Abstract

Based on post-earthquake resilience principles, this study proposes a novel self-centering steel-concrete composite joint. The joint employs prestressed connections, where an assembled column with an embedded steel sleeve in the core region is connected to a steel-concrete composite beam via high-strength bolts. Energy dissipation is achieved through dedicated energy-dissipating plates. Three interior joint specimens were designed and modeled using ABAQUS finite element software to investigate their seismic performance under low reversed cyclic loading. The effects of energy-dissipating plates and prestressed steel strands on joint behavior, including bearing capacity, failure mode, self-centering capability, and energy dissipation, were systematically analyzed. Furthermore, the formula for calculating the joint’s shear capacity was derived using the superposition method. Two joint specimens derived from the prestressed self-centering (PSC) prototype were designed to benchmark the proposed formula’s computational results against finite element analysis outcomes, thereby validating the formula’s accuracy in assessing the actual shear capacity of joint core regions. Results demonstrate that the proposed joint exhibits high bearing capacity, excellent energy dissipation, and effective self-centering. Prestressed steel strands significantly reduce residual drift and provide self-centering capability, while energy-dissipating plates mitigate stress fluctuations in the strands, preventing premature yielding. Crucially, damage localizes primarily within the replaceable energy-dissipating plates, enabling post-earthquake functional recovery through plate replacement. The load-bearing mechanism of the novel self-centering steel-concrete composite joint conforms to the strut-and-tie mechanism. The calculated values from the formula show good agreement with the results obtained from finite element simulations.

1 Introduction

Amid rapid construction and industrialization initiatives, precast structures have gained prominence due to advantages in reduced labor demand, accelerated construction, and enhanced sustainability [1,2,3]. Beam-column connections in these systems are primarily classified as wet connections or dry connections. Compared to wet connections, dry connections better align with green building objectives due to their expedited construction process, driving increased research focus on high-strength bolted steel-concrete composite joints in recent years.

Quasi-static tests on bolted precast joints [4,5,6] confirm their efficient construction and satisfactory load-bearing capacity, with ductility comparable to cast-in-place systems. However, these connections exhibit inadequate seismic performance, frequently failing in the joint core region. Three primary damage-control strategies have emerged to address this limitation: utilizing bolt energy dissipation [7,8,9], adding supplemental energy-dissipating components [10,11,12], and weakening the beam end region [13,14,15]. These strategies aim to enhance energy dissipation capacity, transfer damage away from the core region, and thereby improve seismic performance. Regarding bolt energy dissipation, Zhang et al. [16] and Ding and Zhang [17] conducted experimental investigations comparing precast steel-concrete composite joints featuring energy-dissipating bolts with cast-in-place joints. Their studies revealed that plastic deformation predominantly concentrates at bolt locations. This energy dissipation mechanism effectively mitigates damage in column-end core regions while enabling post-earthquake repair through bolt replacement. Regarding supplemental energy-dissipating components, Vidjeapriya and Jaya [18] experimentally examined bolted joints incorporating stiffened angle steel for energy dissipation. Their research confirmed that such components protect precast column elements from damage. However, these joints exhibit relatively low peak load-bearing capacity. Notably, ductility and energy dissipation capacity improve with increasing numbers of stiffeners. Concerning beam-end weakening strategies, Yang et al. [19] and Wang et al. [20] performed comparative experimental studies between bolted steel-concrete composite joints with dog-bone-shaped flanges and conventional cast-in-place joints. Results indicate that this joint configuration delivers favorable ductility and energy dissipation capacity. The dog-bone-shaped flange weakening technique successfully relocates the beam-end plastic hinge outward from the column face to the intentionally weakened zone, thereby preventing significant damage to the connection interface itself.

Overall, bolted connections in precast concrete frame joints offer significant advantages, including high construction efficiency and minimal technical barriers to specification compliance. However, they inherently suffer from inadequate energy dissipation capacity and uncontrolled damage localization. Although beam-end weakening and supplementary energy-dissipating components can partially mitigate these deficiencies, the improved joints still exhibit excessive residual deformations, difficult post-earthquake repairs, and critically, lack self-centering capacity. To overcome these challenges, this work proposes a novel self-centering steel-concrete composite joint integrating:

Prestressed connections with post-tensioned strands: The strands provide self-centering capability and reduce joint residual deformations. The single-span beam internal tensioning configuration prevents interference with strands during core region failure.

Precast columns featuring embedded core-region steel sleeve: The steel sleeve enhances concrete confinement and shear resistance while providing anchorage for bolted connections.

High-strength bolted composite beam connections: High-strength bolts deliver energy dissipation capacity and mitigate column-end core region damage. Bolt replacement enables post-earthquake repairs.

Dedicated replaceable energy-dissipating plates: These plates dissipate energy through buckling deformation of energy-dissipating steel bars, reducing steel beam damage while preventing premature yielding of prestressed strands. Plate replacement facilitates post-earthquake rehabilitation.

In the prestressed connections with post-tensioned strands, anchor plates are welded to the steel beam ends serving as stressing ends. High-strength bolted composite beam connections utilize high-strength bolts to connect dedicated replaceable energy-dissipating plates to the steel beams. Horizontally slotted holes are provided in the energy-dissipating plates to enhance the rotational capacity of the composite beams. The prestressed strands are anchored at one end to the steel beam anchor plates and at the other end to the composite beam anchor plates.

The influence of dissipating plates and prestressing strands on seismic performance metrics (load capacity, failure mode, self-centering, and energy dissipation) is evaluated by Finite element analysis using ABAQUS. Moreover, the shear capacity calculation formula applicable to this type of joint was derived, thereby serving as a reference for guiding practical engineering applications.

2 Proposal and design of novel self-centering steel-concrete composite joints

2.1 Conceptual proposal of novel self-centering joints

To resolve critical limitations in conventional joints – including inadequate energy dissipation, challenging post-earthquake repairs, and safety risks from high-altitude strand tensioning – this study proposes a novel self-centering steel-concrete composite joint (Figure 1). The system integrates precast RC columns with embedded square steel tubes, steel-concrete composite beams, steel beams, and specialized energy-dissipation assemblies comprising replaceable energy-dissipating plates, high strength bolt, and web connection plates with horizontally slotted holes. Unbonded post-tensioned strands provide self-centering capability [21], while high-strength bolts and web connection plates enable efficient dry connections that eliminate in-situ welding and facilitate rapid component replacement after seismic events [22].

Schematic representation of self-centering steel-concrete composite joint.

Anchorage plates are welded to the extremities of the steel beams to facilitate tensioning of the prestressed strands. The composite beams interface with steel beams via high-strength bolts securing both the energy-dissipating plates and web connection plates. Horizontally slotted holes in the web connection plates enhance the rotational capacity of the composite beams. Prestressed strands are anchored at one terminus to the anchorage plate of the steel beam and at the opposite terminus to the corresponding anchorage plate on the composite beam. Energy dissipation is primarily achieved through the replaceable energy-dissipating plates, while self-centering functionality is provided by post-tensioned unbonded strands. Post-earthquake serviceability can be restored through the replacement of damaged energy-dissipating plates.

The replaceable energy-dissipating plates utilize buckling deformation of energy-dissipating steel bars to enhance joint energy dissipation capacity while reducing damage to steel beams and preventing premature yielding of prestressed strands. Compared to core-region running through strand configurations, the proposed single-span tensioning system not only isolates strands from core-joint failure effects but also improves construction efficiency through pre-tensioning, eliminating high-altitude operations.

2.2 Design methodology for novel self-centering joints

To evaluate the seismic influence of energy-dissipating plates and prestressed strands on the novel self-centering steel-concrete composite joint (PSC joint), three precast interior joint specimens were designed:

PSC: with prestressed strands and energy-dissipating plates;

Post-tensioned concrete (PC): with prestressed strands only (no energy-dissipating plates); and

Reinforced self-centering (RSC): with energy-dissipating plates only (no prestressed strands).

