opened a private forestry school in 1811, from which the Tharandt State Forestry University was established in 1816. In 1819, the classes were expanded to include chemical soil science. The first laboratory was established in 1844, and today, the school is part of TU Dresden, Forest Sciences (Niemz et al. 2023a). In 1896, the Faculty of Forestry was officially established at the University of Freiburg. This made Freiburg one of Germany’s premier institutions for scientific forestry education and research, alongside other key centres like Tharandt and Eberswalde. New schools spread widely from these first schools, and German foresters were invited, e.g., to Russia to take charge of forest management and educate foresters (Shirley 1958, 1964). Examples of schools founded with inspiration from the German system were the Imperial Forestry Institute (Lesnoy Institut) at the Naval Cadet Corps Academy in St. Petersburg, Russia (1803) now known as the Saint Petersburg State Forest Technical University which is the oldest forestry university in Russia and one of the earliest in the world., “Brukssocietetens Skogsinstitut” (a Forestry Institute), Bysala, Sweden (1839), School of Forestry, Turin, Italy (1848), and in Japan, forestry education was introduced during the Meiji Restoration in the late 19th century, among others. In the late 1800s, forestry education was gradually introduced in Norway, influenced by developments in Germany and other parts of Central Europe, where scientific forestry was already well-established. The formalisation of forestry education in Norway culminated with the founding of the Higher Agricultural College at Ås (Den høiere Landbruksskole på Ås) in 1859, located outside Oslo. This institution later became the Norwegian College of Agriculture (Norges Landbrukshøgskole, NLH) and is known today as the Norwegian University of Life Sciences (NMBU).

Analogue developments also took place in France, with Henri-Louis Duhamel du Monceau (1700−1782) as an early initiator. He was a French agronomist, botanist, and engineer who significantly contributed to agriculture, forestry, and naval engineering. He was a prominent figure in the 18th century and is best known for his pioneering work on the cultivation and management of forests, as well as his studies on plant physiology and wood properties. The first education was at the French National School of Forestry (École nationale des eaux et forêts), Nancy, France (1824).

In Africa, the German Forstmeister school approach was also introduced. 1906 Joseph Storr Lister (1852−1927) founded the South African Forestry School in Tokai, Cape Town. The forestry training in Africa started to a greater extent in the 1920s and 1930s, largely focused on producing forest workers and vocational and technical staff. It was not until the 1950s that professional degree training began to become more widespread and was introduced in what was expected to serve as regional schools e.g. College of Forestry in Monrovia (1959), Department of Forestry at Ibadan University in Nigeria (1963), Makerere University, Uganda (1970), University of Dar es Salaam, Tanzania (1973), University of Dschang in Cameroon in (1975), L’Ecole Nationale Superieure Agronomique in Republic of Cote d’Ivoire, (1975), and others (Temu et al. 2006).

In Asia, Dietrich Brandis (1824−1908) was a pioneer and founded the Imperial Forest School (1878) in Dehradun, India for the British Imperial Forestry Service (today, incorporated into the Indian Forest Research Institute, Dehradun). Other early schools included the Forestry programs (from 1897) in the Faculty of Agriculture, the newly established Kyoto Imperial University in Japan, and the Forestry Department at Zhili Higher Agricultural School (1904) in Hebei Province, China.

In 1895, the industrial entrepreneur George W. Vanderbilt (1862−1914) brought Carl A. Schenck (1868−1955) from Germany to the Biltmore Estate in western North Carolina to manage the vast expanses of forest lands on the estate’s property. The following year, Schenck founded a practical forestry school on the Biltmore Estate. The Biltmore Forest School was the first school of forestry in North America. The school grounds are now part of Pisgah National Forest in Transylvania County, the Cradle of Forestry in North America. This historic site features exhibits on the history of forestry and forest conservation (Figure 2).

![Figure 2:

The first forestry school in North America. (a) The schoolhouse of Biltmore Forest School was built in 1898. (b) The Biltmore stick, used for estimating the diameter of tree trunks at breast height, was a popular tool, and its use spread throughout the United States. Its principle is still used in forestry crushing sticks. [Photo: D. Sandberg; incl. publication approval by the person shown].](/document/doi/10.1515/hf-2025-0033/asset/graphic/j_hf-2025-0033_fig_002.jpg)

The first forestry school in North America. (a) The schoolhouse of Biltmore Forest School was built in 1898. (b) The Biltmore stick, used for estimating the diameter of tree trunks at breast height, was a popular tool, and its use spread throughout the United States. Its principle is still used in forestry crushing sticks. [Photo: D. Sandberg; incl. publication approval by the person shown].

At the managerial staff level in South America, forestry education has been actively promoted. In 1960, there were only six schools, but this number had increased to 18 by 1974 (Bucarey 1975). Professional forester schools (for managerial staff) were established in Argentina (Nacional de Córdoba in Santiago del Estero, 1958), Bolivia (Universidad Boliviana Misael Saracho, 1967), Brazil (Federal de Paraná, Curitiba, 1960), and Chile (Universidad). de Chile (Stgo.), Concepcion (Univ. Catolica 1992, before Forest technique in Los Angelos) and Univ. Austral de Chile in Valdivia (around 1960,1966−1972 project from Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, Echborn, Germany, with several German professors and submission for PhD students from Chile to Germany 1952), Colombia (Univ. Distrital Fco. José de Caldas 1950), Ecuador (Univ. Vargas Torres, Esmeralda 1970), Peru (Univ. Nacional de La Molina 1962), Uruguay (Univ. de la República, Montevideo 1960), Venezuela (Univ. de Los Andes, Mérida 1943).

Several forestry universities were later integrated into larger units as faculties e.g. Moscow State Forest University was incorporated into Bauman Moscow State Technical University in 2016, and the Royal Saxon Forestry Academy of Forestry in Tharandt was integrated with the Technical University Dresden (TUD) in 1929. Similar mergers of schools continue to this day. Many universities worldwide strive for a high international ranking, resulting in a focus on more prestigious basic research in the fields of materials science, chemistry, biology and physics rather than applied wood-technology research.

In Western Europe and the USA, education in the traditional field of wood has long been in decline and increasingly focused on the fundamentals of micro- and ultrastructure. A trend that continues to this day. In Austria, Germany, Switzerland, and some other Central European countries, universities of applied sciences dominate teaching in the technological field, although they are also increasingly conducting research. The practical relevance is essential, and in some cases, there is also a dual education (University of Cooperative Education), such as at vocational academies, where students spend about 50 % of their time working in a company and 50 % of their time training at university.

An overview of wood science research and some technological research can be found in Mai et al. (2022), Matejak and Niemz (2011), Niemz (1993), Köstler et al. (1960). The development of wood science, along with some aspects of technology, is well documented by Coté et al. (1967). Early books on technology, including wood technology, were published by Beckmann (1777) and later by Karmarsch (1851), and were translated into several other languages from the German original. Various encyclopaedias from the 18th and 19th centuries are also excellent sources for early wood research. An extensive compilation of old books of essentially historical value and contemporary books in wood science and technology can be found in Niemz et al. 2023b, 2025a). The suggested books are primarily in English and German, although many interesting and high-quality books are also available in other languages.

3 Research organisations and early research activities

Wood properties were also studied and tested in the emerging forestry schools as part of the education. The research activities were gradually developed into more systematic studies, which, over time, became organised research, and aspects related to wood biology and wood chemistry were also progressively added into the research (Nördlinger 1860). In some cases, large chemical departments, such as that at the Naval Cadet Corps in St. Petersburg, were affiliated with forestry faculties. At the TU Dresden in Tharandt, chemical research has for a long time been an essential part of education and research led by institute directors with such competence. Plant chemistry was pursued very intensively at an early stage.

