Abstract

Purpose

The purpose of this study is to critically analyze various parameters that improve the latent heat transfer in heat exchangers. There has been a continuous increase in greenhouse gases because of industrial activities across the world. Consequently, it has become critical to harness renewable energy as a powerful substitute for meeting future energy needs. Thus, phase change materials (PCM) and heat transfer fluids have been instituted as alternatives for activities related to heat transfer enhancement employing heat exchangers with different fin configurations.

Methodology

The present work deals with the comparative analysis of thermal performance of longitudinal and circular finned heat exchangers. For creating a detailed summary of various computational cum experimental endeavours, efforts have been made to compile a refined picture of design variations and thermal performances of PCM-based latent thermal energy storage system (PCM – LTESS).

Findings

The comparative analysis of longitudinal as well as circular finned tube arrangement revealed that the latter has better thermal characteristics. However, various fin arrangements have also been explored as part of this review.

Originality

A significant improvement in heat transfer is observed when heat sinks clubbed with PCM-based arrangement are integrated with pin fins. These are frequently instituted for heat transfer enhancement or thermal energy management of various electronic goods with optimum number and size of fins.

Nomenclature

- ANN

-

Artificial Neural Network

- B m

-

Bingham number

- C p

-

Specific heat (kJ/kg K)

- D, d

-

Diameter (m)

- F o

-

Fourier Number

- H

-

Heat Transfer coefficient (W/m2 K)

- HTF

-

Heat-transfer fluid

- HXs

-

Heat exchangers

- K

-

Thermal conductivity (W/m K)

- L,l

-

Length (m)

- LHTES

-

Latent heat thermal energy storage

- LHTESS

-

Latent heat thermal energy storage system

- M

-

Mass (kg)

- m

-

Mass flow rate (kg/s)

- NTU

-

Number of transfer units

- Nu

-

Nusselt number

- Pr

-

Prandtl number

- PCM

-

Phase-change material

- Ra

-

Rayleigh number

- Re

-

Reynolds number

- r

-

Tube radius (m)

- SHTES

-

Sensible heat thermal energy storage

- Ste

-

Stefan number

- t

-

Time (s), thickness (m)

- T

-

Temperature (°C or K)

- TESS

-

Thermal energy storage system

- TTHX

-

Triplex tube heat exchanger

- T m

-

Melting temperature (°C or K)

- V

-

Velocity (m/s)

- x, y, z

-

x, y, z-component in a Cartesian coordinate system

- Z

-

Fin height (m)

Greek Letters

- α

-

Thermal diffusivity of PCM (m2/s)

- β

-

Coefficient of volumetric expansion (1/K)

- ε

-

Eemissivity, emittance

- γ

-

Liquid fraction

- η

-

Efficiency

Subscripts

- eff

-

Effective

- f

-

Fluid

- fin

-

Fin

- i

-

Inner (inlet)

- I

-

Liquid

- M

-

Melting

- O

-

Outer

- P

-

Phase-change material

- Ref

-

References

- s

-

Solid

1 Introduction

The present annual energy requirement (thermal and electrical) is recognised as 2.3 × 1011 MWh by the end of the year 2035 (Zhang et al. 2016). Various kinds of industrial and non-industrial entities are heavily dependent on fossil fuels as far as their daily needs are concerned. Quite intriguingly, the previous data show a huge amount of energy losses (31%) as a part of the conversion from raw form to useful version apart from several eco-related issues (Tian and Zhao 2013). Keeping this in view, the research community has been givev huge thrust upon achievement of the better degree of sustainability as far as the consumption of scarce thermal entities is concerned (Taneja et al. 2013, 2021). Further, solar being most cheapest renewable energy fuel, stands out as a better and a convenient option in comparison to other alternatives such as wind or geothermal for all types of domestic and non-domestic purposes. Also, to address night-time thermal energy requirements for a variety of applications, solar-integrated thermal units have become the talk of the days, with the help of which availability of thermal energy can be ensured throughout the complete year (Erek et al. 2005). In continuation of the same, sensible and latent heat accumulations are the types of thermal energy storage systems (TESS) that are most commonly employed for harnessing the thermal content of solar energy (Fisch et al. 1998). Depending on the configuration of the storage system, there must be adherence to temperature and design-related specifications, and energy storage in huge quantities must be customized in nature as well (Fernandez et al. 2010).

In line with the same, Trp (2005) diagnosed the charging and discharging behaviour of phase change material (PCM) paraffin wax (RT30) for shell and tube heat exchanger configuration through detailed experimental and non-experimental approaches. Post comprehensive comparative exploration of different configurations like liquid–gas, solid–solid and solid–liquid are considered to identify charging/discharging properties (Regin et al. 2008). Despite many disadvantageous features of PCM, there is always a need for special care as far as appropriate selection of the same is concerned in line with the particular kind of application. Also, several research initiatives have been put in place such as the use of PCMs in blended mode in combination with nanoparticles, use of multiple tube arrangement, involving microencapsulation, and modified design of TESS to seek a better degree of thermal performance (Jegadheeswaran and Pohekar 2009, Ho and Gao 2009, Fan and Khodadadi 2012, Dhaidan et al. 2013, Mahdi and Nsofor 2016, Mozafari et al. 2022, Elbahjaoui and Qarnia 2017). In a similar row, most fruitful heat transfer calibre/abilities were adjudged to be associated with fin-based heat exchanger configurations. Therefore, the present approach not only compiles end results from various configurations/approaches, but also through a broad light on performance entities/derivatives such as thermal efficiency, geometrical parameters and few other conforming and some non-conforming design-related features (Agyenim et al. 2009, 2011, Mat et al. 2013, Al-Abidi et al. 2014, Rathod and Banerjee 2015).

2 PCM-assisted latent heat thermal energy storage system (LHTESS)

Basically, storage materials are used in two forms for the storage of energy, i.e. solid or liquid, which can be released or used in line with temperature–time combinations. The thermal energy is usually collected in the PCM-assisted latent energy storage device under certain specified temperature conditions. So, in view of space constraints, it seems highly imperative that latent thermal energy storage entities must be highly efficient as well as suitable for a variety of PCM materials owing to their being less conductive (k ≤ 0.2 W/m K) and environment-dependent nature particularly when it undergoes charging and discharging protocols and sometimes in case of overheating related problems (Morrison and Abdel-Khalik 1978, Ghoneim 1989). So, it makes good sense to develop such TESS which would undoubtedly assist in harnessing the highest possible energy potential associated with thermal performance.

2.1 Classification of PCMs

As far as the classification of PCM materials is concerned, they fall into the categories of solid, liquid and gas, and a combination of the mentioned types, i.e., solid–liquid and liquid–gas, etc., to find the most suitable combination/blend for a particular kind of heat exchanger configuration. The broad classification of PCMs is displayed in Figure 1.

2.2 Selection criterion of the PCM

There must be keen focus on the key characteristics/considerations of PCM materials as far as thermal energy storage applications are concerned, particularly features pertaining to thermodynamic as well as non-thermodynamic domain and of course economic considerations in accordance with charging and discharging behaviour. For example, there is a requirement for optimum value of thermal conductivity for domestic heating applications in the temperature range 0°–65° (Abhat 1983). Besides, fulfilling crystal growth is immensely needed for recovery of heat content from LHTESS apart from securing better nucleation rate at high-temperature gradients, in line with chemical properties such as non-virulent, non-flammable and non-fulminating, and the availability of the same at low-cost value (Lamberg et al. 2004).

2.3 Design configuration of PCM-based LHTESS

It is paramount to note that the role of design parameters associated with PCM-assisted heat exchanger units has quite significant and impactful bearing on the energy conversion rate as well as the thermal behaviour of the entire system. Various configurations of the generally used PCM containers are represented in Figure 2.

Moreover, as far as the suitability of a PCM about its applications is concerned, it must have close conformation with the same. The characterization of PCM-based LHTESS, i.e., cylindrical (Figure 2a), rectangular (Figure 2b) and the spherical (Figure 2c) is shown in Figure 2. The cylindrical heat exchangers are employed for commercial purpose activities owing to small volumetric space and much higher efficiency (Tan et al. 2009, Venkata-chalapathy et al. 2015).

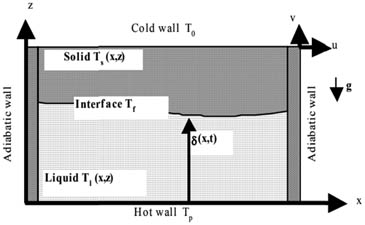

The cylindrical heat exchanger configuration is shown in Figure 2a, where, the PCM fills the outer shell while the heat transfer fluid (HTF) flows through the inner pipe. As per the literature finding of Hosseini et al. (2014), it has been identified that upon raising the temperature of PCM from 70 to 75°C and 75 to 80°C, the efficiency of charging and discharging characteristics of PCM increases to 5.6 and 1.7%, respectively. Besides, the effect of the Reynolds Number has also been studied while exploring melting and solidification characteristics (Jesumathy et al. 2012). Among various configurations instituted to harness solar energy, the rectangular model was found to be of significant value, particularly in entities such as solar energy systems, nuclear reactors and geothermal energy units (Arasu and Mujumdar 2012, Jellouli et al. 2007). On a similar note, Lamberg et al. (2004) experimentally as well as numerically explored the discharging behaviour of the PCM in a rectangular enclosure, even in natural convection conditions where the PCM was found to exhibit a close match with analytical outcomes only in the beginning stage. In addition, as the melting proceeds, the experimental interface secures a position far ahead of its analytical counterpart (Stritih 2004). Thus, many researchers have shown deep interest in the rectangular configuration because of shape simplicity and easily implementable boundary conditions, making them ideal geometry for thermal energy storage purposes for a variety of applications.

