Abstract

Fast-growing wood is an abundant and low-cost material and is widely used for structural building and furniture construction. However, inferior mechanical properties and dimensional instability limit its application in advanced engineering structures. Herein, we developed a simple, effective and “green” method to transform bulk poplar into a high-performance wood composite. The wood composite was prepared by the impregnation of the itaconic acid (IA) solution acting as a grafting anchor into the wood matrix, followed by in situ polymerization of styrene upon heating to form a hydrophobic polymer within the wood scaffold. Scanning electron microscope (SEM) analysis revealed that hydrophobic polystyrene (PS) was deposited in wood cell walls and lumens, leading to a reduced water uptake and remarkably enhanced dimensional stability, as well as generally improved mechanical properties. In addition, the PS generated improvement in the thermal stability of the wood composite in comparison with that of natural wood (W).

Introduction

Wood, the most common building materials, has been used for thousands of years due to its lightweight and high-strength properties. However, wood has an obvious shortcoming as an engineering material – hygroscopicity (H). It is easy for wood to absorb or release moisture under changes in relative humidity, causing swelling and shrinking of dimension. In this case, fungal decay and cracking will occur within the wood structure, leading to hidden dangers of wood constructions (Keplinger et al. 2015). So, inhibition of water intrusion is imperative. Modification and functionalization of wood is an effective approach to extend the longevity of wood-based products (Hill 2007; Berglund and Burgert 2018).

Wood is mainly composed of cellulose, hemicellulose and lignin, containing a lot of hydroxyl groups, which is the cause of hydrophilicity. In recent years, functionalizing hydroxyl groups via chemical modification, esterifications (Mattos et al. 2015; Cabane et al. 2016; Chai et al. 2016; Sun et al. 2018), etherifications (He et al. 2016; Matsuda 2017; Yao et al. 2017) and silylations (Kumar et al. 2016, 2017) is used to improve dimensional stability. However, none of these methods can satisfy the required product properties and practical production (e.g. long-term dimensional stability, environmental/health safety, demanding production process, etc.). Two-step grafting is an effective method to improve wood physical properties that has been proved by some research works (Ermeydan et al. 2014; Wang et al. 2018). In general, a hydrophobic modifier can provide wood good dimensional stability and water repellency. However, it is difficult for the hydrophobic agent to penetrate the hygroscopic wood tissue and react with the hydroxyl groups of the natural carbohydrate (cellulose, hemicellulose and lignin). Based on this, one feasible approach is to introduce multi-functional hydrophilic reactants that can also react with hydrophobic agents into wood structure and establish stable covalent bonds with hydroxyl groups at first. Then, some hydrophobic molecules can be locked in wood via chemical linkage, which endows wood with superior hydrophobicity and permanent dimensional stability.

With advances in sustainable and environmental awareness, chemical building blocks derived from renewable resources have gained more and more importance. In this respect, itaconic acid (IA) has gained considerable attention, as it has been biotechnologically produced from natural polymers on an industrial scale (Robert and Friebel 2016). In addition, it is composed of two carboxyl groups and an α,β-unsaturated double bond, which makes it a promising bridging agent for chemical reactions (Geilen et al. 2010; Medway and Sperry 2014). Among the hydrophobic monomers studied, styrene has some advantages related to up-scale possibilities and easy polymerization at mild temperature. Styrene monomer is not good for human health. However, polystyrene (PS) is non-toxic and it has been widely used to strengthen military armor, wind power turbines, cushion bicycle helmets and food packaging because of its strength, durability, comfort and safety. (Rani et al. 2014; Abdallah et al. 2018). In addition, PS was used in green building applications due to its superior insulation property (Cai et al. 2017). So, we combined the aforementioned two excellent chemicals to manufacture a “green”, high-dimensional stability and cost-effective wood composite.

The first objective of this study was to bring in unsaturated IA with conjugated double bonds and two carboxyl groups as a grafting anchor for the second-step hydrophobic chemical polymerization, which was proven effective in our previous report (Han et al. 2018). In this study, we optimized the IA “activation” procedure, resulting in hydrophobic styrene monomer in situ polymerization within the wood cell walls and lumens, which achieved an improvement in the mechanical properties and dimensional stability of poplar wood.

Materials and methods

Materials

Poplar wood (Populus euramericana cv. “I-214”) with dimensions of 20×20×20 mm3 (longitudinal×radial×tangential) was prepared from sapwood sections. IA, acetone, ethanol, styrene and 2,2′-azobis (2-methylpropionitrile) (AIBN) were purchased from Sigma Aldrich (Beijing, China). Deionized water (DW) was used throughout the study.