However, between 1600 and 1800 and before the forestry schools, research on wood properties was also performed and published in various encyclopaedias and scientific writings published by academies and the like, e.g. the Proceedings of the Royal Swedish Academy of Sciences (1739−1974). However, wood was also frequently used as a material for testing in classical areas of physics and mechanics. An overview of this field can be found in Matejak and Niemz (2011) and Radkau (2007), which provide an overview of the history of wood utilisation. Wood is not found in today’s materials science faculties, with few exceptions. Ceramics, metals, and plastics dominate, and research on, e.g., functionalisation, i.e., tailoring wood’s structure through chemical modification to introduce enhanced or novel functional performance, is increasingly being carried out on.

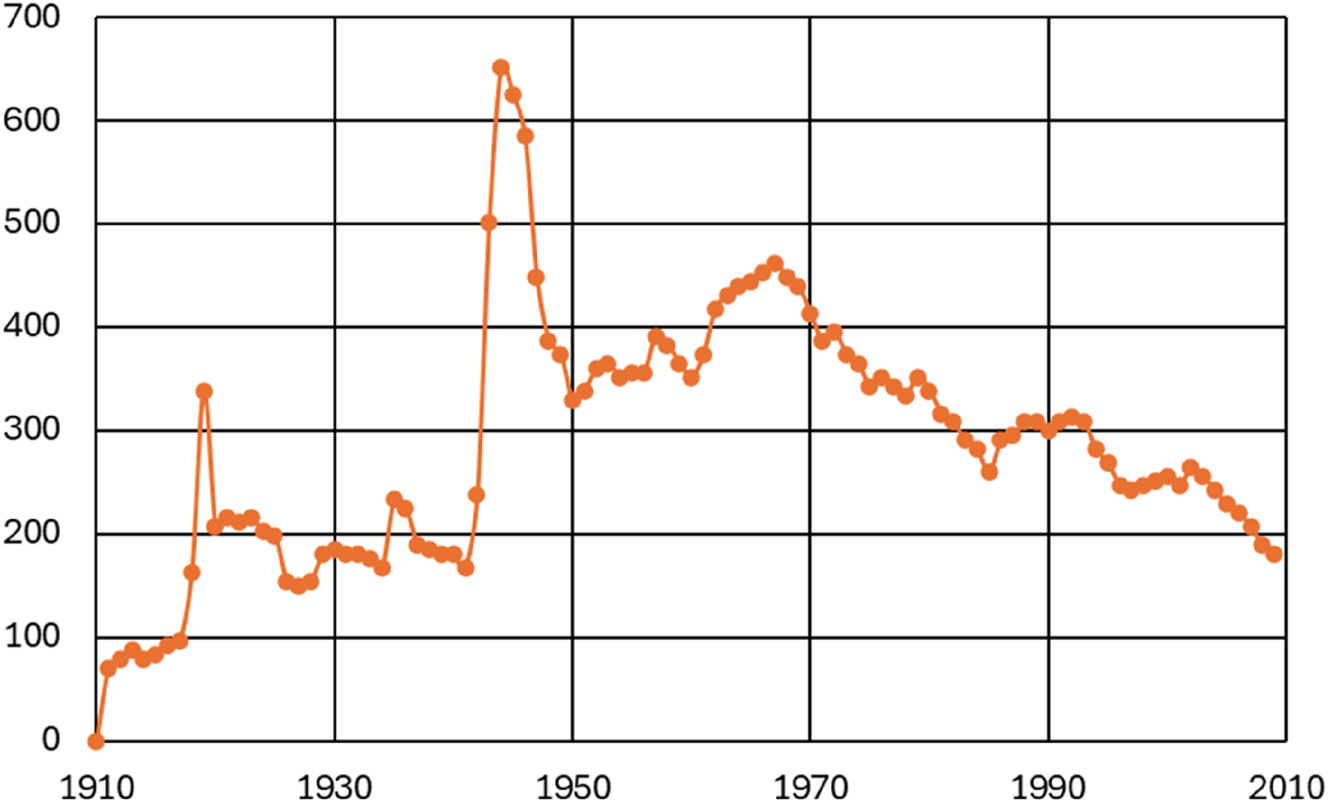

The development of wood science as an independent field, as it is understood today, began with the founding of the Forest Products Research Institute, Dehra Dun, India, in 1906 and at the Forest Products Laboratory (FPL), Madison (WI), USA, in 1910 (Köstler et al. 1960). Table 1 provides an overview of some early-established institutes in wood science and technology. The activities at most of these institutes expanded significantly until the 1950s, after which they declined. Following the turn of the millennium in 2000, the decline in traditional wood research has been global and extensive. Figure 3 shows the evolution of the number of employees at FPL since the institute’s inception. Numerous institutes around the world followed a similar development.

Some early established wood-research institutes.

| Founded | Institute |

|---|---|

| 1906 | Forest Products Research Institute, Dehra Dun, India |

| 1910 | The United States Department of Agriculture (USDA), Forest Products Laboratory (FPL), Madison (WI), USA |

| 1913 | Institut für Holz- und Zellstoffchemie, Eberswalde, Germany |

| 1913 | Forest Products Laboratory, Montreal, Canada |

| 1917 | Norwegian Forest Research Institute (NISK) |

| 1918 | Forest Products Laboratory, Vancouver, Canada |

| 1919 | Forest Products Laboratory, Melbourne, Australia |

| 1919 | Moscow Forest Engineering Institute, since 1993, Moscow State Forest University (MSFU). In 2016, MSFU was merged into Bauman Moscow State Technical University (BMSTU), Moscow, Russia |

| 1923 | Forest Products Research Laboratory, Princes Risborough, UK |

| 1929 | Institute for Wood Technology, St. Petersburg, Russia |

| 1933 | Centre Technique du Bois, Paris, France |

| 1942 | Laboratory for Wood Technology, Helsinki, Finland |

| 1943 | Wood Department at Swiss Federal Laboratories for Materials Science and Technology (EMPA), Dübendorf, Switzerland |

| 1944 | Sukachev Institute of Forest, originally located in Moscow but in 1959 relocated to Krasnoyarsk, the Soviet Union |

| 1945 | Swedish Institute for Forest Product Research (today Research Institutes of Sweden, RISE), Sweden |

| 1946 | Latvian Academy of Sciences, Institute of Wood Chemistry, today the Latvian State Institute of Wood Chemistry, Riga, Latvia |

| 1946 | Institute for Wood Research (iVTH), today Fraunhofer Institute for Wood Research, Germany |

| 1947 | The Slovenian Forestry Institute (SFI), from 1952 the Slovenian Institute for Forestry and Timber Industry, and from 1954, the Slovenian Institute for Forestry and Timber Economy, and in 1993, the Slovenian Forestry Institute |

| 1947 | State Institute for Wood Research Bratislava (SDVU), Slovakia (this no longer exists in its original form, a small part is integrated into the Paper Institute) |

| Forest Research Institute (today SION), Rotorua, New Zealand | |

| 1948 | Austrian Wood Research Institute Vienna (today Holzforschung Austria), Austria |

| 1950 | Federal Institute of Forestry and Wood Research (today the Johann Heinrich von Thünen-Institut), Thünen, Germany |

| 1952 | Institute for Wood Technology and Fibre Materials Technology (today the Institute for Wood Technology (IHD)), Dresden, Germany |

| 1952 | Institute for Wood Research and Wood Technology (today Holzforschung München), München, Germany |

| 1954 | Institute of Wood Technology, Poznan, Poland |

| 1955 | The Institute of Wood Science (IWSc), Bangor, UK (2009 it merged with IOM3, the Institute of Materials, Minerals and Mining) |

| 1955 | The Japan Wood Research Society, Tokyo, Japan |

Development of the number of employees 1910−2010 at the USDA Forest Products Laboratory in Madison (WI), USA. Based on data from USDA Forest Products Laboratory.