The configuration of the rectangular heat exchanger is shown in Figure 2b. Further, several research studies have been reported for the spherical shape type TESS also, as shown in Figure 2c. UmaMaheswari and Reddy (2004) performed some numerical investigation for spherical shape type heat exchangers. On a similar approach, Assis et al. (2007a) executed some numerical as well as experimental studies on determination of thermal properties of Paraffin Wax PCM (RT27) with 98% PCM packing in spherical container as a necessary condition simulation. The heat transfer rate was found to be significantly influenced by geometrical as well as thermal characteristics in case of normal PCM, whereas nano-particle assisted PCM improves the thermal conductivity in line with a decrement in latent heat of fusion (Assis et al. 2009). Moreover, researchers have also reported that the role of random packing was more prominent as compared to customized packing, i.e., encapsulation properties have an important impact on thermal energy storage characteristics of heat exchanger (Xia et al. 2010). For further details, refer Tables 1–3.

Different cylindrical configurations of PCM-based LHTESS

| Refs. | Nature of study | Design configurations | Figure/geometry | PCM used | Materials of constructions | Varying parameter | Major findings |

|---|---|---|---|---|---|---|---|

| a. Condition: Cylindrical design configuration for charging | |||||||

| Niyas and Muthukumar (2013) | Numerical (charging) | Shell and tube |

|

Paraffin RT-50 | Copper | Heat flux, PCM mass | Increasing charging rate |

| Mat et al. (2013) | Numerical (charging) | Triplex tube heat exchanger (TTHX) |

|

Rubitherm GmbH-Germany (RT82) | Copper | Heat flux | Enhancing charging rate, Reducing charging time |

| Mahfuz et al. (2014) | Experimental (charging) | Shell and tube |

|

Paraffin Wax | Copper | HTF mass flow rate, Energy, exergy | Enhancing mass flow rate, Reducing life cycle price |

| Agyenim et al. (2010a) | Experimental (charging) | Shell and multiple tubes |

|

Erythritol | Aluminium and copper tube | HTF directions: Axil, radial and angular | Enhancing melting rate, Reducing melting time |

| Ng et al. (1998) | Numerical (charging) | Annulus |

|

n-Octadecane | — | Heat flux | Improving charging and discharging rate |

| Agyenim et al. (2009) | Experimental (charging) | Concentric tube |

|

Erythritol | Aluminium and copper | HTF mass flow rate, HTF initial temperature | For a specified (8-h) charge, melting was not complete |

| b. Condition: Cylindrical design configuration for discharging | |||||||

| Hosseini et al. (2014) | Numerical and experimental (discharging) | Shell and tube |

|

Paraffin RT50 | Copper | HTF, Initial temperature | Enhancing heat transfer rate, reducing charging time, Decreasing heat transfer rate and charging fraction |

| Akgün et al. (2007) | Experimental (discharging) | Concentric annulus |

|

Paraffin wax | Mild steel and stainless steel | HTF mass flow rate -Re | Increasing Re and mass flow rate, Increasing heat transfer rate, melt fraction |

| Jian-you (2008) | Experimental and numerical (discharging) | TTHX |

|

n-Hexacosane | Copper | HTF mass flow rate, HTF initial temperature | Improving mass flow rate, improving charging rate, reducing charging time |

Different rectangular configurations of PCM-based LHTESS

| Refs. | Nature of study | Design configurations | Figure/geometry | PCM used | Materials of constructions | Varying parameter | Major findings |

|---|---|---|---|---|---|---|---|

| a. Condition: Rectangular design configuration for charging | |||||||

| Jellouli et al. (2007) | Numerical (charging) | Rectangular |

|

— | — | Heat flux | Enhancing natural convection |

| Stritih (2004) | Experimental and numerical (charging) | Rectangular |

|

RUBITHERM, RT 30 Paraffin | Steel | Heat flux | Enhancing the conduction heat transfer |

| Lamberg et al. (2004) | Experimental and numerical (charging) | Rectangular |

|

Technical grade paraffin | Solid aluminium, tufnol phenolic fabric, 6063-T5 aluminium | Heat flux | Enhancing natural convection |

| Arasu and Mujumdar (2012) | Numerical (charging) | Rectangular |

|

Paraffin wax | — | Heat flux | Enhancing the thermal conductivity of heat transfer |

| b. Condition: Rectangular design configuration for discharging | |||||||

| Gharebaghi and Sezai (2007) | Numerical (charging and discharging) | Rectangular |

|

Rubitherm RT27 | Aluminium | — | In a rectangular system, the minimum augmentation rate attained with widely separated fins was three times higher |

| Talukdar et al. (2019) | Numerical and experimental (charging and discharging) | Rectangular |

|

Water | Stainless Steel | Compressor, a condenser, and an expansion valve | Enhancing heat transfer rate |

| Motahar et al. (2017) | Experimental (discharging) | Rectangular |

|

n-Octadecane | Acrylic Glass | Fourier number (Fo), Rayleigh number (Ra), solid Stefan number (St), Bingham number and mass fraction of nanoparticles | Solidification rate was enhanced by dispersing nanoparticles |

| Gürel (2020) | Numerical (discharging) | Rectangular plate |

|

RT-35 and n-octadecane | Perspex | Plate geometry HTF initial temperature PCMs | Enhancing heat transfer rate and reduce solidification time |

Different rectangular configurations of PCM-based LHTESS

| Refs. | Nature of study | Design configurations | Figure/geometry | PCM used | Materials of constructions | Varying parameter | Major findings |

|---|---|---|---|---|---|---|---|

| a. Condition: Spherical design configuration for charging | |||||||

| Tan et al. (2009) | Numerical and experimental (charging) | Spherical |

|

n-Octadecane | Glass | Heat flux | For less charging point in capsule due to enhancing phase change rate |

| Hosseinizadeh et al. (2012) | Numerical (charging) | Spherical |

|

RT27 | Plexiglas | Heat flux | Enhancing PCM charging rate |

| Assis et al. (2007b) | Numerical and experimental (charging) | Spherical |

|

RT27 | — | Heat flux and operating temperature | Enhancing PCM charging rate |

| Gao et al. (2019) | Numerical (charging) | Spherical |

|

n-Octadecane | — | Ra, Pr, α | Increasing PCM charging rate |

| Liao et al. (2018) | Numerical (charging) | Spherical |

|

NaNO3 | Steel | Heat flux, encapsulations | Enhancing PCM charging rate |

| Amin et al. (2014) | Numerical (charging) | Spherical |

|

Water | Medium-density polyethylene | Heat flux, encapsulations | Enhancing phase change rate |

| b. Condition: Spherical design configuration for discharging | |||||||

| Assis et al. (2009) | Numerical and experimental (discharging) | Spherical |

|

RT27 | Plastic | Heat flux | Enhancing PCM charging rate |

| Cho and Choi (2000) | Experimental (discharging and charging) | Spherical |

|

n-Tetradecane (C14H30), n-hexadecane (C16H34) and water | Acryl | Re, initial temperature | Enhancing heat transfer coefficient up to 40% |

| Singh et al. (2023) | Experimental and numerical (discharging) | Spherical |

|

Paraffin wax | Pyrex, glass | Total time, Melt fractions | Enhancing heat transfer rate |

| Galione et al. (2015) | Experimental and numerical (charging and discharging) | Spherical |

|

n-Octadecane | Glass | Flow pattern, thermophysical properties | Enhancing heat transfer rate |

| Eames and Adref (2002) | Experimental (discharging and charging) | Spherical |

|

Water | Glass | HTF temperature | Enhancing the charging and discharging rate of spherical ice thermal storage elements |

| Lago et al. (2020) | Experimental (discharging) | Spherical |

|

Pure water or a mixture of polyethylene glycol and water) | Polystyrene | Super cooling polyethylene glycol | Enhancing the diameter of the spherical shell is found to increase the time for complete solidification |

3 Heat transfer augmentation techniques

Rising energy costs and material costs have compelled academics all around the world to find new techniques to improve heat transfer performance in all types of heat exchangers over the last several decades (HXs). Enhancing heat transfer in a latent heat thermal storage can be done in a number of ways: enhancement of thermal conductivity using low-density materials such as carbon fibres and paraffin composites exchanger (Sun et al. 2007), porous materials such as metal foams (copper or aluminium) or porous materials like graphite exchanger (Jegadheeswaran and Pohekar 2009, Wang et al. 2009b, Tian and Zhao 2011), metal matrices exchanger (Srivatsa et al. 2014), and encapsulation methods using graphite (Trelles and Dufly 2003), polymers, or the nickel film coating of PCM copper spheres exchanger (Amaral et al. 2017), enhancement with fins (expanded surface of metal) exchanger (Sciacovelli et al. 2015), and multiple PCMs exchanger (Sun et al. 2007), and direct heat transfer procedures exchanger (Wang et al. 2009a). The utilization of expanded surfaces such as fins and multiple PCMs with various melting points is the most common improvement strategy. Ibrahim et al. (2017) conducted a general overview of some of these strategies. Details are shown in Figure 3.