Key design parameters are detailed in Table 1.

Design of joints

| Model | Energy-dissipating plates | Prestressed steel strands | Initial prestress (kN) |

|---|---|---|---|

| PSC | √ | √ | 150 |

| PC | / | √ | 150 |

| RSC | √ | / | 0 |

Reinforcement detailing remains identical across all joints’ precast concrete beams and columns. The specimens differ solely in their connection configurations:

The PC joint omits energy-dissipating plates compared to the PSC joint.

The RSC joint omits prestressed strands compared to the PSC joint.

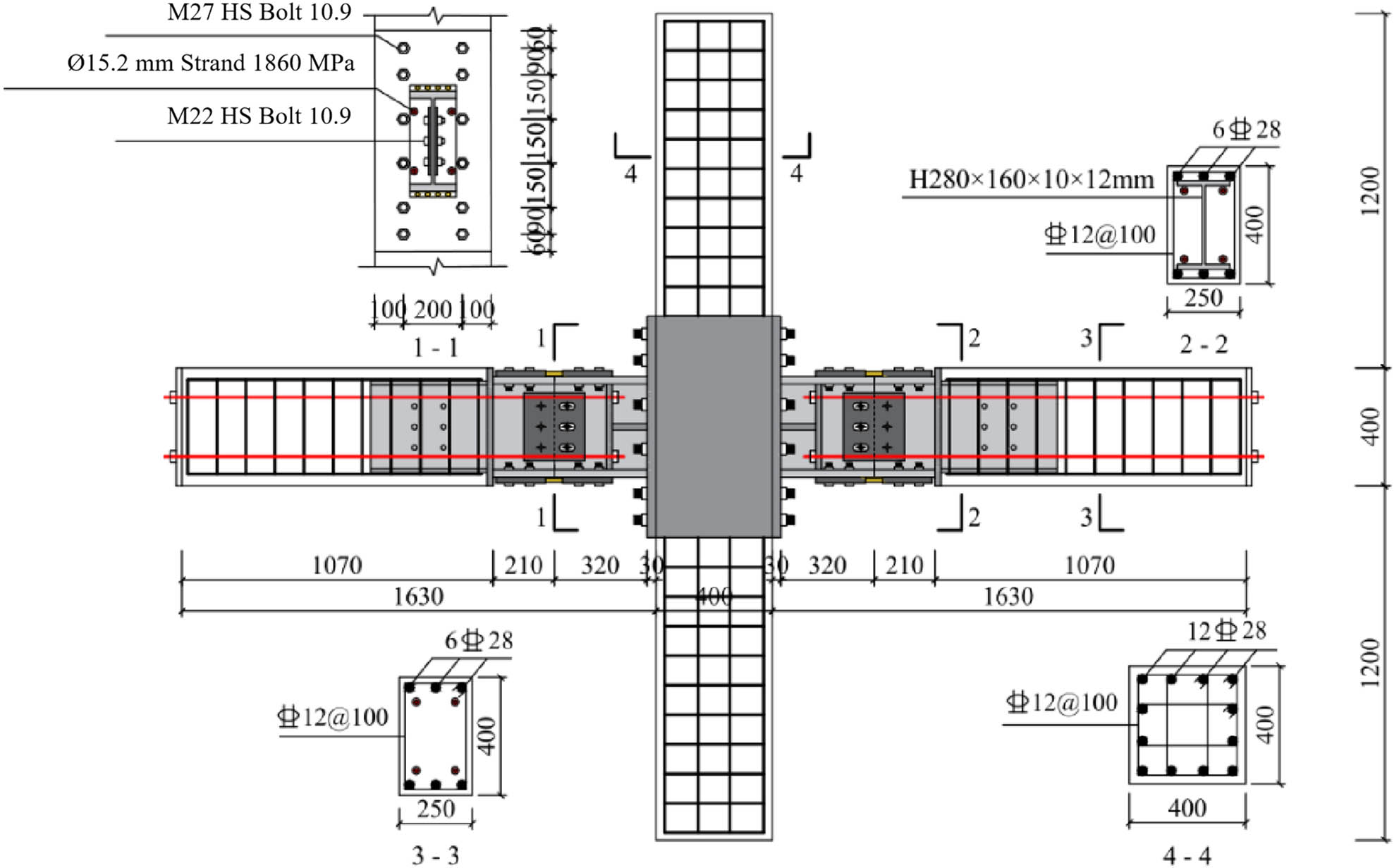

Using the PSC joint as the reference configuration, detailed dimensions and reinforcement are specified (Figure 2). All reinforcing bars in the joints utilized HRB400 steel (hot-rolled ribbed bars, characteristic yield strength f y = 400 MPa). The PSC joint configuration employs precast concrete columns with 400 mm × 400 mm cross-sections and prestressed steel-concrete composite beams spanning 1,630 mm on each side. Beam cross-sections measure 250 mm × 400 mm, cast from C40 concrete. Reinforcement configured as twelve 28 mm-diameter longitudinal bars and 12 mm-diameter stirrups spaced at 80 mm within plastic hinge zones and 100 mm elsewhere (4-legged arrangement).

Dimensional and reinforcement details of the PSC joint.

To enhance core-zone shear capacity: stirrups are densely spaced in the joint core region and a 400 mm × 400 mm × 14 mm square steel tube extends 750 mm vertically through the core. Energy-dissipating components utilize Q235 steel, while all other structural steel is Q345 grade. Connections employ M27 Grade 10.9 high-strength bolts passing through 30 mm-diameter holes in precast columns.

The prestressed steel-concrete composite beam system comprises four integrated subsystems:

Steel beam: H340 × 280 × 10 × 25 cross-section, 320 mm long. Anchorage plates (20 mm thick) and stiffening ribs are welded to its mid-section, with a 30 mm-thick end plate at the column interface.

Composite beam assembly: Total length 1,280 mm, containing: Reinforced concrete beam (1,050 mm long) with six 28 mm-diameter longitudinal bars and 12 mm-diameter 2-legged stirrups spaced at 100 mm. Encased steel beam (400 mm long, H280 × 160 × 10 × 12). End steel beams (210 mm long, H340 × 280 × 10 × 25) welded to 20 mm-thick end plates. Longitudinal steel bars are welded to encased beam flanges over 370 mm.

Energy-dissipation system: Four 8 mm-diameter steel bars (60 mm long). Two 20 mm-thick flange connection plates

Connection system: 10 mm-thick web connection plates. M22 Grade 10.9 high-strength bolts.

Energy dissipation plates and 10 mm-thick web connection plates connect the steel beams to the steel-concrete composite beams employing Grade 10.9 M22 high-strength bolts and prestressing strands. Four 15.2 mm-diameter 1860-grade prestressing strands (1 × 7 standard type) are symmetrically arranged along the concrete beam length. Each strand is tensioned to 150 kN.

2.3 Loading procedure

The axial compression ratio at each joint is 0.3. The loading method employs column-end displacement control, with the loading point located 200 mm from the top of the column. The loading diagram is shown in Figure 3. The displacement angles for the first three loading stages are 0.25, 0.5, and 0.75%, with each stage cycled once; Subsequent loading displacement angles are 1.0, 1.5, 2%, etc. (i.e., each loading displacement angle increases by 0.5% sequentially), with each level cycled twice. Loading is stopped when any of the following conditions are met: the steel exhibits obvious buckling, the concrete suffers severe damage, or the prestressed steel strands reach their nominal yield strength.

Loading setup schematic.