New institutions have recently been established, particularly in Central and Eastern European Countries (CEECs), with the support of national state and EU funding, e.g. in the Czech Republic, Hungary, Romania, and Slovenia. InnoRenew CoE in Slovenia was established in 2017 as an independent research institute that targets renewable materials and sustainable buildings to transfer scientific knowledge into industrial practice.

The first applied publications on forestry and the use of wood came from France. They were published in French, for example, La physique des arbres by Duhamel du Monceau (1758), which describes a broad spectrum of wood use in military applications, including construction, shipbuilding, and others (Figure 4). In the period 1850−1950, German literature was dominated by researchers such as Kollmann (1936, 1951), Trendelenburg (1939), Hartig (1885), and Nördlinger (1860). After that, there was a gradual and extensive switch to English. Today, most scientific publications in wood science and technology are published in English and can be easily accessed on the Internet, for example, through the Web of Science. This significantly contributes to a global exchange of information and enhances the visibility of researchers’ work. However, specialised books are often still printed in local languages, as the terminology is essential for teaching and practice. The journals have today also a wider distribution and are often more general than 50 years ago, resulting in a higher impact factor (IF) than traditional journals specific focusing on wood science or wood technology which in general results in low impact factors, e.g. for 2023: Wood Research IF 0.9, Bio Resources IF 1.3, Holzforschung 2.2, Wood Material Science & Engineering IF 2.2, Forests IF 2.4, Wood Science and Technology IF 3.1.

Early type of testing machines for wood (Duhamel du Monceau 1758).

Wood research has been strongly promoted in times of scarcity and high demand for raw materials. During the First and Second World Wars, numerous research projects on wood were carried out, and wood products were developed until they were ready for use. Aircraft and their propellers were made from wood (Figure 5), chemicals were extracted through various chemical processes, adhesives for moisture-resistant bonding were developed (e.g. the Aerodux A185 adhesive), and densified veneer impregnated with synthetic resins was created at the beginning of the 20th century and is still produced (Sandberg et al. 2021). Steinsiek (2008) provides an overview of wood research in Germany before and during the Second World War.

The use of wood in the aviation industry during the Second World War. (a) Production of aircraft propellers from densified wood (USDA Forest Products Laboratory, Madison (WI), USA). (b) One of the first flying wing aircraft to be powered by jet engines, produced by the brothers Reimar and Walter Horten, Waggonfabrik Gotha, Germany. The fighter/bomber was made of plywood.

Engineered wood products (EWPs), also named wood composites, wood-based materials, etc., became more important after the Second World War. Developing synthetic adhesives with high strength and moisture resistance also accompanied this. EWPs can be based on sawn timber, veneer, strands, strips, chips, particles or fibres. They can also be used for structural or aesthetic purposes as a single type of or a hybrid of several EWPs or in combination with non-wood materials (Miloshevska Janakieska et al. 2024).

Today’s focus is on renewable materials and the ecological significance of the materials supporting a circular economy, which are promoted by using bio-based adhesives and EWPs such as cross-laminated timber and glued-laminated timber, which are, in some cases, manufactured with wooden-dowel connections instead of adhesive.

4 Development of research in the field of wood physics

The research field of wood physics focuses on studying the physical properties, behaviours, and performance characteristics of wood and wood-based materials under various conditions. Wood physics can be divided into four main fields of research:

wood-water relations,

mechanical and rheological properties of wood and wood-based materials,

modified wood, i.e. wood modification by e.g. chemical or thermo-hydro-mechanical treatments, and

modelling structure-property relationships.

Research in this area has been extensive, with notable researchers, as shown in Table 2.

Overview of selected work on wood physics (adapted after Niemz and Sonderegger 2021).

| Year | Scientists | Field of work |

|---|---|---|

| 1758 | Du Hamel du Monceau | Basics of forest utilisation |

| Leclerc de Buffon | The strength properties of the wood | |

| 1848 | Chevandier and Wertheim | Relationship between moisture and bulk density of the wood |

| 1850 | Struwe | Thermal properties |

| 1882 | Hartig | Textbook of rot diseases |

| 1882 | Sachs and Hartig | Cell-wall density |

| 1885–1895 | Hartig | Relationship between growth-ring width and strength of the wood and the influence of heartwood on wood properties |

| 1896 | Volbehr | Swelling and shrinkage of wood |

| 1906–1907 | Tiemann | Fibre-saturation point |

| 1907–1927 | Stamm | Electrical properties |

| 1921 | Hankinson | Influence of fibre and growth-ring orientation on strength properties |

| 1922 | Baumann | Relationship between fibre orientation and tensile strength, the influence of knots on the strength, and calculation of shear modulus |

| 1923–1935 | Hörig | Studies on elastic and shear modulus |

| 1928 | Huber | Studies on shear modulus |

| 1929–1930 | Kraemer and Winter | Strength of laminated veneer lumber (LVL) |

| 1932 | Mörath | Studies on hardness and dielectric properties |

| 1934 | Schmidt | Measurement of the logarithmic decrement on wood |

| 1935 | Roth | Rheological properties |

| 1938 | Ivanov | Investigations into the fatigue strength |

| 1938 | Nilakantan | Magnetic properties |

| 1944 | Kollmann and Dosoudil | Investigations into the fatigue strength of wood and wood-based materials under dynamic loading |

| 1946 | Weatherwax and Stamm | Thermal properties |

| 1950− | Perkitny, Raczkowski and Krauss | Swelling pressure |

| 1950− | Bodig, Fahrni, Himmelheber, Fischer, Flemming, Jayne, Klauditz, Kehr, Keylwerth, Kollmann, Plath, Scheibert | Structural properties of particleboards |

| 1966− | Bucur, Burmester, James, Pellerin, Ross | Acoustic properties, sound propagation |

| 1968− | Ansell, Beall, Landis, Molinski, Niemz | Acoustic emission |

| 1970− | Bryant, Conners, Fukada, Funt, Hansson, Hirai, James, Knuffel, Morén | Physical properties of wood for use in quality control (optoelectronic, electrical, acoustic properties, X-ray, laser technology) in e.g. timber drying |

| 1980− | Gressel, Hanhijärvi, Hunt, Mårtensson, Niemz, Ranta-Maunus | Creep and mechano-sorption in wood |

| 1990− | Meder, Niemz, Wienhaus | Utilisation of spectrometric properties for quality control |

| Dai, De Borst, Gamstedt, Gril, Gustafsson, Harrington, Hofstetter, Landis, Nairn, Navi, Ormarsson, Persson, Serrano, Svensson | Modelling (wood properties, swelling, wood-based materials), multi-scale modelling | |

| 2000− | Burgert, Gindl, Navi, Niemz, Salmén, Stanzl-Tschegg, Teischinger, Wimmer | Micromechanics (mechanical tests), nanoindentation, dynamic mechanical analysis, Raman spectroscopy, small-angle X-ray scattering, atomic force microscopy |

| Bucur, Forsberg, Keunecke, Mannes, Niemz, Sonderegger, Van Acker | X-ray microtomography, synchrotron radiation, in situ stress tests, neutron and X-ray radiation for measuring moisture distribution and moisture change in wood | |

| Carlsson, Gérardin, Hill, Jones, Kutnar, Mai, Millitz, Obataya, Sandberg, Tjeerdsma, Van Acker, Westin, and others | A considerable focus on and an increase in research on wood modification due to environmental concerns |

The Japan Wood Research Society (JWRS) has played a pivotal role in advancing wood science and technology over its 70-year history since its founding in 1955. Its research activities encompass various disciplines related to wood and lignocellulosic materials. Through its publication, Journal of the JWRS (Mokuzai Gakkaishi), the Society has disseminated thousands of peer-reviewed papers. JWRS continues to serve as a hub for interdisciplinary research, bringing together physicists, chemists, engineers, biologists, and architects to explore and expand the potential of wood as a sustainable, high-performance material.