3.1 Fin-based heat transfer augmentation techniques

Since low thermal conductivity is a highly undesirable feature of most PCMs, it is quite pertinent to address this problem for seeking augmentation in heat transfer characteristics of PCMs. In order to seek fulfilment of the statement just mentioned above, various shapes of fins such as longitudinal, circular, spiral, plate and pin–fin arrangements are incorporated in PCMs to secure better thermal ratings of LHTESS. Moreover, the decision related to the use of a particular shape of fin depends on factors such as space, enhancement in heat transfer surface, low construction cost and most importantly ease of fabrication. The above-mentioned fins are shown in Figure 4.

3.1.1 Longitudinal fins

It is interesting to note that most of the researchers have achieved significant success in understanding the thermodynamic behaviour of LHTESS wherein the fins are mounted on the circumference of the PCM container. Also, simplicity and ease of fabrication played a pivotal role in securing better thermal performance in line with the statement mentioned above. Similarly, Gharebaghi and Sezai (2007) performed the simulation exercises on a rectangular PCM container coupled with horizontal fins added to the vertical heated walls. Both (vertical or horizontal) the heated walls were maintained at a temperature higher than the melting point of PCMs. There has been an intriguing outcome of the above-mentioned technique, i.e., vertical walls in association with horizontal fins, which enhanced the overall heat transfer of the system. In another similar research initiative, Al-Abidi et al. (2014) identified the role of mass flow rates on PCM melting as well as the impact of steady/unsteady conditions on HTF inlet temperature. Further, Velraj et al. (1997) employed circular pipe having longitudinal fins on the inner surface to study the behaviour of PCM in terms of thermal resistance decreases.

Moreover, the time taken for solidification without fin arrangement was reported to be n times higher than that of fin arrangement. Besides, the same author has presented its study on outward cylindrical solidification for a double pipe heat exchanger system wherein the PCM employed in the free cooling arrangement was empirically examined. Therefore, this can be concluded that longitudinal fins increase the cooling rate thereby reducing the solidification time exchanger (Rathod and Banerjee 2015, Solomon and Velraj 2013). For all the sorts of fins configuration, i.e., internal, external or a combination thereof in the PCM container, the preferred fin material primarily is copper exchanger (Solomon and Velraj 2013) as detailed in Table 4.

Fin enhancement techniques in PCM-based LHTESS

| Refs. | Nature of study | Design configurations | Figure/geometry of fin | Materials constructions of fin | Varying parameters | Major findings |

|---|---|---|---|---|---|---|

| Condition: Longitudinal fin configuration | ||||||

| Velraj et al. (1997) | Experimental (discharging) | Cylindrical |

|

Aluminium | Heat flux | Enhancing heat cooling rate and reducing discharging time |

| Rathod and Banerjee (2015) | Experimental (charging and discharging) | Shell and tube |

|

Brass | Heat flux, HTF, initial temperature | Heat transmission rises as the HTF-initial temperature rises faster than the HTF mass flow rate |

| Baba et al. (2018) | Experimental study | Double pipe |

|

Stainless steel | HTF, Reynolds number | Enhancing heat transfer rate in the finned tube HXs is 90–98% greater than the heat transfer rate in plain tube HXs |

| Agyenim et al. (2009) | Experimental (charging) | Concentric tube |

|

Copper | HTF, mass flow rate, HTF, initial temperature | Using longitudinal fin PCM charging completed |

| Li et al. (2010) | Experimental (charging and discharging) | Circular tube |

|

Copper | Heat flux | On the PCM, there is a consistent temperature range |

| Gharebaghi and Sezai (2007) | Numerical (charging) | Rectangular |

|

Aluminium | Heat flux | Using longitudinal fin enhancing the heat transfer rate |

| Al-Abidi et al. (2014) | Experimental (charging and discharging) | TTHX |

|

Copper | HTF, Mass flow rate, HTF, initial temperature | The temperature of the HTF’s inlet has a greater impact than the temperature of the HTF mass flow rate on the PCM |

| Mat et al. (2013) | Numerical (charging) | TTHX |

|

Copper | Heat flux | Enhancing charging rate utilizing the fin |

| Sharifi et al. (2011) | Numerical (charging) | Rectangular |

|

Copper | Heat flux | Enhancing charging rate utilizing the fin |

| Lamberg et al. (2004) | Numerical (charging and discharging) | Rectangular |

|

Aluminium | HTF, temperature | Using longitudinal fin enhancing the heat transfer rate |

| Condition: Circular fin configurations | ||||||

| Choi and Kim (1995) | Experimental (discharging) | Shell and tube with annular fin |

|

Stainless steel | HTF, mass flow rate, HTF, initial temperature | Enhancing cooling rate and radial temperature distribution |

| Lacroix (1993) | Numerical (charging) | Shell and tube with circular fin |

|

Copper | HTF, mass flow rate, HTF, initial temperature | Increasing the PCM energy storage |

| Seeniraj et al. (2002) | Numerical (charging) | Shell and tube with circular fin |

|

— | HTF, exit temperature | Enhancing the PCM energy storage |

| Ermis et al. (2007) | Experimental and numerical (charging and discharging) | Pipe circular fin |

|

Bronze | HTF, mass flow rate, HTF, initial temperature | The ANN approach worked well in predicting the total quantity of heat stored. |

| Groulx and Ogoh (2009) | Numerical (charging) | Cylindrical with circular fin |

|

Copper | Heat flux | Enhancing PCM phase change |

| Mosaffa et al. (2012) | Analytical (discharging) | Shell and tube with circular fin |

|

Highly conductive base material | HTF, mass flow rate, HTF, initial temperature | Easily and fast solidify in cylindrical compared to rectangular container |

| Robak et al. (2011) | Experimental (charging) | Circular tube |

|

Aluminium and copper | Heat flux | Fins did not work well. |

| Condition: Spiral fin configurations | ||||||

| Banaszek et al. (1999) | Experimental (charging and discharging) | Cylindrical with spiral geometry |

|

Copper | HTF, solid liquid phase change | Enhancing the charging and discharging rate |

| Erek and Ezan (2006) | Experimental and numerical (charging) | Spiral tube |

|

Polyethylene | Flow rate and temperature | Obtain an optimum geometrical, flow and thermal conditions for TESS |

| Bahiraei et al. (2019) | Numerical (charging) | Helical coil tube |

|

Aluminium | HTF initial temperature and Re | Enhancing the heat transfer rate |

| Borhani et al. (2019) | Numerical (charging) | Spiral fin tube |

|

Copper | HTF initial temperature | Enhancing the charging rate |

| Lu et al. (2021) | Experimental (charging and discharging) | Vertical shell and spiral fin tube |

|

Copper | HTF initial temperature charging and discharging time | Enhancing the charging and discharging rate |

| Noorbakhsh et al. (2020) | Numerical (charging) | Twisted tape in double pipe heat exchanger |

|

— | Pressure drop, Nusselt number and coefficient of performance | Enhancing the heat transfer rate |

| Condition: Plate fin configurations | ||||||

| Campos-Celador et al. (2013) | Numerical (charging) | Heat sink |

|

Aluminium | Heat flux | PCM performance is influenced by the enclosure aspect ratio |

| Ye et al. (2011) | Numerical (charging and discharging) | Rectangular |

|

Aluminium | Heat flux, HTF, initial temperature | Enhancement of heat transfer rate and storage of PCM |

| Rahimi et al. (2014) | Numerical (charging and discharging) | Rectangular |

|

Aluminium and stainless steel | Operating temperature | Enhancing the storage of PCM |

| Saha and Dutta (2010) | Experimental (charging and discharging) | Shell and tube |

|

Aluminium | HTF, initial temperature | Reducing the charging and discharging time |

| Condition: Pin fin configuration | ||||||

| Fok et al. (2010) | Experimental (charging) | Heat sink |

|

Aluminium | Heat flux | Enhancing heat transfer rate |

| Jaworski (2012) | Experimental and numerical (discharging) | Radiator |

|

Copper and aluminium | Heat flux | Enhancing cooling rate |

| Baby and Balaji (2013) | Experimental and numerical (discharging) | Heat sink |

|

Aluminium | Heat flux | Improvement of heat transfer rate |

| Rajabifar et al. (2016) | Numerical (charging) | Micro pin fin heat sink |

|

Silicon | Heat flux | Enhancement of heat transfer rate due to nano encapsulation on the PCM |

| Srikanth and Balaji (2017) | Experimental (charging) | Heat sink with discrete heating |

|

Silicon | Heat flux | Enhancement of heat transfer rate |

3.1.2 Circular fins

Extending the previous discussion, this section deals with the circular fins. In order to augment the heat transfer rates in different cylindrical containers, the circular fins were instituted to achieve the desired purpose. Mosaffa et al. (2012) suggested an analytical model for performance assessment of shell and finned based tube used in air conditioning exercise. The solidification characteristics found to have similar nature for cylindrical as well as rectangular PCM container bearing the same heat transfer area. In a separate kind of research initiative, Lacroix (1993) proposed a numerical approach to study the melting behaviour of PCM in a shell with annular fins around the tube’s circumference. Jung and Boo (2014) proposed an analytical protocol to forecast unsteady/transient thermal characteristics of PCM-packed finned heat pipe-assisted LHTESS in the absence of natural convection.

