Influence of artificial weathering on the colour of wood Eucalyptus benthamii Maiden et Cambage treated with different finishing products

-

Alexsandro Bayestorff da Cunha

, Camila Alves Corrêa

, Ângela Silva dos Santos

, Helena Cristina Vieira

, Martha Andreia Brand

und Polliana D’Angelo Rios

Abstract

Eucalyptus benthamii has been identified as one of the main forest species for planting in the southern region of Brazil due to its resistance to low temperatures. Current studies with the species are restricted to forestry and the processing of wood from short-rotation plantations. However, the greatest added value occurs in processing, where the application of paints and varnishes can change the characteristics of the wood. The objective of the study was to evaluate the colour changes of E. benthamii wood, coming from long rotation plantations, subjected to artificial weathering, with two finishing products. The surfaces of the pieces were treated with marine varnish and power stain and subjected to three cycles in the weathering chamber (240 h, 480 h, and 720 h), following the standard ASTM G154 (2006. Standard practice for operating fluorescent light apparatus for UV exposure of nonmetallic materials (ASTM G154-06)). To measure colourimetric parameters, a Konica Minolta colourimeter (model CR-400) was used. The artificial weathering process caused darkening of the wood and a very appreciable variation in the surface colour after 240 h. After 720 h, all samples showed a tendency towards a yellow–brownish tone, with a standardisation in colour after accelerated ageing. This characteristic is interesting for marketing, considering consumers’ preference for the natural colour of wood.

1 Introduction

Intense cold and the occurrence of frost are the main limiting factors for planting the Eucalyptus genus in southern Brazil. Thus, several companies have invested in experimental plantings with unconventional species of the genus to verify their edaphoclimatic requirements, volumetric increase, technological properties, and behaviour in different industrial processes.

Among these species, Eucalyptus deanei, Eucalyptus dunnii, Eucalyptus smithii, and, mainly, Eucalyptus benthamii Maiden et Cambage stand out, which were introduced into Brazil in the States of Santa Catarina and Paraná by Embrapa Florestas in the year 1988 (Santos et al. 2020). Its trees have rapid growth and excellent bole shape (Hall et al. 2020; Kruchelski et al. 2022; Yu and Gallagher 2015); however, in young plantations, they provide wood with elevated levels of retractability (Benin et al. 2017; Muller et al. 2014).

This characteristic and growth stresses explain the intensity of defects in the unfolding and drying process (Beltrame et al. 2012; Higa and Pereira 2003). Thus, researchers warn that the exploitation of the species’ trees in short rotations is only suitable for producing energy, stakes, poles, and posts (Lima et al. 2007; Nones et al. 2015; Silva et al. 2015).

Regardless of the species used in the production of wood and finished products, it is essential to conduct research to understand the material that will be used. This includes investigating its behaviour through the application of finishing products, which can alter the wood’s natural characteristics, such as colour, texture, and shine.

According to Bonfatti Junior and Lengowsky (2018), colour determination must be incorporated into planning, aiming at the technological characterisation of wood to meet the most noble uses, such as the production of furniture, flooring, wooden structures, shipbuilding, and high-standard joinery. Furthermore, the performance of this material during use can provide important parameters, making the material more attractive to the consumer market.

It is known that the performance of wood is affected in external environments, in the long term, by sunlight, and this rate can be increased by temperature, humidity, environmental pollutants and oxidative agents, causing colour change and gradual erosion of the wood (Pace et al. 2018; Williams and Feist 1999). It is noteworthy that the speed of degradation can also be affected by the species and composition of wood, since there are components such as extractives and lignin (Pandey 2005).

This degradation process is due to chemical and physical reactions caused by the interaction of light photon energy with the wood surface, promoting the formation of free radicals that attack compounds present in the extractives and depolymerise lignin and cellulose in the cell wall (Lesar et al. 2011; Nikafshar and Nejad 2022). The evaluation of wood exposed to these conditions can be conducted quickly in the laboratory, with the use of accelerated weathering chambers, allowing the specification, through ASTM G154 (2006), of radiation conditions, humidity levels, and temperature.

In this context, there is the work of Pace et al. (2018), who evaluated the action of artificial weathering on the surface finish and colour of wood Corymbia citriodora and Khaya ivorensis, noting that the process caused significant changes in the wood analysed. In the same way, studying the colourimetric behaviour in Micropholis venulosa wood, Mesquita et al. (2020), demonstrated that the artificial weathering process caused the degradation of the chemical components of the wood and changes in the colour of the pieces.

The effects on the colour of wooden pieces, exposed to external environments and/or controlled in a camera, are the most macroscopically noticeable consequences. According to Dunningham et al. (1992), the change in colour during the initial period of weathering occurs linearly over time, while in the long term, the wood becomes less yellow and less red, tending towards a grey colour. This fact was observed by Soares et al. (2018) with fresh wood of Eucalyptus grandis after exposure to several cycles of radiation, precipitation, and condensation, and by Mattos et al. (2013) with Eucalyptus saligna, Eucalyptus terenticornis, and C. citriodora after outdoor exposure.

To maintain the surface quality of the pieces in the long term, sanding processes and the application of finishing products can be used, such as paints with UV absorbers and/or antioxidants, water repellents, varnishes, stains, and organic finishes (Baysal et al. 2013). Sanding provides surfaces free of visible defects, making them more uniformly absorbent, facilitating the application of coatings. Meanwhile, finishing products have well-defined technical characteristics, not only regarding the type of material to which they must be applied, but also the application methods.

However, these coatings are also subject to degradation due to the weather, since UV light and humidity are harmful to the binder polymers present in the composition of these products, and exposure for prolonged periods causes an increase in brittleness, the appearance of cracking and peeling of the coating (Grull et al. 2014). Thus, studies covering weathering or accelerated ageing of sanded and coated wood systems have demonstrated that protection depends not only on the performance of the finish but also on the substrate and mainly on the wood/coating interface.