3 Validation of the finite element model

3.1 Specimen details for validation

Based on experimental data on self-centering steel-concrete composite joints, this study validates the finite element modeling approach using the ZJD-3 prestressed joint. The details of Specimen ZJD-3 are illustrated in Figure 4 [23]. Specimen ZJD-3 shares identical beam-column dimensions and reinforcement details with the proposed joint, but it features prestressed strands passing directly through the joint core, whereas the novel joint employs a ground-level single-span post-tensioning approach (increasing susceptibility to adverse effects during core failure and requiring elevated-level strand tensioning during testing). The ZJD-3 system comprises:

Precast columns with embedded steel sleeves.

Steel-concrete composite beams with 400 mm-long Q235 steel beams (HN200 × 100 × 5.5 × 8).

Encased steel beams welded to 30 mm-thick Q345 end plates.

440 mm-long main steel beam (HN350 × 175 × 7 × 11).

Connections via 10.9-grade high-strength bolts and four 15.2 mm-diameter 1860-grade prestressing strands.

![Figure 4

Dimensional and reinforcement details of ZJD-3 [23].](/document/doi/10.1515/rams-2025-0151/asset/graphic/j_rams-2025-0151_fig_004.jpg)

Dimensional and reinforcement details of ZJD-3 [23].

Validation simulations replicated the experimental conditions: axial compression ratio of 0.3 and reversed cyclic loading at the column end.

3.2 Finite element modeling methodology

This study employs the plastic damage model to simulate the mechanical behavior of concrete, based on the uniaxial stress-strain relationship recommended in the Chinese national standard Code for Design of Concrete Structures [24] as its constitutive relationship, as illustrated in Figure 5(a). To simulate bond-slip behavior between reinforcing steel and concrete, a bilinear constitutive model (Figure 5(b)) was implemented for reinforcing bars, structural steel, and bolts; prestressed strands lacking a distinct yield plateau were modeled using a linear elastic constitutive model (Figure 5(c)). Except for reinforcing bars and steel strands, which use T3D2 elements, all other joint components employ C3D8R elements.

![Figure 5

Constitutive relations of materials [24]. (a) Uniaxial stress-strain relationship. (b) Bilinear constitutive model. (c) Linear elastic constitutive model.](/document/doi/10.1515/rams-2025-0151/asset/graphic/j_rams-2025-0151_fig_005.jpg)

Constitutive relations of materials [24]. (a) Uniaxial stress-strain relationship. (b) Bilinear constitutive model. (c) Linear elastic constitutive model.

Mesh sensitivity critically governs computational accuracy, convergence behavior, and solution efficiency in finite element simulations. Following rigorous convergence studies, optimized element sizes were implemented: structural concrete at 50 mm; reinforcement systems (rebars and prestressing strands) at 75 mm; steel assemblies (sleeves, connection plates, structural shapes, end plates, and stiffeners) at 20 mm; and critical connectors (bolts and energy-dissipating bars) at 5 mm. Contact interactions employed hard contact pressure-overclosure for normal behavior and a penalty friction formulation for tangential behavior – with friction coefficients of µ = 0.35 for steel-to-bolt nut interfaces, µ = 0.6 for steel-to-concrete [25], and frictionless conditions (µ = 0) for bolt shank interactions with steel or concrete [26]. Constraint definitions utilized embedded region formulations to simulate concrete-rebar and concrete-encased steel interactions, while MPC-beam constraints governed the kinematic coupling between prestressing strands and concrete components.

Finite element boundary conditions were rigorously aligned with experimental protocols by constraining degrees of freedom consistent with the column-end loading methodology. The column base was fully fixed against translations in all directions and rotations about the x and y axes, while the column top was restrained vertically and in rotational degrees of freedom. Both beam ends were constrained against transverse displacements and rotations. To optimize computational efficiency while ensuring convergence, the analysis employed a quasi-static displacement protocol mirroring experimental sequences, stepping through drift ratios of 0.1, 0.2, 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, and 4.0% with single-cycle implementation at each increment.

3.3 Analysis of finite element simulation results

The equivalent plastic strain (PEEQ) is the cumulative result of plastic strain during deformation and reflects the degree of plastic damage in the material throughout the loading process. Figure 6(a) shows the final failure mode of the simulated joint under low cyclic loading. As can be seen from the figure, plastic damage is primarily concentrated in the end plates and the upper and lower flanges of the steel beams near the end plates. No significant plastic damage occurs in other parts of the joint, which is consistent with the failure mode of the tested joint (Figure 6(b)).

![Figure 6

Failure mode comparison: numerical simulation vs experimental test. (a) Numerical model. (b) Test specimen [23].](/document/doi/10.1515/rams-2025-0151/asset/graphic/j_rams-2025-0151_fig_006.jpg)

Failure mode comparison: numerical simulation vs experimental test. (a) Numerical model. (b) Test specimen [23].

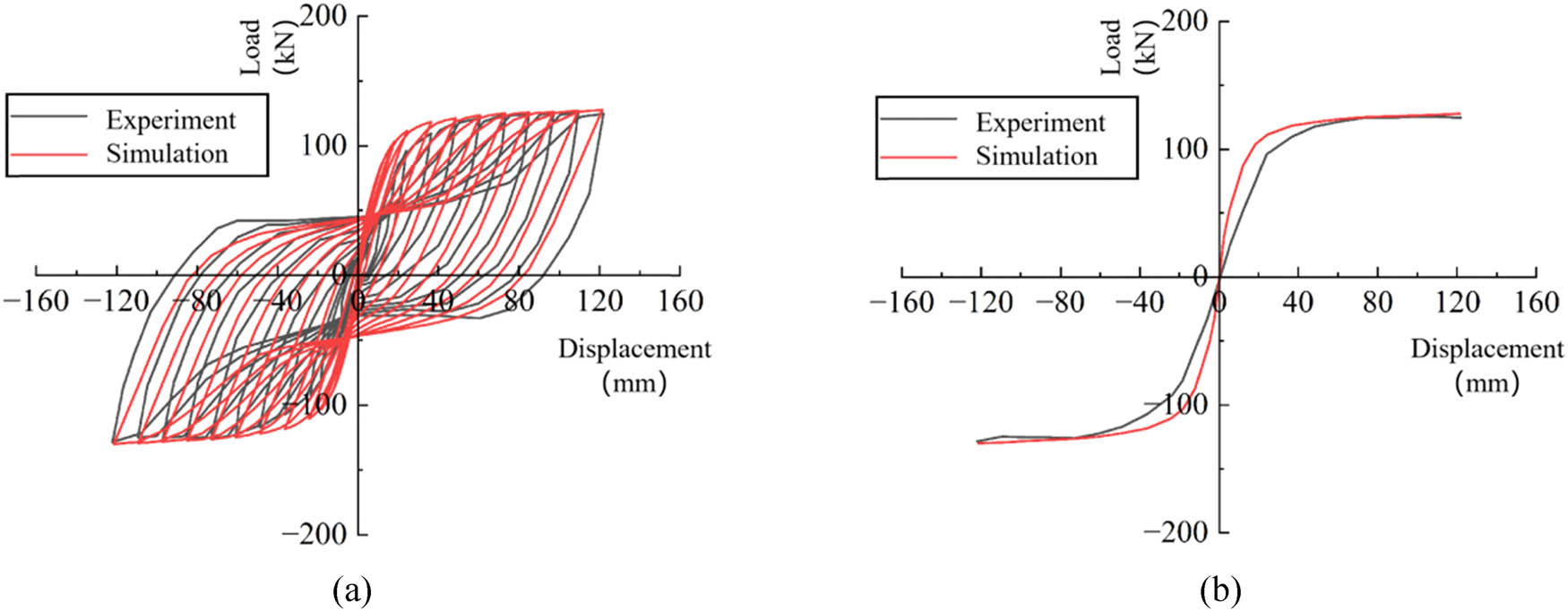

Hysteresis loop comparison and envelope skeleton curve comparison were illustrated in Figure 7. Figure 7(a) demonstrates strong agreement between experimental and finite element hysteresis curves, with marginal differences in load values at maximum displacements – confirming the simulation’s effectiveness in replicating specimen stress states. The ABAQUS model exhibits marginally higher initial stiffness due to idealized bound connections representing welded joints and unaccounted material imperfections. This simplification omits cyclic damage progression in steel components, resulting in moderately elevated structural stiffness compared to physical tests. Nevertheless, Figure 7(b) reveals closely matched skeleton curves, with only 1.8% variance in peak load capacity. This sub-2% discrepancy validates the simulation methodology’s accuracy and establishes its reliability for seismic performance assessment.