In an intriguing numerical exercise, Ermis et al. (2007) implemented artificial neural network (ANN) Feed Forward Back Propagation algorithm to solve the governing equations meant for HTF, Pipe Wall and PCM, to unearth or estimate the impact of fin and flow parameters upon overall performance of TESS. The results showed quite a close match of predicted values with simulated ones. Therefore, it could be perfectly concluded that upon addition of circular fins to the LHTESS, a substantial rise in heat transfer capabilities was reported for the said system apart from improved liquid fraction rate during melting and solidification process as given in Table 4.

3.1.3 Spiral fins

The compact shape and rapid heat transfer rates are the characteristics of spiral fins heat exchanger and thus their thermodynamic performance is excellent. In a similar direction, several research initiatives are going on to seek further improvement in their thermodynamic performances. Bharadwaj et al. (2009) investigated the pressure drop and heat transfer behaviour of a flow (Laminar/Turbulent) through a spirally grooved tube having twisted tape inserts inside it, wherein the heat transfer rates had a substantial rise. Further, Naphon (2011) performed experimental investigation of heat transfer and flow properties of a horizontal spiral coil tube arrangement wherein Nusselt number and pressure drop were found to have a higher magnitude in comparison with its straight tube counterpart as given in Table 4.

On the same lines, Li et al. (2012) devised an approach to improve heat transfer behaviour of a smooth helical tube wherein whirling motion was ascertained as the main reason responsible for the better degree of heat transfer at the cost of slightly higher pressure drop in the current system. Another similar research by Pongsoi et al. (2014) unearthed the air-side performance of spiral fin and tube heat exchangers. Moreover, the counter current spiral heat exchanger was studied by Nguyen and San (2016a). Also, the optimal Number of Transfer Units at maximum heat transfer effectiveness increases as the number of spiral turns increases exchanger (Nguyen and San 2016b). Besides, Nunez et al. (2009) presented a design approach for spiral heat exchanger wherein it was discovered that heat transfer coefficient, which was the main reason behind pressure drop owing to friction, was used as a parameter to decide the dimension of heat exchanger. In addition, the constant changes in the direction of fluid flow resulted in an increased magnitudes of heat transfer coefficient values exchanger (Son and Shin 2001). In another related study, the heat transfer characteristics of a spirally coiled circular fin-tube heat exchanger were examined (Altac and Altun 2014). Apart from the above-mentioned research, the researcher has also calculated parameters, such as frost thickness, pressure drop, heat transfer rate, and Nusselt number (Lee et al. 2011) as depicted in Table 4.

3.1.4 Plate fins

The plate fins generally made of aluminium exchanger (Ye et al. 2011) and stainless-steel exchanger (Rahimi et al. 2014) are widely employed for constructing LHTESS mainly because of properties such as high thermal conductivity. In addition, Campos-Celador et al. (2013) roped in three solver approaches, such as analytical, numerical and simpler numerical methods, for assessing the thermal performance of LHTESS with plate fins. Owing to the inability of analytical approach to comprehensively judge the thermal performance of long fins, a simpler numerical approach was designed which is easier for computation of thermal performances for a variety of fins. In the same direction, Ye et al. (2011) numerically explored the pattern of energy storage as well as release in plate fin-based LHTESS under uniform thermal conditions in heating as well as cooling mode.

Extending the similar exercise, Wang and Li (2016) investigated traditional design practices for multi–stream plate fin heat exchangers and dealt with the development of methods for layer pattern design. From the above-mentioned discussion, this could be concluded that finned plate technology is the best-suited approach for LHTESS, having rectangular shape as a key design configuration which not only facilitates space integration but also simplifies the production process owing to plane surfaces being used as depicted in Table 4.

3.1.5 Pin fins

The thermal management has quite significant role as far as heat transmission in electrical as well as electronic components is concerned. The optimum heat transfer is the outcome of appropriate thermal management of equipment working within permissible temperature limits that too in line with robust design and construction of the same. Further, it is quite understandable that the low thermal conductivity value of PCM is the main deterrence in the design of PCM-assisted electrical cooling devices. However, to address the above deficiencies, the PCM-based heat sinks were modified by adding pin fins to bring qualitative improvement in the performance of LHTESS.

In line with the above discussion, Pakrouh et al. (2015) determined the energy transfer rates of pin fin heat sinks using PCMs to judge their effectiveness for electronics equipment. Some studies similar to Jaworski’s (2012) assessed the performance characteristics of pin fin type heat sink having PCM injected into the tubes of heat exchanger. Additionally, Fok et al. (2010) conducted a series of experimentations on PCM-assisted cooling of electronic equipment using pin fin type heat sinks only to identify that the copper/aluminium made pin fins compensate for the low thermal conductivity value of PCM-assisted heat transfer operations as given in Table 4.

3.1.6 Novel fins

In some miscellaneous occurrences, few of the researchers identified some novel design combinations, using which the charging and discharging efficiency could be optimised. In the same line, Sciacovelli et al. (2015) involved single or double bifurcation tree-shaped fin to conclude that discharging efficiency is raised as high as up to 24%. Besides, Kurnia et al. (2013) quantitatively examined the PCM-based LHTESS in connection with design configurations, such as U-tube, U-tube with plane/staggered fins inside apart from an innovative festoon design as shown in Figure 5. The involvement of innovative design has led to higher heat transmission rate during charging and discharging conditions. The present review has compiled some of the novel studies that state that sometimes different shapes and designs play some crucial role in heat transfer enhancement as far as LHTESS is concerned as given in Table 5.

(a) U-tube, (b) U-tube with in-line fins, (c) U-tube with staggered fins and (d) Festoon design in the PCM-LHTESS (Kurnia et al. 2013).

Novel fin configurations

| Design configurations | Varying parameter | Nature of study | Major findings | Refs. |

|---|---|---|---|---|

| Rectangular, with straight fin | Operating temperature | Numerical (discharging) | Enhancement of heat transfer rate | Humphries and Griggs (1977) |

| Shell and tube, with spiral twisted | Heat flux | Experimental (charging) | Enhancement of heat transfer rate, reducing pre-charging time | Liu et al. (2005a) |

| Shell and tube, with spiral twisted | Heat flux | Experimental (discharging) | Enhancement of cooling rate, natural convection | Liu et al. (2005b) |

| u-tube, u-tube with inline fin, u-tube with staggered fin | Heat flux | Numerical (charging and discharging) | Enhancing the heat transfer rate | Kurnia et al. (2013) |

| Shell and tube, with tree fin | Heat flux | Numerical (discharging) | Enhancing the efficiency of LHTESS | Sciacovelli et al. (2015) |

| Rectangular, with stepped fins | Heat flux operating temperature | Numerical (charging) | Increasing the heat transfer rate | Nakhchi and Esfahani (2020) |

| Tapered shell and tube | Heat flux | Numerical (charging) | Enhancing the charging rate | Rudra Murthy et al. (2021) |

The schematic diagram of finned thermal storage system and plane tube are shown in Figures 6–8.

Schematic view of finned thermal storage system (Nakhchi and Esfahani, 2020). (a) Stepped fins downward. (b) Stepped fins upward.

Plain tube with and without fins, cross-sectional views (Tay et al. 2013).

Dimensions, thermocouple location and notational of a cylindrical and tapered CLHS model (Rudra Murthy et al. 2021).

4 Parametric assessment of PCM-based LHTESS

Several investigators across the world studied the performances of PCM-based LHTESS in connection with variation of dimensional parameters of fins, number of fins, geometrical configurations of fins and size and shape of fins, etc., wherein it was found that a subtle relationship exists between variation of fin parameters and performance characteristic of the thermal energy storage unit. In an extension to the above statement, one study revealed that

Increase in fin size does not increase heat transfer all the times

Increasing number of fins does not improve the heat transfer considerably

There is a strong impact of dimensionless quantities on thermal performances of LHTESS

Thermal entity such as charging/discharging, melted volume fraction and temperature profile provides a comprehensive picture of results.

In line with the aforementioned discussions, Hosseini et al. (2015a) both experimentally and numerically explored the role of fin height as well as Stefan number on the thermal efficiency of pipe heat exchanger. In continuation of a similar exercise, Tiari et al. (2015) probed the effects of pipe spacing, fin length, fin number and natural convection upon the thermal performances of LHTESS. In addition, Al-Abidi et al. (2013a) studied the dependence of dimensionless quantities, fin parameters and PCM design module on operational characteristics of LHTESS. Following a similar approach, Ismail et al. (2001) looked into the impact of axial fins on solidification process in relation to quantities, such as fin parameters, annular spaces and aspect ratios. All these were found to significantly affect the fin characteristics.

4.1 Effect of fin geometry on thermodynamic performance of LHTESS

The present section provides a detailed coverage about geometrical aspects of extended surfaces or fin parameters on charging/discharging rate, total time for complete phase transition, molten or solidified mass percentage and stored energy potential, have been explored in this section.