Examples of this situation can be found in the work of Silva et al. (2007), with five commercial tropical woods and two different types of finishes, in which they observed that both varnish and stain darkened all woods after application, but varnish provided greater protection for Tabebuia impeginosa wood and Manilkara huberi, and the stain for Bagassa guianensis and Mezilaurus sp. In the same sense, Siebra et al. (2020) evaluated the change in the colour of Amazonian wood, Aspidosperma sp., and Apuleia leiocarpa treated with varnish and sealant and found that the application of varnish resulted in a more noticeable darkening of the wood.

Considering the importance of final colour analysis to guarantee a quality standard required on the world market, and the differences that are observed between species, it is important to develop studies that attest to the effectiveness of different finishing products when subjected to accelerated ageing. Thus, the objective of the present study was to evaluate, through colourimetry, the surface of sawn wood pieces of E. benthamii from long rotation plantations, after the application of coating products and exposure to temperature and humidity in a storage chamber, weathering.

Based on the chemical composition and physical characteristics of the finishing products used, it was hypothesised that the application of varnish and stain would reduce the intensity of colour changes in E. benthamii wood caused by artificial ageing, compared to uncoated surfaces. Furthermore, varnish was expected to offer greater protection than stain due to its film-forming properties, although stain might result in greater colour stability over time owing to its pigment content and ability to penetrate the wood. Finally, it was hypothesised that the colourimetric parameters (L*, a*, b*) would show statistically significant differences depending on the type of coating and exposure time, indicating distinct degradation patterns for each treatment.

2 Materials and methods

2.1 Raw material and material preparation

The E. benthamii wood used in this study belonged to a 23-year-old experimental plantation, located at the Experimental Station of the Agricultural Research and Rural Extension Company of Santa Catarina (EPAGRI), in the Municipality of Lages (Santa Catarina), Brazil.

Five trees were selected, with an average total height of 37.16 m, a commercial height (defined as the height up to a minimum stem diameter of 8 cm) of 31.36 m, and an average diameter at breast height (DBH, measured at 1.30 m above ground) of 49 cm. From each tree, 2.40 m logs were cut, starting from the DBH position. The logs were unfolded tangentially, creating pieces of sawn wood with an average width and thickness of 200 mm and 33 mm, respectively. These pieces were dried in a climatic chamber with a temperature of 20 °C and a relative humidity of 65 % until a moisture content of 12 %. Subsequently, they were planed and sanded with 150-grit sandpaper in a direction parallel to the wood grain. Samples measuring 150 mm × 70 mm × 25 mm (length × width × thickness) were cut from these pieces to carry out the tests.

2.2 Experimental plan

The experiment was organised in a completely randomised design with a 4 × 3 bifactorial arrangement, with the factors being the coating products with three levels (in natura, varnish, and stain) and the weathering time with four levels (0 h, 240 h, 480 h, and 720 h).

A total of 27 E. benthamii wood samples were selected based on the most similar visual and anatomical characteristics possible, to minimise the effects of wood heterogeneity. These samples were equally divided into three treatments: in natura (control), stain application, and varnish application, with nine samples per treatment. On each sample, four points were selected for colourimetric evaluation, resulting in a total of 36 measurement points per treatment. All samples were initially evaluated for colour before exposure to artificial weathering, and subsequently at intervals of 240 h (equivalent to 20 chamber cycles), up to a total of 720 h of exposure (Table 1).

Two-factor experimental design.

| Treatment | Time (h) | Sample (n) | Points per sample | Total measurements | Assessments |

|---|---|---|---|---|---|

| In natura | 0 | 9 | 4 | 36 | Initial colour |

| 240 | Post-240 h colour | ||||

| 280 | Post-480 h colour | ||||

| 720 | Post-720 h colour | ||||

| Varnish | 0 | 9 | 4 | 36 | Initial colour |

| 240 | Post-240 h colour | ||||

| 280 | Post-480 h colour | ||||

| 720 | Post-720 h colour | ||||

| Stain | 0 | 9 | 4 | 36 | Initial colour |

| 240 | Post-240 h colour | ||||

| 280 | Post-480 h colour | ||||

| 720 | Post-720 h colour |

Two widely available finishing products from the Eucatex brand were used in this study, both featuring triple sunscreen protection. The first was a colourless marine varnish with a glossy finish, composed of alkyd resin, aliphatic and aromatic hydrocarbon solvents, organometallic driers, and additives, according to the manufacturer’s technical data sheet. This product does not contain benzene or heavy metals. The second coating was Power Stain, a stain with antifungal properties and a satin finish. Its formulation includes water repellents, modified alkyd polymers, UV absorbers, aliphatic hydrocarbons, driers, inert mineral fillers, transparent pigments, and additives with bactericidal, fungicidal, and algicidal action. Like the varnish, it contains no benzene.

The varnish was diluted with 10 % mineral spirits, while the stain was applied undiluted; both products were applied using a brush, as instructed by the manufacturer. Two coats were applied to each sample with a 12-h interval between applications. After applying the varnish, a dry film with an approximate thickness of 80 µm was formed. For the stain, consistent with the technical data sheet, no film formation occurred. Samples were also produced in natura, that is, without any coating product, as a witness.

2.3 Weathering and colourimetry test

With the in natura samples and those impregnated with coating products, the first prints were made using a Konica Minolta colourimeter (model CR-400) equipped with a D65 illuminating source, observation angle of 10°, and aperture 8 mm aperture sensor, according to the CIE-L*a*b* standard. The parameters obtained at four fixed points of each sample were the luminosity (L*), the red–green chromatic coordinate (a*), the yellow–blue chromatic coordinate (b*), the colour saturation (C*), and the hue angle (H*).

After printing, the samples were exposed to 20, 40, and 60 cycles in the Bass weathering chamber (model UUV-Spray-1.0, 2019), with colourimetric measurements repeated at the same points after each 20-cycle interval. Each cycle comprises a total of 12 h, consisting of 8 h of exposure to UV radiation at a temperature of 60 °C ± 3 °C, 15 min with water spraying without light and temperature control, and 3 h and 45 min of condensation at 50 °C, as prescribed in ASTM G154 (2006). This code prescribes exposure cycles according to the material being evaluated. In this paper, Cycle 7 was considered, being the same used for the test of wood coatings erosion. Average irradiation considered was 0.89 W/m2/nm, using UVA lamps (340 nm wavelength). As recommended by ASTM G154 (2006), the samples were periodically repositioned during the exposure period in the chamber to ensure equal UV radiation exposure among specimens.