The Japan Wood Research Society has close ties with the International Academy of Wood Science, a non-profit assembly of wood scientists that recognises all fields of wood science with their associated technological domains and secures worldwide representation. Its permanent Secretariat was established on 1 January 1966.

4.1 Wood and water relations

Wood is formed in a water-saturated environment within the living tree, and its cellular structure remains in this state until the water flow from the roots is interrupted, such as by heartwood formation or the tree’s felling. The wood then begins to lose most of its moisture through drying, resulting in changes to its physical properties, and it becomes a moisture-absorbing material that interacts with the surrounding environment. These changes, their relationship to the environment to which the wood is subsequently exposed, and how they influence wood properties are the subject of research in the area of wood and water relations. The field encompasses processes such as timber drying and vacuum-pressure impregnation with various liquids, and is also closely related to other fields, including wood modification.

Before the 1850s technical breakthrough in the sawmill industry, hewn and sawn timber was dried mainly in the open air (seasoning). However, other drying methods, such as sand, smoke, or solar drying, existed and date back to at least the 1700s. When wood was used locally, it was either dried at the processing site of the logs or after transport to the site where it was to be used. Initially, drying was considered primarily a storage and logistics problem. Research related to timber drying began at the start of the 20th century, when multiple ideas to improve the drying process required a deeper understanding of the wood material and the fundamental moisture transport mechanisms. Parallel with the introduction of the drying method based on increased temperature, researchers such as Tiemann (1915, 1920) actualised the interest in the effect of temperature on dimensional stability, hygroscopicity, and mechanical properties.

It is not known when or by whom the first attempts to use kilns for timber drying were made, but a manufacturer in northern Massachusetts, USA, made practical attempts as early as 1855 (Whitmore 1894), and the benefits of forced air circulation were acknowledged around 1850 (Campean 2010). At the beginning of the 1900s, and especially in the USA during the First World War, the so-called self-circulating dryers were equipped with fans and dampers for the supply and exhaust of air. Thereby, a foundation was also laid for the extensive development and research in timber drying that is still ongoing today (Sandberg 2015). Various systems for timber drying have been developed since the early start. It is possible to find at least 30 different drying methods that have been tested; however, most of these new ideas have had little to no industrial success. As a somewhat unusual example, experiments with centrifugal dryers were initiated in the late 1930s to remove free water from freshly sawn timber and achieve a more uniform initial moisture content for subsequent drying in a kiln (Sandberg 2015). The advantages were improved drying quality, reduced drying time (halved) and reduced cost. Centrifugal drying was applied at least at one sawmill in Sweden, Kastets sawmill (Korsnäs AB), which had three centrifugal dryers during the 1940s that were used for drying sideboards with initial very high moisture content, each of which could dry up to 19,000 m3 of sawn timber annually. The centrifugal dryer should not be confused with the carousel dryer, in which the slow rotation of the timber packages achieves the airflow. IUFRO Wood drying conference series, starting in 1987 at Luleå University of Technology (LTU) in Skellefteå, Sweden, initiated by Professors Ove Söderström (KTH, Stockholm) and Tom Morén (LTU), has been an active international area of research in wood drying and a platform to discuss problems and opportunities for processing the many different commercial wood species available worldwide. The industrial timber-drying processes for softwood advanced considerably during the 1990s.

The kiln-drying of timber is a critical process in timber manufacturing, underscoring the need for comprehensive information based on scientific studies of how different species behave under varying temperatures and due to other drying methods. Those involved in the woodworking industry, or the use of wood products, are acutely aware of the challenges in effectively removing moisture from timber without damaging it, as well as the timber’s ongoing sensitivity to atmospheric conditions even after thorough drying. Cracking is especially critical for the use of dried timber. Various techniques have been used for detecting cracks in timber, and e.g., acoustic emission has been successful. Bernatowicz and Militzer (1992) showed that crack-free wood had only about 10 per cent of the emissions of wood with cracks. They used the amplitude distribution to separate plastic deformations, macro- and microcracks.

Early research found that drying wood at high temperatures increased its dimensional stability while reducing its hygroscopicity and strength (Koehler and Pillow 1925; Koehler and Thelen 1926; Pillow 1929; Stamm and Hansen 1937; Tiemann 1915). Following the First World War, extensive studies were conducted in the United States on the effects of kiln drying and temperature on wood strength, particularly for the aviation industry (Tiemann 1920; Wilson 1920). These findings eventually contributed to the development of thermal modification processes to enhance wood’s resistance to decay caused by fungi, as investigated by Stamm et al. (1946). Thunell and Elken (1948) and Buro (1954, 1955) continued Stamm’s work, exploring the thermal treatment of wood in various gaseous environments. Later, Burmester (1970, 1973) investigated the effects of temperature, air pressure, and moisture on wood properties in a closed system, reporting significant improvements in dimensional stability, resistance to brown-rot fungi, and minimal loss of strength. Burmester named this process Feuchte−Wärme−Druck (FWD) in German (English: Humidity−Heat−Pressure). Thus, the industrial thermal modification process was introduced.

The research literature related to wood-water relations is extensive, and Table 3 provides some examples of essential book references related to wood-water relations and thermal modification.

Examples of essential reference books related to wood-water relations and thermal modification.

| Title | Field | References |

|---|---|---|

| Praktische Untersuchungen zum Holzfeuchtigkeits-Gleichgewicht | Sorption properties from wood | Keylwerth (1969) |

| Wood and Cellulose Science | Wood-water relations, thermal modification | Stamm (1964) |

| Experimentelle und Theoretische Grundlagen der Trocknung | Wood-water relations, timber drying | Lykow (1955) |

| Transport Processes in Wood | Wood-water relations | Siau (1984) |

| Wood-Water Relations | Wood-water relations | Skaar (1988) |

| Failure of Wood as Influenced by Moisture and Duration of Load | Wood-water relations related to mechanical properties | Hoffmeyer (1990) |

| Wood: Influence of Moisture on Physical Properties | Wood-water relations | Siau (1995) |

| Seasoning of Wood. A Treatise on the Natural and Artificial Processes Employed in the Preparation of Lumber for Manufacture, with Detailed Explanations of Its Uses, Characteristics and Properties | Timber drying | Wagner (1917) |

| The Kiln Drying of Lumber | Timber drying | Koehler and Thelen (1926) |

| Die Trocknungstechnik. Grundlagen, Berechnung, Ausführung und Betrieb der Trockeneinrichtungen | Timber drying | Hirsch (1927) |

| Künstliche Holztrocknung und Holzlagerung | Timber drying | Kollmann (1932) |

| Die wissenschaftlichen Grundlagen der Trocknungstechnik (Erster Band) | Wood-water relations, timber drying | Krischer and Kröll (1956) |

| Trocknungstechnik: Trockner und Trocknungsverfahren (Zweiter Band) | Timber drying | Krischer and Kröll (1959) |

| Das Trocknen | Timber drying | Kneule (1959) |

| Internal Stresses in Wood Caused by Drying | Timber drying | Ugolev (1969) |

| Kiln-drying of Lumber | Timber drying | Keey et al. (2000) |

| Fundamentals of Wood Drying | Timber drying | Perré (2007) |

| Wood Technology – Constitution, Properties and Uses. | Thermal modification | Tiemann (1942) |

| Influence of Moisture on Dimension Stability of Wood – Theory and Improvements | Thermal modification | Burmester (1970) |

| Wood Modification – Chemical, Thermal and Other Processes | Thermal modification | Hill (2006) |

| Thermo-hydro-mechanical Processing of Wood | Thermal modification | Navi and Sandberg (2012) |

| Wood Modification Technologies. Principles, Sustainability, and the Need for Innovation | Thermal modification | Sandberg et al. (2021) |

| Springer Handbook of Wood Science and Technology | Wood-water relations, timber drying, thermal modification | Niemz et al. (2023c) |

Modifying the wood chemistry often leads to changes in wood–water interactions. The wood-water interaction of fungus-infested wood may change, as the fungi also regulate the humidity of their surroundings and thereby actively manipulate the moisture content of the wood they attack, even though the fungus does not always cause decay. Therefore, characterising these is an integral part of understanding the properties of the modified material (Engelund Tybring and Fredriksson 2023).