Besides, this section is divided into four subsections for investigation:

The impact of Fin number

Thickness

Length

Distance between the fins: fin form and angle

4.1.1 Impact of fin count, width and lengths

The characteristics of fin count, width and lengths are linked to the heat transfer area and can thus have a significant impact on the performance characteristics pertaining to phase change process of PCM. However, the variation of properties depends upon whether the fins are horizontally mounted or vertically in relation to melting or solidification of PCM. Also, the presence of fins with variable geometrical features has a subtle bearing upon the temperature distribution and flow fields of the PCM in certain conditions. In line with the same Lacroix and Benmadda (1997) discovered that for a vertical rectangular tank having horizontal fins mounted on it (long as well as short fins), assist in heat transfer process mainly by way of conduction mechanism in line with more number of fins in place. According to some previous research surveys (Zhang and Faghri 1996, Padmanabhan and Murthy 1986, Hosseini et al. 2015b), a definite increment in lengths of fins would develop a corresponding rise in melting rate of PCM.

However, Kamkari and Shokouhmand (2014) displayed that the involvement of partially horizontal fins are responsible for higher melting rates especially over the fin surfaces owing to the formation of a vortex. Besides that, the melting rate had experienced a subtle fall mainly because of increasing the fins width and decreasing the profile length. In addition, it was revealed that the melting time of PCM increases with increasing fin thickness in the presence of sunlight (Acır and Canlı 2018). Apart from that, for spirally twisted fins, reductions in fin width and fin pitch are some of the prominent ways to speed up the PCM melting process light (Liu et al. 2005a). Further, Ismail et al. (2001) investigated the impact of several parameters on the solidification process, i.e., reduction in solidification time owing to increases in the fin thickness. Furthermore, the solidification time is reduced by almost 60% when the wall temperature is raised from 5.4 to 20.1°C light (Nóbrega et al. 2019).

4.1.2 Impact of fin spacing

With regard to the aforementioned feature, Gharebaghi and Sezai (2007) examined the thermal performance of PCM–filled finned flat storage modules in melting and solidification modes under forced convection conditions to conclude that for large fin spacing, it is always on the beneficial side to maintain a small gap between the fins to enhance heat transmission vis a vis thickness of modules, mainly because of the fact that smaller fin spacing leads to reduction in time it takes for both the modules to charge and discharge. Furthermore, decreasing the distance between the fins diminishes the strength of natural convection, which slows down the melting process (Lacroix and Benmadda 1998).

4.1.3 Impact of fin angle

The angle at which fins are mounted in a circular container plays an important role in estimation of phase change rate of PCM. In line of the same, the study on melting parameters of PCM in the horizontal circular enclosure was executed by Yuan et al. (2016) for five fin angles configurations to find optimum melting rate in purely vertically mounted fins. Post that, Kazemi et al. (2018) identified that increasing the fins angle from 60° to 120° for the triple–fin geometry and reducing the angle from 150° to 45° for double-fin arrangement decreases the melting time.

4.1.4 Impact of fin shape

Many researchers have proposed that the unique form of fin geometry can be used in a cylindrical or rectangular enclosure. In view of the same, Agyenim et al. (2007) recognised that a system with longitudinal fins is thermodynamically more stable in charging and discharging modes than that of the system with circular fins counterparts. Similarly, Eslami and Bahrami (2017) examined the thermal performance of I-shaped, V-shaped and Pencil-shaped fins in a rectangular enclosure with the same amount of material. Apart from the above-mentioned studies, single and double Y-shaped fins were installed in the LHTES unit to speed up the discharging process. In fact, adoption of multiple Y-shaped fins boosts discharging efficiency roughly by a percentage value of 24% (Sciacovelli et al. 2015, Lohrasbi et al. 2016b). Apart from the previous discussion, V-shaped fins were shown to have been solidified at a rate 1.5 times faster than their basic counterparts (Lohrasbi et al. 2016a). On a similar note, Abdulateef et al. (2017, 2018) recommended the use of triangular fins in the triplex tube storage system so as to improve the thermal behaviour. Quite intriguingly, in comparison to a longitudinal fin arrangement, the results pertaining external triangular finned tube arrangement improve the solidification and melting processes by 18 and 15%, respectively.

4.1.5 Interactive effects between fin and HTF

Till date, the focus of aforementioned discussion was on the effect of fin number, size and shape on heat transfer behaviour of LHTES system, while geometrical aspects are understood in line with other parameters such as HTF flow rate and temperature. The magnitude of HTF mass flow rate has a significant bearing upon thermal energy stored capacity of the unit (Pakrouh et al. 2015). Other than that, in reality, raising the volumetric flow rate and switching from a laminar to a turbulent flow regime provides a sharp increment in convective heat transfer coefficient, which accelerates the heat transfer rate between the HTF and the PCM. Moreover, another interesting aspect of HTF is to bring about the positive impact on thermal performance of LTHESS by way of increasing HTF velocity accompanied by large number of fins (Ogoh and Groulx 2012). The importance of natural convection is certainly diminished in the present situation. Also, the position of the melting interface is greatly influenced by HTF velocity. Furthermore, an increase in the flow rate of cold HTF in a system leads to greater amount of energy recovery during simultaneous charging and discharging conditions (Murray and Groulx 2014a, b).

4.1.6 Impact of fin location

Depending upon the application of LHTESS, primarily two kinds of varieties of LHTESS are being employed for solar water heating as well as for electronic cooling. In both cases, the packed PCM system having HTF as working fluid is used, however in the latter case, hot/ cold boundary wall conditions are involved for analysis. Also, relative heat transfer is the parameter used for placement of fins in the storage system. Moreover, PCM-packed heat sinks involving pins or plate fins are being extensively utilised in cooling electronic equipment (Lacroix 1993, Akhilesh et al. 2005). Heat sinks with vertical and horizontal fins emerge from the heated vertical and bottom surface, respectively (Shatikian et al. 2005, 2008). Therefore, the discussion points to the fact that in PCM-based LHTESS, the design and inclination of the fins have a significant bearing on overall performance related to melting and solidification exercises of PCM.

5 Performance analysis of LHTESS with and without placement of fins

In the numerous studies performed so far, it has been exercised to ascertain the best possible fin structure to seek optimum phase change rate and a better quality of temperature distribution profile across various charging as well as discharging regimes. Additionally, Kumar et al. (2022) developed a comprehensive mathematical representation for estimation of thermal performance of LHTESS in conjunction with or without placement of longitudinal fins (external–internal) inside the storage structure. In addition, it was unearthed that there is a significant reduction in charging as well as discharging times (50–90 min) owing to the placement of fins inside the storage structure. Further, there is substantial change in heat transfer characteristics of LHTESS, in line with consideration of entities such as number of fins, geometrical parameters of fins, heat exchanger material, Stefan Number and PCM design module. Besides that, Agyenim et al. (2009) examined three design configurations of LHTESS, such as no fins, circular fins and longitudinal fins, wherein it was found out that the thermal performance was recorded as best in the third case by way of enhancing thermal responsiveness during melting regime and decrement in sub-cooling behaviour upon solidification regime. Therefore, keeping in view the comprehensive discussion about fin and placement thereof in storage units, it was quite intriguing to reveal that placement of fins in an appropriate manner/number always assists in better thermal transmission while maintaining the same energy density and the same is adjudged as the most effective technique for a variety of shell and tube configurations (Al-Abidi et al. 2013b).

6 Conclusion

In recent times, several research works have been executed on PCM-assisted Latent Heat Thermal Energy Storage System (PCM – LHTESS) in connection with features such as unit design, behaviour of PCM during phase transition, optimization approaches in line with enrichment of heat transfer enhancement. The above set of researches provide a comprehensive information regarding restrictions and features of prolonged surface apart from in-depth study of charging and discharging behaviour of PCM during heat transfer phenomena. Owing to poor thermal conductivities of PCMs, the prominent technique of heat transfer enhancement is utilization of PCM-filled fins having variety of geometrical shapes such as longitudinal, circular and spiral. Besides, the present research endeavour provides subtle compilation of complex entities such as geometrical fin factors, HTF tube, enclosure shape, and flow parameters related to HTF. Consequently, the longitudinal fin configuration was adjudged as the most suitable/preferable fin configuration, mainly because of its simple design, less cost as well as ease of fabrication. For numerous shell and tube heat exchanger configurations, a circular finned tube configuration fin arrangement was ascertained to be more effective than its pinned counterpart.

The optimization of the thermal performance of PCM-based LHTESS depends upon the careful selection of parameters such as geometrical entities, fin parameters, e.g. HTF tube and enclosure shape and flow parameters associated with HTF. Consequently, the rate of heat transfer in a finned tube arrangement depends on the optimum numbers of fins as well as their geometrical dimension in the arrangement.

Despite the fact, variation (usually increment) in the number and size of fin configuration results in better heat transmission, presence of more number of fins in the arrangement might lead to reduction in flow of convective current and thus restricting heat transfer augmentation.

Besides the above discussed facts, it has also been unearthed that variation in fin length as well as increment in fin number, rather than fin thickness, has been found to have profound impact on thermal performance of system. In nutshell, fin thickness has a mild adverse effect on charging time with no major change in discharging time.

The results of various empirical or computational studies are only available for a given system with its own set of characteristics, such as PCM type, enclosure size, HTF temperature and corresponding flow rates.

Although, most novel fin shapes have been proved to have produced comparatively better charging/discharging rates than that of its simple longitudinal or radial counterparts. Also, selection of optimal fin shape for the melting or solidification process is no doubt a difficult exercise.