After each cycle in the accelerated weathering chamber, the samples were conditioned at 20 ± 2 °C and 65 ± 5 % relative humidity until reaching equilibrium moisture content before colour measurements were performed.

From the total average of the colourimetric parameters of the 36 points (4 points, 9 samples) of each treatment, the colour of the wood was characterised according to Camargos and Gonçalez (2001). The determination of the total colour variation between treatments was determined using Equation (1). The classification developed by Hikita et al. (2001) based on naked eye perception levels was used to determine the colour variation (0–0.5: negligible; 0.5–1.5: slightly noticeable; 1.5–3.0: notable; 3.0–6.0: appreciable; 6.0 to 12.0: very appreciable).

where: ΔE: colour variation between the treatment and the control; ΔL*: variation in brightness; Δa*: variation of coordinate a*; Δb*: variation of coordinate b*.

The colourimetric parameters were first tested for compliance with the assumptions of parametric analyses. Normality was assessed using the Shapiro–Wilk test, and homogeneity of variances using Bartlett’s test, both at the 5 % significance level. The variables a* and b* met these assumptions without adjustment (p > 0.05). However, the variables L*, C*, and H* violated at least one assumption (p < 0.05). To address this, a Box–Cox transformation was applied, which successfully normalised the data and stabilised variances, as confirmed by subsequent retests (p > 0.05).

Statistical analyses were performed in R software (version 4.3.1; R Core Team 2023), using the packages lme4, lmerTest, and emmeans. The effects of treatment (finishing products), evaluation time, and their interaction were assessed using a linear mixed-effects model, with treatment, time, and their interaction specified as fixed effects, and sample (ID) included as a random intercept to account for the non-independence of repeated measures. The significance of fixed effects was tested by Type III ANOVA using the Kenward–Roger approximation. Effect sizes were estimated as partial eta squared (η2p) with 95 % confidence intervals. When significant effects were detected (p < 0.05), pairwise comparisons of adjusted means were performed using Tukey’s test with correction for multiple comparisons.

3 Results

Table 2 shows that treatment, time, and their interaction significantly affected all colourimetric parameters. Strong effects of both treatment and time were observed for L*, a*, and C*, while for b*, the treatment effect was dominant, and the effect of time was weaker. For H*, time had the strongest influence, with treatment and the interaction contributing only modestly.

Results of the type III ANOVA (linear mixed-effects model): p-values, effect sizes, and confidence intervals for fixed effects.

| L* | ||||

|---|---|---|---|---|

| F value | p-value | η 2 p | 95 % CI | |

| Treatment | 171.2 | <0.001 | 0.97 | [0.93, 1.00] |

| Time | 806.5 | <0.001 | 0.99 | [0.98, 1.00] |

| Treatment × time | 15.8 | <0.001 | 0.79 | [0.63, 1.00] |

|

|

||||

| a* | ||||

|

|

||||

| Treatment | 119.2 | <0.001 | 0.96 | [0.90, 1.00] |

| Time | 163.4 | <0.001 | 0.95 | [0.91, 1.00] |

| Treatment × time | 7.1 | <0.001 | 0.61 | [0.34, 1.00] |

|

|

||||

| b* | ||||

|

|

||||

| Treatment | 74.5 | <0.001 | 0.94 | [0.85, 1.00] |

| Time | 7.8 | <0.001 | 0.47 | [0.19, 1.00] |

| Treatment × time | 9.6 | <0.001 | 0.68 | [0.45, 1.00] |

|

|

||||

| C* | ||||

|

|

||||

| Treatment | 196.9 | <0.001 | 0.98 | [0.94, 1.00] |

| Time | 121.0 | <0.001 | 0.93 | [0.88, 1.00] |

| Treatment × time | 14.1 | <0.001 | 0.76 | [0.58, 1.00] |

|

|

||||

| H* | ||||

|

|

||||

| Treatment | 17.2 | <0.001 | 0.49 | [0.28, 1.00] |

| Time | 104.9 | <0.001 | 0.90 | [0.84, 1.00] |

| Treatment × time | 4.4 | 0.0018 | 0.43 | [0.15, 1.00] |

Table 3 presents the average values of colourimetric parameters for each type of finish across the four weathering periods, along with the results of the Tukey test. The L* parameter, before weathering (T0h), decreased significantly with the application of finishing products, indicating that the wood darkened, more notably with the varnish, and even more so with the stain. Within each finishing type, significant darkening was observed between the initial (T0h), intermediate (T240h and T480h), and final (T720h) periods. Among the untreated and treated samples, varnish led to the greatest darkening after extended exposure, followed by the untreated wood and stain, the latter demonstrating greater stability.

Colour parameters (L*, a*, b*, C*, and H*) of Eucalyptus benthamii wood samples subjected to accelerated weathering, for three surface treatments: in natura (untreated), varnish, and stain (n = 9 per treatment and time).