The neutron’s high sensitivity to hydrogen and the importance of moisture content for the utilisation of wood make the wood-water interaction the predominant topic when investigating wood properties using neutron imaging methods (Mannes et al. 2024). Only three years after the discovery of the neutron by English physicist James Chadwick in 1932, neutron imaging began with the work of Hartmut Kallmann and Ernst Kuhn in Berlin, Germany, from 1935 to 1944 (Brenizer 2013). Neutron imaging in wood science was particularly developed at ETH Zurich in collaboration with the Paul Scherrer Institute in Villigen, Switzerland. Complicated studies were performed to determine the moisture concentration at adhesive joints and under coatings in a controlled environment. A review on neutron imaging of wood and wood-based material is presented by Mannes et al. (2024).

The development of the dynamic vapour sorption (DVS) technique has enabled the possibility of studying and modelling sorption kinetics, reducing the time required for studying wood’s moisture sorption behaviour. For example, the time required to determine a material’s sorption isotherm is approximately 10–100 times shorter than conventional methods.

4.2 Mechanical and rheological properties of wood and wood-based materials

The research field of mechanical and rheological properties of wood and wood-based materials focuses on studying the performance characteristics of wood and its engineered products under loading in various climates. This area combines aspects of mechanical engineering and materials science, focusing on understanding how wood and wood-based materials respond to various forces, deformations, and stresses. Some key components of this research field are:

Mechanical properties

Strength is how wood and wood-based materials withstand tensile, compressive, and shear forces.

Stiffness describes how much the material resists deformation when subjected to force.

Hardness means the material’s resistance to indentation or surface deformation.

Elasticity and plasticity describe how wood deforms under stress and returns to its original shape or permanently deforms.

Fatigue and failure describe how wood and wood-based materials (including glued solid wood) behave under repeated loading/unloading and how they fail over time.

Strength grading is a method for determining a material’s strength. In the industry, sawn timber was initially strength-graded visually based on its visual features. However, around 1980, the first automatic mechanical grading systems for sawn timber were developed and industrialised.

Rheological properties

Viscoelasticity, i.e. investigating how wood behaves under both elastic and viscous conditions, especially under prolonged loading and under changes in moisture content (exposed to varying environmental climates).

Flow behaviour, i.e. the study of how wood-based materials (fibres, particles etc.) behave when processed.

Time-dependent behaviour, i.e. how wood responds to stress over time, is particularly important in construction and manufacturing settings.

The first extensive studies on creep were made in Australia, England and Germany, and later in Scandinavia, between the 1960s and 1990s (Boyd 1982; Gressel 1971; Mårtensson 1992; Ranta-Maunus 1973; Sandberg 1998). At the Commonwealth Scientific and Industrial Research Organisation in Melbourne, Australia, Armstrong and Kingston (1960) made the epoch-making discovery of the effect of moisture variations on creep in wood, known as the mechano-sorptive effect (CSIRO 1959, 1960, 1961).

The discoveries in the rheology of wood quickly gained great practical importance in timber engineering. Further research focused on the wood of timber dimensions to achieve more accurate strength calculations in construction, leading to the development of new or updated standards. For example, research by Hanhijärvi (1995) greatly impacted progress in this field.

The so-called COST (European Cooperation in Science and Technology) Actions, a long-standing EU-funded program that supports collaborative research networks across Europe and beyond, have effectively promoted wood research in Europe and elsewhere for approximately 30 years, dating back to as early as 1990. A vital contribution in the field of wood mechanics is that of COST E8 and COST 508 on wood mechanics, both chaired by Professor Pierre Morlier at Laboratoire de Rhéologie du Bois de Bordeaux (LRBB) in Bordeaux, France, which have continued the activity of the European Society for Wood Mechanics, which has been organising regular scientific conferences.

Over the past 10–15 years, there has been a significant increase in research on the rheological properties of solid wood, often in conjunction with studies on different anatomical scales and modelling. However, relatively little practice-oriented research has been conducted on the properties of wood and wood-based materials. These often fail due to the lengthy time required and the high costs. The current focus is on fundamental research on various scales and with comparatively short test times without extrapolation. These are usually carried out during periods of doctoral study work, which is typically 3–4 years. There is also work on the creep behaviour of bonded materials, such as glued-laminated timber and pure adhesive films (Bachtiar 2017).

The influence of the adhesive joint alone is complex, and it is difficult to isolate from that of the wood itself. However, in phenolic resins commonly used in moisture-resistant particleboard, the alkali content and higher moisture content of the wood substance significantly impact creep behaviour. As the alkali content increases, moisture-induced creep deformation in these materials increases.

In composite materials such as cross-laminated timber and glued-laminated timber, as well as in particle-based materials bonded with urea-formaldehyde or polymeric methyl diphenyl diisocyanate (PMDI), isolating the influence of the adhesive joint experimentally remains particularly challenging.

Advanced experimental techniques, including stress-strain testing, dynamic mechanical analysis, and numerical modelling, are employed to simulate and predict wood and wood-based materials’ mechanical and rheological behaviours under varying climatic conditions.

Modern measurement technologies, such as X-ray and neutron-based methods, digital image correlation (DIC), acoustic emission analysis, atomic force microscopy, and Raman spectroscopy, have been widely adopted in wood research. Structural changes under load are frequently determined in situ. The study of structural-property relationships has expanded considerably, allowing real-time recording and quantification of structural modifications. Research is often supported by modelling approaches from physics, civil engineering, mechanics, and mechanical engineering, with investigations now extending to the atomic level (Kulazinski 2015).

Table 4 gives some examples of essential references related to the mechanical and rheological properties of wood and wood-based materials.