The optimal value for fin number is based on mass flow rates of HTF and its temperature in line with the studies available on the interaction between fin qualities and HTF.

In view of all the facts discussed in the present compilation, it has been understood primarily that design as well as optimization of fin parameters are in fact a complex activity apart from its being a computationally expensive given the transient nature of the system.

Thus, designing of altogether a new model of fin is an indeed an important activity as far as heat transfer enhance is concerned particularly with regard to its extended applications in posterity, e.g. TESS and that too in connection with parameters such as mass flow rates, temperature and geometrical entities of the fin.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have read and agreed to the published version of the manuscript. Ankit Yadav: Initial Literature Survey, Problem Formulation; Gurjeet Singh: Conceptualization, Methodology; Himanshu Kumar: Detailed Literature Review, Original draft preparation; Sumit Taneja: Manuscript Review and Editing, Correspondence and Comments addressal.

-

Conflict of interest: The authors declare that there are no conflicts of interest.

-

Data availability statement: All the data used are made available in the present work.

References

Abdulateef A. M., Abdulateef J., Mat S., Sopian K., Elhub B., and Mussa M. A. (2018). “Experimental and numerical study of solidifying phase-change material in a triplex – tube heat exchanger with longitudinal/triangular fins,” Int. Commun. Heat Mass Transf., vol. 90, pp. 73–84, https://www.sciencedirect.com/science/article/abs/pii/S0735193317302658. 10.1016/j.icheatmasstransfer.2017.10.003Search in Google Scholar

Abdulateef A. M., Mat S., Sopian K., Abdulateef J., and Gitan A. A. (2017). “Experimental and computational study of melting phase-change material in a triplex tube heat exchanger with longitudinal/triangular fins,” Sol. Energy, vol. 155, pp. 142–153, https://www.sciencedirect.com/science/article/abs/pii/S0038092X17305273. 10.1016/j.solener.2017.06.024Search in Google Scholar

Abhat A. (1983). “Low temperature latent heat thermal energy storage: Heat storage materials,” Sol. Energy, vol. 30, no. 4, pp. 313–332, https://www.sciencedirect.com/science/article/abs/pii/0038092X8390186X. 10.1016/0038-092X(83)90186-XSearch in Google Scholar

Acır A. and Canlı M. E. (2018). “Investigation of fin application effects on melting time in a latent thermal energy storage system with phase change material (PCM),” Appl. Therm. Eng., vol. 144, p. 1071, https://www.sciencedirect.com/science/article/abs/pii/S1359431118310792. 10.1016/j.applthermaleng.2018.09.013Search in Google Scholar

Agyenim F., Eames P., and Smyth M. (2007). “A comparison of heat transfer enhancement in medium temperature thermal energy storage heat exchanger using fins and multitubes,” ISES Sol. World Congr., vol. 4, p. 2726, https://link.springer.com/chapter/10.1007/978-3-540-75997-3_550. 10.1007/978-3-540-75997-3_550Search in Google Scholar

Agyenim F., Eames P., and Smyth M. (2009). “A comparison of heat transfer enhancement in a medium temperature thermal energy storage heat exchanger using fins,” Sol. Energy, vol. 83, no. 9, pp. 1509–1520, https://www.sciencedirect.com/science/article/abs/pii/S0038092X09000942. 10.1016/j.solener.2009.04.007Search in Google Scholar

Agyenim F., Eames P., and Smyth M. (2010a). “Heat transfer enhancement in medium temperature thermal energy storage system using a multitube heat transfer array,” Renew. Energy, vol. 35, no. 1, pp. 198–207, 10.1016/j.renene.2009.03.010. Search in Google Scholar

Agyenim F., Hewitt N., Eames P., and Smyth M. (2010b). “A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS),” Renew. Sustain. Energy Rev., vol. 14, no. 2, pp. 615–628, https://www.sciencedirect.com/science/article/abs/pii/S1364032109002469. 10.1016/j.rser.2009.10.015Search in Google Scholar

Agyenim F., Eames P., and Smyth M. (2011). “Experimental study on the melting and solidification behaviour of a medium temperature phase change storage material (Erythritol) system augmented with fins to power a LiBr/H2O absorption cooling system,” Renew. Energy, vol. 36, no. 1, pp. 108–117, https://www.sciencedirect.com/science/article/abs/pii/S0960148110002612. 10.1016/j.renene.2010.06.005Search in Google Scholar

Akgün M., Aydin O., and Kaygusuz K. (2007). “Experimental study on melting/solidification characteristics of a paraffin as PCM,” Energy Convers. Manag., vol. 48, no. 2, pp. 669–678, https://www.sciencedirect.com/science/article/abs/pii/S0196890406001786. 10.1016/j.enconman.2006.05.014Search in Google Scholar

Akhilesh R., Narasimhan A., and Balaji C. (2005). “Method to improve geometry for heat transfer enhancement in PCM composite heat sinks,” Int. J. Heat Mass Transf., vol. 48, no. 13, pp. 2759–2770, https://www.sciencedirect.com/science/article/abs/pii/S0017931005001419. 10.1016/j.ijheatmasstransfer.2005.01.032Search in Google Scholar

Al-Abidi A. A., Mat S., Sopian K., Sulaiman M. Y., and Mohammad A. T. (2013a). “Internal and external fin heat transfer enhancement technique for latent heat thermal energy storage in triplex tube heat exchangers,” Appl. Therm. Eng., vol. 53, no. 1, pp. 147–156, https://www.sciencedirect.com/science/article/abs/pii/S1359431113000410. 10.1016/j.applthermaleng.2013.01.011Search in Google Scholar

Al-Abidi A. A., Mat S., Sopian K., Sulaiman M. Y., and Mohammad A. T. (2013b). “Numerical study of PCM solidification in a triplex tube heat exchanger with internal and external fins,” Int. J. Heat Mass Transf., vol. 61, pp. 684–695, https://doi.org/10.1016/j.ijheatmasstransfer.2013.02.030. 10.1016/j.ijheatmasstransfer.2013.02.030Search in Google Scholar

Al-Abidi A., Mat S., Sopian K., Sulaiman M. Y., and Mohammad A. T. (2014). “Experimental study of melting and solidification of PCM in a triplex tube heat exchanger with fins,” Energy Build., vol. 68, pp. 33–41, https://www.sciencedirect.com/science/article/abs/pii/S0378778813005707. 10.1016/j.enbuild.2013.09.007Search in Google Scholar

Al-Maghalseh M. and Mahkamov K. (2018). “Methods of heat transfer intensification in PCM thermal storage systems: Review,” Renew. Sustain. Energy Rev., vol. 92, pp. 62–94, https://www.sciencedirect.com/science/article/abs/pii/S1364032109002469. 10.1016/j.rser.2018.04.064Search in Google Scholar

Altac Z. and Altun O. (2014). “Hydrodynamically and thermally developing laminar flow in spiral coil tubes,” Int. J. Therm. Sci., vol. 77, pp. 96–107, https://www.sciencedirect.com/science/article/abs/pii/S1290072913002561. 10.1016/j.ijthermalsci.2013.10.020Search in Google Scholar

Amaral C., Vicente R., Marques P., and Timmons A. (2017). “Phase change materials and carbon nanostructures for thermal energy storage: A literature review,” Renew. Sustain. Energy Rev., vol. 79, pp. 1212–1228. https://sciencedirect.com/science/article/abs/pii/S1364032117307293. 10.1016/j.rser.2017.05.093Search in Google Scholar

Amin N. A., Bruno F., and Belusko M. (2014). “Effective thermal conductivity for melting in PCM encapsulated in a sphere,” Appl. Energy, vol. 122, pp. 280–287, https://www.sciencedirect.com/science/article/abs/pii/S0306261914001020. 10.1016/j.apenergy.2014.01.073Search in Google Scholar

Arasu A. V. and Mujumdar A. S. (2012). “Numerical study on melting of paraffin wax with Al2O3 in a square enclosure,” Int. Commun. Heat Mass Transf., vol. 39, no. 1, pp. 8–16, https://www.sciencedirect.com/science/article/abs/pii/S0735193311002156. 10.1016/j.icheatmasstransfer.2011.09.013Search in Google Scholar

Assis E., Katsman L., Ziskind G., and Letan R. (2007a). “Numerical and experimental study of melting in a spherical shell,” Int. J. Heat Mass Transf., vol. 50, no. 10, p. 1790, https://www.sciencedirect.com/science/article/abs/pii/S0017931006005503. Search in Google Scholar

Assis E., Katsman L., Ziskind G., and Letan R. (2007b). “Numerical and experimental study of solidification in a spherical shell melting in a spherical shell,” Int. J. Heat Mass Transf., vol. 50, no. 9–10, pp. 1790–1804, https://www.sciencedirect.com/science/article/abs/pii/S0017931006005503. 10.1016/j.ijheatmasstransfer.2006.10.007Search in Google Scholar

Assis E., Ziskind G., and Letan R. (2009). “Numerical and experimental study of solidification in a spherical shell,” J. Heat Transf., vol. 131, no. 2, pp. 1–5, 10.1115/1.2993543. Search in Google Scholar