Hysteresis loop curves and envelope skeleton curves. (a) Hysteresis loop curves. (b) Envelope skeleton curves.

4 Comparative seismic performance analysis of joint configurations

The same simulation method was used to perform finite element analysis on the three prefabricated interior joint models designed in this paper, analyzing the impact of energy-dissipating plates and prestressed steel strands on the seismic performance of the new self-centering steel-concrete composite joint (PSC joint). The joint employed meshing parameters consistent with the validation specimen ZJD-3, utilizing 50 mm sizes for concrete, 75 mm sizes for reinforcing bars and prestressed strands, and 20 mm sizes for square steel tube, connection plates, shaped steel, end plates, stiffeners, spacers, and anchorage plates, with 5 mm sizes applied to bolts and energy-dissipating steel bars to resolve critical localized regions. The T3D2 element type is used to simulate reinforcement and prestressing strands; the C3D8R element type is used to simulate the rest of the joint components. The developed finite element model of the PSC joint, including its mesh discretization, is illustrated in Figure 8.

Schematic illustration of mesh discretization for PSC joint components. (a) Concrete mesh discretization. (b) Reinforcement mesh discretization. (c) Steel component mesh discretization.

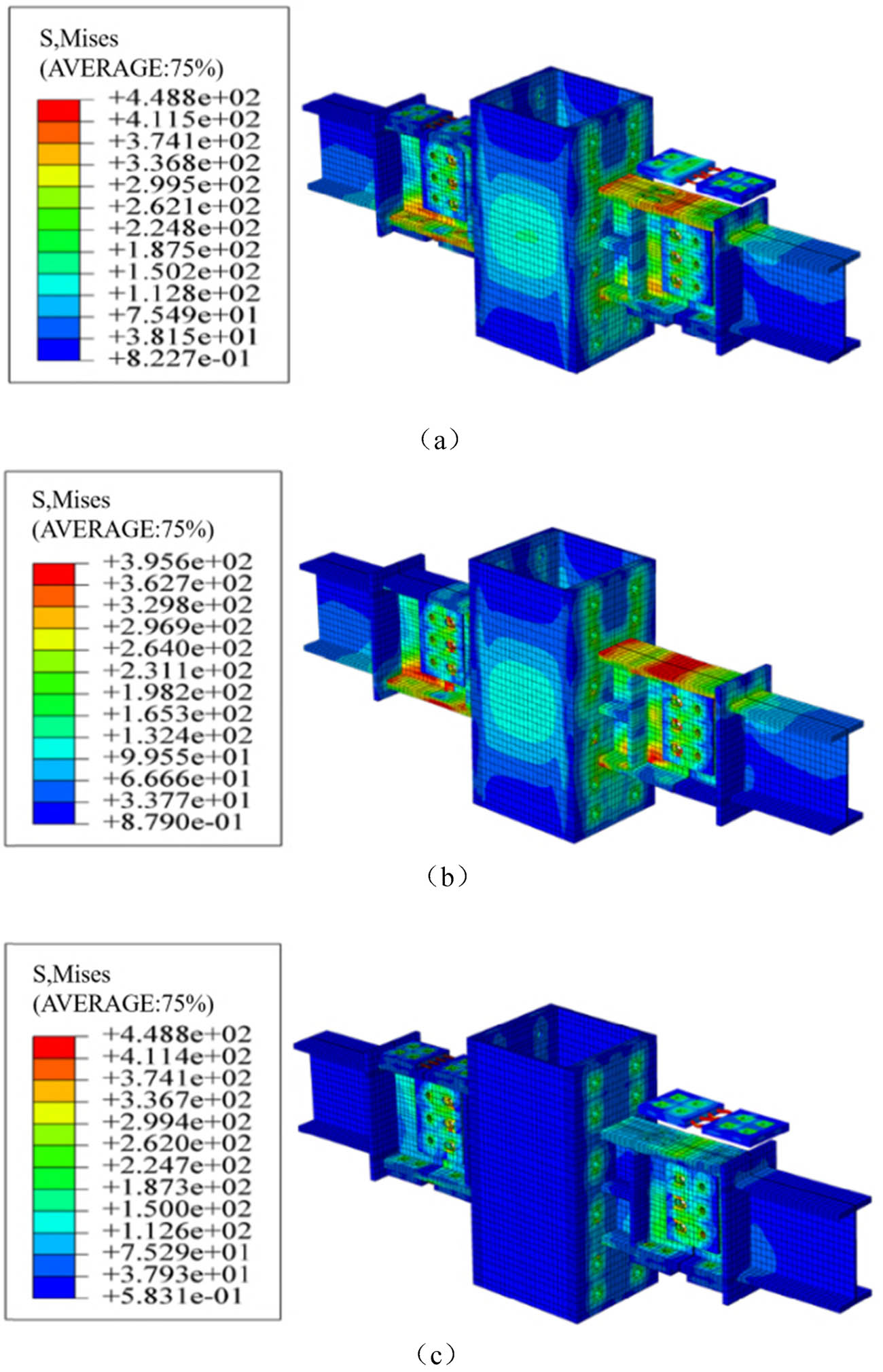

4.1 Failure modes

Figure 9 presents stress contours for structural steel and connection plates across all joint types. For visual clarity, energy-dissipating plates were computationally removed from the compression flange on the right side of PSC and RSC joints. Analysis reveals distinct damage patterns: PSC joints exhibit plastic deformation concentrated in energy-dissipating bars and the compression flange, while PC joints show localized yielding primarily in the compression flange. Crucially, neither joint type demonstrates significant flange buckling, with minimal plastic damage elsewhere. Conversely, RSC joints concentrate deformation exclusively in energy-dissipating bars, preserving flange integrity. Notably, PSC joints substantially reduce beam damage compared to PC variants through controlled energy dissipation, significantly enhancing post-earthquake recoverability by limiting structural steel yielding.

Stress contours of steel sections and connector plates. (a) PSC joint. (b) PC joint. (c) RSC joint.