Examples of scientific references related to mechanical and rheological properties of wood and wood-based materials.

| Title | Field | References |

|---|---|---|

| Investigation of Crushing Strength of Spruce at Varying Angles of Grain | Mechanical properties | Hankinson (1921) |

| Methoden und Resultate der Prüfung der schweiz. Bauhölzer | Euler (elastic) and Tetmajer (plastic) buckling | Tetmajer (1884) |

| Wood Handbook. Wood as an Engineering Material | Mechanical and physical properties | Ross and Anderson (2021); (the first edition was 1935) |

| Die anisotrope Elastizität des Holzes und der Lagenhölzer | Orthotropic properties | Keylwerth (1951) |

| Technologie des Holzes und der Holzwerkstoffe | Mechanical properties | Kollmann (1951) |

| Principles of Wood Science and Technology. Part 1: Solid Wood | Mechanical properties of wood and wood-based composites | Kollmann and Côté (1968) |

| Elastizitätszahlen von Fichtenholz in Abhängigkeit von der Holzfeuchtigkeit | Elastic properties of spruce, timber construction | Neuhaus (1981) |

| Mechanics of Wood and Wood Composites | Mechanical properties | Bodig and Jayne (1982) |

| Wood Handbook | Mechanical properties | Borovikov and Ugolev (1986) |

| In-situ Synchrotron based Tomographic Microscopy of uniaxially loaded Wood: in-situ Testing Device, Procedures and Experimental Investigations | Mechanical properties on the micro level | Zauner (2014) |

| Ingenieurholzbau | Timber construction | Neuhaus (2017) |

| The Creep in Chipboard Series | Mechanical and rheological properties of particleboard | Dinwoodie et al. in the Journal of Wood Science and Technology between 1981 and 1992 |

| Fracture and Fatigue in Wood | Fracture mechanics, modelling | Smith et al. (2003) |

| The Swelling of Wood under Stress. A Discussion of its Hygroscopic, Elastic and Plastic Properties. Based on a Course of Lectures Given at Svenska Träforskningsinstitutet, Stockholm, Sweden, 1948 | Rheology of wood | Barkas (1949) |

| Creep in Timber Structures | Rheology of wood | Mollier (1994) |

| Structure and Properties of Wood | Mechanical properties | Pozgaj et al. (1997) |

| Rheological Behaviour of Wood | Rheology of wood | Salmén et al. (2009) |

| Holzphysik. Physik des Holzes und der Holzwerkstoffe | Mechanical and rheological properties | Niemz and Sonderegger (2021) |

| Springer Handbook of Wood Science and Technology | Mechanical and rheological properties, modelling, fracture mechanics | Niemz et al. (2023c) |

4.3 Properties of modified wood and wood-based materials

Wood modification is implemented to improve the intrinsic properties of wood, produce new materials, and acquire the form and functionality desired by engineers without changing the eco-friendly characteristics of the wood material. An early example of what would today be construed as wood modification was undertaken by Alfred Nobel’s father, Immanuel (1801−1872). His work, patented with Russian colonel Nikolai Aleksandrovich Ogarev in 1844, involved impregnating wood used in carriage wheels with ferric sulphate and an acid, which was then dried slowly in special boxes. After drying, linseed oil and varnish were applied to reduce moisture absorption (Tolf 1976). Alfred J. Stamm (1897–1985) was an American chemist and a pioneering wood scientist in wood modification. He did extensive work developing new wood-modification methods, several of which are presented in his book Wood and Cellulose Science (Stamm 1964).

What today is meant to be wood modification is a branch of wood science and follows the principles of eco-friendly materials and the sustainable development of society. Wood modification is applied to overcome the weak points of the wood material that are mainly related to:

low resistance to bio-deterioration against fungi, insects, marine borers,

moisture sensitivity,

low dimensional stability,

low hardness and wear resistance,

low resistance to UV irradiation and weathering in general, and

to improve aesthetic properties.

Professor Callum Hill (born 1957) made a definition of wood modification in his book Wood Modification – Chemical, Thermal and Other Processes (Hill 2006, p. 20) that today works as guiding principles for further development in wood modification: “Wood modification involves the action of a chemical, biological or physical agent upon the material, resulting in a desired property enhancement during the service life of the modified wood. The modified wood should itself be nontoxic under service conditions, and there should be no release of any toxic substances during service life, or at the end-of-life following disposal or recycling of the modified wood. If the modification is intended for improved resistance to biological attack, then the mode of action should be non-biocidal.”

Wood modification methods often involve chemical treatments or alterations in wood chemistry, such as thermal treatment. However, biology, wood physics, and processing are crucial for evaluating improvements, properties, and industrial applications. Research in this field dates to the 1940s, when Alfred Stamm and colleagues worked on thermal treatment, densification, and dimensional stabilisation. Environmental concerns gained prominence in Europe around 2000, prompting research into modifying native species due to biocide restrictions and a decline in tropical hardwood use.

The European Conference of Wood Modification (ECWM), launched in 2003, has unified research efforts and advanced the field. Some new modification processes have transitioned from labs to production, with Europe producing approximately 750,000 m3 of modified wood annually, mainly thermally modified timber (Jones et al. 2019). Production in other regions, particularly China, is estimated to be similar. Despite this, market growth remains slow due to consumer scepticism, uncertainty about long-term performance, higher costs, and the need for specialised manufacturing equipment.

Today, wood modification research has expanded globally, with Europe leading research and industrial implementation. Since 2000, European studies have been structured through COST Actions, interdisciplinary networks fostering four-year collaborations. The latest, FP 1407 (ModWoodLife), concluded in 2017, documenting the field’s progress (Jones et al. 2019). Annual COST Action conferences and reports provide valuable insights into wood modification developments (Table 5).

COST Actions related to wood modification.

| Year | Name of the COST Action | Main focus |

|---|---|---|

| 1999–2004 | E22: Environmental optimisation of wood protection | Support and encourage the development and implementation of environmentally optimised wood protection technologies |

| 2004–2008 | E37: Sustainability through new technologies for enhanced wood durability | To improve sustainability by ensuring wood durability through quality assurance and performance classification of modified wood as an alternative to traditionally treated wood |

| 2010–2014 | FP 0904: Thermo-hydro-mechanical wood behaviour and processing | To improve the knowledge of wood mechanical and physical behaviour, its chemical degradation during Thermo-Hydro-Mechanical (THM) processing, and its application to wide-ranging wood treatment systems |

| 2011–2015 | FP1006: Bringing new functions to wood through surface modification | Enhanced surface modification of wood and wood products towards higher functionalisation and fulfilment of higher technical, economic and environmental standards |

| 2013–2017 | FP1303: Performance of bio-based building materials | Performance data for environmentally friendly bio-based building materials and suitable comprehensive test methodologies to determine their resistance against mould, stain, and decay |

| 2015–2019 | FP 1407: Understanding wood modification through an integrated scientific and environmental impact approach – ModWoodLife | To examine modification processing and product design, focusing on environmental impacts. This involved analysing the entire value chain – from forest to processing, installation, in-service use, end-of-life, cascading reuse, and final incineration with energy recovery |

Much of the research made within wood modification, especially for thermally modified timber, densified wood, acetylated, and furfurylated wood, which are well-established industrial processes, is well documented in various handbooks; some well-known examples are presented in Table 6.

Handbooks and specific chapters describing modified wood’s chemistry, mechanical and physical properties, processing and environmental aspects.

| Title | Main focus | References |

|---|---|---|

| Wood and Cellulose Science | The physical and related chemical aspects of wood and cellulose science, various methods for dimensional stabilisation of wood, and wood densification | Stamm (1964) |

| Densified Wood | A chapter summarising different methods for wood densification, including resin impregnation (Compreg) | Kollmann et al. (1975) |

| Handbook of Wood Chemistry and Wood Composites | Essential book in wood chemistry and how to modify wood by chemical modification | Rowell (2005) |

| Wood Modification – Chemical, Thermal and Other Processes | Modification of wood properties, chemical modification, thermal modification, surface modification, impregnation modification, and environmental aspects | Hill (2006) |

| Thermo-hydro-mechanical (THM) Processing of Wood | An extensive description of the properties and processing of densified wood. Introduction to thermal treatment, wood bending, and wood welding. A comprehensive review of ancient uses of THM processes and related products | Navi and Sandberg (2012) |

| Wood Modification in Europe: a State-of-the-Art about Processes, Products and Applications | A condensed description of various modification processes such as acetylation, densification, and furfurylation. A country-wise presentation of research and the market situation for modified wood in Europe | Jones et al. (2019) |

| Wood Modification Technologies. Principles, Sustainability, and the Need for Innovation | An extensive overview of wood modification in the combined sustainability, innovation, and industrialisation fields | Sandberg et al. (2021) |

| Wood Modification | A chapter about fundamental and practical aspects of chemical and thermal modification of wood. | Mai and Militz (2023) |

| Forming, Densification and Moulding | Bending and forming solid wood, laminate and veneer. Densification of wood. (a chapter) | Sandberg et al. (2023a) |

| Important Data | An extensive compilation of technical data for wood and wood-based materials, including modified wood | Niemz et al. (2023b) |

| Wood Material and Processing Data: the Most Relevant Data, Tables, and Figures | An extensive compilation of technical data for wood and wood-based materials, including modified timber | Niemz et al. (2025b) |

Today, significant advancements are being made in functionalisation, involving both wood itself and, in some cases, its surface treatment. However, widespread implementation remains a challenge. It took decades for thermal modification to reach industrial scale, and even now, its practical use remains limited but is increasing.