| Parameter | Time (h) | In natura | Varnish | Stain |

|---|---|---|---|---|

| L* | 0 | 70.2 aA | 62.9 aB | 59.3 aC |

| 240 | 52.9 bA | 45.0 bC | 48.3 bB | |

| 480 | 52.7 bA | 44.0 bC | 46.9 bcB | |

| 720 | 49.9 cA | 41.1 cC | 45.7 cB | |

| a* | 0 | 12.8 cB | 17.4 cA | 17.8 cA |

| 240 | 21.4 aC | 31.4 aA | 25.2 aB | |

| 480 | 22.8 aB | 30.5 abA | 25.1 aB | |

| 720 | 18.8 bC | 28.6 bA | 22.1 bB | |

| b* | 0 | 22.2 bB | 31.9 aA | 30.2 aA |

| 240 | 28.7 aB | 33.4 aA | 28.1 abB | |

| 480 | 27.6 aB | 34.0 aA | 28.2 abB | |

| 720 | 26.4 aB | 31.5 aA | 26.8 bB | |

| C* | 0 | 25.7 cB | 36.4 cA | 35.1 bA |

| 240 | 35.8 aB | 45.8 aA | 37.8 aB | |

| 480 | 35.9 aB | 45.7 aA | 37.8 aB | |

| 720 | 32.4 bC | 43.4 bA | 34.8 bB | |

| H* | 0 | 60.1 aA | 61.4 aA | 59.5 aA |

| 240 | 53.2 bcA | 46.8 bB | 48.1 bB | |

| 480 | 50.4 cA | 48.1 bA | 48.3 bA | |

| 720 | 54.4 bA | 47.8 bB | 50.5 bB |

-

Values represent means. Means followed by the same capital letter within rows (comparison between treatments for the same time) and the same lowercase letter within columns (comparison across times within each treatment) do not differ significantly according to the Tukey test (α = 0.05). ΔE values corresponding to the same samples are presented in Table 4.

Total colour variation (ΔE) and visual classification of E. benthamii wood samples after Weathering. aClassification of colour variation, proposed by Hikita et al. (2001), based on levels of perception. Numbers in parentheses indicate the standard deviations.

| Treatment | Time (h) | ΔE | Classificationa |

|---|---|---|---|

| In natura | 0–240 | 20.9 (1.4) | Very appreciable |

| 240–480 | 3.2 (0.9) | Appreciable | |

| 480–720 | 5.3 (1.1) | Appreciable | |

| Varnish | 0–240 | 22.8 (1.5) | Very appreciable |

| 240–480 | 3.7 (0.9) | Appreciable | |

| 480–720 | 5.6 (2.5) | Appreciable | |

| Stain | 0–240 | 13.5 (1.5) | Very appreciable |

| 240–480 | 1.8 (0.5) | Notable | |

| 480–720 | 4.2 (1.5) | Appreciable |

For the a*, b*, and C* parameters, Table 3 shows a significant increase in values following the application of finishing products, relative to untreated wood at T0h. This resulted in redder (a*) and more yellowish (b*) surface tones. After weathering began, the parameters remained higher in varnished samples, whereas those treated with stain showed values statistically similar to untreated wood, except for a*, which was higher after 240 h and 720 h of exposure, suggesting that the colour stability of stained samples resulted in a post-weathering appearance more similar to untreated wood.

The a* parameter increased after 240 h of exposure for all treatments. It remained stable at 480 h, and subsequently decreased at 720 h, except in varnished samples, where no reduction was observed, indicating a redder tone than in the untreated or stained samples.

For the b* chromatic coordinate, an increase was observed after 240 h of exposure in the untreated samples. The C* coordinate exhibited a pattern similar to that of a* in the untreated and varnished samples, with a slight increase followed by a reduction. The b* and C* coordinates showed less variation in the stained samples, with only a reduction observed after 720 h.

The hue angle values (H*) did not vary with the application of finishing products at T0h. However, after 240 h of exposure, treated samples showed a reduction in H* relative to the untreated control. Overall, the average H* values were positioned closer to the red axis, which helps explain the characteristic colour of E. benthamii wood.

The total colour variation for both treated and untreated samples over the three artificial weathering periods is presented in Table 4. The greatest change occurred during the initial exposure period (0 h–240 h), with values classified as very appreciable across all treatments. Stained surfaces exhibited the lowest total variation, indicating greater stability throughout the cycles, whereas varnished samples showed the highest variation.

Between subsequent time intervals, the variation was classified as appreciable for all treatments, except for stained samples between 240 h and 480 h, where the change was classified as noticeable, reflecting lower colour instability.

Figure 1 shows the average colours determined for each treatment and at each end of the cycle. According to the colour classification chart by Camargos and Gonçalez (2001), the untreated wood at the beginning of the test was close to the greyish-pink category.

Approximate colour visualisation of Eucalyptus benthamii wood surfaces subjected to different finishing treatments (in natura, varnish, and stain) and exposure times (0 h, 240 h, 480 h, and 720 h) in an accelerated weathering chamber. The colours shown were reconstructed based on the mean CIELAB coordinates (L*, a*, b*) obtained from colourimetric measurements at each time point. These colours serve as an illustrative representation of the chromatic variation.

Still considering the table by Camargos and Gonçalez (2001), the surfaces of the samples that received varnish and stain could initially be classified as yellow–orange. It was also found that, after a period of 720 h of accelerated weathering, all samples (in natura, with stain, or with varnish) demonstrated a tendency to reclassify into the yellow-brownish colour class.