Preparation of the esterification catalyst La3+~SO42−/TiO2-SiO2

The esterification catalyst was prepared according to a previous paper (Li et al. 2013): 10 g mixture of Ti(SO4)2 and Na2SiO3 were dissolved in 90 g DW under vigorous stirring, and the molar ratio of Ti and Si was 25:1. Aqueous ammonia (28 wt%) was added drop-wise to adjust the pH value of the aforementioned solution to the range of 9–10. The addition continued until slowly reaching solidification. Subsequently, the obtained TiO2-SiO2 solid was separated and washed with DW, and was dried at 100°C for 24 h. An appropriate amount of La2O3 was dissolved in 2 mol l−1 H2SO4 to prepare a mixture solution, and the concentration of the La3+ ion was 0.07 mol l−1. The TiO2-SiO2 was immersed into the aforementioned mixture solution for 2 h and its ratio was 15 g TiO2-SiO2 per 100 ml solution. Finally, the precipitate was evaporated and calcined at 500°C to obtain La3+~SO42−/TiO2-SiO2.

Activation of wood using water-soluble IA

Before activation, all wood samples were oven-dried at 103±2°C for 6 h, and the oven-dried weight and dimensions of the samples were measured. The following abbreviations will be used: natural wood (W), IA-activated wood (WIA) and in situ IA-activated wood (WIA/PS). The wood samples were activated as follows: dried wood cubes were evacuated in a glass container under high vacuum for 30 min. In another beaker, 20 g IA and 0.2 g La3+~SO42−/TiO2-SiO2 were dissolved in 1000 ml DW at room conditions under stirring. Subsequently, the aforementioned solution was squashed into the glass container having the wood samples under atmospheric pressure. The glass container was vacuumed, sealed and maintained at 55°C for 2.5 h and then cooled to room temperature. After removing residual chemicals, the treated wood was dried at 103±2°C until weight constancy. Thus, activated wood samples were obtained, and the weight percent gain (WPG) and dimensions were determined.

Graft copolymerization of styrene monomers

The styrene oligomer solution was prepared by mixing styrene monomer and ethanol at a volume ratio of 1:1, containing 1 wt% AIBN as the initiator. The activated wood samples were placed at the bottom of a glass container and immersed in the aforementioned styrene oligomer solution. Then the glass container was vacuumed and heated at 70°C in water bath for 1.5 h; thus, the activated wood samples were subjected to vacuum-heat immersion treatment. After reaction completion, the wood cubes were washed with acetone, then with water and finally dried in the oven at 103±2°C for 24 h. The WPG and dimensions were measured.

Characterization

The chemical compositions of both natural wood and modified wood were qualitatively analyzed by the KBr pellet technique using a Fourier transform infrared (FTIR) spectrometer (Tensor 27, Bruker, Ettlingen, Germany). Mid-IR spectra were obtained by averaging 32 scans from 2000 to 400 cm−1 at a spectral resolution of 4 cm−1. For thermogravimetric analysis (TGA), roughly 5 mg of powdered wood samples were analyzed on a thermogravimetric analyzer (DTG-60, Shimadzu, Kyoto, Japan) (10°C min−1 in N2 atmosphere, 50–600°C). The microstructure morphologies of the modified and reference wood samples were visualized using a field emission scanning electron microscope (FE-SEM, SU 8010, Hitachi, Tokyo, Japan) operating at 3.0 kV. X-ray diffraction (XRD) analysis was carried out using an XRD Bruker D8 ADVANCE (Germany) (Cu Kα radiation with graphite monochromator, 40 kV and 40 mA). The patterns were obtained between 5° and 40° with 0.05° steps and a scan speed of 2° min−1. According to the peak height method developed by Segal et al. (Segal et al. 1959) for native cellulose, the XRD crystallinity index (CrI) was calculated from the following height ratio:

where I002 was the maximum intensity of the 002 diffraction peak at 2θ=22.5° and Iam was the height of the minimum at 2θ=18°.

Mechanical properties

Twelve specimens of natural and modified wood were analyzed using a universal mechanical testing machine (AG-100KNIMO, Tokyo, Japan). Tests were carried out according to the following Chinese standards: GB/T 1936.1–2009, GB/T 1935–2009 and GB/T 1933–2009. The surface hardness was tested using a TH210 durometer (Beijing TIME High Technology Ltd., Beijing, China) and the data were expressed using shore D hardness according to ASTM D2240. The mean result of 20 specimens was considered the final hardness.