4.4 Modelling the wood structure-property relationship

When timber is employed in engineering applications, it is essential to understand and characterise its material behaviour and the performance of structural elements and assemblies. This understanding is fundamental for enabling accurate predictions. Consequently, developing and applying models capable of qualitatively and quantitatively predicting forces, stress levels, deformations, or strains is critical for designing safe, durable, and reliable engineered products and structures. Such predictive capability can be achieved through various analytical and numerical methods. Structural design standards generally recommend analytical approaches for designing elements and mechanical connections, utilising internal forces or stresses derived from analytical or numerical structural analyses. Nonetheless, the advantages of numerical methods and their widespread use in engineered wood products and timber structures should not be underestimated, and have shown success in parallel with the development of the computer capacity.

Modelling the structure-property relationship of wood and wood-based materials is a critical area of research, particularly in engineered timber products such as cross-laminated timber and glued-laminated timber. Such engineered wood products (EWPs) are increasingly used in construction due to their sustainability, strength, and versatility. Understanding how the internal structure of wood influences its properties is essential for improving the performance and durability of timber-based structures. This involves studying how different structural components of wood, such as the grain and cell structure, contribute to its mechanical behaviour under various conditions.

Another key aspect of modelling is the investigation of moisture-induced stresses and deformations in wood and wood-based materials. Wood’s hygroscopic nature means that moisture content can significantly affect its dimensional stability and mechanical properties. Models that simulate moisture transport and its effects on wood can provide valuable insights into how timber performs in varying environmental conditions. These models help predict timber products’ long-term performance and reliability, especially when exposed to fluctuating moisture levels.

In wood science and timber engineering, models are typically developed to address specific engineering challenges and represent the underlying physical and mechanical phenomena at a level of detail sufficient to enable reliable prediction. Beyond predictive purposes, such models can also be instrumental in identifying critical material characteristics and performance parameters, thereby supporting the efficient utilisation of timber as a natural resource and optimising wood-based products and structural systems. Holistic and integrative modelling approaches, while capable of capturing the complexity of wood’s anisotropic and heterogeneous behaviour, often involve high computational costs. This limits their applicability in practical engineering contexts, where numerous load cases and design scenarios must be considered. Nonetheless, these comprehensive models are valuable tools for advancing the fundamental understanding of complex structure–property relationships in timber and engineered wood products, particularly those not readily observable through experimental methods alone.

Table 7 gives some examples of essential references related to the development of modelling wood and wood-based materials the last 25 years.

Examples of references and research related to modelling wood and wood-based materials.

| Title | Field | References |

|---|---|---|

| Numerical Analysis of Moisture-related Distortions in Sawn Timber | Modelling the distortion of sawn timber | Ormarsson (1999) |

| Micromechanical Modelling of Wood and Fibre Properties | Modelling softwood | Persson (2000) |

| Adhesive Joints in Timber Engineering. Modelling and Testing of Fracture Properties | Modelling glued wood | Serrano (2000) |

| Hierarchical Modelling of Softwood Hygro-elastic Properties | Modelling softwood | Harrington (2002) |

| Modelling Moisture Transfer, Sorption, Swelling and Hysteresis in Wood and Modified Wood | Experimental studies (synchrotron) and simulation | Derome et al. 2013; Engelund Tybring and Fredriksson 2023; Perré 2007 |

| Moisture-induced Stresses in Cross-laminated Wood Panels | Modelling the distortion of sawn timber, CLT | Gereke (2009) |

| Damage Evolution in Wood and Layered Wood Composites monitored in situ by Acoustic Emission, Digital Image Correlation and Synchrotron-based Tomographic Microscopy | Modelling of fracture | Baensch (2015) |

| Adhesive Bonding of Structural Hardwood Elements | Modelling glued wood | Hassani (2015) |

| Physical and Mechanical Aspects of Moisture Adsorption in Wood Biopolymers Investigated with Atomistic Simulations | Modelling on an atomic level | Kulazinski (2015) |

| Modelling and Simulation of Hygro-mechanically Loaded Wooden Structures in Short-term and Long-term Range | Modelling of creep | Reichel (2015) |

| Creep Aspects of Softwood from the Cell-wall Level to Structures | Modelling of creep properties | Bengtsson (2023) |

| Anisotropic Wood-hydrogel Composites: Extending Mechanical Properties of Wood towards Soft Materials’ Applications | Properties of delignified and densified wood | Koch et al. (2023) |

| Comprehensive Creep Compliance Characterization of Orthotropic Materials Using an Automated System | Multiscale modelling of creep properties | Maas and Wittel (2025) |

| Tensile Creep of Norway Spruce on the Tissue Scale | Multiscale modelling of creep properties | Ferrara and Wittel (2025) |

Modelling the mechanical behaviour of wood and timber structures presents distinct challenges due to the material’s inherent heterogeneity and natural variability. As wood’s mechanical response is closely linked to its anatomical structure and the properties of its constituent polymers at the microscale, considerable variation can already be observed at the clear wood level – commonly the reference scale in engineering analyses. This intrinsic variability complicates model validation and hinders direct comparison between numerical predictions and experimental observations.

Viscoelastic creep is strongly affected by loading direction (Schniewind and Barrett 1972), load magnitude (Jiang et al. 2016), and environmental conditions (Bach 1966; Kingston and Armstrong 1951; Schniewind 1968). The response is typically modelled using rheological elements – springs for elasticity and dashpots for viscosity (Navi and Stanzl-Tschegg 2009). However, incomplete datasets hinder comprehensive model calibration. Attempts to scale or combine data across studies, directions, or species (Fortino et al. 2009; Hanhijärvi and Mackenzie-Helnwein 2003; Hassani et al. 2015) often lead to discrepancies between predicted and observed behaviour. At the macroscale, a recent dataset exists for Norway spruce (Maas and Wittel 2025). Microscale studies focus on wood fibres and cell walls, investigating chemical composition, microfibril angle (MFA) (Cai et al. 2022; Wang et al. 2021), and humidity effects (Meng et al. 2015). Yet, tissue-scale behaviour remains poorly understood, with limited studies primarily examining creep parallel to grain (Eriksson and Norén 1965; Robson 1989). While MFA is often considered, the effects of moisture and long durations are rarely addressed.

One practical approach to address this issue involves explicitly incorporating material heterogeneity into numerical models. This allows for predicting mechanical performance variability based on spatial variations in physical and geometrical properties across different scales, i.e. material, element, and structure. The cellular structure accounts for the wide variability in macroscopic properties, bridging the bulk wood with the chemical organisation within the tracheids. Therefore, a thorough characterisation of the different wood tissues is essential to understand the behaviour at the bulk scale fully. Micromechanical models have been developed to elucidate further the relationship between microstructure and mechanical behaviour (e.g. De Borst et al. 2013; Hofstetter and Gamstedt 2009; Navi and Heger 2005, Persson 2000). These models replicate wood’s hierarchical organisation to predict its hygro-thermo-viscoelastic behaviour from microstructural and micromechanical parameters. Comparable multiscale modelling frameworks have also been applied to wood-based products and structural assemblies.