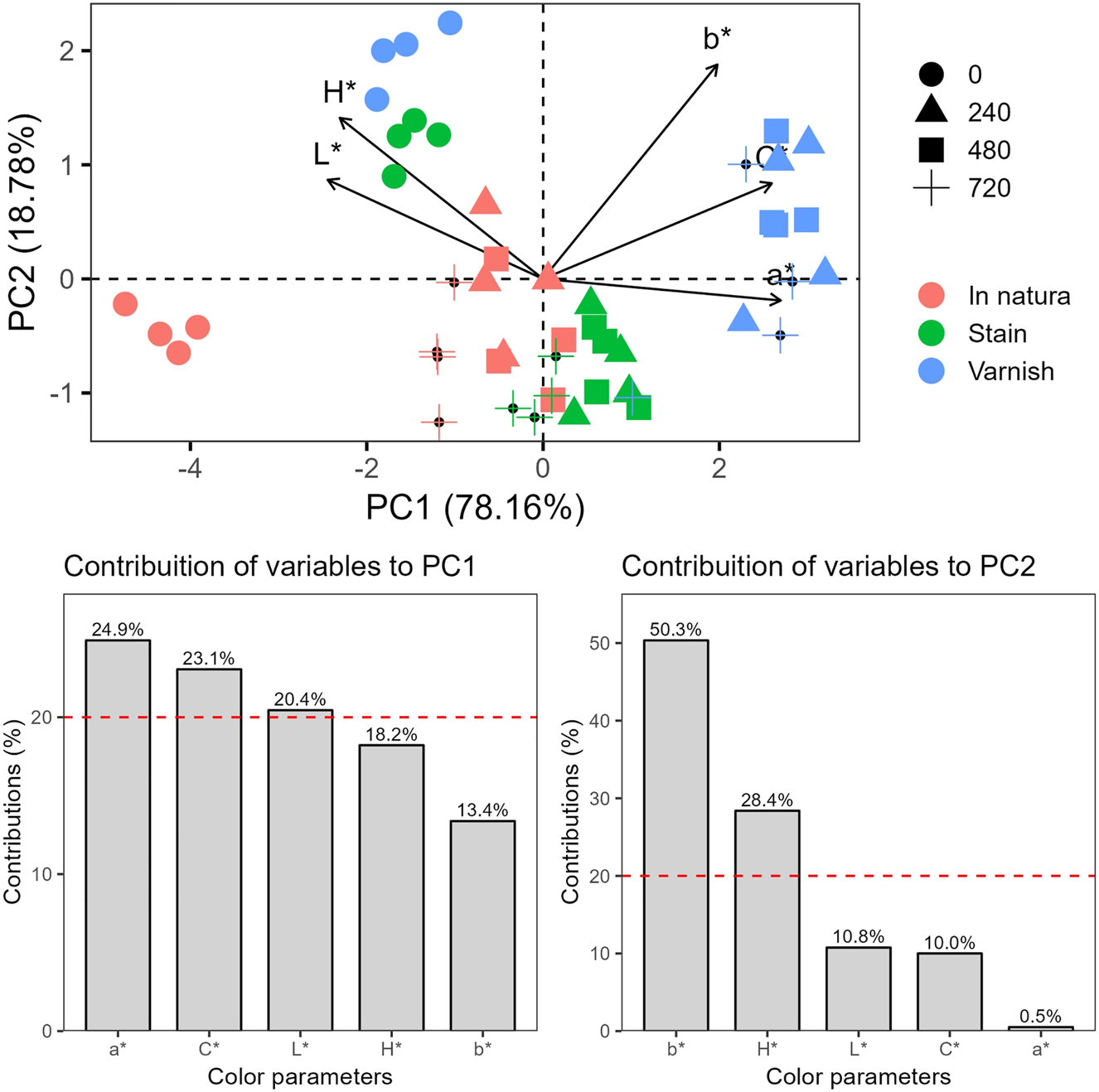

In addition to the mean comparison analysis, principal component analysis (PCA) was applied to better understand the overall behaviour of the samples and to identify multivariate patterns associated with the surface modifications. Although the number of variables was limited, PCA was employed to synthesise the information and enhance data interpretation. The graphical representation of the principal components allowed a more comprehensive view of the distribution and relationships among samples.

The eigenvalue analysis indicated that PC1 and PC2 accounted for the majority of the explained variance, while the contribution of PC3 and subsequent components was negligible. Therefore, only the first two principal components were considered for interpretation.

In Figure 2, it is possible to observe the distribution of sample averages considering the different finishes (in natura, stain, and varnish) and weathering times (0 h, 240 h, 480 h, and 720 h). The first principal component explained 78.16 % of the total variance in the data, while the second explained 18.78 %.

Principal component analysis (PCA) and contribution of colourimetric parameters to principal components (PC) 1 and 2 using weathering cycles (0 h, 240 h, 480 h, and 720 h) for the three finishes analysed (in natura, stain, and varnish).

Table 5 presents the loadings of the colourimetric variables on the first two principal components (PC1 and PC2). For PC1, strong positive loadings were observed for a, b, and C*, while L* and H* showed strong negative loadings. In contrast, the correlations with PC2 were weaker overall, with b* displaying the highest positive loading, whereas a* was the only variable with a negative, albeit low, contribution.

Loadings of the colourimetric variables on the first two principal components (PC1 and PC2), obtained through principal component analysis (PCA).

| PC1 | PC2 | |

|---|---|---|

| L* | −0.8940 | 0.3178 |

| a* | 0.9864 | −0.0693 |

| b* | 0.7232 | 0.6874 |

| C* | 0.9492 | 0.3065 |

| H* | −0.8438 | 0.5162 |

4 Discussion

The reduction in L* following the application of stain corroborates findings by Gonçalez et al. (2010), who reported greater darkening in Cordia alliodora wood finished with stain compared to sealer, due to the product’s composition, either due to darker pigments or to chemical reactions with wood constituents. In the present study, an inversion in L* values between varnish and stain was observed after 240 h of weathering: although stain initially darkened the wood more, varnish caused greater darkening after 20 cycles.

The consistently higher a* values in varnished samples after 720 h align with Petrillo et al. (2019), who observed similar behaviour in Larix decidua under artificial weathering. This was attributed to lignin degradation and photooxidation of CH2 and CH(OH) groups, forming secondary chromophore structures.

Mesquita et al. (2020), in treating M. venulosa with varnish and stain, also observed darkening and increases in a*, b*, and C*, with varnished samples presenting higher a* values after exposure. Similarly, Costa et al. (2011) found reduced lightness and increased red pigmentation (a*) in Hymenaea courbaril wood with increased UV radiation exposure.

According to Gonçalez et al. (2010), a* values above 10 tend to dominate over b*, resulting in a pronounced reddish tone. This study confirms the strong presence of reddish pigmentation in E. benthamii wood, intensified by finishing products and especially evident in varnished samples following artificial weathering.

The increase in b* after 240 h in untreated samples reflects greater yellow pigmentation, a common outcome of photo-induced changes in wood chromophores. The similar behaviour of the C* coordinate to a*, particularly in untreated and varnished samples, suggests a stronger influence of the a* coordinate on colour saturation (Zanuncio et al. 2014). In stained samples, the reduced variation in b* and C* suggests greater colour stability over time.