Baba M., Raju A. V., and Rao M. B. (2018). “Heat transfer enhancement and pressure drop of Fe3O4 -water nanofluid in a double tube counter flow heat exchanger with internal longitudinal fins,” Case Stud. Therm. Eng., vol. 12, pp. 600–607, https://www.sciencedirect.com/science/article/pii/S2214157X18301436. 10.1016/j.csite.2018.08.001Search in Google Scholar

Baby R. and Balaji C. (2013). “Thermal optimization of PCM based pin fin heat sinks: An experimental study,” Appl. Therm. Eng., vol. 54, no. 1, pp. 65–77, https://www.sciencedirect.com/science/article/abs/pii/S1359431113000045. 10.1016/j.applthermaleng.2012.10.056Search in Google Scholar

Bahiraei M., Mazaheri N., and Rizehvandi A. (2019). “Application of a hybrid nanofluid containing graphene nanoplatelet–platinum composite powder in a triple – tube heat exchanger equipped with inserted ribs,” Appl. Therm. Eng., vol. 149, pp. 588–601, https://www.sciencedirect.com/science/article/abs/pii/S1359431118359878. 10.1016/j.applthermaleng.2018.12.072Search in Google Scholar

Banaszek J., Domañski R., Rebow M., and El-Sagier F. (1999). “Experimental study of solid – liquid phase change in a spiral thermal energy storage unit,” Appl. Therm. Eng., vol. 19, no. 12, pp. 1253–1277, https://www.sciencedirect.com/science/article/abs/pii/S1359431198001203. 10.1016/S1359-4311(98)00120-3Search in Google Scholar

Bharadwaj P., Khondge A., and Date A. (2009). “Heat transfer and pressure drop in a spirally grooved tube with twisted tape insert,” Int. J. Heat Mass Transf., vol. 52, pp. 1938–1944, https://www.sciencedirect.com/science/article/abs/pii/S0017931008006066. 10.1016/j.ijheatmasstransfer.2008.08.038Search in Google Scholar

Borhani S. M., Hosseini M. J., Ranjbar A. A., and Bahrampoury R. (2019). “Investigation of phase change in a spiral-fin heat exchanger,” Appl. Math. Model., vol. 67, pp. 297–314, https://www.sciencedirect.com/science/article/pii/S0307904X18305213. 10.1016/j.apm.2018.10.029Search in Google Scholar

Bruno F., Belusko M., Liu M., and Tay N. H. S. (2015). Using solid-liquid phase change materials (PCMs) in thermal energy storage systems, Woodhead Publishing Limited. https://doi.org/10.1533/9781782420965.2.201.10.1533/9781782420965.2.201Search in Google Scholar

Campos-Celador A., Diarce G., González I., and Sala J. (2013). “Development and comparative analysis of the modeling of an innovative finned-plate latent heat thermal energy storage system,” Energy, vol. 58, pp. 438–447, https://www.sciencedirect.com/science/article/abs/pii/S0360544213005306. 10.1016/j.energy.2013.06.032Search in Google Scholar

Cho K. and Choi S. H. (2000). “Thermal characteristics of paraffin in a spherical capsule during freezing and melting processes,” Int. J. Heat Mass Transf., vol. 43, pp. 3183–3196, https://www.sciencedirect.com/science/article/abs/pii/S0017931099003294. 10.1016/S0017-9310(99)00329-4Search in Google Scholar

Choi J. C. and Kim S. D. (1995). “Heat – transfer characteristics of a latent heat storage system using MgCl2·6H2O at the melting point,” Energy, vol. 20, no. 1, pp. 13–25, https://www.sciencedirect.com/science/article/abs/pii/0360544294000514. 10.1016/0360-5442(94)00051-4Search in Google Scholar

Dhaidan N. S., Khodadadi J. M., Al-Hattab T. A., and Al-Mashat S. M. (2013). “Experimental and numerical investigation of melting of phase change material/nanoparticle suspensions in a square container subjected to a constant heat flux,” Int. J. Heat Mass Transf., vol. 6, pp. 672–683, https://www.sciencedirect.com/science/article/abs/pii/S0017931013005346. 10.1016/j.ijheatmasstransfer.2013.06.057Search in Google Scholar

Eames I. W. and Adref K. T. (2002). “Freezing and melting of water in spherical enclosures of the type used in thermal/ice storage systems,” Appl. Therm. Eng., vol. 22, no. 7, pp. 733–745, https://www.sciencedirect.com/science/article/abs/pii/S1359431102000261. 10.1016/S1359-4311(02)00026-1Search in Google Scholar

Elbahjaoui R. and Qarnia H. E. (2017). Transient behavior analysis of the melting of nanoparticle-enhanced phase change material inside a rectangular latent heat storage unit,” Appl. Therm. Eng., vol. 112, pp. 720–738, https://www.sciencedirect.com/science/article/abs/pii/S1359431116325662. 10.1016/j.applthermaleng.2016.10.115Search in Google Scholar

Erek A. and Ezan M. A. (2006). “Experimental and numerical study on charging processes of an ice-on-coil thermal energy storage system,” Int. J. Energy Res., vol. 31, no. 02, pp. 158–176, https://onlinelibrary.wiley.com/doi/abs/10.1002/er.1240. 10.1002/er.1240Search in Google Scholar

Erek A., Ilken Z., and Acar M. A. (2005). “Experimental and numerical investigation of thermal energy storage with a finned tube,” Int. J. Energy Res., vol. 29, no. 4, pp. 283–301, https://onlinelibrary.wiley.com/doi/10.1002/er.1057. 10.1002/er.1057Search in Google Scholar

Ermis K., Erek A., and Dincer I. (2007). “Heat transfer analysis of phase change process in a finned-tube thermal energy storage system using artificial neural network,” Int. J. Heat Mass Transf., vol. 50, pp. 3163–3175, https://www.sciencedirect.com/science/article/abs/pii/S001793100700052X. 10.1016/j.ijheatmasstransfer.2006.12.017Search in Google Scholar

Eslami M. and Bahrami M. A. (2017). “Sensible and latent thermal energy storage with constructal fins,” Int. J. Hydrog. Energy, vol. 42, no. 28, p. 17681, https://www.sciencedirect.com/science/article/abs/pii/S0360319917314866. 10.1016/j.ijhydene.2017.04.097Search in Google Scholar

Fan L. and Khodadadi J. M. (2012). “An experimental investigation of enhanced thermal conductivity and expedited unidirectional freezing of cyclohexane-based nanoparticle suspensions utilized as nano-enhanced phase change materials (NePCM),” Int. J. Therm. Sci., vol. 62, pp. 120–126, https://www.sciencedirect.com/science/article/abs/pii/S1290072911003358. 10.1016/j.ijthermalsci.2011.11.005Search in Google Scholar

Fernandez A. I., Martnez M., Segarra M., Martorell I., and Cabeza L. F. (2010). “Selection of materials with potential in sensible thermal energy storage,” Sol. Energy Mater. Sol. Cell, vol. 94, no. 10, pp. 1723–1729, https://www.sciencedirect.com/science/article/abs/pii/S0927024810003296?via%3Dihub. 10.1016/j.solmat.2010.05.035Search in Google Scholar

Fisch M. N., Guigas M., and Dalenbäck J. O. (1998). “A review of large-scale solar heating systems in Europe,” Sol. Energy, vol. 63, no. 6, pp. 355–366, https://www.sciencedirect.com/science/article/abs/pii/S0038092X98001030?via%3Dihub. 10.1016/S0038-092X(98)00103-0Search in Google Scholar

Fok S., Shen W., and Tan F. (2010). “Cooling of portable hand-held electronic devices using phase change materials in finned heat sinks,” Int. J. Therm. Sci., vol. 49, pp. 109–117, https://www.sciencedirect.com/science/article/abs/pii/S1290072909001471. 10.1016/j.ijthermalsci.2009.06.011Search in Google Scholar

Galione P. A., Lehmkuhl O., Rigola J., and Oliva A. (2015). “Fixed-grid numerical modeling of melting and solidification using variable thermo-physical properties- Application to the melting of n-Octadecane inside a spherical capsule,” Int. J. Heat Mass Transf., vol. 86, pp. 721–743, https://www.sciencedirect.com/science/article/abs/pii/S0017931015002914. 10.1016/j.ijheatmasstransfer.2015.03.033Search in Google Scholar

Gao Z., Yao Y., and Wu H. (2019). “Validation of a melting fraction-based effective thermal conductivity correlation for prediction of melting phase change inside a sphere,” Int. J. Therm. Sci., vol. 142, pp. 247–257, 10.1016/j.ijthermalsci.2019.04.029. Search in Google Scholar

Gasia J., Miró L., and Cabeza L. (2016). “Materials and system requirements of high temperature thermal energy storage systems: A review Thermal conductivity enhancement techniques,” Renew. Sustain. Energy Rev., vol. 60, pp. 1584–1601, https://www.sciencedirect.com/science/article/abs/pii/S0017931019301449. 10.1016/j.rser.2016.03.019Search in Google Scholar

Gharebaghi M. and Sezai I. (2007). “Enhancement of heat transfer in latent heat storage modules with internal fins,” Numer. Heat Transf., Part. A: Appl., vol. 53, no. 7, pp. 749–765, 10.1080/10407780701715786. Search in Google Scholar

Ghoneim A. A. (1989). “Comparison of theoretical models of phase-change and sensible heat storage for air & water-based solar heating systems,” Sol. Energy, vol. 42, no. 3, pp. 209–220, https://www.sciencedirect.com/science/article/abs/pii/0038092X89900133Accessed May 1, 2023.10.1016/0038-092X(89)90013-3Search in Google Scholar