Hygroscopicity (H), anti-swelling efficiency (ASE) and leachability

The H of both natural and modified wood was evaluated according to the Chinese standard method for determination of the water absorption of wood (GB/T 1934.1–2009). Specifically, the specimens were oven-dried and then were immersed in water for 10 days at room condition. After immersion, the excess water on the surface was removed using a soft cloth, and specimens were weighed immediately. The water uptake by the specimens increases with the immersion time. The increase in weight was calculated according to the following formula:

where Wt is the weight after immersion in water for a specific time period, and Wo is the weight of the original oven-dried sample.

The ASE of natural and modified samples was measured according to ASTM-1037 (1999) (Adebawo et al. 2016). Ten oven-dried specimens for each treatment with a dimension of 20×20×10 mm (radial×tangential×longitudinal) were immersed in a water bath at a temperature of 20±1°C for 240 h; weight and dimension of specimens were determined before and after soaking.

ASE was calculated according to equations (3) and (4) as follows:

where Sn=volumetric swelling coefficient of natural wood samples; Sm=volumetric swelling coefficient of modified wood samples;

The volumetric swelling coefficient (S) was calculated as follows:

where V1=volume of wood before soaking; V2=volume of water after soaking.

After 10 days of immersion, all specimens were oven-dried at 103±2°C to a constant weight before measurement. Leachability (L) due to water immersion was calculated as follows:

where M0 and M1 are the dry weights of modified wood specimens before and after immersion, respectively.

Results and discussion

In the first step, wood was activated by introducing double bonds into the wood structure (cell walls and interface between cell walls and lumens), via covalent bonding between hydroxyl groups of the wood cell wall components and carboxylic groups of IA as shown by the result of the FTIR analysis. In the second step, the activated wood was immersed into a styrene solution containing the initiator (AIBN). As styrene is a hydrophobic molecule, it was dissolved into an ethanol-water mixture to facilitate wood cell penetration. The in situ polymerization of styrene was then conducted for 1.5 h at 70°C in wood cell walls and lumens. Figure 1 presents the scheme of the construction process.

Scheme of the modification route: activation of wood fibers with itaconic acid (IA), followed by in situ polymerization of styrene monomer.

Physical and mechanical properties

The physical and mechanical properties of the W, WIA and WIA/PS are shown in Table 1. Both WIA and WIA/PS have a higher density than W. The air-dried density was increased by 11.63% and 48.84% from 0.43 g·cm−1 to 0.48 g·cm−1 and 0.64 g·cm−1, respectively. In addition, the oven-dried density also was increased by 12.20% and 53.66% from 0.41 g·cm−1 to 0.46 g·cm−1 and 0.63 g·cm−1, respectively. The aforementioned results are in accordance with the increasing tendency of WPG. Treatment with IA induced a good bending strength (88.01 MPa, 17.69% increment) and compressive strength parallel to the grain (62.31 MPa, 40.18%). These results demonstrated that IA had a limited promotion for physical and mechanical properties, and it mainly played a grafting anchor role in the construction process. After introducing PS within the WIA, the WIA/PS exhibited significantly enhanced bending strength (143.56 MPa) and compressive strength parallel to the grain (96.88 MPa), which increased by 91.98% and 117.95%, respectively, compared with that of the W. Furthermore, all three cut sections of WIA/PS hardness also increased (Figure 2 ). These results demonstrated that in situ polymerization of styrene monomer effectively contributed to the mechanical performance of the material.

Physical and mechanical properties of natural wood and modified wood.

| Property | W | WIA | WIA/PS |

|---|---|---|---|

| Air-dried density (g cm−3) | 0.43±0.025 | 0.48±0.006 | 0.640±.024 |

| Oven-dried density (g cm−3) | 0.41±0.080 | 0.46±0.068 | 0.63±0.043 |

| Bending strength (MPa) | 74.78±9.32 | 88.01±8.56 | 143.56±10.76 |

| Compressive strength parallel to the grain (MPa) | 44.45±4.24 | 62.31±2.38 | 96.88±6.47 |

| WPG (%) | – | 3.68±0.90 | 10.69±1.24 |

W, Natural wood; WIA, IA-activated wood; WIA/PS, in situ IA-activated wood; WPG, weight percent gain.

Hardness of natural wood (W), IA-activated wood (WIA) and in situ IA-activated wood (WIA/PS).