As noted by Mattos et al. (2013), lower C* values are associated with reduced colour intensity or increased opacity. Therefore, the higher C* values found in varnished samples indicate greater retention of colour vividness after artificial weathering, which is a typical feature of varnish finishes.

The hue angle (H*) values support these findings. While no changes occurred at T0h, a reduction in H* was observed in treated samples after 240 h, indicating a shift in hue towards the red axis. This is consistent with the average colour characteristics of E. benthamii and aligns with the results reported by Talgatti et al. (2021) for E. grandis, which also presented hue angles close to the red spectrum (a* = 12.88; b* = 25.19; H* = 59.30).

The significant total colour variation observed in the first 240 h of exposure can be attributed to the initial photodegradation of surface compounds and the sensitivity of the wood’s chromophores to UV radiation and moisture. The classification of this variation as very appreciable across all treatments highlights the pronounced visual changes that occur in the early stages of weathering. This result is consistent with that reported by Pánek and Reinprecht (2016), who observed that the L*, a*, and b* colour coordinates changed most during the initial stages of weathering in Kusian woods (Nauclea diderrichii Merril), Bangkirai (Shorea obtusa Wall. and Sh. spp.), Massaranduba (Manilkara bidentata A. Chev. and M. spp.), and Jatobá (H. courbaril L.) treated with vegetable oil.

The lower ΔE* values for stained samples throughout the exposure cycles confirm the product’s stabilizing effect on wood colour, likely due to its pigment composition and hydrophobic characteristics. Similar results were reported by Kim and Kim (2021), who also found less colour variation in stained wood samples compared to those varnished or left unfinished. In contrast, varnished surfaces underwent greater colour change, possibly due to increased gloss, which accentuates tonal shifts under weathering.

The classification of variation as appreciable between most intervals is consistent with progressive degradation, while the lower variation in stained samples between 240 h and 480 h reflects a slower alteration rate, suggesting greater resistance to mid-term photochemical changes.

In Figure 2, the tendency for grouping wooden pieces is highlighted, considering not only the preparation of the sample surfaces with finishing products but also the time of exposure to artificial weathering. Still in the PCA, it is evident that the distinction of the samples at time 0 is greater. For the other times analysed, there is a tendency for confusion; this can be explained because the colorimetric parameters are more similar between the times of 240 h, 480 h, and 720 h, as previously analysed.

Another factor that can also be observed in the Principal Component Analysis is the distribution of Loadings, represented in Figure 2 by arrows. Corroborating what was previously described, it is confirmed that the distribution of the analysed samples is influenced by the colorimetric parameters. It is also observed that the parameters L* and H* show the same tendency to influence the distribution of the samples. It should be noted that this behaviour was not expected for the hue angle (H*), since its value is derived from the use of the values of the chromatic coordinates a* and b*. On the other hand, C* showed the expected trend, following a similar pattern to the chromatic coordinates a* and b* in influencing the distribution of the samples.

In addition to observing that Main Component 1 was responsible for explaining 78.2 % of the distribution of the samples analysed, there was also an analysis of the contribution of each colorimetric parameter. Thus, it was evident that in PC1, there is a greater balance in the influence of the analysed parameters, with the chromatic coordinate a* presenting the greatest contribution, being responsible for 24.9 % of all the influence of PC1 on the distribution of samples.

For Main Component 2, there was a behaviour change, since there was a large discrepancy between the contributions of the colorimetric parameters. In this case, just considering the chromatic coordinate b*, a contribution percentage of 50.3 % was already obtained. While the chromatic coordinate a* presented only 0.51 % contribution to the distribution of samples in PC2.

In general, when analysing the results of the contributions of the colorimetric parameters in PC1 and PC2, it was possible to observe an inversely proportional behaviour. Those parameters that contributed most to explaining the distribution of samples in PC1 did not contribute equally to PC2. This result is interesting and proves that all colorimetric parameters analysed are important in the distribution of samples in the Principal Component Analysis.

5 Conclusions

Changes were evident in the colorimetric parameters of the surface of E. benthamii wood in natura and treated with varnish and stain, after the artificial weathering process. As effects of exposure to temperature and humidity in the accelerated aging chamber, darkening of the wood and a very appreciable variation in the surface colour of the samples were observed after 240 h. On the other hand, after 720 h, all samples (in natura, with stain, or with varnish) demonstrated a tendency to reclassify to yellow-brownish. Thus, it was possible to confirm that there was a standardization in colouring after the accelerated aging process, regardless of the treatment applied, demonstrating an interesting characteristic, mainly for the commercialization of wood, considering the interest of consumers in general for the natural colour of wood.

Funding source: Coordination for the Improvement of Higher Education Personnel

Award Identifier / Grant number: 001

Acknowledgments

This work was supported by the Santa Catarina State Research and Innovation Support Foundation – FAPESC.

-

Research ethics: Not applicable. This study did not involve human participants, animal subjects, or sensitive data.

-

Informed consent: Not applicable.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission. ABC: conceptualization, supervision, writing review and editing, and project administration. CAC: writing original draft, conceptualization, formal analysis, investigation, methodology, validation. ÂSS: writing original draft, data curation, resources. HCV: writing original draft, conceptualization, data curation, formal analysis, investigation, software, validation, visualization. MAB: supervision, writing review and editing, project administration. PDR: conceptualization, funding acquisition, supervision, writing review and editing, and project administration.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: The authors state no conflict of interest.

-

Research funding: Coordination for the Improvement of Higher Education Personnel – Brazil (CAPES) – Financing Code 001.

-

Data availability: The data supporting the findings of this study are not publicly available due to confidentiality restrictions. However, they can be made available upon reasonable request to the corresponding author. Access to the data is subject to approval and, if necessary, the signing of a confidentiality agreement.