The use of wood in engineering extends beyond traditional construction, with widespread application in sectors such as furniture manufacturing. Emerging fields are also exploring wood-based materials as sustainable alternatives to synthetic and polymer composites. For example, recent research has investigated the use of wood components in the automotive industry (Jost et al. 2018), emphasising the need for robust and reliable material models to support such innovation. Accurate modelling of mechanical behaviour is, therefore, essential to realising the potential of wood as a substitute for conventional materials.

Due to the dimensional limitations of sawn timber, a range of EWPs has been developed. These typically comprise laminated wood elements bonded to form structural components such as beams, plates, and shells. Although tree growth produces a naturally optimised material structure, the sawing process introduces defects that disrupt load paths and reduce mechanical efficiency. Moreover, growth stresses and drying-induced deformations often lead to distortion in sawn timber. The development of EWPs is thus driven not only by geometric, economic, and ecological considerations, but also by the need to minimise mechanical variability, primarily achieved by reducing the influence of local defects.

Analytical and numerical models are crucial for predicting the mechanical performance of timber and EWPs, helping to reduce reliance on extensive physical testing. These models commonly begin by treating wood as a macro-homogeneous orthotropic continuum and incorporate constitutive laws to describe mechanical responses, along with formulations for moisture transport and deformation under environmental (relative humidity and temperature) and mechanical loads. Accurate simulations require appropriate constitutive models capable of capturing orthotropic elasticity, plasticity, brittle failure, and the coupled effects of moisture, temperature, and time. The primary state variables in these simulations – displacements and rotations – are governed by the material’s load history. For a more comprehensive review of wood material and timber structure modelling, cf. Bader and Ormarsson (2023).

In practice, a balance between computational efficiency and model complexity is essential. Adaptive modelling strategies, which integrate one- to three-dimensional models of varying resolution, can facilitate efficient structural analyses. Alternatively, a hierarchical modelling approach can be adopted, wherein detailed sub-models provide input for global structural analysis and vice versa – for instance, to evaluate local stress concentrations in connections. A continuing challenge in numerical modelling is the consideration of model uncertainty. This includes assessing sensitivity to input parameters and explicitly stating modelling assumptions and limitations to ensure transparency and facilitate external validation.

5 Summary and outlook

Early modern research on the basics of wood’s physical and mechanical properties was integrated into forestry schools, evolving into systematic studies with a focus on wood biology and chemistry. Before formal forestry schools, wood research was published in encyclopaedias and academic writings. The development of wood science as an independent field began in the early 20th century with the establishment of wood technology institutes.

Forestry schools have been essential in advancing wood science, particularly wood physics, which integrates biology, chemistry, mechanics, and material science to study wood properties. The Industrial Revolution sparked increased wood exploitation, leading to innovations like steam saws, paper-pulp production, and various wooden products based on these processes. This period also saw the rise of forestry education, with early institutions emerging in Germany and later spreading globally. Johann (Hannß) Carl von Carlowitz and Heinrich Cotta helped lay the foundation for sustainable forestry practices. By the 20th century, forestry education expanded across Europe, Africa, Asia, and the Americas. The evolution of wood science and technology has, in recent decades, shifted towards more basic research in materials science. In contrast, applied wood technology education is increasingly offered at universities of applied sciences. However, practical training and study remain central to education in the forestry value chain.

While traditional wood research declined in the post-1950s, new institutions have emerged, particularly in China and in Central and Eastern Europe, focusing on renewable materials. Global wood research has shifted towards circular economy applications. The study of wood for industrial uses surged during wartime, leading to innovations in wood products and engineered wood products (EWPs). Today, the focus is on sustainability and new EWPs for high-rise buildings.

Wood physics research is focused on four key areas: wood-water relations, mechanical and rheological properties, properties of modified wood, and modelling structure-property relationships. Together, these research areas contribute to advancing the understanding and application of wood and wood-based materials as renewable materials in construction and furniture manufacturing.

Current research in wood science also focuses on functionalisation, which involves modifying wood properties and surface treatments, though practical applications are still in development. Decades of research have also established foundational work in bonding, such as developing temperature-resistant polyurethanes and optimising fire behaviour in wood-based materials. Interdisciplinary approaches have been key to success, such as the one-component polyurethane adhesive, which is still being refined after 30 years of development.

Today, timber construction is at the forefront of research and implementation, with practical innovations emerging directly within the construction industry. However, research in structural mechanics, fire behaviour, and fracture mechanics has been crucial to this development.

Much of the technical and technological progress comes from industrial mechanical engineering rather than academic institutions. Large wood processing companies and machine manufacturers often fund the implementation of new technologies. Wood technology research is declining in technologically focused universities, with a few dedicated chairs in Europe, China, and overseas. However, today China leads global wood research, with a growing influence on the quantity and quality of research due to the country’s numerous large research institutions (Niemz 2015).

Wood science and technology are at a critical juncture, with significant opportunities for innovation driven by research and industrial demands. Over recent decades, the focus has shifted substantially from basic research to more practical, application-oriented developments in technology, led by the industry. In contrast, the academic sector continues to contribute through fundamental studies in wood science. Despite advances in areas such as adhesives, wood modification, and engineered wood products such as cross-laminated timber and glued-laminated timber, a gap remains between academic research and industrial implementation. This disparity underscores the need for closer collaboration between academia and industry to bridge the divide and push the boundaries of what is possible in wood technology.

One of the major driving forces in the future of wood science and technology will be the need for sustainability and resource efficiency. As environmental concerns continue to shape industrial practices, the demand for bio-based, renewable materials like wood is set to increase. Wood-based materials are already viewed as a more sustainable alternative to traditional construction materials such as steel and concrete, due to their lower carbon footprint and renewable nature. However, significant changes in functionalisation and modification will be necessary to capitalise on this potential fully. Developing multifunctional wood products, which are durable and possess unique properties like fire resistance, enhanced moisture stability, and UV protection, will be a key area of research. Functionalisation will likely extend beyond wood’s natural properties, integrating technologies such as nanotechnology, metal-organic frameworks, and polymers to create innovative materials that respond dynamically to environmental changes.

The technological advancement of wood processing techniques will also be essential. Currently, much of the technological development in the wood sector is driven by machine manufacturers rather than research institutions. This trend will continue as companies seek to improve processing efficiency and product quality. However, there remains a need for further basic research in areas such as machining, drying, and wood-based material optimisation to enhance the capabilities of modern processing equipment. Integrating advanced manufacturing technologies such as 3D printing, automation, robotics, X-ray computed tomography, machine learning, and artificial intelligence will likely open up new possibilities for the precision production of wood products, enabling highly customised and complex designs, e.g. construction applications.

The future of wood technology also depends on education and training to develop the next generation of experts. The demand for skilled personnel with expertise in wood science, technology, and engineering is set to increase as new developments in the field continue. Universities and research institutes will need to focus not only on high-impact publications but also on fostering practical, industry-oriented research that can be applied to real-world challenges. Specialised funding programmes will be crucial in supporting academic and industrial research.

Finally, industry-driven innovations will remain central to the future of wood technology. Despite the challenges in scaling up new technologies, the wood sector’s ability to adapt to emerging demands and technological advancements will continue to drive progress. The engineering of wood-based products will likely focus on increasing performance while reducing environmental impact, with the ultimate goal of creating sustainable, multifunctional materials that serve a wide range of applications from construction to biomaterials.