Polymer distribution studied with FE-SEM

FE-SEM was conducted to study the polymer distribution at the wood cell level after the in situ polymerization of the WIA sample (Figure 3). The SEM image of WIA confirmed that the wood morphology remains almost unchanged after the modification. This result was consistent with a similar WPG result (Table 1). The only visible change of W and WIA was the more compact WIA cell walls. This was attributed to the IA linkage effect pulling neighboring wood fibers together (Figure 3b). After the in situ polymerization of styrene, almost all of the vessels and tracheids were completely filled with PS (Figure 3c), indicating this polymerization process occurred substantially. The magnification image of WIA/PS (Figure 3d) showed that the cell wall became very dense and some structures (such as ray) were covered by PS. There is a seamless connectivity at the interface between lumens and cell walls, which is crucial to prevent water invasion. From the aforementioned results, the hydrophobic PS was compactly distributed in cell walls and lumens, which can comprehensively enhance water repellence, leading to a durable dimensional stability.

FE-SEM images of transverse section.

(a) Natural wood (W), (b) IA-activated wood (WIA) and (c, d) in situ IA-activated wood (WIA/PS).

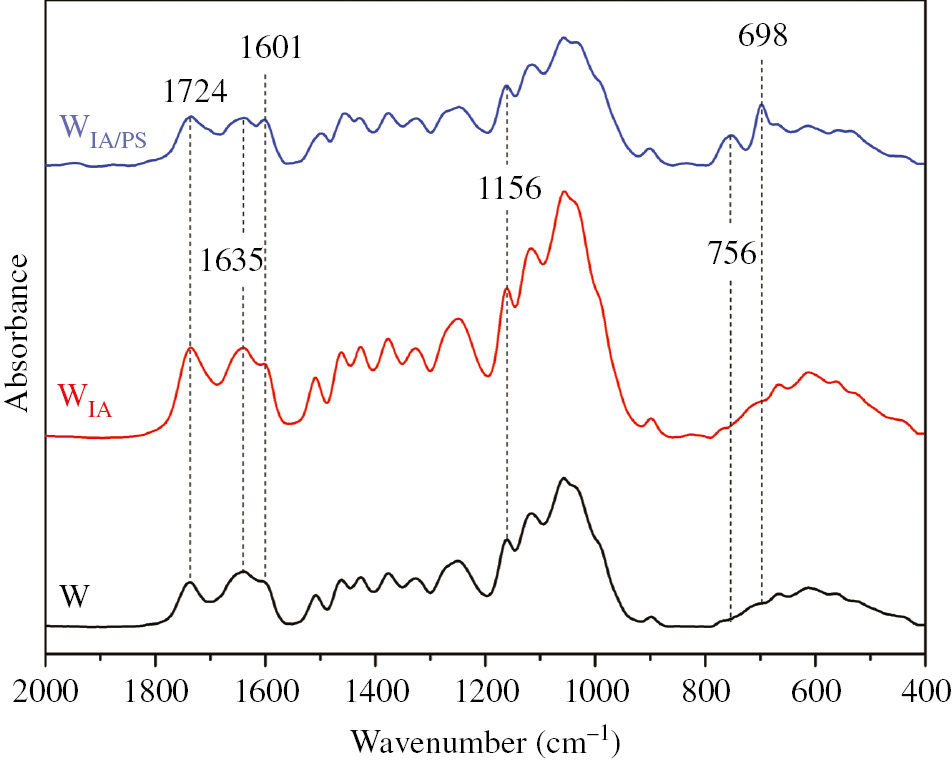

FTIR analysis

In order to confirm the esterification and in situ polymerization, the W, WIA and WIA/PS were characterized by FTIR spectroscopy (spectra are shown in Figure 4). The IR spectrum for the W reveals the characteristic peaks from holocellulose and lignin. After modification with IA, the presence of carboxylic acid groups can be confirmed by the clear increased peak intensities corresponding to the carbonyl C=O vibration at 1724 cm−1, the C–O stretching at 1156 cm−1 and the alkene stretching at 1635 cm−1 (Tammer 2004). For the WIA/PS, the typical peaks of PS at 698 and 756, and 1601 cm−1 appeared, which can be attributed to the out-of-plane C–H bending of the aromatic ring, and an aromatic ring breathing mode, respectively (Socrates 2004). Moreover, the intensity of the double bond has a clear decrease, indicating the styrene was successfully grafted to the WIA (Table 2).

FTIR spectra curves of natural wood (W), IA-activated wood (WIA) and in situ IA-activated wood (WIA/PS), and absorption band assignment (1724 cm−1, C=O stretching vibrations; 1635 cm−1, C=O stretching vibrations; 1601 cm−1, C=O stretching vibrations; 1156 cm−1, C=O stretching vibrations; 756 cm−1, C=O stretching vibrations; 698 cm−1, C=O stretching vibrations).