References

American Society for Testing and Materials. (2006). Standard practice for operating fluorescent light apparatus for UV exposure of nonmetallic materials (ASTM G154-06).Suche in Google Scholar

Baysal, E., Tomak, E.D., Ozbey, M., and Altin, E. (2013). Surface properties of impregnated and varnished Scots pine wood after accelerated weathering. Color. Technol. 130: 140–146, https://doi.org/10.1111/cote.12070.Suche in Google Scholar

Beltrame, R., Lazarotto, M., Haselein, C.R., Santini, E.J., Schneider, P.R., and Aguiar, A.M. (2012). Determination of longitudinal residual deformations due to growth stresses in Eucalyptus spp. Ciência Florest. 22: 343–351, https://doi.org/10.5902/198050985741.Suche in Google Scholar

Benin, C.C., Watzlawick, L.F., and Hillig, E. (2017). Physical and mechanical properties of Eucalyptus benthamii wood under the effect of planting spacing. Ciência Florest. 27: 1375–1384, https://doi.org/10.5902/1980509830219.Suche in Google Scholar

Bonfatti Junior, E.A. and Lengowski, E.C. (2018). Colorimetry applied to wood science and technology. Braz. J. For. Res. 38: 1–13, https://doi.org/10.4336/2018.pfb.38e201601394.Suche in Google Scholar

Camargos, J.A.A. and Gonçalez, J.C.A. (2001). Colorimetry applied as an instrument in the elaboration of a wooden color chart. Bras. Florest. 71: 30–41.Suche in Google Scholar

Costa, J.A., Gonçalez, J.C., Camargos, J.A.A., and Gomes, I.A.S. (2011). Photodegradation of two species of tropical woods: Jatobá (Hymenaea courbaril) and tauari (Couratari oblongifolia) subjected to ultraviolet radiation. Cerne 17: 133–139, https://doi.org/10.1590/S0104-77602011000100016.Suche in Google Scholar

Dunningham, E.A., Plackett, D.V., and Singh, A.P. (1992). Weathering of chemically modified wood. Natural weathering of acetylated radiata pine. Preliminary results. Holz als Roh-Werkst. 50: 429–432, https://doi.org/10.1007/BF02662780.Suche in Google Scholar

Gonçalez, J.C., Félix, T.L.F., Gouveia, F.N., Camargos, J.A.A., and Ribeiro, P.G. (2010). Effect of ultraviolet radiation on the color of Freijó wood (Cordia goeldiana Huber) after receiving finishing products. Ciência Florest. 20: 657–664, https://doi.org/10.5902/198050982424.Suche in Google Scholar

Grull, G., Forsthuber, B., Tscherne, F., and Spitaler, I. (2014). Weathering indicator for artificial and natural weathering of wood coatings. Eur. J. Wood Wood Prod. 72: 681–684, https://doi.org/10.1007/s00107-014-0807-7.Suche in Google Scholar

Hall, K.B., Stape, J.L., Bullock, B.P., Frederick, D., Wright, J., Scolforo, H.F., and Cook, R. (2020). A growth and yield model for Eucalyptus benthamii in the southeastern United States. For. Sci. 66: 25–37, https://doi.org/10.1093/forsci/fxz061.Suche in Google Scholar

Higa, R.C.V. and Pereira, J.C.D. (2003). Potential uses of Eucalyptus benthamii Maiden et Cambage. Technical Report 100, Embrapa Florestas, Paraná, Brazil., pp. 1–5.Suche in Google Scholar

Hikita, Y., Toyoda, T., and Azuma, M. (2001). Weathering testing of timber: discoloration. In: Imamura, Y. (Ed.). High performance utilization of wood for outdoor uses: report on research project, Grant-in-Aid for Scientific Research. Press-Net, Kyoto, pp. 27–32.Suche in Google Scholar

Kim, J.Y. and Kim, B.R. (2021). Hygroscopicity and ultraviolet (UV) deterioration characteristics of finished woods. J. Korean Wood Sci. Technol. 49: 471–481, https://doi.org/10.5658/WOOD.2021.49.5.471.Suche in Google Scholar

Kruchelski, S., Trautenmüller, J.W., Orso, G.A., Roncatto, E., Triches, G.P., Behling, A., and Moraes, A. (2022). Modeling of the height-diameter relationship in eucalyptus in integrated crop–livestock systems. Pesqui. Agropecuária Bras. 57: 1–10, https://doi.org/10.1590/S1678-3921.pab2022.v57.02785.Suche in Google Scholar

Lesar, B., Pavlič, M., Petrič, M., Skapin, A.S., and Humar, M. (2011). Wax treatment of wood slows photodegradation. Polym. Degrad. Stab. 96: 1271–1278, https://doi.org/10.1016/j.polymdegradstab.2011.04.006.Suche in Google Scholar

Lima, E.A., Silva, H.D., Magalhães, W.L.E., and Lavoranti, O.J. (2007). Individual characterization of Eucalyptus benthamii trees for energy use. Technical Report 35. Embrapa Florestas, Paraná, Brazil, pp. 1–26.Suche in Google Scholar

Mattos, B.D., Cademartori, P.H.G., Lourençon, T.V., and Gatto, D.A. (2013). Color changes of Brazilian Eucalyptus wood by natural weathering. Int. Wood Prod. J. 5: 33–38, https://doi.org/10.1179/2042645313Y.0000000035.Suche in Google Scholar

Mesquita, R.R.S.D., Paula, M.H.D., and Gonçalez, J.C. (2020). Mid-infrared colorimetry and spectroscopy in curupixá wood against artificial weathering with finishing products. Ciência Florest. 30: 688–699, https://doi.org/10.5902/1980509831248.Suche in Google Scholar

Muller, B.V., Rocha, M.P., Cunha, A.B., Klitzke, R.J., and Nicoletti, M.F. (2014). Evaluation of the main physical and mechanical properties of Eucalyptus benthamii Maiden and Cambage wood. Floresta Ambient. 21: 535–542, https://doi.org/10.1590/2179-8087.050413.Suche in Google Scholar

Nikafshar, S. and Nejad, M. (2022). Evaluating efficacy of different UV-stabilizers/absorbers in reducing UV-degradation of lignin. Holzforschung 76: 235–244, https://doi.org/10.1515/hf-2021-0147.Suche in Google Scholar