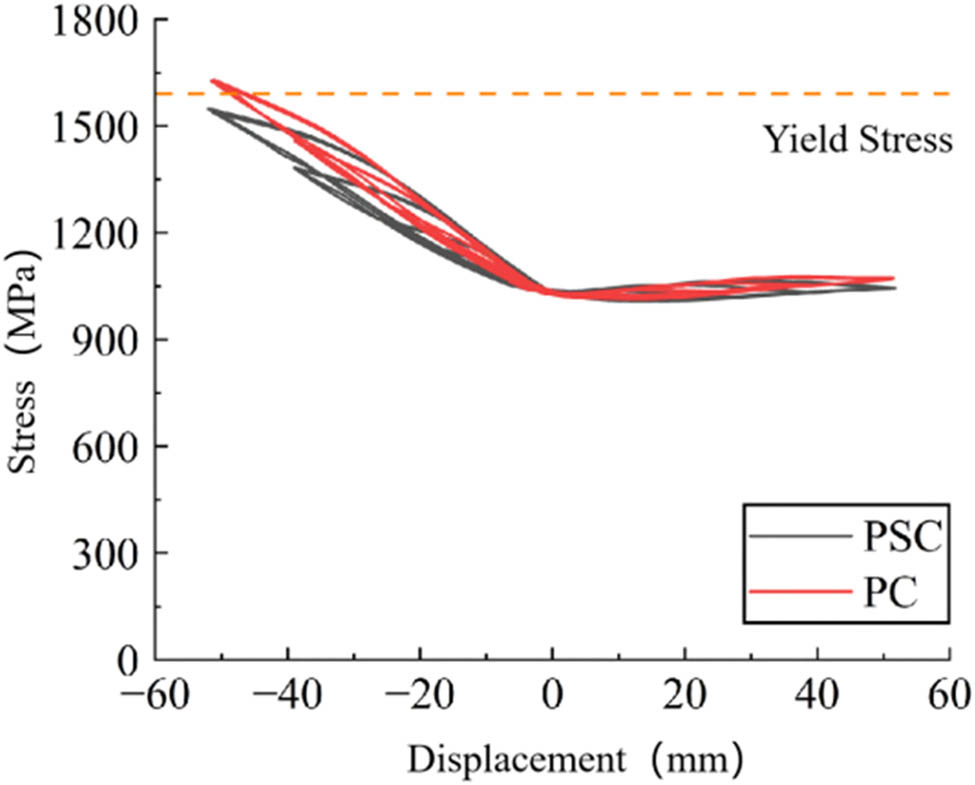

Figure 10 compares prestressing strand stress-displacement responses in PSC and PC joints, revealing two critical findings:

PC joint strands exceed yield stress during loading, inducing failure through strand yielding that compromises structural safety. Conversely, PSC joint strands remain strictly within the elastic range, precluding yielding and maintaining structural integrity.

The addition of energy-dissipating plates increases the stiffness of the rotating section of the steel-concrete composite beam, reducing the rotational capacity of the PSC joint under the same displacement. This reduces the elongation of the steel strands, resulting in a slower rate of stress change in the PSC joint compared to the PC joint.

Stress-displacement curves of steel strands.

Overall, the failure modes of PSC joints and RSC joints mainly manifest as obvious buckling deformation of the energy-dissipating steel bars in the energy-absorbing plates, while the failure mode of PC joints mainly manifests as yielding of the prestressed steel strands. In all three types of assembled middle joints, the concrete in the joints remained largely undamaged, and the failure modes all manifested as bending failure at the beam ends.

4.2 Hysteretic loops and skeleton curves

Hysteresis loop area quantifies a specimen’s energy absorption capacity, with fuller loops indicating superior seismic energy dissipation. In Figure 11, flag-shaped hysteresis curves demonstrate self-centering capability with minimal residual displacement, enabling rapid post-earthquake recovery, while Z-shaped curves reveal structural vulnerabilities signaling inadequate energy dissipation and large residual deformations requiring mitigation. The skeleton curve traces peak load-bearing capacity versus lateral displacement, defining the load-deformation relationship throughout loading cycles. Figure 11 presents hysteresis and skeleton curves for all joint configurations, revealing three key performance distinctions. First, PSC and PC joints exhibit minimal residual deformation with hysteresis loops evolving from linear to flag-shaped configurations, while RSC joints display substantially larger residual deformations and spindle-to-Z-shaped hysteresis transitions. This behavioral divergence stems from RSC’s reduced initial stiffness, amplifying angular displacements at joint interfaces that intensify friction and sliding in web connection plates. Second, PSC joints demonstrate 18.1% higher yield load and 14.5% greater ultimate load than PC joints, confirming that energy-dissipating plates enhance load-bearing capacity beyond self-centering functionality. Most significantly, PSC joints achieve 93.1 and 142.1% improvements in yield and ultimate loads, respectively, over RSC joints – demonstrating that prestressing strands not only enable self-centering but fundamentally transform structural resistance mechanisms through active clamping forces.

Hysteretic behavior with envelope skeleton curves. (a) Hysteresis loops. (b) Envelope skeleton curves.

4.3 Ductility

The ductility of each joint was calculated using the tangent method [27]. The characteristic values of the skeleton curve and the ductility coefficients are shown in Table 2. As shown in the table, the displacement ductility coefficients of PC joints and RSC joints are greater than those of PSC joints. This is because PSC joints incorporate both energy-dissipating plates and prestressed steel strands, which increase the overall stiffness of the joint, thereby reducing its rotational capacity. This delays the joint’s entry into plastic deformation, resulting in an increase in the joint’s yield displacement and a corresponding reduction in ductility. The displacement ductility coefficients of all joints exceed 3.0, meeting the seismic code requirement for structural ductility coefficients greater than 3.0 [28], indicating that although the proposed PSC joints have reduced ductility, they still possess good deformation capacity.

Characteristic values and ductility coefficients of skeleton curves

| Model |

|

|

|

|

|

|---|---|---|---|---|---|

| PSC | 176.06 | 14.91 | 259.11 | 51.27 | 3.44 |

| PC | 149.07 | 13.56 | 226.23 | 51.53 | 3.80 |

| RSC | 91.17 | 9.98 | 107.03 | 51.56 | 5.17 |

Note:

4.4 Stiffness degradation and self-centering capability

The trend of stiffness degradation at each joint is represented using the secant stiffness [29]. The secant stiffness is defined as the ratio of the sum of the absolute values of the peak loads under the same positive and negative loading displacements to the sum of the corresponding absolute values of the displacements. The stiffness degradation curves for each joint are shown in Figure 12(a). As shown in Figure 12(a):

The stiffness of each joint decreases with increasing loading displacement, and the rate of stiffness degradation gradually slows down.

The initial stiffness of PSC joints is greater than that of PC joints, and the tangent stiffness of PSC joints at all loading displacements is also greater than that of PC joints, indicating that the addition of energy-dissipating plates can enhance the initial stiffness of joints.

The initial stiffness of PSC joints is approximately 1.52 times that of RSC joints, indicating that the addition of prestressed steel strands can significantly enhance the initial stiffness of joints, with a relatively large contribution to the initial stiffness.

Stiffness degradation curves and residual deformation angle curves. (a) Stiffness degradation curves. (b) Residual deformation angle curves.

Residual deformation angle – defined as residual displacement divided by the column height from loading point to base – serves as the key metric for joint self-centering capability, with values ≤0.2% indicating fully recoverable structures [30]. Figure 12(b) demonstrates that all joints exhibit progressively increasing residual angles with displacement amplitude, though PSC joints show marginally higher residual angles than PC joints across loading stages due to energy-dissipating plate inclusion. Crucially, both remain well below the 0.2% recoverability threshold, confirming effective self-centering functionality advantageous for post-earthquake repair, with PSC joints demonstrating superior resilience. Conversely, the residual deformation angles of RSC joints are significantly larger than those of PSC and PC joints at all stages, and the residual deformation angle at the end of loading is far greater than 0.2%, indicating that RSC joints lack self-centering capability due to the absence of prestressed steel strands.

4.5 Energy dissipation capacity

Cumulative energy consumption and equivalent viscous damping coefficient were employed as metrics to evaluate the energy dissipation capacity of each joint type, as illustrated in Figure 13(a). Key observations from Figure 13(a) are as follows:

Comparison between self-centering joints (PSC vs PC): The cumulative energy dissipation of the PSC joints, incorporating energy dissipation plates, consistently exceeded that of the PC joints without such plates. The disparity in cumulative dissipation progressively increased with loading cycles, culminating in the PSC joints achieving approximately 1.66 times the cumulative dissipation of the PC joints. This demonstrates that the integration of energy dissipation plates significantly enhances joint energy dissipation capacity.