FTIR absorption band assignment.

| Band position (cm−1) | Assignment |

|---|---|

| 1724 | C=O stretching vibrations |

| 1635 | C=C stretching vibrations |

| 1601 | Polystyrene |

| 1156 | C–O vibrations |

| 756 | Polystyrene |

| 698 | Polystyrene |

FTIR, Fourier transform infrared.

XRD analysis

Figure 5a presents the XRD patterns of the natural and modified wood samples. All of the wood samples showed diffraction peaks around 15.6, 22.5 and 35° 2θ indicating the (101), (002) and (040) crystal planes of the cellulose I structure (Cave 1997). Comparing the three curves, the position of the peaks did not change, indicating modification treatments do not destroy the crystalline structure of cellulose, which is important for the physical and mechanical properties of WIA and WIA/PS. The only difference among samples was the intensity change in the peaks, denoting changes in the wood crystallinity (Figure 5b). Compared with W (27.8% crystallinity), the WIA (26.0% crystallinity) had a slight decrease, showing IA just plays a grafting anchor role. As expected, the WIA/PS (15.05% crystallinity) had a significant decrease compared to WIA, which is attributed to the in situ polymerization of styrene monomer in wood hierarchical structure, increasing the proportion of the amorphous region.

XRD patterns of natural wood (W), IA-activated wood (WIA) and in situ IA-activated wood (WIA/PS) (a) and the corresponding crystallinity (b).

TGA analysis

The TGA and derivative thermogravimetric (DTG) curves for the W, WIA and WIA/PS are presented in Figure 6 . Wood is vulnerable to thermal decomposition and its three main components (cellulose, hemicellulose and lignin) have different thermal stabilities due to their different structures (Kim et al. 2004; Schirp and Su 2016; Qiao et al. 2019). Typically, hemicellulose is easy to be degraded, and its pyrolysis is focused at 220–315°C. The pyrolysis of cellulose mainly happened at 315–400°C, while that of lignin covered a whole temperature range (150–600°C) (Yang et al. 2007). It can be observed the thermal degradation of WIA is faster than that of W between 200 and 330°C, which indicates IA has an acid hydrolysis for hemicellulose, making it easier to be pyrolyzed. For the WIA/PS, the TG and DTG curves are shifted to higher temperature regions, indicating PS has a strong connection with wood components and it can effectively prevent wood from thermal degradation. PS has a good thermal stability and the hydrolysis section at 400–500°C is related to it (Liu et al. 2019). There is no doubt that modified wood using PS will obtain a good thermal stability. There is more residual weight (ash content) at 600°C for the WIA/PS, also reflecting the full polymerization of styrene monomer in wood tissue.

TGA (a) and DTG (b) curves of natural wood (W), IA-activated wood (WIA) and in situ IA-activated wood (WIA/PS).

Water-repellent property and leachability

The H values of the samples were measured to evaluate the water repellency of the W, WIA and WIA/PS upon water soaking for 10 days (Figure 7a). Within this time period, the W and WIA showed almost same hygroscopic tendencies and they gained about 133% and 126% water, respectively. When styrene monomer underwent in situ polymerization within the WIA, the H value of the WIA/PS was reduced by more than half of W. It can be attributed to the polymerization of the hydrophobic styrene with the cell wall components and cell lumens’ bulk filling of PS, which occupied the flow path (vessels and tracheids) originally available for water and obstructed water uptake. In addition, after 10 days of washing, the leaching tests showed that the WIA/PS has a very low leaching rate (3.51%) compared to the W (3.22%) (Figure 7b). This behavior represents PS has been firmly connected to the wood structure and there is no residual styrene monomer in WIA/PS. Consequently, such WIA/PS could be potentially utilized as a reliable engineering material for outdoor construction due to its superior durability in water.

(a) Water uptake of natural wood (W) (A), IA-activated wood (WIA) (B) and in situ IA-activated wood (WIA/PS) (C). (b) Leachability of natural and modified wood samples.