Groulx D. and Ogoh W. (2009). “Solid-liquid phase change simulation applied to a cylindrical latent heat energy storage system,” Proceedings of the 5th Annual COMSOL Conference, Boston USA, https://www.uk.comsol.com/papers/6414/download/Groulx.pdf. Search in Google Scholar

Gürel B. (2020). “Thermal performance evaluation for solidification process of latent heat thermal energy storage in a corrugated plate heat exchanger,” Appl. Therm. Eng., vol. 174, p. 115312, 10.1016/j.applthermaleng.2020.115312. Search in Google Scholar

Ho J. C. and Gao J. Y. (2009). “Preparation and thermophysical properties of nanoparticle-in-paraffin emulsion as phase change material,” Int. Commun. Heat Mass Transf., vol. 36, no. 5, pp. 467–470, https://www.sciencedirect.com/science/article/abs/pii/S0735193309000414. 10.1016/j.icheatmasstransfer.2009.01.015Search in Google Scholar

Hosseini M. J., Rahimi M., and Bahrampoury R. (2014). “Experimental and computational evolution of a shell and tube heat exchanger as a PCM thermal storage system,” Int. Commun. Heat Mass Transf., vol. 50, pp. 128–136, https://www.sciencedirect.com/science/article/abs/pii/S0735193313002194. 10.1016/j.icheatmasstransfer.2013.11.008Search in Google Scholar

Hosseini M. J., Rahimi M., and Bahrampoury R. (2015a). “Thermal analysis of PCM containing heat exchanger enhanced with normal annular fines,” Mech. Sci., vol. 6, pp. 221–234, 10.5194/ms-6-221-2015.Search in Google Scholar

Hosseini M. J., Ranjbar A. A., Rahimi M., and Bahrampoury R. (2015b). “Experimental and numerical evaluation of longitudinally finned latent heat thermal storage systems,” Energy Build., vol. 99, p. 263, https://www.sciencedirect.com/science/article/abs/pii/S0378778815003448. 10.1016/j.enbuild.2015.04.045Search in Google Scholar

Hosseinizadeh S. F., Darzi A. A. R., and Tan F. L. (2012). “Numerical investigations of unconstrained melting of nano-enhanced phase change material (NEPCM) inside a spherical container,” Int. J. Therm. Sci., vol. 51, pp. 77–83, 10.1016/j.ijthermalsci.2011.08.006. Search in Google Scholar

Humphries W. R. and Griggs E. I. (1977). A design handbook for phase change thermal control and energy storage devices, NASA Technical Paper 1074, https://ntrs.nasa.gov/citations/19780007491. Search in Google Scholar

Ibrahim N., Al-Sulaiman F., Rahman S., Yilbas B., and Sahin A. (2017). “Heat transfer enhancement of phase change materials for thermal energy storage application: A critical review,” Renew. & Sustain. Energy Rev., vol. 74, pp. 26–50, https://www.sciencedirect.com/science/article/abs/pii/S1364032117301739. 10.1016/j.rser.2017.01.169Search in Google Scholar

Ismail K. A. R., Alves C. L. F., and Modesto M. S. (2001). “Numerical and experimental study on the solidification of PCM around a vertical axially finned isothermal cylinder,” Appl. Therm. Eng., vol. 21, no. 1, pp. 53–77, https://www.sciencedirect.com/science/article/abs/pii/S1359431100000028. 10.1016/S1359-4311(00)00002-8Search in Google Scholar

Jaworski M. (2012). “Thermal performance of heat spreader for electronics cooling with incorporated phase change material,” Appl. Therm. Eng., vol. 35, pp. 212–219, https://www.sciencedirect.com/science/article/abs/pii/S1359431111005746. 10.1016/j.applthermaleng.2011.10.036Search in Google Scholar

Jegadheeswaran S. and Pohekar S. D. (2009). “Performance enhancement in latent heat thermal storage system: A review,” Renew. Sustain. Energy Rev., vol. 13, no. 9, pp. 2225–2244, https://www.sciencedirect.com/science/article/abs/pii/S1364032109001221. 10.1016/j.rser.2009.06.024Search in Google Scholar

Jellouli Y., Chouikh R., Guizani A., and Belghith A. (2007). “Numerical study of the moving boundary problem during melting process in a rectangular cavity heated from below,” Am. J. Appl. Sci., vol. 4, no. 4, pp. 251–256, https://thescipub.com/abstract/ajassp.2007.251.256. 10.3844/ajassp.2007.251.256Search in Google Scholar

Jesumathy S. P., Udayakumar M., and Suresh S. (2012). “Heat transfer characteristics in latent heat storage system using paraffin wax,” J. Mech. Sci. Technol., vol. 26, pp. 959–965, https://www.sciencedirect.com/science/article/abs/pii/S0735193313002194. 10.1007/s12206-011-1017-4Search in Google Scholar

Jian-you L. (2008). “Numerical and experimental investigation for heat transfer in triplex concentric tube with phase change material for thermal energy storage,” Sol. Energy, vol. 82, no. 11, pp. 977–985, https://www.sciencedirect.com/science/article/abs/pii/S0038092X08001096. 10.1016/j.solener.2008.05.006Search in Google Scholar

Jung E. G. and Boo J. H. (2014). “Thermal analytical model of latent thermal storage with heat pipe heat exchanger for concentrated solar power,” Sol. Energy, vol. 102, pp. 318–332, https://www.sciencedirect.com/science/article/abs/pii/S0038092X13004805. 10.1016/j.solener.2013.11.008Search in Google Scholar

Kamkari B. and Shokouhmand H. (2014). “Experimental investigation of phase change material melting in rectangular enclosures with horizontal partial fins,” Int. J. Heat Mass Tranfer, vol. 78, p. 839, https://www.sciencedirect.com/science/article/abs/pii/S0017931014006450. 10.1016/j.ijheatmasstransfer.2014.07.056Search in Google Scholar

Kazemi M., Hosseini M. J., Ranjbar A. A., and Bahrampoury R. (2018). “Improvement of longitudinal fins configuration in latent heat storage systems,” Renew. Energy, vol. 116, p. 447, https://www.sciencedirect.com/science/article/abs/pii/S0960148117309679. 10.1016/j.renene.2017.10.006Search in Google Scholar

Kumar R., Rao Y. A., Yadav A. S., Balu A., Taneja S., and Sharma A. (2022). “Application of phase change material in thermal energy storage systems,” Mater. Today Proc., vol. 63, pp. 798–804, 10.1016/j.matpr.2022.06.152.Search in Google Scholar

Kurnia J. C., Sasmito A. P., Jangam S. V., and Mujumdar A. S. (2013). “Improved design for heat transfer performance of a novel phase change material (PCM) thermal energy storage (TES),” Appl. Therm. Eng., vol. 50, no. 1, pp. 896–907, https://www.sciencedirect.com/science/article/abs/pii/S1359431112005376. 10.1016/j.applthermaleng.2012.08.015Search in Google Scholar

Lacroix M. (1993). “Study of the heat transfer behavior of a latent heat thermal energy storage unit with a finned tube,” Int. J. Heat Mass Transf., vol. 36, pp. 2083–2092, https://www.sciencedirect.com/science/article/abs/pii/S1364032109002469. 10.1016/S0017-9310(05)80139-5Search in Google Scholar

Lacroix M. and Benmadda M. (1997). “Numerical simulation of natural convection-dominated melting and solidification from a finned vertical wall,” Numer. Heat Transf. Part. A Appl., vol. 31, no. 1, pp. 71–86, https://www.tandfonline.com/doi/abs/10.1080/10407789708914026. 10.1080/10407789708914026Search in Google Scholar

Lacroix M. and Benmadda M. (1998). “Analysis of natural convection melting from a heated wall with vertically oriented fins,” Int. J. Numer. Methods Heat Fluid Flow., vol. 8, no. 4, p. 465, https://www.emerald.com/insight/content/doi/10.1108/09615539810213241/full/html. 10.1108/09615539810213241Search in Google Scholar

Lago T. G., Ismail K. A., Lino F. A., and Arabkoohsar A. (2020). “Experimental correlations for the solidification and fusion times of PCM encapsulated in spherical shells,” Exp. Heat Transf., vol. 33, no. 5, pp. 440–454, https://www.tandfonline.com/doi/pdf/10.1080/08916152.2019.1656301.10.1080/08916152.2019.1656301Search in Google Scholar

Lamberg P., Lehtiniemi R., and Henell A. M. (2004). “Numerical and experimental investigation of melting and freezing processes in phase change material storage,” Int. J. Therm. Sci., vol. 43, no. 3, pp. 277–287, https://www.sciencedirect.com/science/article/abs/pii/S1290072903001303. 10.1016/j.ijthermalsci.2003.07.001Search in Google Scholar

Lee M., Kang T., Joo Y., and Kim Y. (2011). “Heat transfer characteristics of spirally-coiled circular fin-tube heat exchangers operating under frosting conditions,” Int. J. Refrig., vol. 34, no. 1, pp. 328–336, https://www.sciencedirect.com/science/article/abs/pii/S0140700710001854. 10.1016/j.ijrefrig.2010.08.013Search in Google Scholar