Comparison between joints with energy dissipation plates (PSC vs RSC): Conversely, the cumulative energy consumption of the PSC joints (featuring prestressed strands) was consistently lower than that of the RSC joints lacking prestressed strands. Ultimately, the cumulative energy consumption of the PSC joints was 16.4% less than that of the RSC joints. This indicates that the inclusion of prestressed steel strands moderately reduces the joint’s energy dissipation capacity; however, the magnitude of this effect is notably smaller than the enhancement provided by energy dissipation plates.

Energy dissipation curves. (a) Cumulative energy dissipation curves. (b) Equivalent viscous damping ratios curves.

The equivalent viscous damping coefficients for each joint type are presented in Figure 13(b). Analysis of Figure 13(b) reveals the following key findings:

Trends in damping evolution: The equivalent viscous damping coefficients for all joint types exhibited generally consistent trends, increasing progressively with displacement amplitude. Notably, the coefficients for both the PSC joints and the RSC joints (both incorporating energy-dissipation plates) consistently surpassed those of the PC joints (without plates).

Damping values at ultimate displacement: At the ultimate displacement level, the equivalent viscous damping coefficients, calculated from hysteresis loops, were 0.128 for the PSC joints, 0.093 for the PC joints, and 0.248 for the RSC joints. In comparison, conventional reinforced concrete joints typically exhibit an equivalent viscous damping coefficient of approximately 0.1 [31]. These results demonstrate that joints equipped with energy-dissipation plates (PSC and RSC) exhibit superior energy dissipation capacity, whereas the PC joint (lacking energy-dissipation plates) demonstrates limited energy dissipation capability.

Based on the above analysis, it can be concluded that the proposed new joint type can ensure self-centering while balancing energy dissipation and ductility. The presence of energy dissipation plates can enhance the joint’s energy dissipation capacity, while the presence of prestressed steel strands can enhance the joint’s self-centering capacity. Overall, the new joint type meets the energy dissipation requirements of seismic design.

5 Core region shear capacity formulation

5.1 Calculation method for the shear bearing capacity of the joint core area

Joints serve as critical load-transferring components in structures, where joint failure precipitates simultaneous failure of beams and columns. The joint core region typically experiences a triaxial stress state combining axial compression, bending, and shear. Shear failure represents a prevalent failure mode in RC frame joint cores, characterized by diagonal cross-cracks or inclined concrete crushing. Hence, particular attention must be devoted to rational assessment of shear capacity in joint core design to mitigate brittle failure characteristics associated with core shear failure.

The shear capacity formula for beam-column joints is therefore a core theoretical tool in structural design, serving to quantify the shear resistance of the joint core region. This quantification is fundamental to ensuring the seismic design principle of strong-joint weak-component is achieved under extreme loading, particularly seismic actions. By providing a rational assessment of whether the joint can effectively transfer bending moments and shear forces from the beam ends, the formula plays a vital role in preventing shear failure within the core region. This prevention, in turn, safeguards the structural integrity, ductility, energy dissipation capacity, and overall collapse resistance of the structure.

Consequently, this formula finds wide application in engineering practice, including the seismic design of frame structures, the strengthening evaluation of existing buildings, and the connection design of prefabricated structures. Its importance extends beyond safety considerations, such as preventing catastrophic collapses triggered by brittle joint failure, to encompass economic efficiency. Through precise calculation, the formula enables engineers to balance necessary safety margins with material cost optimization.

The novel joint proposed in this study enhances core shear capacity through integrated square steel tubes within the joint core region. Analysis based on strut-and-tie theory reveals its load-resisting mechanism. During the initial loading stage, when the joint is in the elastic phase, shear force is primarily resisted by the inclined compressive struts formed by the concrete in the core region of the joint. At this stage, the shear deformation of the concrete in the core region is essentially consistent with that of the web of the square steel tube. As loading increases, multiple diagonal cracks develop in concrete, reducing the shear resistance contribution of concrete struts while inducing deformation incompatibility between concrete and square steel tubes. This leads to progressively increased shear resistance contribution from the square steel tubes. When further plastic deformation occurs, concrete’s strut action significantly diminishes due to crack propagation and spalling, concurrently mobilizing greater shear resistance from stirrups. Consequently, the total shear capacity of the novel joint comprises three components: core concrete contribution, square steel tube contribution, and stirrup contribution.

5.1.1 Shear capacity contribution of the core region concrete

Due to the pre-tension force of high-strength bolts and the confinement effect provided by the square steel tube, the novel self-centering steel-concrete composite joint significantly enhances the shear capacity of the core region concrete. Furthermore, the presence of energy dissipation plates can reduce the flexural capacity at the beam ends, promoting the formation of plastic hinges at these locations and thereby protecting the prefabricated columns. Consequently, when joint failure occurs, no significant damage is observed in the core region concrete, and neither the longitudinal reinforcement nor the horizontal stirrups experience yielding due to their lower stress levels. The load-bearing mechanism of the joint conforms to the “Strut-and-Tie Mechanism”. Therefore, the contribution of the core region concrete to the overall shear capacity in the novel joint is analyzed using the Strut-and-Tie Model, with the calculation formula given as follows:

where

The sectional height of the joint

Assuming

where

where

Substituting Eq. (4) into Eq. (5) yields the expression:

5.1.2 Shear capacity contribution of a square steel tube

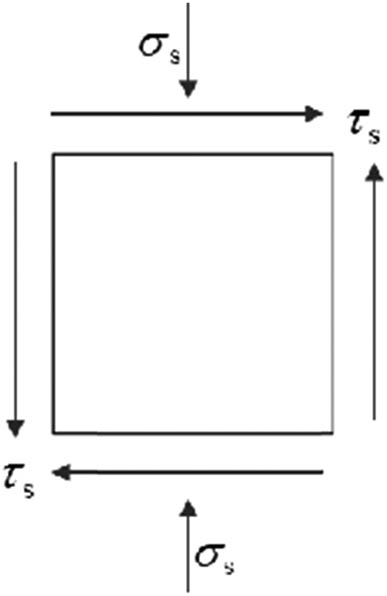

According to the research findings in reference [33], the contribution of the flanges of the square steel tube to the shear capacity of the joint is relatively small; therefore, the influence of the flanges may be neglected in the shear capacity calculation. The web of the square steel tube in the core region is subjected to a combined shear-compression stress state under the concurrent action of compressive stress and shear stress, as shown in Figure 14.

Stress state of the square steel tube web.

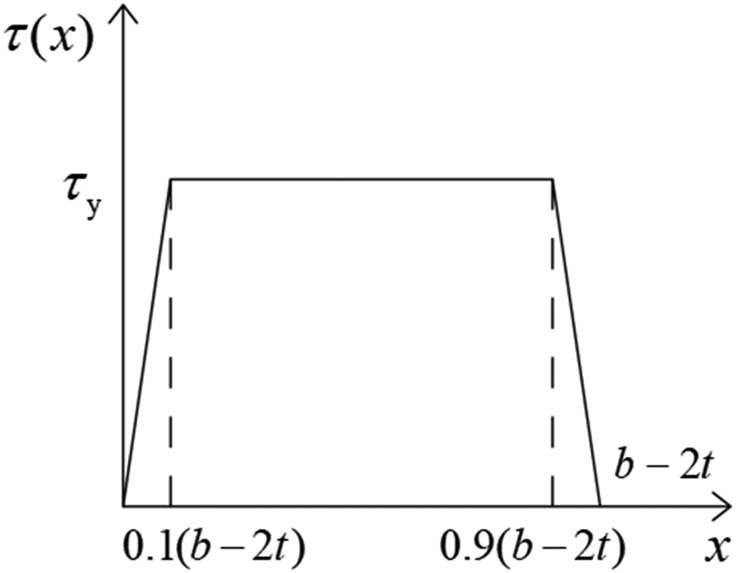

Based on the distribution of shear stress at yield in the square steel tube web [34], illustrated in Figure 15, the shear capacity of the web can be determined. The calculation formula is given as follows:

Shear stress distribution in the square steel tube web.

where

In the elastic stage, the principal stresses at each point on the web are:

When the joint reaches the ultimate bearing capacity, the steel reaches the plastic flow state, which conforms to the Mises yield rule:

where

Substituting the principal stress expression into Eq. (11) yields the shear stress at web yield:

The research shows that the axial pressure has little effect on the shear capacity of the square steel tube web [35]. Therefore, the shear stress expression when the web yields can be simplified as:

At joint failure, the web of the square steel tube does not yield. Based on recommendations from the Architectural Institute of Japan (AIJ) [31], a reduction factor of 0.5 is applied to derive the calculation formula for the shear capacity of the square steel tube web, as shown in Eq. (14).