Dimensional stability

The ASE was determined to evaluate the dimensional stability of the treated wood upon water soaking cycles (Figure 8). The sample with a lower S and higher ASE value can possess better dimensional stability. When the W was activated using IA, the S of the modified wood dropped by 25.97%, from 14.26% to 11.32%. According to Figure 8, the effect of styrene polymerization on S and ASE was significant. The S of WIA/PS was 101.70% and 60.11% smaller than the W and WIA, respectively. The incorporation of PS into the wood leads to a further increase in the ASE when compared to the WIA: after 10 days in water, the ASE of WIA is about 22.91%, while that of WIA/PS can be up to 50.46%. The obtained ASEs were also in good agreement with the results of the FE-SEM, XRD and H measurements. Lumen filling can decrease the space available for water, block cell cavities (such as pits) and consequently delays, and avoids water entrance into the cell walls (Hadi and Massijaya 2018). Wood cell wall modification is an efficient way for improving dimensional stability (Kong et al. 2018). So, excellent dimensional stability of the WIA/PS can be achieved through the reinforcement of the cell walls by the modification of IA and styrene and their polymerization in the wood cell lumens.

S and ASE values of natural wood (W), IA-activated wood (WIA) and in situ IA-activated wood (WIA/PS).

Conclusion

In this study, we showed a simple and effective method to promote the low-grade poplar wood in terms of mechanical properties and dimensional stability through the activation of the wood fibers by trifunctional IA, followed by in situ polymerization of styrene monomers. The derived WIA/PS possesses a remarkably improved water-repellent property and dimensional stability (ASE up to 50.46%) over the W due to dense filling of hydrophobic PS in wood cell walls/lumens. The inserted PS also helps to reinforce the wood scaffold, resulting in enhanced physical and mechanical properties. Leachability results showed that the hydrophobic PS was firmly fixed in the wood hierarchical structure, suggesting a long-term protection of wood in service. Such desirable improvements will help promote the use of fast-growing wood in outdoor building and construction.

Author contributions: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

Research funding: This work was sponsored by a special Fund from the Beijing Common Construction Project and the Beijing Forestry University, Grant no. 2016HXKFCLXY001.

Employment or leadership: None declared.

Honorarium: None declared.

References

Abdallah, M.A.-E., Sharkey, M., Berresheim, H., Harrad, S. (2018) Hexabromocyclododecane in polystyrene packaging: a downside of recycling? Chemosphere 199:612–616.10.1016/j.chemosphere.2018.02.084Search in Google Scholar PubMed

Adebawo, F., Naithani, V., Sadeghifar, H., Tilotta, D., Lucia, L., Jameel, H., Ogunsanwo, O. (2016) Morphological and interfacial properties of chemically-modified tropical hardwood. RSC Adv. 6:6571–6576.10.1039/C5RA19409ASearch in Google Scholar

ASTM D2240. Standard test method for rubber property-durometer hardness. ASTM International, West Conshohocken, PA, 2015, www.astm.org.Search in Google Scholar

Berglund, L.A., Burgert, I.J. (2018) Bioinspired wood nanotechnology for functional materials. Adv. Mater. 30:1704285.10.1002/adma.201704285Search in Google Scholar PubMed

Cabane, E., Keplinger, T., Künniger, T., Merk, V., Burgert, I. (2016) Functional lignocellulosic materials prepared by ATRP from a wood scaffold. Sci. Rep. 6:31287.10.1038/srep31287Search in Google Scholar PubMed PubMed Central

Cai, S., Zhang, B., Cremaschi, L. (2017) Review of moisture behavior and thermal performance of polystyrene insulation in building applications. Build. Environ. 123:50–65.10.1016/j.buildenv.2017.06.034Search in Google Scholar

Cave, I.D. (1997) Theory of X-ray measurement of microfibril angle in wood. Wood Sci. Technol. 31:225–234.10.1007/BF00702610Search in Google Scholar

Chai, Y., Liu, J., Wang, Z., Zhao, Y. (2016) Dimensional stability and mechanical properties of plantation poplar wood esterified using acetic anhydride. BioResources 12:912–922.10.15376/biores.12.1.912-922Search in Google Scholar

Ermeydan, M.A., Cabane, E., Gierlinger, N., Koetz, J., Burgert, I. (2014) Improvement of wood material properties via in situ polymerization of styrene into tosylated cell walls. RSC Adv. 4:12981–12988.10.1039/c4ra00741gSearch in Google Scholar

GB/T 1933-2009 (2009) Method for determination of the density of wood. Chinese National Standardization Management Committee, Beijing, China.Search in Google Scholar

GB/T 1934.1-2009 (2009) Method for determination of the water absorption of wood. Chinese National Standardization Management Committee, Beijing, China.Search in Google Scholar

GB/T 1935-2009 (2009) Method of testing in compressive strength parallel to grain of wood. Chinese National Standardization Management Committee, Beijing, China.Search in Google Scholar

GB/T 1936.1-2009 (2009) Method of testing in bending strength of wood. Chinese National Standardization Management Committee, Beijing, China.Search in Google Scholar