Nones, D.L., Brand, M.A., Cunha, A.B., Carvalho, A.F., and Weise, S.M.K. (2015). Determination of the energy properties of wood and charcoal produced from Eucalyptus benthamii. Floresta 45: 57–64, https://doi.org/10.5380/rf.v45i1.30157.Suche in Google Scholar

Pace, J.H.C., Carvalho, A.M., Nascimento, A.M., Latorraca, J.V.F., and Dias Junior, A.F. (2018). The action of weathering interferes with the surface finish and color of the wood of forest species. Amazon J. Agric. Environ. Sci. 61: 1–7, https://doi.org/10.22491/rca.2018.2442.Suche in Google Scholar

Pandey, K.K. (2005). Study of the effect of photo-irradiation on the surface chemistry of wood. Polym. Degrad. Stab. 90: 9–20, https://doi.org/10.1016/j.polymdegradstab.2005.02.009.Suche in Google Scholar

Pánek, M. and Reinprecht, L. (2016). Effect of vegetable oils on the colour stability of four tropical woods during natural and artificial weathering. J. Wood Sci. 62: 74–84, https://doi.org/10.1007/s10086-015-1519-2.Suche in Google Scholar

Petrillo, M., Sandak, J., Grossi, P., and Sandak, A. (2019). Chemical and appearance changes of wood due to artificial weathering–dose–response model. J. Near Infrared Spectrosc. 27: 26–37, https://doi.org/10.1177/0967033518825364.Suche in Google Scholar

R Core Team. (2023). R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria.Suche in Google Scholar

Santos, P.E.T., Paludzyszyn Filho, E., Magalhães, W.L.E., Ben, T.J., and Moreira, S. (2020). Genetic improvement of subtropical eucalyptus: contributions to the species Eucalyptus benthamii, 1st ed. Embrapa Florestas, Colombo Paraná.Suche in Google Scholar

Siebra, M.B.S., Fernandes, N.C.L., Ribeiro, P.G., and Lobão, M.S. (2020). Alteration of the color of two Amazonian woods treated with finishing products. Sci. Nat. 2: 64–67.Suche in Google Scholar

Silva, J.O., Pastore, T.C.M., and Pastore, F.Jr. (2007). Resistência ao intemperismo artificial de cinco madeiras tropicais e de dois produtos de acabamento. Ciência Florest. 17: 17–23, https://doi.org/10.5902/198050981931.Suche in Google Scholar

Silva, D.A., Muller, B.V., Kuiaski, E.C., Eloy, E., Behning, A., and Colaço, C.M. (2015). Properties of Eucalyptus benthamii wood for energy production. Pesquisa Florestal Brasileira 35: 481–485, https://doi.org/10.4336/2015.pfb.35.84.677.Suche in Google Scholar

Soares, A.K., Pereira, R.L., Cademartori, P.H.G., Dalla Costa, H.W., and Gato, D.A. (2018). Artificial weathering of four coatings applied to wood from two forest species. Native 6: 313–320, https://doi.org/10.31413/nativa.v6i3.5145.Suche in Google Scholar

Talgatti, M., Silveira, A.G., Santini, E.J., Bianchini, N.H., and Mariano, L.G. (2021). Technological characterization of the wood of two species of Eucalyptus submitted to hydrothermal treatment and freezing. Pesquisa Florestal Brasileira 41: 1–10, https://doi.org/10.4336/2021.pfb.41e201902037.Suche in Google Scholar

Williams, R.S. and Feist, W.C. (1999). Water repellents and water-repellent preservatives for wood. Technical Report 109. Forest Products Laboratory, United States, pp. 1–12.10.2737/FPL-GTR-109Suche in Google Scholar

Yu, A. and Gallagher, T. (2015). Analysis on the growth rhythm and cold tolerance of a five-year-old Eucalyptus benthamii plantation for bioenergy. Open J. For. 5: 585–592, https://doi.org/10.4236/ojf.2015.56052.Suche in Google Scholar

Zanuncio, A.J.V., Farias, E.D.S., and Silveira, T.A. (2014). Heat treatment and colorimetry of Eucalyptus grandis wood. Floresta Ambient. 2: 85–90, https://doi.org/10.4322/floram.2014.005.Suche in Google Scholar

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Frontmatter

- Wood Physics/Mechanical Properties

- Stabilization of hygro-deformation and interaction between earlywood and latewood in Chinese fir

- Esterification of wood with citric acid and sorbitol: effect of the copolymer on the properties of the modified wood. Part 2: swelling and shrinking, sorption behaviour and liquid water uptake

- Moisture response characteristics of the rheological behavior of heat-treated North American alder wood during the moisture absorption process

- Influence of artificial weathering on the colour of wood Eucalyptus benthamii Maiden et Cambage treated with different finishing products

- Moisture-dependent elastic and plastic properties of pine wood and bamboo cell wall layers measured by nanoindentation

- Wood Technology/Products

- Durability of tannin-citric acid modified Scots pine against weathering and fungal exposures

- Wood Science – Non-Tree Plants

- Hygroscopic behavior, dimensional stability, and chemical structure of bamboo after thermal treatments under dry and wet conditions

Artikel in diesem Heft

- Frontmatter

- Wood Physics/Mechanical Properties

- Stabilization of hygro-deformation and interaction between earlywood and latewood in Chinese fir

- Esterification of wood with citric acid and sorbitol: effect of the copolymer on the properties of the modified wood. Part 2: swelling and shrinking, sorption behaviour and liquid water uptake

- Moisture response characteristics of the rheological behavior of heat-treated North American alder wood during the moisture absorption process

- Influence of artificial weathering on the colour of wood Eucalyptus benthamii Maiden et Cambage treated with different finishing products

- Moisture-dependent elastic and plastic properties of pine wood and bamboo cell wall layers measured by nanoindentation

- Wood Technology/Products

- Durability of tannin-citric acid modified Scots pine against weathering and fungal exposures

- Wood Science – Non-Tree Plants

- Hygroscopic behavior, dimensional stability, and chemical structure of bamboo after thermal treatments under dry and wet conditions