5.1.3 Shear capacity contribution of stirrups

The presence of stirrups restrains crack propagation in the core region concrete and reduces shear deformation. Stirrups primarily contribute to shear resistance after cracking of the core region concrete. The calculation formula for their shear capacity contribution is expressed as follows:

where

The proposed novel joint’s shear capacity derives from three primary mechanisms: concrete resistance in the core region, confinement by the square steel tube, and shear reinforcement from stirrups. The calculation formula is therefore given by

5.2 Verification of shear capacity calculation accuracy

Analysis of the failure mode in the aforementioned PSC joint reveals that failure manifested at the beam ends, concentrating on the energy-dissipating steel bars. The joint core concrete exhibited no significant damage, and no shear failure occurred in the core region. To evaluate the accuracy of the proposed shear capacity calculation formula, two additional joint specimens were designed based on the prototype PSC joint. Key parameter variations in their core regions are detailed in Table 3. By reducing the strength grades of the square steel tubes and stirrups, along with decreasing the core region stirrup reinforcement ratio, the shear capacity of the joint core was intentionally compromised. Through refined finite element simulations, this study examines whether the proposed formula accurately assesses the actual shear capacity when core region shear failure is induced.

Variation of core region parameters in joint models

| Model | Rebar grade | Core region stirrups | Energy-dissipating steels diameter (mm) | Controlled tensile stress |

|---|---|---|---|---|

| PSC | HRB400 | Ø 12/100 (2) | 10 |

|

| PSC-I | HRB335 | Ø 8/80 (4) | 10 |

|

| PSC-II | HRB335 | Ø 10/80 (4) | 10 |

|

Comparison between calculated and simulated shear capacity values revealed certain discrepancies. This occurred because the designed joint model lost its load-bearing capacity prior to failure in the core region, leading to termination of loading. Therefore, to further verify the accuracy of the proposed shear capacity calculation formula, two joint models were designed following the weak-joint strong-component principle. The shear capacity of the joint core region was intentionally reduced by decreasing the strength grades of the square steel tube and stirrups, along with reducing the stirrup reinforcement ratio in the core region. This approach ensured the occurrence of shear failure in the joint core region. Variations in core region parameters for the joint models are presented in Table 3.

A comparison between the calculated shear capacity values and finite element simulation results for the joint models with intentionally weakened core regions is presented in Table 4. The ratios of calculated to simulated values are consistently close to unity, demonstrating that the proposed shear capacity calculation formula can serve as a reliable reference for practical engineering applications of this novel joint.

Comparison between calculated and finite element simulation values of shear capacity

| Model | Simulation (kN) | Calculated (kN) | Calculated/simulation |

|---|---|---|---|

| PSC-I | 1484.68 | 1433.99 | 0.97 |

| PSC-II | 1604.66 | 1603.82 | 1.00 |

6 Conclusion

This study proposes a novel self-centering steel-concrete composite joint, which is more reasonable and easier to repair after an earthquake. This joint validates a dual-mechanism joint with prestressed strands and replaceable energy-dissipating plates and demonstrates excellent seismic resilience through compliant failure modes, synergistic self-centering, and energy dissipation mechanisms. Based on experimental verification, FEM simulation, and theoretical derivation, key findings are summarized as follows:

The proposed novel self-centering joint integrates prestressed steel strands and replaceable energy-dissipating plates. When designed properly, it can exhibit consistent beam-end flexural failure modes with minimal concrete damage in core regions, confirming compliance with seismic design principles of strong columns – weak beams and strong joints – weak components.

Prestressing strands effectively mitigate residual deformations to provide robust self-centering capability, while energy-dissipating plates regulate strand stress fluctuations to prevent premature yielding. These plates further concentrate plastic deformation within replaceable steel bars, reducing beam damage and enabling post-earthquake functional recovery. The synergistic combination of both systems simultaneously achieves structural recentering and repairability.

The novel self-centering steel-concrete composite joint, incorporating energy-dissipating plates and prestressed steel strands, exhibits excellent energy dissipation and self-centering capabilities, while maintaining high load-bearing capacity. These characteristics indicate that the proposed joint design demonstrates superior seismic performance.

The shear resistance of this joint is primarily undertaken by the square steel tube, the concrete in the core region, and the stirrups collectively. The formula for calculating the joint’s shear capacity is derived using the superposition method. The calculated values from the formula show good agreement with the results obtained from finite element simulations.

-

Funding information: This research was supported by the National Natural Science Foundation of China (Grant No. 52078138, Grant No. 51208114), the University-Industry Collaborative Innovation Science and Technology Program Project of Fujian Province in 2024 (No. 2024Y4013), and the Natural Science Foundation of Fujian Province (Grant No. 2018J01770).

-

Author contributions: Suguo Wang: writing – review and editing, supervision, methodology, conceptualization, and funding acquisition. Jing Lin: writing – review and editing, validation, formal analysis, and data curation. Zhiquan Xing: supervision, investigation, validation, and data curation. Binghui Fan: conceptualization, supervision, validation, and data curation. Yu Chen: conceptualization, supervision, investigation, and funding acquisition. Zhiqing Deng: writing – original draft, validation, formal analysis, and data curation. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The raw/processed data required to reproduce these findings cannot be shared at this time, as the data form part of an ongoing study.

References

[1] Nie, X., D. Huang, L. Zhuang, J. Fan, and N. Deng. Precast concrete connections for alleviating reinforcement congestion: A state-of-the-art review. Engineering Structures, Vol. 331, 2025, id. 119985.10.1016/j.engstruct.2025.119985Search in Google Scholar

[2] Guaygua, B., A. J. Sánchez-Garrido, and V. Yepes. A systematic review of seismic-resistant precast concrete buildings. Structures, Vol. 58, 2023, id. 105598.10.1016/j.istruc.2023.105598Search in Google Scholar

[3] Balineni, H., D. C. K. Jagarapu, and A. Eluru. Analysis of dry and wet connections in precast beam-column joint using ABAQUS software. Materials Today: Proceedings, Vol. 33, 2020, pp. 287–295.10.1016/j.matpr.2020.04.073Search in Google Scholar

[4] Ding, K., Y. Ye, and W. Ma. Seismic performance of precast concrete beam-column joint based on the bolt connection. Engineering Structures, Vol. 232, 2021, id. 111884.10.1016/j.engstruct.2021.111884Search in Google Scholar

[5] Huang, W., G. Hu, and J. Zhang. Experimental study on the seismic performance of new precast concrete beam-column joints with replaceable connection. Structures, Vol. 35, 2022, pp. 856–872.10.1016/j.istruc.2021.11.050Search in Google Scholar

[6] Ye, M., J. Jiang, H. M. Chen, H. Y. Zhou, and D. D. Song. Seismic behavior of an innovative hybrid beam-column connection for precast concrete structures. Engineering Structures, Vol. 227, 2021, id. 111436.10.1016/j.engstruct.2020.111436Search in Google Scholar