Geilen, F.M., Engendahl, B., Harwardt, A., Marquardt, W., Klankermayer, J., Leitner, W.J. (2010) Selective and flexible transformation of biomass-derived platform chemicals by a multifunctional catalytic system. Angew. Chem. Int. Ed. 49:5510–5514.10.1002/anie.201002060Search in Google Scholar PubMed

Hadi, Y.S., Massijaya, M.Y. (2018) Polystyrene impregnated wood resistance to marine borer Attack. In: The 12th Conference of The Pacific Rim Termite Research Group, Yogyakarta, Indonesia.Search in Google Scholar

Han, X., Yin, Y., Zhang, Q., Li, R., Pu, J. (2018) Improved wood properties via two-step grafting with itaconic acid (IA) and nano-SiO2. Holzforschung 72:499–506.10.1515/hf-2017-0117Search in Google Scholar

He, X., Xiao, Z., Feng, X., Sui, S., Wang, Q., Xie, Y. (2016) Modification of poplar wood with glucose crosslinked with citric acid and 1,3-dimethylol-4,5-dihydroxy ethyleneurea. Holzforschung 70:47–53.10.1515/hf-2014-0317Search in Google Scholar

Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes. John Wiley & Sons, West Sussex, England, 2007.10.1002/0470021748Search in Google Scholar

Keplinger, T., Cabane, E., Chanana, M., Hass, P., Merk, V., Gierlinger, N., Burgert, I. (2015) A versatile strategy for grafting polymers to wood cell walls. Acta Biomater. 11:256–263.10.1016/j.actbio.2014.09.016Search in Google Scholar PubMed

Kim, H.-S., Yang, H.-S., Kim, H.-J., Park, H.-J. (2004) Thermogravimetric analysis of rice husk flour filled thermoplastic polymer composites. J. Therm. Anal. Calorim. 76:395–404.10.1023/B:JTAN.0000028020.02657.9bSearch in Google Scholar

Kong, L., Guan, H., Wang, X. (2018) In situ polymerization of furfuryl alcohol with ammonium dihydrogen phosphate in poplar wood for improved dimensional stability and flame retardancy. ACS Sustain. Chem. Eng. 6:3349–3357.10.1021/acssuschemeng.7b03518Search in Google Scholar

Kumar, A., Ryparová, P., Škapin, A.S., Humar, M., Pavlič, M., Tywoniak, J., Hajek, P., Žigon, J., Petrič, M. (2016) Influence of surface modification of wood with octadecyltrichlorosilane on its dimensional stability and resistance against Coniophora puteana and molds. Cellulose 23:3249–3263.10.1007/s10570-016-1009-8Search in Google Scholar

Kumar, A., Richter, J., Tywoniak, J., Hajek, P., Adamopoulos, S., Šegedin, U., Petrič, M. (2017) Surface modification of Norway spruce wood by octadecyltrichlorosilane (OTS) nanosol by dipping and water vapour diffusion properties of the OTS-modified wood. Holzforschung 72:45–56.10.1515/hf-2017-0087Search in Google Scholar

Li, L., Liu, S., Xu, J., Yu, S., Liu, F., Xie, C., Ge, X., Ren, J. (2013) Esterification of itaconic acid using Ln~ SO42−/TiO2–SiO2 (Ln=La3+, Ce4+, Sm3+) as catalysts. J. Mol. Catal. Chem. 368:24–30.10.1016/j.molcata.2012.11.008Search in Google Scholar

Liu, W., Zhang, L., Ye, X. (2019) Preparation and characterisation of wood flour/polystyrene composites by subcritical fluid-assisted reactive extrusion. Plast. Rubber Compos. 48:307–316.10.1080/14658011.2019.1621072Search in Google Scholar

Matsuda, H. (2017) Chemical modification of solid wood. In: Chemical Modification of Lignocellulosic Materials. Routledge, New York, NY, USA. pp. 159–183.10.1201/9781315139142-6Search in Google Scholar

Mattos, B.D., Lourençon, T.V., Serrano, L., Labidi, J., Gatto, D.A. (2015) Chemical modification of fast-growing eucalyptus wood. Wood Sci. Technol. 49:273–288.10.1007/s00226-014-0690-8Search in Google Scholar

Medway, A.M., Sperry, J. (2014) Heterocycle construction using the biomass-derived building block itaconic acid. Green Chem. 16:2084–2101.10.1039/C4GC00014ESearch in Google Scholar

Qiao, Y., Wang, B., Ji, Y., Xu, F., Zong, P., Zhang, J., Tian, Y. (2019) Thermal decomposition of castor oil, corn starch, soy protein, lignin, xylan, and cellulose during fast pyrolysis. Bioresour. Technol. 278:287–295.10.1016/j.biortech.2019.01.102Search in Google Scholar PubMed

Rani, M., Shim, W.J., Han, G.M., Jang, M., Song, Y.K., Hong, S.H. (2014) Hexabromocyclododecane in polystyrene based consumer products: an evidence of unregulated use. Chemosphere 110:111–119.10.1016/j.chemosphere.2014.02.022Search in Google Scholar PubMed

Robert, T., Friebel, S. (2016) Itaconic acid – a versatile building block for renewable polyesters with enhanced functionality. Green Chem. 18:2922–2934.10.1039/C6GC00605ASearch in Google Scholar

Schirp, A., Su, S. (2016) Effectiveness of pre-treated wood particles and halogen-free flame retardants used in wood-plastic composites. Polym. Degrad. Stab. 126:81–92.10.1016/j.polymdegradstab.2016.01.016Search in Google Scholar

Segal, L., Creely, J., Martin Jr, A., Conrad, C.M. (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 29:786–794.10.1177/004051755902901003Search in Google Scholar

Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts. John Wiley & Sons, West Sussex, England, 2004.Search in Google Scholar

Sun, Y., Gu, J., Tan, H., Zhang, Y., Huo, P. (2018) Physicochemical properties of starch adhesives enhanced by esterification modification with dodecenyl succinic anhydride. Int. J. Biol. Macromol. 112:1257–1263.10.1016/j.ijbiomac.2018.01.222Search in Google Scholar PubMed

Tammer, M.G. Sokrates: Infrared and Raman Characteristic Group Frequencies: Tables and Charts. Springer, Leipzig, Germany, 2004.10.1007/s00396-004-1164-6Search in Google Scholar

Wang, K., Dong, Y., Yan, Y., Zhang, S., Li, J. (2018) Improving dimensional stability and durability of wood polymer composites by grafting polystyrene onto wood cell walls. Polym. Compos. 39:119–125.10.1002/pc.23912Search in Google Scholar

Yang, H., Yan, R., Chen, H., Lee, D.H., Zheng, C. (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788.10.1016/j.fuel.2006.12.013Search in Google Scholar

Yao, M., Yang, Y., Song, J., Yu, Y., Jin, Y. (2017) Melamine formaldehyde modified furfurylation to improve Chinese fir’s dimensional stability and mechanical properties. BioResources 12:3057–3066.10.15376/biores.12.2.3057-3066Search in Google Scholar

©2019 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- An effective technique for constructing wood composite with superior dimensional stability

- Numerical analysis of moisture-induced strains and stresses in glued-laminated timber

- Contribution of lignin to the stress transfer in compression wood viewed by tensile FTIR loading

- Effect of enzymatic hydrolysis lignin on the mechanical strength and hydrophobic properties of molded fiber materials

- Investigating tool engagement in groundwood pulping: finite element modelling and in-situ observations at the microscale

- Defoliation by insects reduces the wood quality and cellulosic pulp production

- Effect of pulp fibers on the surface softness component of hygiene paper

- Cellulose triacetate from different sources: modification assessment through thermal and chemical characterization

- Incorporation of nano lignin reverse micelles on the transparency, UV-blocking and rheological properties of high-density polyethylene films

- Cellulose nanocrystals/silver nanoparticles: in-situ preparation and application in PVA films

- Larch-derived hierarchical nitrogen-doped carbon with echinus-like architecture for supercapacitor applications

Articles in the same Issue

- Frontmatter

- An effective technique for constructing wood composite with superior dimensional stability

- Numerical analysis of moisture-induced strains and stresses in glued-laminated timber

- Contribution of lignin to the stress transfer in compression wood viewed by tensile FTIR loading

- Effect of enzymatic hydrolysis lignin on the mechanical strength and hydrophobic properties of molded fiber materials

- Investigating tool engagement in groundwood pulping: finite element modelling and in-situ observations at the microscale

- Defoliation by insects reduces the wood quality and cellulosic pulp production

- Effect of pulp fibers on the surface softness component of hygiene paper

- Cellulose triacetate from different sources: modification assessment through thermal and chemical characterization

- Incorporation of nano lignin reverse micelles on the transparency, UV-blocking and rheological properties of high-density polyethylene films

- Cellulose nanocrystals/silver nanoparticles: in-situ preparation and application in PVA films

- Larch-derived hierarchical nitrogen-doped carbon with echinus-like architecture for supercapacitor applications