[7] Ma, W., Y. Li, K. Ding, B. Cheng, J. Liu, J. Hao, et al. Mechanical properties of new dry-type beam-column bolt connection joint. Sustainability, Vol. 11, 2019, id. 3348.10.3390/su11123348Search in Google Scholar

[8] Zhang, Y. and D. Li. Seismic behavior and design of repairable precast RC beam–concrete-filled square steel tube column joints with energy-dissipating bolts. Journal of Building Engineering, Vol. 44, 2021, id. 103419.10.1016/j.jobe.2021.103419Search in Google Scholar

[9] Ding, F., Y. Chen, L. Wang, Z. Pan, C. Li, T. Yuan, et al. Hysteretic behavior of CFST column-steel beam bolted joints with external reinforcing diaphragm. Journal of Constructional Steel Research, Vol. 183, 2021, id. 106729.10.1016/j.jcsr.2021.106729Search in Google Scholar

[10] Li, Y. and B. Huang. Research on load-bearing performance of new fabricated steel structure beam-column joints with energy-dissipating elements. Structures, Vol. 38, 2022, pp. 492–501.10.1016/j.istruc.2022.02.001Search in Google Scholar

[11] Wang, C. L., Y. Liu, and L. Zhou. Experimental and numerical studies on hysteretic behavior of all-steel bamboo-shaped energy dissipaters. Engineering Structures, Vol. 165, 2018, pp. 38–49.10.1016/j.engstruct.2018.02.078Search in Google Scholar

[12] Cai, X., N. Gong, C. C. Fu, Y. Zhu, and J. Wu. Seismic behavior of self-centering prestressed precast concrete frame subassembly using steel top and seat angles. Engineering Structures, Vol. 229, 2021, id. 111646.10.1016/j.engstruct.2020.111646Search in Google Scholar

[13] Momenzadeh, S., M. T. Kazemi, and M. H. Asl. Seismic performance of reduced web section moment connections. International Journal of Steel Structures, Vol. 17, 2017, pp. 413–425.10.1007/s13296-017-6004-xSearch in Google Scholar

[14] Sofias, C. and D. Tzourmakliotou. Reduced beam section (RBS) moment connections-analytical investigation using finite element method. Civil Engineering Journal, Vol. 4, 2018, pp. 1240–1253.10.28991/cej-0309170Search in Google Scholar

[15] Sofias, C. E. and D. T. Pachoumis. Assessment of reduced beam section (RBS) moment connections subjected to cyclic loading. Journal of Constructional Steel Research, Vol. 171, 2020, id. 106151.10.1016/j.jcsr.2020.106151Search in Google Scholar

[16] Zhang, J., Z. Pei, and X. Rong. Experimental seismic study of an innovative precast steel–concrete composite beam–column joint. Soil Dynamics and Earthquake Engineering, Vol. 161, 2022, id. 107420.10.1016/j.soildyn.2022.107420Search in Google Scholar

[17] Ding, K. and Y. Zhang. Experimental study on seismic performance of fabricated bolted joint under low-cycle reciprocating loads. Results in Engineering, Vol. 9, 2021, id. 100208.10.1016/j.rineng.2021.100208Search in Google Scholar

[18] Vidjeapriya, R. and K. P. Jaya. Experimental study on two simple mechanical precast beam-column connections under reverse cyclic loading. Journal of Performance of Constructed Facilities, Vol. 27, 2013, pp. 402–414.10.1061/(ASCE)CF.1943-5509.0000324Search in Google Scholar

[19] Yang, Y., S. Feng, Y. Xue, and Y. Yu. Experimental investigation on the seismic behaviour of innovative self-centring precast steel-concrete hybrid frames. Engineering Structures, Vol. 239, 2021, id. 112222.10.1016/j.engstruct.2021.112222Search in Google Scholar

[20] Wang, Z., J. Zhu, H. Qin, J. Lu, and J. Tian. Study on influencing factors of hysteretic performance of cantilever fully-bolted prefabricated beam-column joint. Journal of Building Engineering, Vol. 82, 2024, id. 108324.10.1016/j.jobe.2023.108324Search in Google Scholar

[21] Li, D., Y. Chai, W. Li, and R. Xiang. Experimental study and finite element analysis of seismic behaviour of novel precast prestressed concrete frames. Structures, Vol. 38, 2022, pp. 402–415.10.1016/j.istruc.2022.02.019Search in Google Scholar

[22] Feng, Y., M. Wei, X. Chong, Q. Jiang, Z. Zhang, and H. Wen. Seismic performance of earthquake resilient steel frame joints with replaceable buckling-restrained flange cover plates. Journal of Earthquake Engineering, Vol. 27, 2023, pp. 4639–4663.10.1080/13632469.2023.2188566Search in Google Scholar

[23] Yang, Y. Experimental study on seismic behavior of frame joints in a novel dry-connection assembled hybrid structure. Master’s thesis, Xi’an Univ. Archit. Technol., Xi’an, China, 2020 [in Chinese].Search in Google Scholar

[24] GB 50010-2010. Code for design of concrete structures, China Architecture and Building Press, Beijing, 2024 [in Chinese].Search in Google Scholar

[25] Baltay, P. and A. Gjelsvik. Coefficient of friction for steel on concrete at high normal stress. Journal of Materials in Civil Engineering, Vol. 2, 1990, pp. 46–49.10.1061/(ASCE)0899-1561(1990)2:1(46)Search in Google Scholar

[26] Feng, Y., M. Wei, X. Chong, Q. Jiang, and Y. Zhu. Design and numerical analysis of steel frame joints with replaceable buckling-restrained links. Journal of Constructional Steel Research, Vol. 196, 2022, id. 107415.10.1016/j.jcsr.2022.107415Search in Google Scholar

[27] Han, L. H. Concrete filled steel tubular structures, 4th ed., Science Press, Beijing, 2022 [in Chinese].10.1007/978-981-99-2170-6_3Search in Google Scholar

[28] GB 50011-2010. Code for seismic design of buildings, China Architecture and Building Press, Beijing, 2024 [in Chinese].Search in Google Scholar

[29] JGJ/T 101-2015. Specification for seismic test of buildings, China Architecture and Building Press, Beijing, 2015 [in Chinese].Search in Google Scholar

[30] ATC-58. Guidelines for seismic performance assessment of buildings, Applied Technology Council (ATC), Washington, USA, 2009.Search in Google Scholar

[31] Mao, W. F. Development and research of bolted end-plate steel beams and reinforced concrete columns composite structures. Master’s thesis. Hunan University, Changsha, China, 2005 [in Chinese].Search in Google Scholar

[32] AIJ design guidelines for composite RCS joints. AIJ Composite RCS Structures Sub-Committee, Architectural Institute of Japan (AIJ), Tokyo, 1994 [in Japanese].Search in Google Scholar

[33] Du, G. F., X. M. Bie, Z. Li, and W. Q. Guan. Study on constitutive model of shear performance in panel zone of connections composed of CFSSTCs and steel-concrete composite beams with external diaphragms. Engineering Structures, Vol. 155, 2018, pp. 178–191.10.1016/j.engstruct.2017.11.024Search in Google Scholar

[34] Parra-Montesinos, G. and J. K. Wight. Modeling shear behavior of hybrid RCS beam-column connections. Journal of Structural Engineering, Vol. 127, 2001, pp. 3–11.10.1061/(ASCE)0733-9445(2001)127:1(3)Search in Google Scholar

[35] Wang, J. Experimental study on mechanical properties of prefabricated frame structure beam-column joint. Master’s thesis. Dalian University of Technology, Dalian, China, 2014 [in Chinese].Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods